Abstract: This article introduces three common serial data standards: RS-232, RS-422, and RS-485, according to their technical specifications and electrical interfaces. It discusses cable termination techniques, the use of multiple loads, RS-232 daisy chain connections, conversion from RS-232 to RS-485, conversion from RS-485 to RS-232, and powering RS-485 conversion from RS-232 ports.

Introduction “The wonderful thing about standards is that there are so many to choose from.” This statement was made at a recent conference on optical cables, but it also applies to electrical interface standards. With the independent development of serial data standards across different industries, we have never had so many standards available.

The most successful serial data standard in the PC and telecommunications application fields is likely RS-232. Similarly, RS-485 and RS-422 are among the most successful standards in industrial applications. These standards are not directly compatible. However, for control and instrumentation applications, it is often necessary to communicate between different standards. This article discusses the different standards (physical layer specifications), introduces how to convert one standard to another, and demonstrates how to combine different standards in the same application.

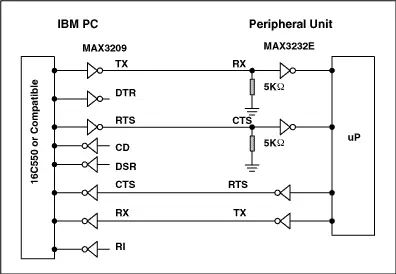

Electrical Specifications and Typical Connections of RS-232 The RS-232 link was originally used to support modem and printer applications on IBM PCs. However, this standard now supports communication between various peripherals and PCs. The RS-232 standard is defined as a single-ended standard, used to improve serial communication distance at lower baud rates (<20kbps). Over the years, this standard has undergone several changes to support faster drivers, such as the MAX3225E, which can provide a data transmission rate of 1Mbps. To be compatible with RS-232, transceivers like the MAX3225E must meet the electrical specifications listed in Table 1. As shown in the typical connection (Figure 1), hardware handshaking is used to control data flow.

Table 1. Summary of Key Electrical Specifications for RS-232 Standard

| Parameter | Condition | Minimum | Maximum | Unit |

|---|---|---|---|---|

| Driver Output Voltage, Open Circuit | 25 | V | ||

| Driver Output Voltage, Loaded | 3kΩ < RL < 7kΩ | ±5 | ±15 | V |

| Driver Output Resistance, Off | -2V < V < 2V | 300 | ||

| Voltage Change Rate | 4 | 30 | V/µs | |

| Maximum Load Capacitance | 2500 | pF | ||

| Receiver Input Resistance | 3 | 7 | kΩ | |

| Receiver Input Threshold: | ||||

| Output = Mark (Logic 1) | -3 | V | ||

| Output = Space (Logic 0) | 3 | V |

Figure 1. Typical RS-232 Connection.

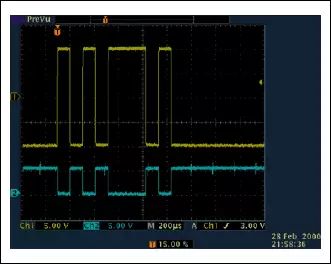

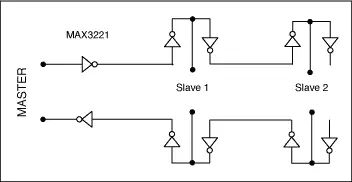

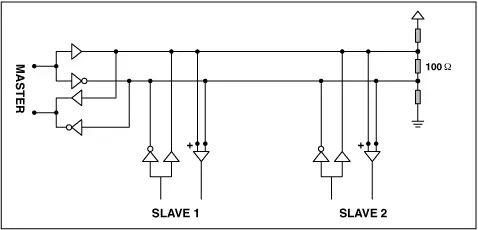

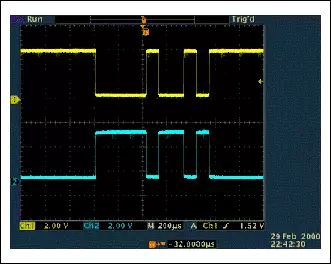

The typical swing range of RS-232 signals (Figure 2, CH1) is both positive and negative. Note the relative position of the 0V trace marker on the left side of the coordinate axis. Although RS-232 data is inverted, the conversion from TTL/CMOS to RS-232 and back to TTL/CMOS restores the original polarity of the data. The typical transmission distance for RS-232 rarely exceeds 100 feet. There are two reasons for this: first, the difference between the transmit level (±5V) and the receive level (±3V) only allows for 2V of common-mode rejection; second, the distributed capacitance of longer cables may exceed the specified maximum load (2500pF), thus reducing the slew rate. Since RS-232 is designed as a point-to-point interface, not a multi-node interface, its driver specifications are for a single load of 3kΩ to 7kΩ. Therefore, multi-node interface applications typically use a daisy chain connection method (Figure 3).

Figure 2. RS-232 Receiver Supports Bipolar Input Signals (Upper Trace, CH1), Outputs Inverted TTL/CMOS Signals (Lower Trace, CH2).

Figure 3. Daisy Chain Method Allows Multiple Slave Receivers to be Connected on a Single RS-232 Link.

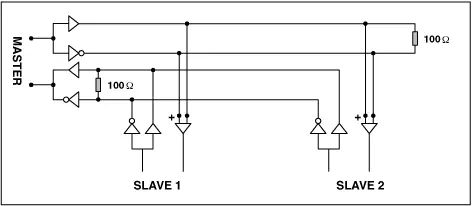

Daisy Chain Devices and Their Limitations In a daisy chain configuration, RS-232 signals pass through the first receiver and loop back to the transmitter. This configuration is repeated for subsequent devices in the data transmission line. The main problem with this technique is cable breakage. If a break occurs between Slave 1 and Slave 2, it prevents all downstream devices from sending or receiving data. Another multi-node RS-232 technique involves pre-buffering or RS-232 output boosting (to drive multiple parallel 5kΩ inputs).

To avoid issues related to daisy chain networks, Maxim developed the MAX3322E/MAX3323E, specifically designed for multi-node applications. These unique devices feature a 5kΩ logic switch input resistance. When the device is not selected, its input resistance remains in a high-impedance state, allowing communication with other devices on the shared bus to continue.

Another solution to the daisy chain network problem is to convert the RS-232 Rx and Tx signals to RS-422 signals (see Table 2). RS-422 is a differential standard that allows for much longer transmission distances. The higher input impedance of RS-422, combined with its higher driving capability, allows for the connection of up to 10 nodes (Figure 4). Another advantage of RS-422 is its independent transmit and receive pathways, eliminating the need for direction control. Necessary handshaking between devices can be achieved using software (XON/OFF handshaking) or hardware (a set of separate twisted pairs). The MAX3162 provides an economical way to convert signals between RS-232 and RS-422. For more information, see the RS-232/RS-485 protocol converter section below.

Table 2. Summary of Key Specifications for RS-422

| Parameter | Condition | Minimum | Maximum | Unit |

|---|---|---|---|---|

| Driver Output Voltage, Open Circuit | ±10 | V | ||

| Driver Output Voltage, Loaded | RL = 100Ω | 2-2 | V | |

| Driver Output Resistance | A to B | 100 | Ω | |

| Driver Output Short-Circuit Current | Each Output to Common Connection | 150 | mA | |

| Driver Output Rise Time | RL = 100Ω | 10 | % Bit Width | |

| Driver Common Mode Voltage | RL = 100Ω | ±3 | V | |

| Receiver Sensitivity | VCM < ±7V | ±200 | mV | |

| Receiver Common Mode Voltage Range | -7 | 7 | V | |

| Receiver Input Resistance | 4 | kΩ | ||

| Differential Receiver Voltage | Operational | ±10 | V | |

| Survivable | ±12 | V |

Figure 4. A Typical RS-422 System Allows Up to 10 Receivers to be Connected on a Differential Transmission Line.

Differences Between RS-485 and RS-422 and Their Applications RS-422 and RS-485 transceivers are often confused, with one being mistaken for the full-duplex version of the other. However, the electrical differences in common-mode range and receiver input resistance make these standards suitable for different applications. Since RS-485 meets all RS-422 specifications (Table 3), RS-485 drivers can be used in RS-422 applications. However, the reverse is not true. The common-mode output of RS-485 drivers ranges from -7V to +12V, while the common-mode range of RS-422 is only ±3V. The minimum receiver input resistance for RS-422 drivers is 4kΩ, while for RS-485 drivers it is 12kΩ.

Table 3. Summary of Key Specifications for RS-485

| Parameter | Condition | Minimum | Maximum | Unit |

|---|---|---|---|---|

| Driver Output Voltage, Open Circuit | 1.5-1.5 | 6-6 | VV | |

| Driver Output Voltage, Loaded | RL = 100Ω | 1.5-1.5 | 5-5 | VV |

| Driver Output Short-Circuit Current | Each Output to Common Connection | ±250 | mA | |

| Driver Output Rise Time | RL = 54ΩCL = 50pF | 30 | % Bit Width | |

| Driver Common Mode Voltage | RL = 54Ω | ±3 | V | |

| Receiver Sensitivity | -7V < VCM < 12V | ±200 | mV | |

| Receiver Common Mode Voltage Range | -7 | 12 | V | |

| Receiver Input Resistance | 12 | kΩ |

To reduce wiring costs and achieve longer line lengths, RS-485 transceivers have become the standard widely adopted in point-of-sale, industrial, and telecommunications applications. The wider common-mode range of RS-485 also supports longer line lengths and higher per-node input resistance, allowing for more nodes to be connected on the bus (Figure 5).

Figure 5. Compared to RS-422, RS-485 Connects Higher Input Impedance and Wider Common Mode Range, Supporting Longer Line Lengths.

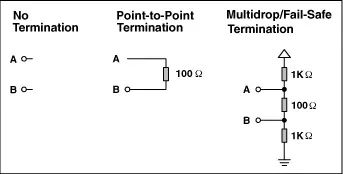

The differential RS-485 transmission (Figure 6) generates opposite currents and magnetic fields on each line of the twisted pair cable, canceling out the reverse magnetic fields around each wire, thereby minimizing radiated electromagnetic interference (EMI). To transmit over longer cables or at higher data rates, the cable acts as a transmission line and should be terminated using the characteristic impedance of the cable. This aspect of RS-485 connections can be confusing. Does the transmission line need termination? If so, how should it be terminated? If the designer is not the end-user, should these questions be left to the installer to solve? For most RS-485 transceivers, the data sheet indicates a simple choice between no termination and simple point-to-point termination when the cable acts as a transmission line (Figure 7). Termination resistors between the A-B terminals are harmless. By default, termination should be applied at the last transceiver on the bus.

Figure 6. The Opposite Polarity Signals on the RS-485 Line Cancel Each Other’s Magnetic Fields, Minimizing EMI. The GND reference on the Oscilloscope Screenshot Above is Shifted (Offset), Clearly Displaying the Opposite Polarity of the RS-485 Output Signal.

Figure 7. The Choice of Termination Resistor for Transmission Lines Depends on Specific Applications.

Failure Protection Determining whether termination resistors are needed is just one of the issues faced when implementing an RS-485 system. Normally, if A is greater than B by +200mV or more, the RS-485 receiver outputs a “1”; if B is greater than A by 200mV or more, the transceiver outputs a “0”. In a half-duplex RS-485 network, the host transceiver puts the bus into a tri-state after sending a message to the slave. So, if no signal is driving the bus, the receiver output state is undefined because the difference between A and B tends to 0V. If the receiver output RO is “0”, the slave interprets it as a new start bit and tries to read the subsequent byte. Since no stop bit occurs, the result is a framing error. The bus becomes masterless, and the network stalls.

Unfortunately, for a 0V differential input, different chip tests can produce different output signals. Prototypes may work correctly, but specific nodes may fail in production testing. To address this issue, as shown in the multi-node/failure protection termination in Figure 7, the bus is biased. Biasing the bus ensures that the receiver output remains “1” when the bus is in a tri-state. Alternatively, you can use “true failure protection” receivers, such as the MAX3080 (5V) and MAX3070 (3V) series, which change the receiver threshold to -50mV, ensuring that the RO output is “1” when the differential input is 0V.

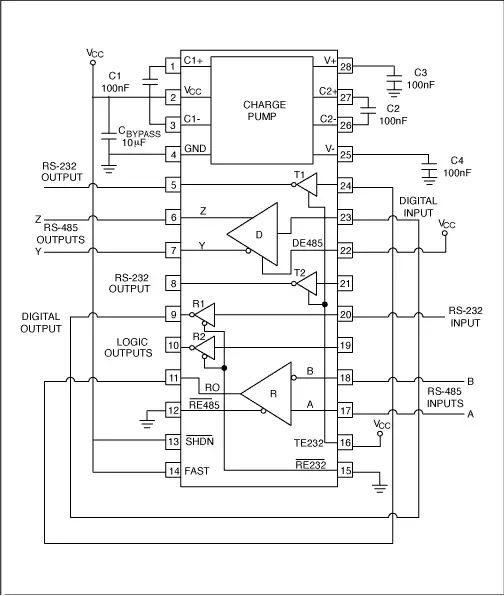

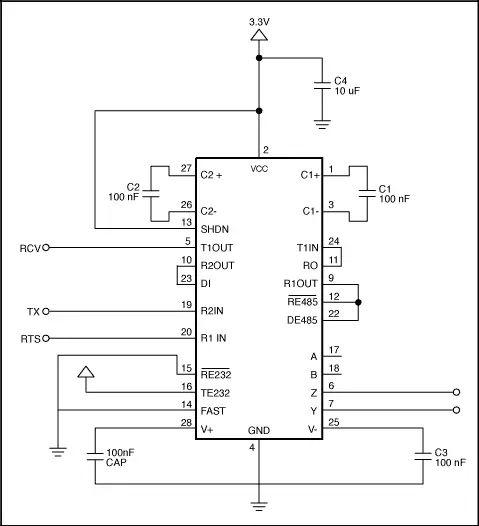

RS-232/RS-485 Protocol Converter The MAX3162 is a unique device that includes RS-232 and RS-485 receivers and transmitters. This wide-range communication device is integrated into a single IC and supports bidirectional independent conversion between RS-232 and RS-485 signals. In the circuit shown in Figure 8, the MAX3162 is configured for bidirectional conversion between RS-232 and RS-485 signals in point-to-point applications.

Figure 8. MAX3162 Bidirectionally Converts RS-232 and RS-485 Signals in Point-to-Point Applications.

Figure 9 shows the MAX3162 configured as an RS-232/RS-485 multi-node protocol converter. The conversion direction is controlled by the RTS signal R1IN. The single-ended RS-232 receiver input signal is converted to the differential RS-485 transmitter output; similarly, the differential RS-485 receiver input signal is converted to the single-ended RS-232 transmitter output. The RS-232 data received on R2IN is sent as RS-485 signals on Z and Y; the RS-485 signals received on A and B are sent as RS-232 signals on T1OUT.

The RTS line is a shared line used to control the bus direction of the circuit that converts between RS-232 and RS-485. This line controls whether the RS-485 transceiver acts as a transmitter or receiver on the RS-232 port (Figure 9). Note that the system is uncertain whether the data byte in the UART transmission buffer has been sent unless the system monitors the input DI of the RS-485 driver. That is, the system must allow for a fixed delay or actively monitor the DI input before using the DE input to change the bus direction.

Other direction control techniques include using microcontrollers and utilizing data-driven DE inputs while polling the A-B line voltage difference (using a pull-up resistor to connect A to 5V and a pull-down resistor to connect B to ground). The values of these resistors change with cable capacitance, but typical values are 1kΩ.

Figure 9. MAX3162 Bidirectionally Converts RS-232 and RS-485 Signals in Multi-Node Applications.

Port-Powered Devices Many RS-232 to RS-485 converters are “port-powered converters,” which power RS-485 through the RS-232 RTS line (or sometimes a combination of RTS and CTS (DTR) lines). Since the power available from the RS-232 port is limited, when a port-powered converter is used with (for example) 100 RS-485 endpoints, the startup voltage for RS-485 cannot be reached. However, the lower receiver threshold (200mV) allows for better margin for error. This technique is widely used in systems with shorter lines and no termination resistors between A and B endpoints.

Hot Swapping Inserting a circuit board into a live or powered backplane can cause differential interference on the data bus, leading to data errors. When inserting a circuit board, the data communication processor first enters its power-up sequence. During this period, the processor logic output driver is in a high-impedance state and cannot drive the DE and /RE inputs of MAX3060E/MAX3080E to the specified logic level. The leakage current of the processor logic driver in a high-impedance state can be as high as ±10mA, which may cause the standard CMOS enable inputs of the transceiver to drift to incorrect logic levels. Additionally, the parasitic capacitance of the circuit board may cause VCC or GND to couple to the enable inputs. If hot swapping is not supported, these factors can erroneously enable the driver or receiver of the transceiver.