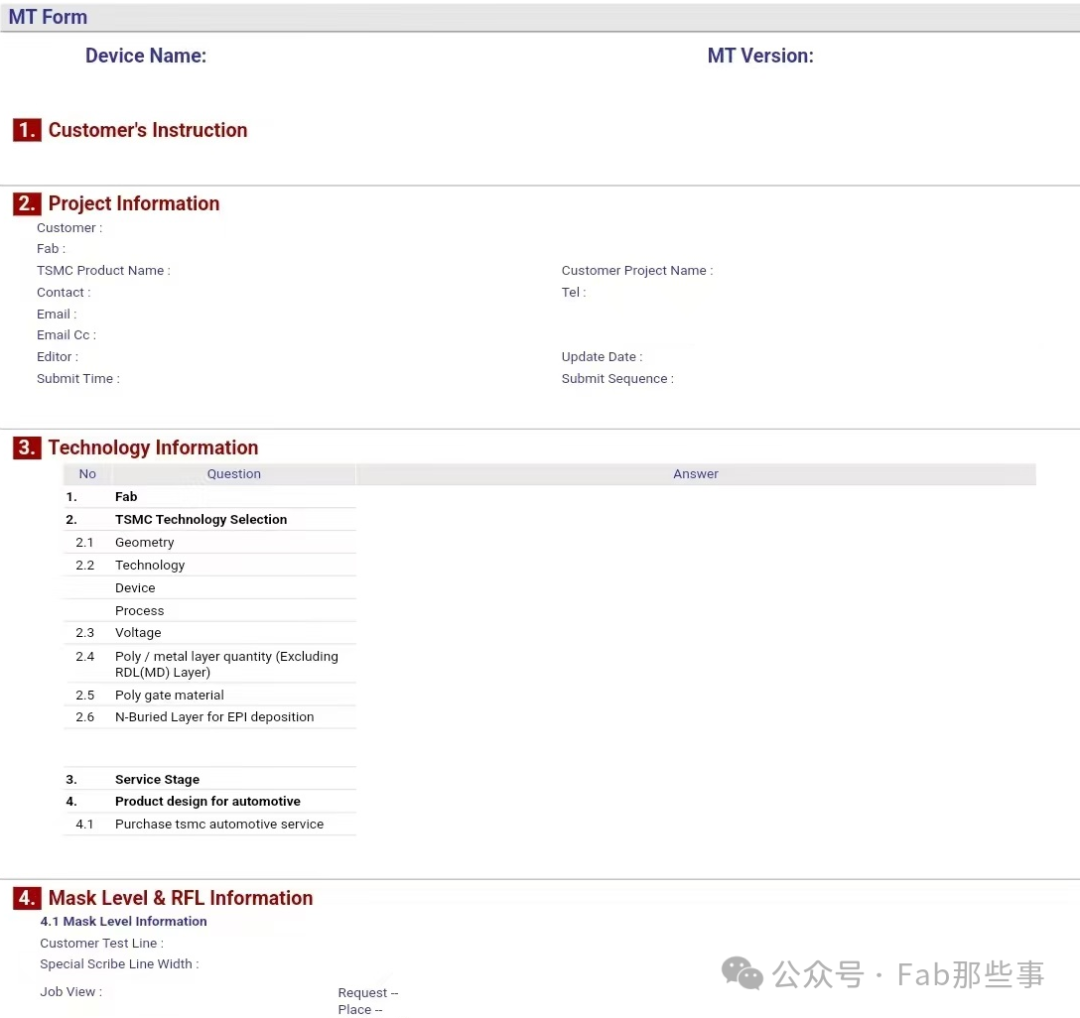

In the previous article “Chip Journey 3 – Dedicated Vehicle or Ride-Sharing”, the design company has finalized the form of the tapeout. This issue introduces how design communicates requirements to the Fab and the preliminary alignment preparations.After completing the design plan, based on the maturity of the interface with the Fab, the design team and PDE will jointly conduct preliminary communication with the Foundry. After confirming the initial intent, the Fab CE customer engineer will intervene in the early tapeout process and work with the design company to confirm the interface details. In some cases, assistance from PIE/Tapeout may be required for confirmation.Once the preliminary requirements are confirmed, the design company’s needs must be communicated through documentation, typically using the Foundry Service Form. This can be understood as a specific and detailed menu, including how the customer places orders, what dishes are ordered, the specific quantities of ingredients, and any special dietary restrictions. Some domestic foundries refer to this as the MT Form. (Partial Screenshot)The MT Form for T*Fab is shown in the figure, and due to space constraints, only part of it is listed. The main content generally includes the following sections:1. Customer IntroductionA brief introduction to the type and scale of the customer, which can be summarized or omitted.2. Project InformationCustomer code, internal code, email and contact information of the customer representative, etc.3. Brief Technical InformationFab platform code, selected process platform and node, types of devices used and threshold voltages, number of poly/metal interconnect layers, whether EPI is included, etc.4. Mask InformationWhether to use a Fab partner mask factory or specify an external purchase, and the contact information of the mask factory.5. Chip InformationIncludes chip geometric dimensions, whether there is a seal ring for cutting protection, and other relevant information, the version of the DRC scripts used by the design company, and the cloud storage address of the customer design layout in the foundry.6. IP InformationWhether IP is used, which IP is provided by the fab or a third party, and whether it has passed DRC design rule checks, ERC electrical rule checks, LVS layout verification, etc.7. Specific Devices and Composition Layers Used in the ChipFor example, if HV NMOS and HV PMOS are used during design, the corresponding devices must be selected from the platform device library, and the mask layer composition must be confirmed. Common device types include high, medium, and low voltage MOSFETs, as well as variable capacitors, SRAM, etc.8. Metal Layer InformationIncluding the number of metal layers, whether there is a need for thickening the top metal layer, and whether to add dummy shapes (dummy shapes are graphics that do not participate in electrical connections, enhancing process performance from a graphic density perspective).9. All Layer InformationBased on all the above information, it is necessary to reconfirm all layer information used in this tapeout, ensuring that the currently selected mask layers can achieve the customer’s chip implementation.10. Other Special RequirementsAfter completing the Service information, the CE, as the technical liaison, will check with Tapeout and PIE. Once confirmed to be correct, the internal tapeout process officially begins. At this point, the design company and related engineers can enter a slightly more relaxed period, while the PDE responsible for interfacing with the foundry will become busy.During this process, in addition to interfacing with the foundry for tapeout, the design company PDE will also calculate the time required for tapeout, the mask production time, the start time of tapeout, and the cycle for running goods. The batch plan for the tapeout also needs to be communicated to the Fab in a timely manner. Additionally, the PDE must coordinate with the packaging and testing factory according to the overall project cycle, confirming the packaging and testing plan and schedule. Working overtime is essential to expedite tapeout and obtain test results as soon as possible for subsequent revisions or mass production requirements.To add a bit of business knowledge:Most domestic fabs do not have their own mask factories, only some partner mask factories. For example, S* operates a self-owned mask factory model, where the mask is considered company property and is disposed of by the fab after the product cycle ends. In contrast, for other foundry partner models, the mask belongs to the customer, and when the product is discontinued or the lifecycle ends, the fab must return the mask to the customer. In the latter case, sometimes the design company may take the mask to another fab for production after finding a cheaper foundry, while self-owned foundries can prevent this operation. Generally, only strong foundries will establish their own mask factories.Furthermore, the tapeout cycle and tapeout price of the design company are closely related. If there is an urgent need for the fab to respond to the tapeout process immediately, the manufacturing department of the foundry will provide the highest priority support, and such operations will incur additional costs.With the confirmation of pre-tapeout requirements, the next issue will mainly introduce the process from Tapeout to NTO wafer offline.Feel free to bookmark, like, support, and donate, and welcome comments and discussions!

(Partial Screenshot)The MT Form for T*Fab is shown in the figure, and due to space constraints, only part of it is listed. The main content generally includes the following sections:1. Customer IntroductionA brief introduction to the type and scale of the customer, which can be summarized or omitted.2. Project InformationCustomer code, internal code, email and contact information of the customer representative, etc.3. Brief Technical InformationFab platform code, selected process platform and node, types of devices used and threshold voltages, number of poly/metal interconnect layers, whether EPI is included, etc.4. Mask InformationWhether to use a Fab partner mask factory or specify an external purchase, and the contact information of the mask factory.5. Chip InformationIncludes chip geometric dimensions, whether there is a seal ring for cutting protection, and other relevant information, the version of the DRC scripts used by the design company, and the cloud storage address of the customer design layout in the foundry.6. IP InformationWhether IP is used, which IP is provided by the fab or a third party, and whether it has passed DRC design rule checks, ERC electrical rule checks, LVS layout verification, etc.7. Specific Devices and Composition Layers Used in the ChipFor example, if HV NMOS and HV PMOS are used during design, the corresponding devices must be selected from the platform device library, and the mask layer composition must be confirmed. Common device types include high, medium, and low voltage MOSFETs, as well as variable capacitors, SRAM, etc.8. Metal Layer InformationIncluding the number of metal layers, whether there is a need for thickening the top metal layer, and whether to add dummy shapes (dummy shapes are graphics that do not participate in electrical connections, enhancing process performance from a graphic density perspective).9. All Layer InformationBased on all the above information, it is necessary to reconfirm all layer information used in this tapeout, ensuring that the currently selected mask layers can achieve the customer’s chip implementation.10. Other Special RequirementsAfter completing the Service information, the CE, as the technical liaison, will check with Tapeout and PIE. Once confirmed to be correct, the internal tapeout process officially begins. At this point, the design company and related engineers can enter a slightly more relaxed period, while the PDE responsible for interfacing with the foundry will become busy.During this process, in addition to interfacing with the foundry for tapeout, the design company PDE will also calculate the time required for tapeout, the mask production time, the start time of tapeout, and the cycle for running goods. The batch plan for the tapeout also needs to be communicated to the Fab in a timely manner. Additionally, the PDE must coordinate with the packaging and testing factory according to the overall project cycle, confirming the packaging and testing plan and schedule. Working overtime is essential to expedite tapeout and obtain test results as soon as possible for subsequent revisions or mass production requirements.To add a bit of business knowledge:Most domestic fabs do not have their own mask factories, only some partner mask factories. For example, S* operates a self-owned mask factory model, where the mask is considered company property and is disposed of by the fab after the product cycle ends. In contrast, for other foundry partner models, the mask belongs to the customer, and when the product is discontinued or the lifecycle ends, the fab must return the mask to the customer. In the latter case, sometimes the design company may take the mask to another fab for production after finding a cheaper foundry, while self-owned foundries can prevent this operation. Generally, only strong foundries will establish their own mask factories.Furthermore, the tapeout cycle and tapeout price of the design company are closely related. If there is an urgent need for the fab to respond to the tapeout process immediately, the manufacturing department of the foundry will provide the highest priority support, and such operations will incur additional costs.With the confirmation of pre-tapeout requirements, the next issue will mainly introduce the process from Tapeout to NTO wafer offline.Feel free to bookmark, like, support, and donate, and welcome comments and discussions!