Let’s discuss the aspects of chip design, tapeout, verification, manufacturing, and costs; tapeout is like taking a major exam for chip design.

The importance of tapeout lies in its ability to verify whether the chip design is successful. It is a critical step in chip manufacturing, where the finalized design is handed over to the chip fabrication plant to produce samples. This process checks whether the designed chip meets the specifications or if further optimization is needed; if a chip that meets the requirements can be produced, then mass production can commence.

The input of the above process is the chip project design, and the output is the completed chip wafer.

1. Wafer Terminology

1. Chip (chip, die), device (device), circuit (circuit), microchip (microchip), or bar: all these terms refer to the microchip patterns that occupy most of the wafer surface;

2. Scribe line (scribe line, saw line) or street (street, avenue): these areas on the wafer are used to separate the spacing between different chips. Scribe lines are usually blank, but some companies place alignment marks or test structures in the spacing areas;

3. Engineering die and test die: these chips differ from the official chips or circuit chips. They include special devices and circuit modules used for electrical testing of the wafer production process;

4. Edge die: chips located at the edge of the wafer that have incomplete mask coverage, resulting in area loss. More edge waste caused by larger individual chip sizes can be compensated by using larger diameter wafers. One of the driving forces for the semiconductor industry to develop larger diameter wafers is to reduce the area occupied by edge chips;

5. Wafer crystal plane: the cross-section in the image indicates the lattice structure beneath the device, and the direction of the device edge relative to the lattice structure is determined;

6. Wafer flats/notches: the illustrated wafer has major flats and minor flats, indicating that this is a P-type <100> oriented wafer. Both 300mm and 450mm diameter wafers use notches as lattice orientation markers. These flats and notches also assist in wafer alignment in some wafer production processes.

2. Chip Tapeout Methods (Full Mask, MPW)

Full Mask and MPW are both methods of tapeout (submitting design results for manufacturing) for integrated circuits. Full Mask means that all masks in the manufacturing process serve a specific design; MPW stands for Multi Project Wafer, which means multiple projects share a single wafer, allowing multiple IC designs to be manufactured in the same process.

1. Full Mask means that all masks in the manufacturing process serve a specific design; a Full Mask chip can produce thousands of dies from a single wafer; then it is packaged into chips to support large-scale customer demand.

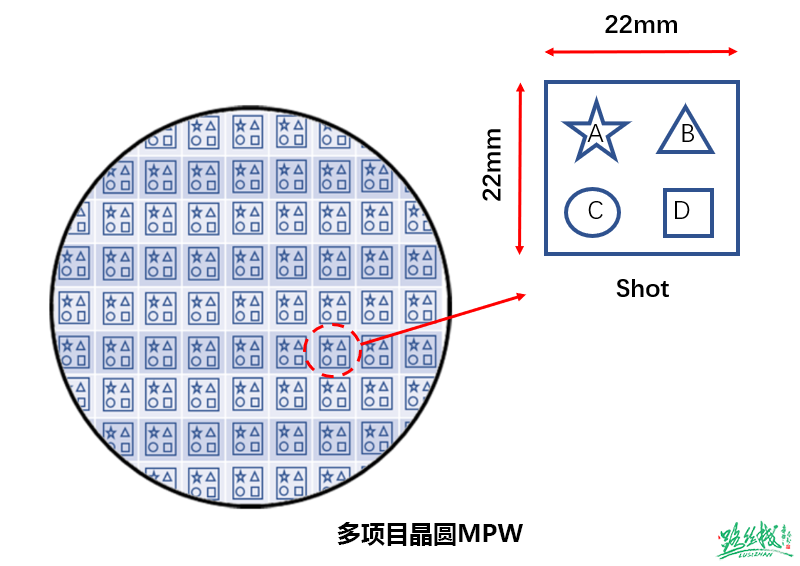

2. MPW, or Multi Project Wafer, is similar to PCB panelization in circuit design. Multiple integrated circuit designs using the same process are placed on the same wafer for tapeout. After manufacturing, each design can obtain dozens of chip samples, which is sufficient for experiments and testing during the prototype design phase. This method can reduce tapeout costs by 90%-95%, significantly lowering chip R&D costs.

Wafer fabs have a fixed number of MPW opportunities each year, called Shuttle, which departs at scheduled times. Different companies share the wafer, and there are rules in place. MPW locks the area by SEAT, where a SEAT is generally a 3mm*4mm area. To ensure that different chip companies can participate in MPW, the number of SEATs reserved for each company is limited (having too many SEATs would increase costs, negating the purpose of MPW). The advantage of MPW is that the tapeout cost is low, generally just a few hundred thousand, which significantly reduces risk; however, it is important to note that from a production perspective, MPW is still a complete production process, so it still takes time. A typical MPW takes about 6 to 9 months, which delays chip delivery times.

Since it is a shared wafer, the number of chips obtained through MPW will be limited, mainly used for internal verification testing by chip companies, and may be provided to a very small number of top customers. From this, it can be understood that MPW is an incomplete, non-mass-producible tapeout.

3. Introduction to MPW from the perspective of wafer production

Chip processing is still a relatively complex process. I believe many friends, after understanding the wafer structure from the previous sections, see the following image, where a box belongs to a chip company.

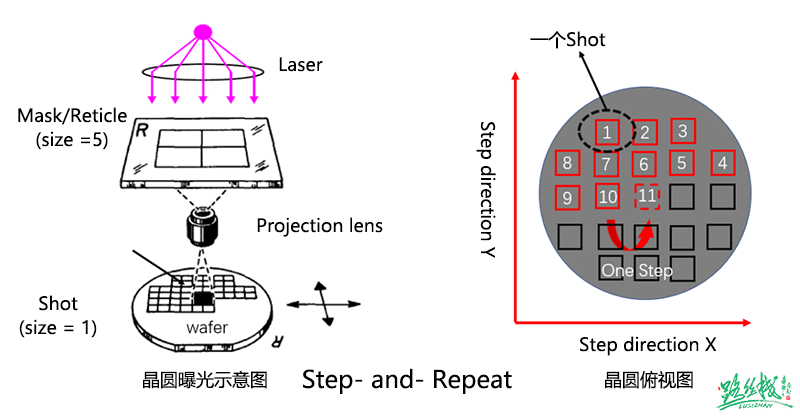

In reality, this is not the case, as it relates to the photolithography technology in the wafer production process; current photolithography technologies such as DUV/EUV mostly use reduction methods for exposure, as shown in the following image:

Using a 1:5 magnified mask for wafer exposure, the rectangular area exposed at one time is usually called a shot. After exposure, the photolithography machine automatically adjusts the wafer position for the next shot, and this process continues (Step-and-Repeat) until the entire wafer is exposed. The area of one shot is the area shared by all participants in the SEAT;

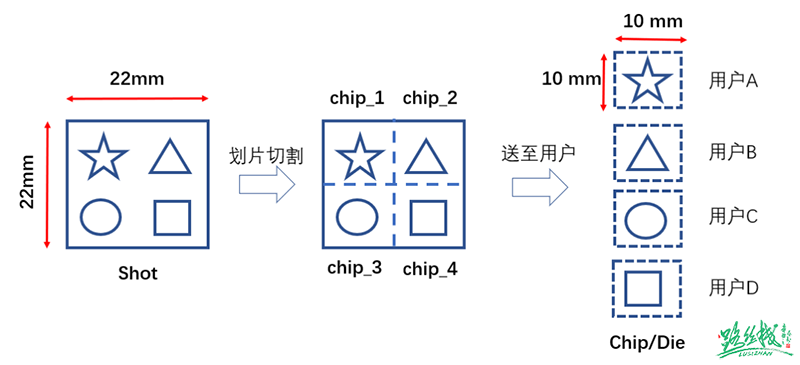

In the diagram below, one shot is divided into four small grids, with each grid allocated to a design from a different vendor. MPW wafers typically have fewer than 20 users.

3. Chip ECO Process

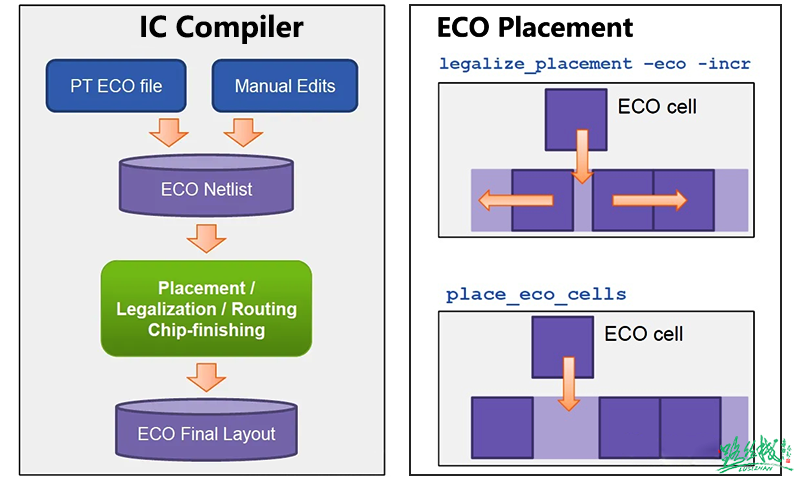

ECO stands for Engineering Change Order. It can occur before, during, or after tapeout; ECO after tapeout may require minor changes to a few metal layers or significant changes to dozens of metal layers, or even a complete tapeout. The implementation process of ECO is shown in the diagram below:

If the chips from MPW or Full Mask verification have functional or performance defects, small-scale adjustments can be made to the circuit and standard cell layout through ECO, maintaining the original design layout and wiring results while optimizing to fix remaining violations, ultimately achieving the chip’s sign-off standards. Violations cannot be fixed through the backend layout and wiring process (repeating the process is too time-consuming) but must be optimized through the ECO process for timing, DRC, DRV, and power consumption.

4. Tapeout Corners

1. Corners in chip manufacturing are a physical process, subject to process variations (including doping concentration, diffusion depth, etching degree, etc.), leading to differences between batches, between different wafers of the same batch, and between different chips on the same wafer.

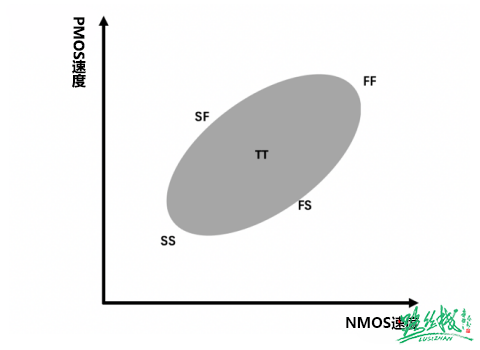

On a wafer, it is impossible for the carrier drift velocity at every point to be the same. With variations in voltage and temperature, their characteristics will also differ, leading to classifications known as PVT (Process, Voltage, Temperature), with Process further divided into different corners: TT: Typical N Typical P FF: Fast N Fast P SS: Slow N Slow P FS: Fast N Slow P SF: Slow N Fast P The first letter represents NMOS, and the second letter represents PMOS, referring to different concentrations of N-type and P-type doping. NMOS and PMOS are processed independently, without affecting each other, but in circuits, NMOS and PMOS operate simultaneously, leading to situations where NMOS is fast while PMOS is also fast or slow, resulting in the four conditions FF, SS, FS, and SF. Adjustments made through Process simulate the speed of devices, and different levels of FF and SS are set based on the magnitude of deviations. Under normal circumstances, most are TT, and the five corners above can cover about 99.73% of the range within +/-3 sigma, which follows a normal distribution.

2. The significance of corner wafers during engineering tapeout is that the FAB will adjust inline variations for key layers, and some may also use backup wafers to ensure that the shipped wafer devices are on target, i.e., near the TT corner. If the goal is merely to produce some samples, corner verification may not be necessary, but if preparing for subsequent mass production, corner considerations are essential. Due to process variations during production, corners are estimates of normal fluctuations in the production line, and the FAB will have corner verification requirements for mass-produced chips. Therefore, corners must be satisfied during the design phase, and circuits must be simulated under various corner and extreme temperature conditions to ensure normal operation across all corners, which will enhance the yield of the final produced chips.

3. Corner Split Table Strategy For products, generally, corners should meet specifications, and under normal circumstances, specifications have 6 sigma, such as FF2 (or 2FF) indicating a shift of 2 sigma towards the fast direction, and SS3 (or 3SS) indicating a shift of 3 sigma towards the slow direction. Sigma primarily represents the fluctuation of Vt; larger fluctuations result in larger sigma. Here, 3 sigma is within the specification line of the process devices, allowing for slight exceedance, as fluctuations on the line cannot perfectly meet specifications.

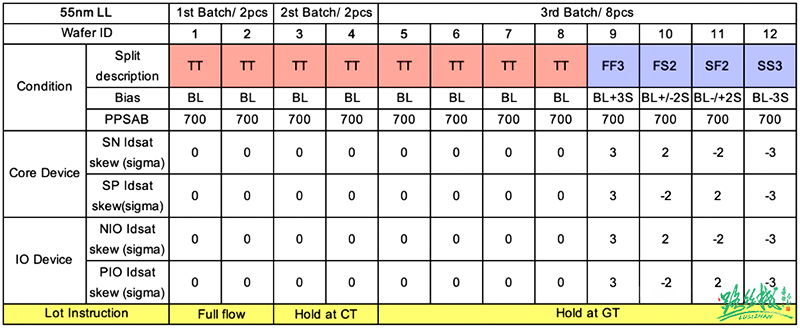

Below is an example of a 55nm Logic process wafer, with a proposed corner split table:

① #1 & #2 Two pilot wafers, one blind sealed, one for CP measurement;

② #3 & #4 Two wafers held at Contact, reserved for later revisions, saving ECO tapeout time;

③ #5~#12 Eight wafers held at Poly, waiting for pilot results to determine if device speed adjustments are needed and to verify corners;

④ In addition to reserving enough chips for testing and verification, Metal Fix, as much as possible, should also reserve wafers for mass production shipments based on project needs.

4. Confirming Corner Results

First, most should fall within the window range determined by the four corners; if there are significant deviations, it may indicate a process shift. If the yield of each corner is unaffected and meets expectations, it indicates that the process window is sufficient. If individual conditions have low yields, adjustments to the process window are necessary. The purpose of corner wafers is to verify design margins and assess whether yield is compromised. Generally, chips exceeding the performance range of this corner constraint are discarded.

Corner verification is benchmarked against WAT test results, generally led by the FAB, but the costs of corner wafers are borne by the design company. For mature and stable processes, chips on the same wafer, from the same batch, or even from different batches have very similar parameters, and the range of deviations is relatively small. Process corners (Process Corner) PVT (Process Voltage Temperature) process errors differ from bipolar transistors, with significant parameter variations in MOSFETs between different chips and batches.

To alleviate the difficulties of circuit design tasks to some extent, process engineers must ensure that device performance remains within a certain range. Generally, they strictly control expected parameter variations by discarding chips that exceed this performance range.

① The speed of MOS transistors refers to the threshold voltage levels, with fast corresponding to low thresholds and slow corresponding to high thresholds. GBW=GM/CC, under the same conditions, a lower vth results in a higher gm value, thus a larger GBW and faster speed (specific situations require specific analysis).

② The speed of resistors. Fast corresponds to small square resistance, slow corresponds to large square resistance.

③ The speed of capacitors. Fast corresponds to the smallest capacitance, slow corresponds to the largest capacitance.

5. Tapeout Costs and Wafer Prices

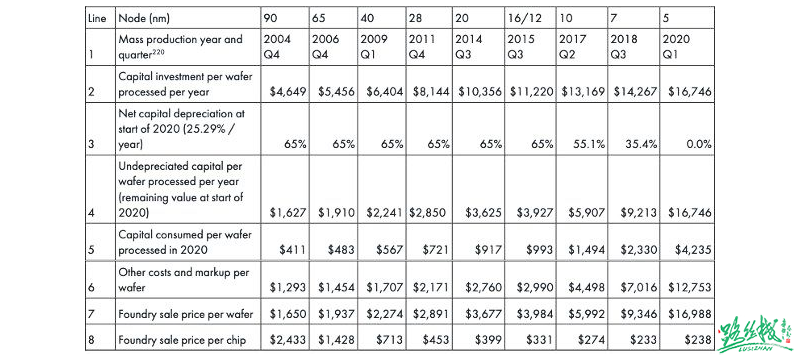

The tapeout mask cost for 40nm is approximately $800,000 to $900,000, and the wafer cost per piece is around $3,000 to $4,000, plus IP merge, totaling around 7 to 8 million RMB.

The tapeout cost for 28nm process is $2 million; for 14nm process, it is $5 million; for 7nm process, it is $15 million; for 5nm process, it is $47.25 million; and for 3nm process, it may exceed $100 million; among the main tapeout costs, masks are the most expensive.

The more advanced the process node, the more mask layers are required; each mask corresponds to a single application of photoresist, exposure, development, and etching, involving material costs and equipment depreciation costs, all of which must be borne by fabless customers!

28nm requires about 40 layers, 14nm requires 60 masks; 7nm requires 80 or even over 100 masks; one mask costs $80,000, so chips must be mass-produced to lower costs!

For example, in a 40nm MCU process: if producing 10 wafers, the cost per wafer is (900,000 + 4,000*10)/10 = $94,000; if producing 10,000 wafers, the cost per wafer is (900,000 + 4,000*10,000)/10,000 = $4,090. (The larger the wafer quantity, the cheaper it becomes; different manufacturers also have different quotes.)

Wafer foundry prices sourced from the internet

Taiwan Semiconductor Manufacturing Company (TSMC) provided the latest quote this year: the most advanced process at 3nm costs $19,865 per wafer, approximately 142,000 RMB.

Conclusion

There are several important stages from chip design to finished product: design -> tapeout -> packaging -> testing, but the cost composition of chips varies significantly, generally comprising 20% labor costs, 40% tapeout, 35% packaging, and 5% testing.

Tapeout is a high-risk endeavor, with risks ranging from 15% to 35%; different teams and chip types have different probabilities. Some analog chip companies, even with complete teams and clear ideas, took 8 years and 18 tapeouts to finally complete the verification of sensor analog computing IP, creating the ideal ultra-low power, ultra-close transmission chip.