How the Intelligent Logistics Drive System Integrates Electric Rollers

(CANopen Devices) with PROFINET Controllers

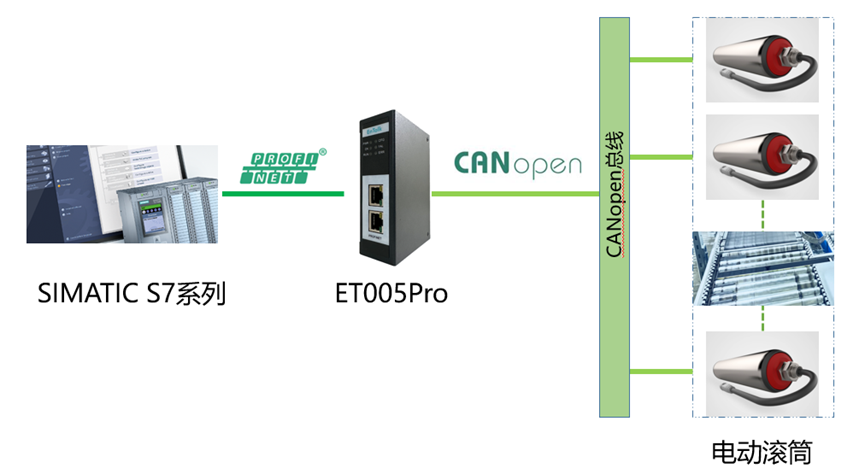

Application Scenario

In a smart factory environment, an efficient logistics system requires an integrated and systematic approach, organically combining various adaptive logistics hardware and software technologies for different operational scenarios.

CANopen is a traditional industrial automation communication protocol, commonly used by slave products such as electric rollers. In a project in Suzhou, the Siemens S7-1500 connects up to 50 electric rollers controlling the position sensors for goods triggering, handling the acceleration and deceleration control of goods.

As is well known, CANopen signals cannot be directly connected to the PROFINET communication system. Equipment suppliers often focus on their core business development and may not spend a lot of time and labor costs developing the PROFINET protocol.

To quickly solve the above problems, we use the ET005Pro protocol gateway to convert the CANopen slave product signals into PROFINET signals, easily achieving the connection between the PROFINET communication system and various CANopen slave nodes, with stable and reliable signal transmission.

Topology Diagram of the Intelligent Logistics Drive System

▼

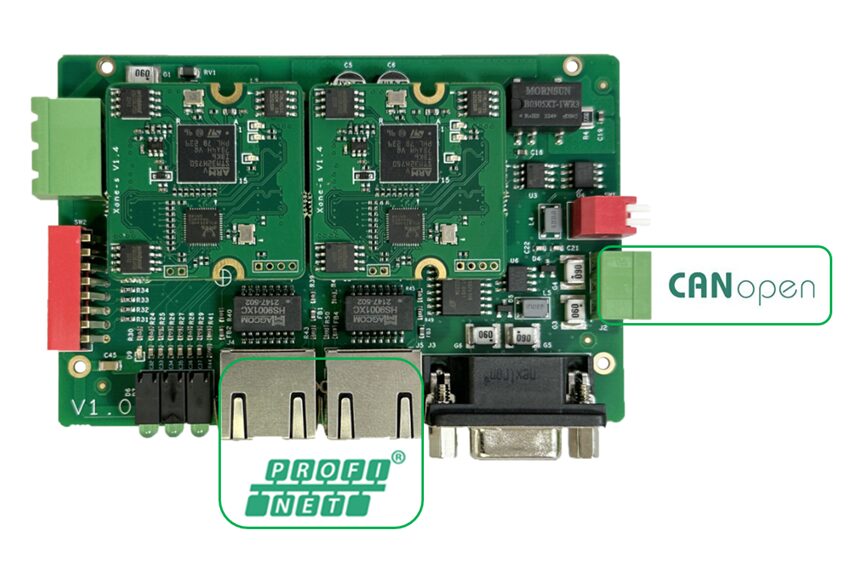

ET005Pro High-Performance Gateway

To improve data processing speed and reduce network system latency, the EnTalk series gateways provide a new architecture design for high-performance applications. The gateway uses two Xone (embedded unified boards) to independently implement different protocols. The two Xone exchange data through a high-speed link. The diagram below shows the framework of the ET005Pro Ethernet to Serial conversion, where Ethernet is the PROFINET industrial Ethernet protocol and Serial is the CAN protocol.

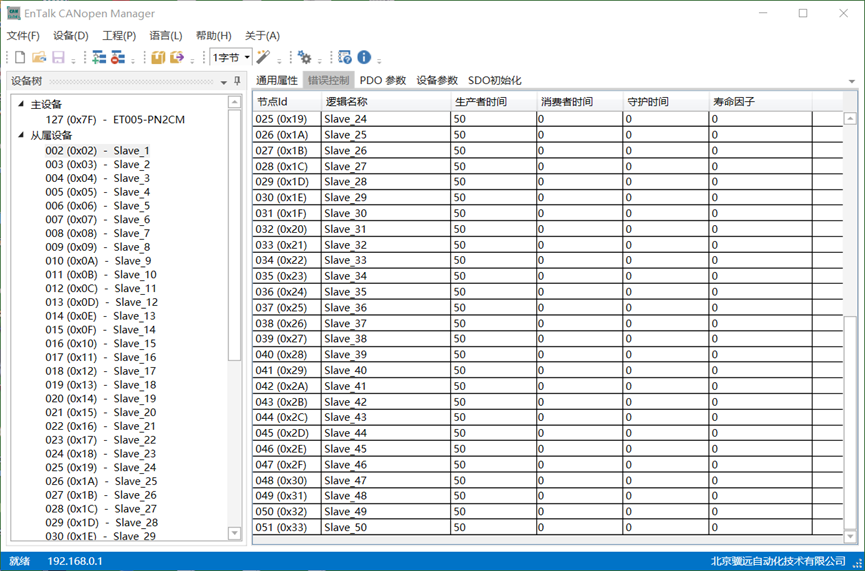

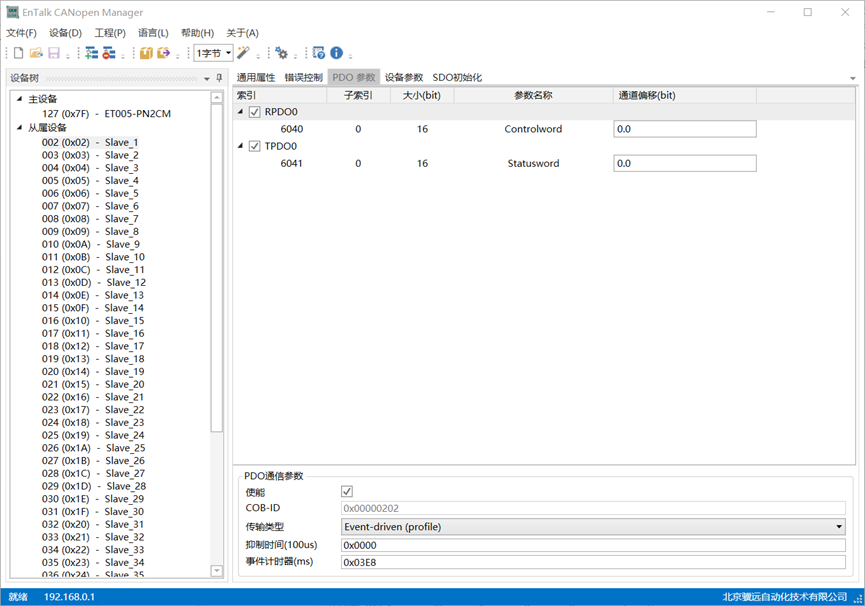

Gateway Configuration

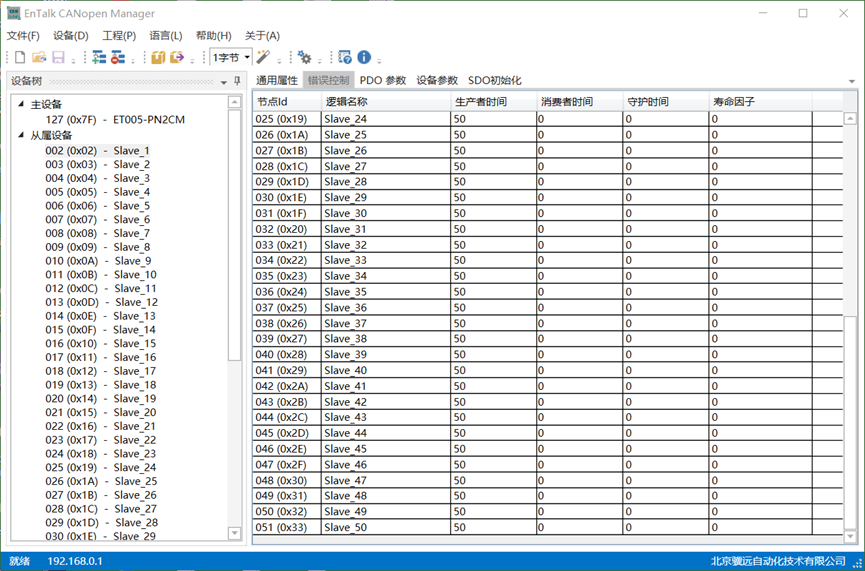

Heartbeat Time Configuration

Process Data Configuration

On-Site Communication Sniffer Testing

The cycle time for the optical sensor trigger signal from the electric roller to the CANopen bus is 10.18ms. The gateway IO update cycle time is 2ms, with a response time of less than 10ms.

On-Site Optical Trigger Time Diagram

EnTalk Series Family Products