CANopen IoT is suitable for networks that do not support embedded internet protocols, allowing access to local and remote CANopen networks through network protocols and communication services.

In many applications, specially designed mobile or tablet applications allow users to remotely control and maintain air conditioning and heating systems from anywhere. These applications also enable status monitoring of automation system components for preventive maintenance.

These applications require access from network-based monitoring or control units to embedded sensors with fieldbus interfaces, and vice versa. This applies to networks that support internet protocols. This access can invoke cloud connectivity or use the cloud for remote data processing or distribution.

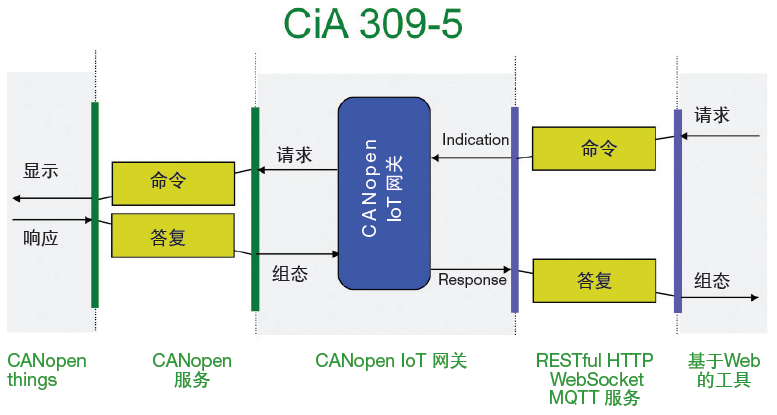

The CiA (CAN in Automation) Special Interest Group (SIG) for CANopen IoT (Internet of Things) has designed the specification CiA 309.5, which allows CANopen embedded network users to access their local and remote CANopen networks using web protocols and communication services (such as Restful HTTP, Websocket, and MQTT).

What is CANopen IoT?

CiA members also intend to provide more comfortable diagnostics by offering enhanced, coordinated visualization. Embedded devices provide diagnostic data in some way. Providing visualization capabilities on embedded devices can meet this requirement.

Thus, any industrial terminal, tablet, mobile phone, remote desktop, etc., can serve as a human-machine interface (HMI) for diagnostic services. Remote diagnostics and maintenance can be conducted bypassing the limitations of a central host controller.

However, providing visualization often requires significant memory. Small sensors without the necessary memory resources need to use HTTP and Websocket to provide visualization with a broadband internet connection.

CANopen IoT is working to help users address these challenges. At the application level, the CiA organization plans to offer function-oriented services. With these new services, coordinated functions tailored to specific applications can be initiated, monitored, and controlled. These functions are communication services of CANopen mapped to Restful HTTP or Websocket through logical addressing. Existing internet infrastructure can be used directly or via the cloud to request/collect functions. The requester/collector is a web-based application, while the provided data resides in the application server of the CANopen IoT gateway.

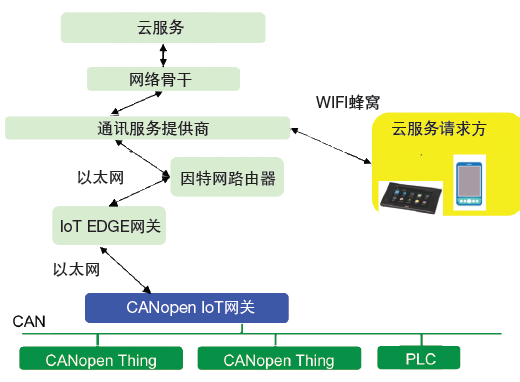

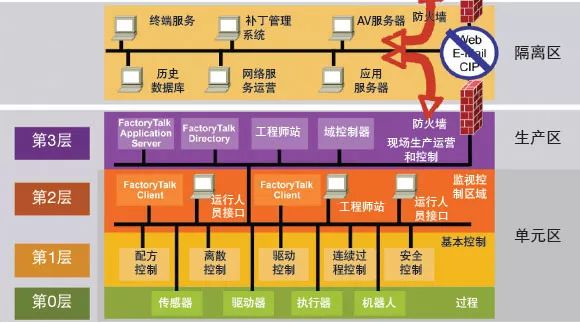

Figure 1: Example of CANopen IoT cloud connection path. Image source: CiA organization

IoT Gateway and Cloud-

The CANopen IoT gateway can tunnel HTTP or transmit requests/responses to web applications via the cloud. If through the cloud, the communication path must include an edge gateway, which is prepared with all tunnel data for preprocessing to meet cloud requirements. Local communication can also be done through the CANopen IoT gateway, including IoT and CANopen functional components and managing interactions between them.

The CANopen functional components communicate with the CANopen embedded network, while the gateway provides the data obtained to other gateway functional components. The IoT functional components prepare embedded CANopen data in JSON format and map it to Restful HTTP requests/responses for transmission to CANopen network/web-based applications.

As CANopen process data or diagnostic information may occur dynamically when data is submitted to the web, using the Websocket protocol can optimize bidirectional communication. Web applications establish Websocket sessions. Once CANopen data appears in the CANopen functional components, it is processed in the IoT components and submitted to the web application. In this case, the web application does not need to poll the gateway for HTTP requests for this data.

Figure 2: CANopen IoT gateway communication

– END –

This article is from the August 2019 issue of CONTROL ENGINEERING China, under the “Technological Advances” column, originally titled: Optimizing Local and Remote Network Communication through CANopen IoT

This Issue

Good News: The CONTROL ENGINEERING China mini-program is online, click the magazine cover to open the mini-program to read past issues.

Recommended Reading

5 Challenges in Implementing Industrial Big Data

Updating the Purdue Model—Creating Big Data Collection and Analysis Architecture Suitable for the Process Industry

Don’t Understand What Blockchain Is? It Turns Out “Mahjong” Is the Earliest Blockchain!

Is AI Ready for Data Analytics?

Read a High-Quality Original Article Every Day, Follow Us!

Every day read a high-quality original article, follow us!