A few days ago, I saw a public account article about eSIM, and I would like to follow up with another piece on the application of eSIM in industrial IoT scenarios.

eSIM is making significant progress! A game changer in the IoT market has arrived.

Why Can’t the IoT Card of Gas Alarm Devices Use eSIM?

This question was posed to me by my supervisor, Engineer Niu, a few years ago. The original quote was: “You see, Apple phones have supported eSIM for a long time, allowing remote number writing. Why can’t our gas alarm devices use it?” Unfortunately, I was not knowledgeable enough to answer this question until I recently studied it, but my understanding is still limited.

-

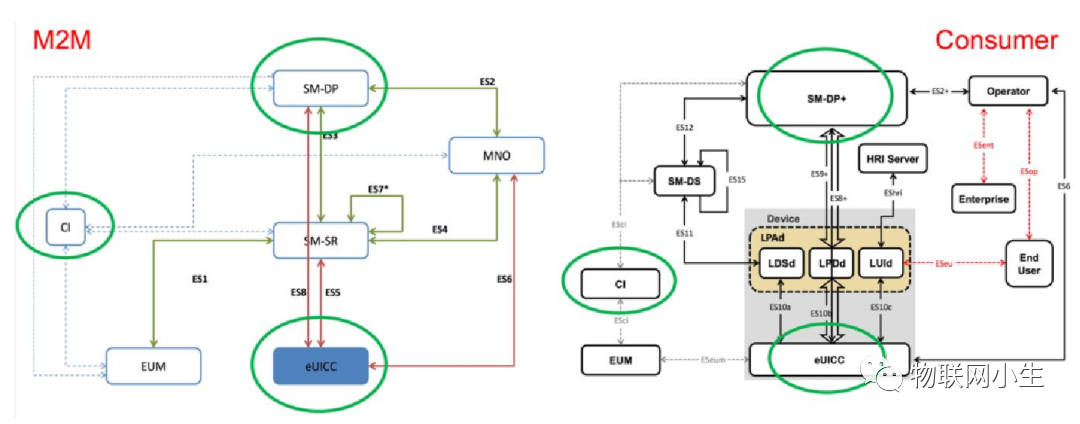

There are two types of eSIM: M2M-eSIM and Consumer-eSIM. Devices like Apple phones and children’s watches use Consumer-eSIM, while IoT devices such as gas alarm devices use M2M-eSIM.

-

The eSIM is empty when it leaves the factory, meaning it lacks operator information, plan details, security algorithms, etc., which are known as configuration files (profiles). Users need to write the profile file to the eSIM for it to function properly.

-

For Consumer-eSIM users, devices typically have an interface, allowing the profile file to be written to the eSIM after user consent, including changing the eSIM operator and plan information.

-

In contrast, M2M-eSIM generally lacks an interface or has limited network environments, requiring remote writing of profiles. For various reasons, writing the profile file requires direct operation by the operator, making it nearly impossible to change operators. Thus, existing IoT terminals using M2M-eSIM must be purchased directly from the operator without the option to switch.

Why Does Industrial IoT Need eSIM?

Or, what problems can eSIM solve for IoT terminals?

-

eSIM is more suitable for complex industrial environments.

We all know that conventional SIM cards are made of plastic. The SIM card slot connects to the metal part of the SIM through spring contacts to enable communication between the wireless module and the SIM card. This leads to the first issue: “The SIM card slot cannot be coated with waterproof paint.” Additionally, high temperatures can deform the plastic part of the SIM card, and dust, corrosion, and high humidity environments can lead to poor contact between the SIM card and the slot. Therefore, while SIM cards may work fine in civilian scenarios, the likelihood of issues arising in industrial environments is much higher. eSIM, being an electronic device, effectively resolves these problems.

-

Cost

The cost here includes both the cost of the SIM card itself and the labor cost associated with changing cards. A regular SIM card costs about 3 yuan, and prolonged use, along with frequent insertion and removal, can lead to wear and even loss of the card. Furthermore, if a user wants to switch operators, they must either send personnel to the site or return the device to the factory, resulting in significant cost pressure. In contrast, eSIM has a low inherent cost, and changing operators can be done remotely, eliminating wear and loss, thereby reducing the hidden costs in subsequent maintenance operations.

-

Resolving Conflicts Between Equipment Manufacturers and Users

Why does the situation of customer-supplied cards exist? Simply put, the prices are different. For example, China Resources Group can obtain SIM cards from operators at a lower price than what we offer. This is negligible for a few thousand cards, but what about tens of thousands or millions? Additionally, if we have a project in a city that connects a million-level devices, the telecom leaders may personally lead a team to stay on-site for a month to resolve and optimize base stations and core networks, while also providing significantly cheaper SIM cards. Therefore, the situation of customer-supplied cards is quite common.

Manufacturers expect devices to come with SIM cards already installed, verifying the networking function during quality inspection and aging tests. However, with the implementation of the “card disconnection action,” a single card can only test one device, necessitating that customer-supplied cards must be sent to the manufacturer before production, with the SIM package needing to be pre-configured.

As the SIM lifecycle ends, users may want to change the operator of the SIM card, which, as mentioned earlier, requires either personnel to be sent on-site or the device to be returned for maintenance.

eSIM effectively resolves this issue, as devices can be produced with empty eSIMs without affecting production or quality checks. After the device arrives on-site, customers can remotely write the package information to the eSIM, enabling subsequent changes to packages or operators to be resolved remotely, effectively addressing the conflict between production and usage of devices.

The achievements of eSIM in the consumer sector are evident, and we look forward to the future where the development of eSIM technology can address the pain points and challenges faced by our IoT enterprises.

Soft Researcher Technical Sharing Community 03 | The Future is Here – Introduction to eSIM Technology