Click the blue text to follow me

From the industrial system to artificial intelligence, from traditional manufacturing to the Internet of Everything, this country has gradually upgraded its industry, overcoming many difficulties, and has finally reached the forefront of the world. Despite being pursued and blocked by various countries, and overcoming countless challenges, the determination of this country to move towards the future cannot be stopped.

China’s industrial Internet is unfolding like a poetic epic.

Sincere, firm, calm, noisy, with flashes of swords and shadows, with golden spears and iron horses, with all things soaring, this is a story of a nation and a people striving to reshape industry amidst turbulent waters.

| Origin: Great Power Game, Industrial Upgrade |

If we must find an origin for the industrial Internet, it must be General Electric (GE). As the world’s largest diversified service company, GE has a comprehensive product system ranging from high-end equipment like aircraft engines and power generation equipment to everyday products like lighting and plastics, along with strong technological strength in manufacturing and rich experience in IoT.

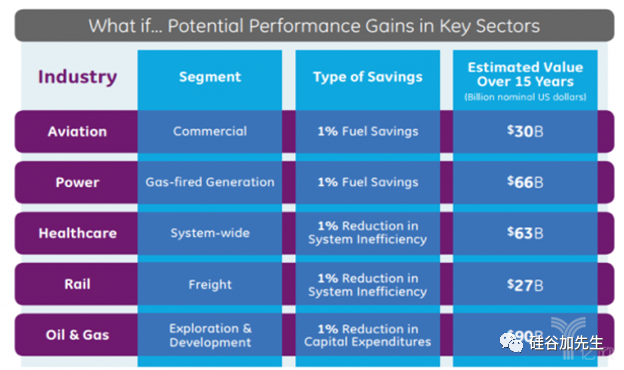

In 2012, GE released the first industrial Internet white paper, defining the core elements of the industrial Internet: linking the most essential equipment, people, and data in industrial production through digitalization. In this groundbreaking white paper of the industrial Internet, GE proposed the concept of “the Power of 1%”, explaining the value brought to global industry by reducing any core industry’s loss by 1% within 15 years: $30 billion in aerospace, $66 billion in energy natural gas, $63 billion in healthcare system support…

GE believes that in the vast market landscape, whether it is meeting the basic business formats of efficiency, safety, and real-time reliability in factory intranets, factory extranets, and identification resolution, or the new business formats generated by intelligent production, networked collaboration, data synchronization, and artificial intelligence transformation, the industrial Internet is the core means of industrial upgrading.

GE’s industrial Internet white paper is hailed as a pioneering work in the industry.

Building on GE’s work, the American Industrial Internet Consortium and industry standards emerged. In response to the government’s “re-industrialization strategy”, the Industrial Internet Consortium (IIC) formed by manufacturing and IT giants and the Digital Manufacturing and Design Innovation Institute (DMDII) organized by the Department of Defense were established, attracting a number of industrial enterprises, universities, research institutes, and business organizations to join, including Boeing, Lockheed Martin, General Electric, Rolls-Royce, Microsoft, GE, and Cisco.

The U.S. leads the trend, while Germany is not to be outdone. In 2013, Germany proposed the Industry 4.0 strategy, aiming to help German companies enhance product competitiveness based on CPS technology, transitioning from a centralized control model to a decentralized enhanced control model, transforming manufacturing into an intelligent process, and improving the global capabilities of enterprises.

Based on Industry 4.0, German industrial giant Siemens took a further step. In 2016, Siemens MindSphere was launched, aimed at helping enterprises connect products, factories, machines, and systems to extract and analyze core performance and application data. In 2018, Siemens upgraded its “Digital Twin” model, integrating these elements into enterprise software, allowing users to optimize processes based on real-time information and improve system performance through real-time product data.

In 2020, MindSphere announced its landing on Alibaba Cloud, continuing to sound the horn for global layout. This reflects Germany and the EU’s development and expansion in advanced manufacturing.

In Germany, Industry 4.0 and the industrial Internet are of the same origin.

Another player not to be underestimated is Japan. The well-known lean manufacturing and craftsmanship spirit may not fully reflect Japan’s determination for new industrialization. In 2017, Japan proposed the “Connected Industries” strategy, prompting national heavyweights like Mitsubishi Electric, Fanuc, DMG Mori, and Hitachi to establish a data exchange mechanism, seeking parity with Germany’s Industry 4.0 and America’s industrial Internet.

According to the China Industrial Information Network, in the article “Japan’s ‘Industrial Internet’ Strategy Insights”, when companies were still focusing on internal connectivity, Japan had already taken a different path, proposing the “industrial value chain” strategy, establishing a unified ecosystem, acquiring German companies, seizing the global factory automation demand, and improving the industrial supply chain. Japan, leading in fields such as big data cloud computing, new materials, resource reuse, and energy storage, faces increasing labor shortages due to an aging population. The industrial Internet is a crucial lever for Japan to maintain its foothold in the new industrialization wave.

Looking back at the era when the industrial Internet began to take root, the idea of industrial upgrading accompanied by the tide of globalization is sweeping across, multinational corporations are responding to each other in a vast imaginative space and huge market share, and the interplay of competition and cooperation among giants is unfolding, while small countries with incomplete industrial systems can only look on in awe at the massive investments and huge workloads.

The industrial Internet is ultimately a battlefield for major powers in this era.

| China: A Call to Arms, Thousands of Sails Competing |

China first proposed the “industrial Internet” in July 2015 with the publication of the “Guiding Opinions on Actively Promoting the ‘Internet +’ Action”, which aimed at developing smart factories and promoting the application of technologies such as cloud computing, IoT, intelligent industrial robots, and additive manufacturing in the production process, accelerating the intelligent upgrade of production equipment, process reform, and basic data sharing.

In November 2017, the “Guiding Opinions on Deepening ‘Internet + Advanced Manufacturing’ Development of the Industrial Internet” was formally established as the programmatic document for China’s development of the industrial Internet. The General Secretary has repeatedly mentioned the industrial Internet on important occasions, which has been included in the government work report for two consecutive years, elevating it to a national strategic level.

At the 2019 Global Industrial Internet Summit, the General Secretary stated, “China attaches great importance to the innovative development of the industrial Internet and is willing to work with the international community to continuously enhance the innovative capabilities of the industrial Internet and promote the integration of industrialization and informatization on a broader, deeper, and higher level.”

Under the vast sky, all land is the king’s land, and all shores are the king’s subjects. The height of national strategy and the broad market prospects have triggered fierce competition among various factions.

Shanghai has made several firsts in the industrial Internet: it was the first to release relevant policies and a three-year action plan; it was the first to collaborate with the Ministry of Industry and Information Technology to create a national-level industrial Internet demonstration city; it was granted the first national industrial Internet demonstration base; and it developed a series of related scenarios such as ABB, Huizhong Automotive Parts, SAIC Lingang Base, Norma High-end Intelligent Hydraulic, and Mitsubishi Elevator Intelligent Robot Warehouse. It has promoted over 300 enterprises in integrated circuits, biomedicine, automotive, aerospace, etc., to innovate in industrial Internet applications; on average reducing costs by 7.3%, improving quality by 6.1%, and increasing efficiency by 9.2%, while helping 100,000 small and medium-sized enterprises to move to the cloud and platforms.

Shanghai has made several industry firsts in the industrial Internet

Shanghai has a complete advanced manufacturing system and strong capital layout. In 2019, industrial investment in Shanghai increased by 11.3%, maintaining double-digit growth for 21 consecutive months. Manufacturing investment in the city grew by 21.1% compared to the previous year. Investment in six key industrial sectors grew by 24.2%: biomedical manufacturing investment increased by 79.0%, automotive manufacturing investment increased by 48.5%, petrochemical and fine chemical manufacturing investment increased by 36.6%, and electronic information product manufacturing investment increased by 12.9%.

Shanghai aims to increase the scale of its core industrial Internet industry from 80 billion yuan to 150 billion yuan by 2022.

Relying on a strong intelligent manufacturing industry, Shenzhen has timely introduced multiple policies to cultivate the industrial Internet ecosystem: establishing the “Shenzhen Industrial Internet Expert Committee”, promoting the joint establishment of the Shenzhen Industrial Internet Alliance by Huawei, Tencent, Foxconn, and other companies, and organizing activities such as the “Industrial Internet Conference” and “Industrial Internet Roadshow” to create a new cross-regional production and manufacturing model of “Headquarters (Shenzhen) + Factory (Pearl River Delta)”.

Achievements in transformation owe much to private enterprises in Shenzhen.: Huawei’s Fusion Plant serves 24,000 enterprise users, with over 880,000 industrial devices connected and more than 2,500 industrial application software; Foxconn has improved production efficiency by 30%, reduced inventory cycles by 15%, serving over 1,100 industrial enterprise users, connecting more than 680,000 industrial devices, and over 1,000 industrial software; Sujia Network has built a collaborative intelligent manufacturing network for traditional mechanical parts manufacturing, intelligently matching supply and demand information, and providing a free SaaS system for transparent production; Yi Global has streamlined channel sales, data operations, product supply, and inventory management, supporting front-end live streaming through back-end rapid response production.

Qingdao, which built itself as a leading city in the industrial Internet in 2015, proposed to construct the “World Industrial Internet Capital” in 2019: gathering 1,833 industrial Internet ecosystem enterprises. Every quarter, it releases 200 “industrial empowerment” and 50 “future city” scenarios, promoting the signing of 158 application scenario transformation and enhancement projects. “Qingdao has a solid industrial foundation and a complete industrial system, covering 39 of the 41 industrial categories, which can provide rich application scenarios for promoting the industrial Internet and developing artificial intelligence.”

Qingdao’s confidence in becoming the “World Industrial Internet Capital” comes from its standing alongside General Electric from the U.S. and Siemens from Germany; it holds three positions in the authorization of the four major international standardization organizations leading the formulation of large-scale customization models and industrial Internet-related standards, and is the only company in the world to have two lighthouse factories in the same country. In 2020, Kaos served 43,000 enterprises, with 330 million users, and is currently the only industrial Internet unicorn enterprise.

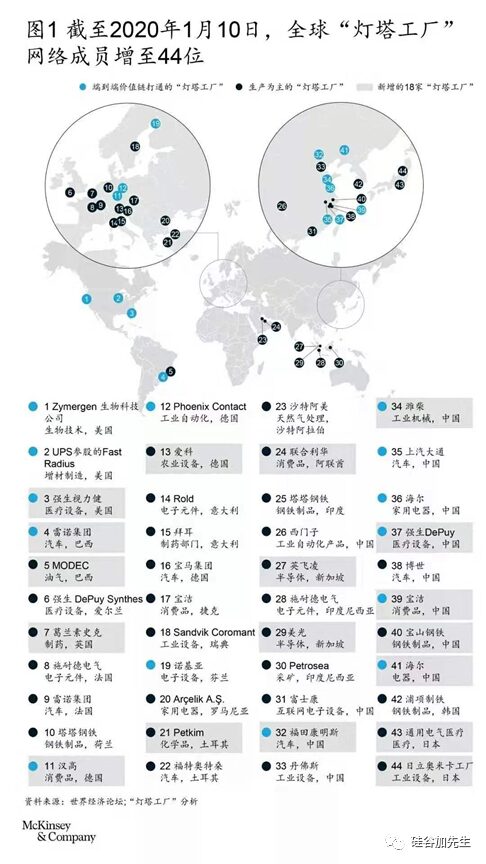

Global distribution map of lighthouse factories

Beijing stated, “Beijing regards the industrial Internet as a strategic choice to promote high-quality urban development, as an important support to consolidate and enhance the level of the real economy, aiming to empower the national digital transformation, and work together with all parties to build a new ecosystem for the innovative development of the industrial Internet, contributing more to the digital transformation of traditional industries nationwide;”

Changzhou stated that the intelligent manufacturing equipment industry cluster was selected as one of the first national strategic emerging industry clusters, with a total of 16 industrial strong base projects, ranking first among prefecture-level cities nationwide, and Jiangsu Province’s first set of major equipment totaling 153, ranking second in the province; a total of 15 national manufacturing single champions, ranking first in the province; and over 200 industry hidden champions, with 66 listed companies domestically and abroad.

Ningbo reported that in 2019, Alibaba Cloud established an industrial Internet center, creating a national-level industrial Internet platform based in Ningbo, serving the Yangtze River Delta, and radiating nationwide. Seven signed projects totaled nearly 2 billion yuan in investment, marking its deep implementation of the digital economy “No. 1 Project”. In the next 2 to 3 years, Ningbo will fully promote industrial Internet platform construction and accelerate the establishment of an industrial Internet development ecosystem.

Shenyang mentioned that industrial Internet giants like Alibaba, Huawei, and Tesla are shining brightly, with renowned domestic and international academicians and experts providing insights, and leading industry enterprises like Brilliance BMW and Neusoft Group giving on-site speeches, with the “Liaoning Province Digital Economy Development Plan” being released on-site, and typical industrial Internet application scenarios like “Smart Steelmaking” and “5G + Smart Manufacturing” created through collaborative 3D shooting methods…

At this moment, a hundred boats are competing and thousands of sails are racing, creating a lively scene.

| Status: Long Road Ahead, Dawn Emerging |

How hot was the industrial Internet in 2020? SAP’s Chief Digital Officer Peng Jun-song said, there are 600 industrial Internet platforms globally, with 500 in China. Even after the pandemic, industrial Internet summits in various cities have reached a fever pitch:

On August 29, 2020, the Ministry of Industry and Information Technology and Beijing held the 2020 Industrial Internet Conference; on September 16, 2020, the organizing committee of the China International Industry Fair held the 2020 International Industrial Internet Conference and Digital Industry Series Summit; on September 17, 2020, the first expert meeting in the industrial Internet field successfully commenced; on September 20, 2020, the 2020 World Industrial Internet Industry Conference opened in Qingdao; on October 10, 2020, Guangzhou hosted the 2020 International Industrial Internet Technology and Application Exhibition; on October 18, 2020, the 2020 Global Industrial Internet Conference opened in Shenyang…

Behind the diverse industrial Internet summits, many core issues in the industry still remain unanswered:

How to make low-cost industrial devices that do not produce data generate data?

How to efficiently open the encryption modules of industrial device production data blocks?

How to unify over 5,000 existing driving protocols in the market?

How to collect data without affecting industrial production progress?

How to coordinate hardware and software configuration issues?

How to maximize the use of data through data mining?

Which data needs to be connected to the network? Which data does not need to be connected? Which data needs to be public? Which data does not need to be public? To what extent should it be made public?

The industrial Internet is a transformation and upgrade of traditional industries.

Digitalization and industrial Internet empowerment are not a panacea. In July 2019, Shenyang Machine Tool, once ranked first in the world and known for initiating Industry 4.0, announced a loss of over a billion yuan, with revenue plummeting, and was ordered to restructure by the Shenyang Intermediate People’s Court. The skepticism from traditional industries regarding industrial Internet platforms is sharp: “We industry insiders can’t solve these problems, do you think just relying on platform docking can do it? That’s too simplistic, each industry has its own challenges, it’s not that easy.”

Overseas platform development is also full of uncertainties: In 2018, GE sold its own Predix platform, which had created several benchmark cases in the industry, ultimately becoming a discarded item in GE’s digitalization efforts. In early 2019, Samsung quietly disbanded its Artik IoT platform team, which had claimed to have 85 partners. According to research firm IoT Analytics, the number of IoT platforms globally peaked at 450, but a third of them have closed or become zombies in the past year.

MIT digital economy research expert George Westerman wrote in the Harvard Business Review, “General Electric is not the first large company to stumble in the process of digital transformation. The toy company LEGO recently announced it was abandoning its digital designer plan; sports brand Nike early on cut its digital hardware division; luxury brand Burberry’s slogan is to become the world’s best digital luxury brand, but its performance has not improved; Ford’s heavy investment in digital transformation has led to increased costs and has dragged down its stock performance.”

From having no data to having data, from single data to multiple data, from a data matrix to a data network, enterprises’ digital transformation (the prerequisite for the industrial Internet) is undergoing a tortuous journey.

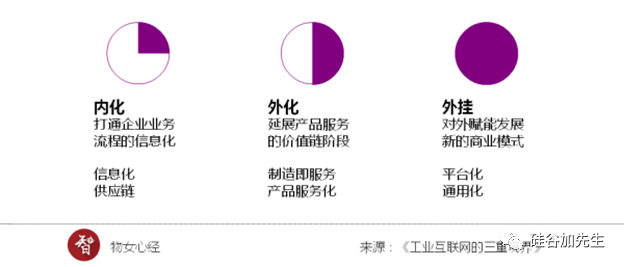

Lin Xueping wrote in “The Three Realms of the Industrial Internet” that “Historically, the process of industries utilizing IT technology for information and digital upgrades can be roughly divided into three stages: internalizing the unification of enterprise business processes, externalizing the integration of manufacturing services, and platforming for industry empowerment.”

The three phases of industrial Internet platform development

According to this logic, the public account “Women’s Heart Sutra” summarized three soul-searching questions for industrial Internet providers:

If a company is struggling to transform into the industrial Internet, how to balance selling equipment and services? If product manufacturing sales decline and product service sales grow slowly, how to balance? How can the old customer base pay for new services?

If a company is saturated in its core business and develops the industrial Internet, is the industrial Internet platform fully applied in-house? Does the company have the operational capacity to build a new business model and platform? Does the methodology output affect the company’s own development?

If a company is steadily replicating the industrial Internet methodology, can its unique advantages based on IP or trade secrets be reproduced? Will “platforming” reduce the competitive advantages of the core business? Does the technology team’s external empowerment nourish competitors? How to balance the relationship with the core business when service revenue is sluggish?

Accenture found that 73% of surveyed companies have yet to formulate a practical action plan for the industrial Internet, while only 7% of surveyed companies reported having developed a comprehensive strategy with corresponding investments. Ultimately, the thin top-level planning of enterprises, the insufficient accumulation of relevant technical talents, and the lack of understanding of the industrial Internet industry value chain lead to significant discrepancies between input-output and investment returns.

However, digital transformation projects are high in cost, long in cycle, and difficult, making enterprises very cautious in their transformations. The process of transitioning the real economy from large to strong is slow and arduous.

| Ambition: With Golden Spears and Iron Horses, All Things Soar|

Industrial Internet is undoubtedly a national strategy for China, backed by the urgent need for industrial structural transformation and upgrading:

-

The growth rate of the manufacturing industry has significantly declined, with issues such as overcapacity, supply-demand imbalance, and slow transition between old and new driving forces becoming prominent. The original growth model, which relied on quantity, scale, and speed, can no longer adapt to, grasp, or lead the new normal of economic development.

-

Currently, China’s manufacturing industry is “large but not strong”: in recent years, the added value rate of China’s manufacturing industry has been around 20%, far below the 35% level of industrialized countries. The industrial Internet will promote the transformation and upgrading of the manufacturing industry, enhancing the overall added value of manufacturing.

-

At this stage, the declining labor population and rising labor costs: although the average annual salary in China’s manufacturing industry has increased 98 times compared to 597 yuan in 1978, in some regions, labor costs have approached the cost of industrial robots. The competitive advantage gained by the manufacturing industry in its early stages through labor cost advantages has been gradually weakened.

Accenture and the National Industrial Information Security Development Research Center’s digital transformation index for Chinese enterprises shows that only 7% of Chinese enterprises have significant transformation results, and many Chinese enterprises have yet to enjoy the economic dividends brought by digitalization.

Only 7% of Chinese enterprises have significant transformation results

Fortunately, there are already successful transformation cases in China, bursting with vitality under the empowerment of advanced productivity:

The traditional clothing factory Kute Intelligent, after more than 10 years and hundreds of millions of investments, has built an intelligent factory from industrial assembly lines to personalized customization: CAD pattern-making, RFID, C2M systems, full process of clothing production, zero inventory with no funds and goods pressure. Production efficiency has increased by 25%, costs have decreased by 50%, profits have increased by 20%, and the order-making cycle for suits has shortened from two or three months to 7 days. In the first half of 2020, revenue grew by 41.66% year-on-year, and it was listed on the Growth Enterprise Market.

Xi’an Shaangu Power operates axial flow compressors, energy recovery turbine devices (TRT), centrifugal compressors, centrifugal blowers, and ventilation fans across five categories with nearly 2,000 varieties applied in more than a dozen pillar industries such as metallurgy, petrochemicals, electric power, and environmental protection. By collaborating with the Beijing Industrial Big Data Innovation Center, they analyze equipment operation and maintenance remotely through platforms, achieving a reduction in normal repair time by over 33.3% and an average savings of 42% in internal management costs for equipment.

Guangzhou Diesel Engine Factory collaborated with Root Interconnection to provide an intelligent service platform for medium and low-speed marine diesel engines based on artificial intelligence, edge computing, and predictive maintenance, ensuring equipment continuity for users of 10,000-ton ships, forming an upstream and downstream linkage in the industrial chain, helping Guangchai reduce equipment management costs by 30%, shorten operational management response time by 20%, and enhance the continuity of diesel engine operations.

Tailong Reducer Company collected data on machine tools based on the XCMG Information Hanyun platform, increasing equipment utilization by 7.65% and reducing equipment operation and maintenance costs by 20%; Business Help collaborative manufacturing management platform empowered 62 small and medium-sized enterprises, receiving 4.7 million production orders for license plates, revitalizing 153 idle devices, and shortening the delivery cycle from 90 days to 14 days…

If digital transformation is the cavalry that breaks through the deadlock for enterprises, the industrial Internet is the macro layout under the national strategy. The industrialization capability of the entire industry is the greatest achievement of this era, particularly evident under the impact of the 2020 pandemic: Looking globally, no one can build a makeshift hospital in weeks with such a powerful industrial system; no one can quickly resume work and production under the shadow of a global pandemic; no one can achieve a grand revival of reform and opening up in just forty years.

Looking at China’s industrial development, from the industrial system to artificial intelligence, from traditional manufacturing to the Internet of Everything, this country has gradually upgraded its industry, overcoming many difficulties, and has finally reached the forefront of the world. Despite being pursued and blocked by various countries, and facing countless challenges, the determination of this country to move towards the future cannot be stopped.

The dawn of China’s industrial Internet is emerging

China’s industrial Internet is unfolding like a poetic epic.

Sincere, firm, calm, noisy, with flashes of swords and shadows, with golden spears and iron horses, with all things soaring, this is a story of a nation and a people striving to reshape industry amidst turbulent waters.

In the past five months, I have interviewed several industrial Internet, smart manufacturing, and traditional manufacturing enterprises, witnessed the industrial dividends brought by SAIC-GM-Wuling’s fully automated production line, seen Kute Intelligent’s semi-customized smart networking SOP process, and observed Hanchuan Intelligent’s advanced manufacturing solutions empowering small and medium-sized enterprises, and witnessed the transformation and upgrading of excavators through digitalization by Leiwo Technology.

From Qingdao’s Kaos to Beijing’s Dongfang Guoxin, from Jinan’s Langchao to Xuzhou’s Xrea, from Shenzhen’s Huawei and Foxconn to Alibaba in Hangzhou; from R&D design to production manufacturing, from business management to equipment operation and maintenance, from customized products to inventory management; under the empowerment and support of platforms, and with the determination and courage of enterprises, traditional industries are being transformed, split, painfully evolving, and sublimating.

Rushing toward the tomorrow of the next era.

References and Citation Materials

Qingdao Release, “The Weight of the Ding, Can Be Asked — Interpretation of Qingdao’s Platform Thinking in Building the ‘World Industrial Internet Capital'”

Chen Xuanbin, “The Industrial Internet Cannot Save the Survival of Millions of SMEs”

China Industrial Information Network, “Japan’s ‘Connected Industries’ Strategy Insights”

Qilu Evening News, “Qingdao Reveals the One-Year Achievement Report on Building the ‘World Industrial Internet Capital'”

Xinhua News Agency, “Shanghai Concentrates on Launching Industrial Internet Projects to Create a 150 Billion Yuan Scale Industry”

Qingji, “Shanghai or Qingdao, Kaos Faces a Difficult Choice”

Peng Jun-song, “Building an Industrial Internet Ecosystem to Promote the ‘External Circulation’ of Service Trade”

Shenzhen Special Zone Daily, “Shenzhen Accelerates Industrial Internet New Infrastructure”

Lin Xueping, “The Three Realms of the Industrial Internet”

Women’s Heart Sutra, “Industrial Internet + 5G, ‘King Bomb’ or ‘Three Against’?”

Industrial Internet Industry Alliance, “2019 Industrial Internet Platform White Paper”

The images are sourced from Unsplash.

Recommended Previous Articles

Jensen Huang

Golden Principles

2018 Reading List

Gifts and Choices

Atypical Going Abroad

Silicon Valley Dining Guide

The Era Belonging to Entrepreneurs

Silicon Valley in the First Half of 2019

The Man Behind Half of Silicon Valley

CES 2019: Prosperity and Undercurrents

The Chinese Jianghu Behind Silicon Valley Incubators

Qingdao’s Ambition: North America and China, Vast Mountains and Seas

Li Haoyang: An AI-style Revolution in Chinese Education

After the Cold Wave of VR/AR, Those Who Still Strive in Reality

Tim Hwang: Building a ‘Bloomberg’ for the AI Era

Wu Ren: AI Should Be ‘Omnipotent and Ubiquitous’

One Day, Three Industries, Twelve Hours, A Glimpse of Shandong’s Economy

GGV Capital’s Tong Shihao: Capital Layout in the Age of Exploration

The Battlefield and Future of AI Contenders: Besides Silicon Valley, There’s Seattle