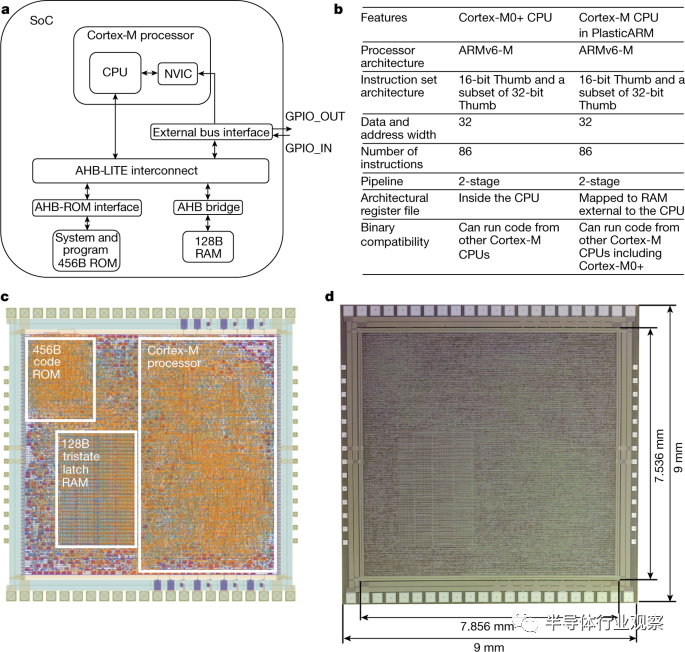

Unlike traditional semiconductor devices, flexible electronic devices are built on substrates such as paper, plastic, or metal foils, utilizing active thin-film semiconductor materials like organic/metal oxides or amorphous silicon. Flexible electronic devices offer advantages such as thinness, uniformity, and low manufacturing costs. Fabricating thin-film transistors (TFTs) on flexible substrates significantly reduces costs, allowing electronic products to achieve novel shapes and costs unattainable with silicon, greatly expanding the range of potential applications.On July 24, British chip design company Arm announced the launch of a new plastic chip named PlasticARM, which uses a flexible polyimide (PI) substrate with a thickness of less than 30μm, combined with metal oxide thin-film transistors (TFTs), to design the world’s first flexible native 32-bit ARM architecture microprocessor, with a production cost of only 1/10 that of similar silicon chips and an integration density 12 times that of comparable chips. Although PlasticARM is not the first flexible chip, it is the most complex.

PlasticARM Architecture and Features (Image Source: Semiconductor Industry Observation)This chip can be produced by directly printing circuits onto paper, cardboard, or even fabric, significantly reducing production costs. It is reported that this technology can connect billions of everyday items (such as clothing and food containers) to the internet for data collection, processing, and transmission—greatly enhancing efficiency for businesses and having significant implications for privacy protection.Arm stated that this will create a new “Internet of Everything” world, with this chip expected to be integrated into “over 1 trillion inanimate objects” in the next decade. The Su Mei Da Da Tian Xia platform believes that the advent of this thin, low-cost flexible microprocessor can open new directions for the smartification of everyday products.In response to this event, TrendBank semiconductor industry analyst Gao Zhanzhan stated that to develop flexible chips, future substrate materials will be high-performance thin-film materials or even transparent thin-film materials, with the future trend of device materials being those that possess excellent bendability and electrical stress resistance.

Source: TrendBank Film Chain

You Might Also Like

Ξ■ Huawei Invests in Oled, Further Enhancing OLED Driver Chips

Ξ■ Samples Sent to BOE, Huawei HiSilicon OLED Driver Chips to Enter Mass Production Next Year

Ξ■ 30.8 Billion, Chinese Chips Set Historical Record in June

Click to View Conference Details:BOE, Ruihua Tai, Guodu Chemical, Institute of Chemistry, Chinese Academy of Sciences, Lusheng, and Zhongshan Xinga have confirmed speeches—2021 TrendBank Polyimide Materials Industry Conference (October 13-14, Suzhou)