Click  Mechanical Frontier” Follow for Updates

Mechanical Frontier” Follow for Updates

Leading the Mechanical Frontier, Mechanical Videos, Automotive, Processing Technology, 3D Printing, Automation, Robotics, Production Processes, Bearings, Molds, Machine Tools, Sheet Metal, and other industry frontiers await you here

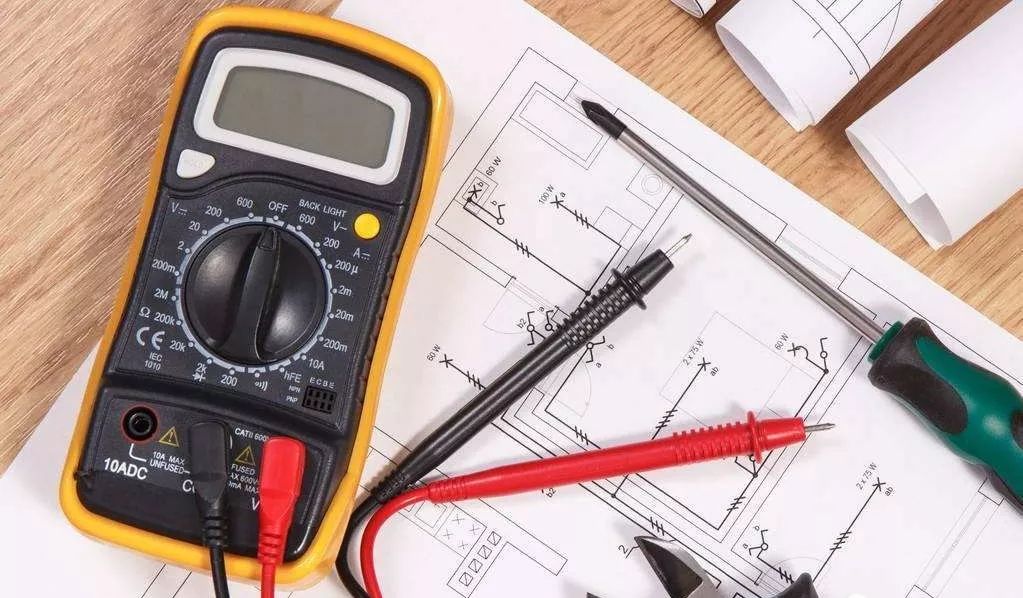

A multimeter, also known as a multi-tester, is a multifunctional and multi-range measuring instrument. Generally, a multimeter can measure DC current, DC voltage, AC voltage, resistance, and audio levels. Some can also measure AC current, capacitance, inductance, and certain parameters of semiconductors (such as β).

First, here’s a mnemonic for using a multimeter:1. Check the range before measuring; do not measure without checking.2. Do not change the range while measuring; switch to the off position after measuring.3. The dial should be level; readings must be aligned.4. The range must be appropriate; readings must be aligned.5. Do not measure resistance while powered; discharge capacitors before measuring capacitance.6. Zero the meter before measuring resistance; adjust zero when changing ranges.7. Remember that black is negative; connect black to + inside the meter.8. Measure current in series; measure voltage in parallel.9. Do not reverse polarity; develop a habit of using one hand.

AC voltage measurement: As shown in Figure 1, the maximum range is 20V, meaning your input voltage cannot exceed this. Insert the red probe into the v/Ω hole and the black probe into the com hole; the display shows the measured AC voltage value.

Figure 1

Figure 1

Figure 2 shows five ranges used for measuring DC voltage.

Figure 2

Figure 2

The four numbers on the top ranges represent the maximum current values that can flow through these ranges, as shown in Figure 3.

Figure 3

Figure 3

These seven ranges are for measuring resistance values, with the maximum resistance values indicated for each range, as shown in Figure 4.

Figure 4

Figure 4

This range is used to test the condition of diodes and check for continuity, as shown in Figure 5.

Figure 5

Figure 5

Figure 6 is the range for measuring capacitance, with the maximum capacitance values indicated for each range.

Figure 6

Figure 6

1. Structure of the Multimeter (Model 500)

The multimeter consists of three main parts: the meter head, measurement circuit, and range switch.

(1) Meter Head

It is a highly sensitive magnetic electric DC ammeter, and the main performance indicators of the multimeter depend on the performance of the meter head. The sensitivity of the meter head refers to the DC current value that causes the pointer to deflect to full scale; the smaller this value, the higher the sensitivity. The internal resistance when measuring voltage should be as high as possible for better performance. The meter head has four scale lines, which function as follows: The first line (from top to bottom) is marked R or Ω, indicating resistance value, read when the range switch is in the ohm position. The second line is marked ∽ and VA, indicating AC and DC voltage and DC current values, read when the range switch is in the AC or DC voltage or DC current position, except for the AC 10V position. The third line is marked 10V, indicating the AC voltage value of 10V, read when the range switch is in the AC or DC voltage position at the AC 10V range. The fourth line is marked dB, indicating audio level.

(2) Measurement Circuit

The measurement circuit converts various measurements into a suitable small DC current for the meter head. It consists of resistors, semiconductor components, and batteries.

It can convert various measurements (such as current, voltage, resistance, etc.) and different ranges into a small DC current within a certain limit for measurement by the meter head through a series of processes (such as rectification, shunting, and voltage division).

(3) Range Switch

The range switch is used to select different measurement circuits to meet various measurement requirements. There are generally two range switches, each marked with different positions and ranges.

2. Symbol Meanings

(1) ∽ indicates AC and DC

(2) V-2.5KV 4000Ω/V indicates that for the AC voltage and 2.5KV DC voltage ranges, the sensitivity is 4000Ω/V

(3) A-V-Ω indicates the ability to measure current, voltage, and resistance

(4) 45-65-1000Hz indicates the frequency range for use is below 1000 Hz, with a standard frequency range of 45-65Hz

(5) 2000Ω/V DC indicates the sensitivity for the DC range is 2000Ω/V

The symbols on clamp meters and shake meters are similar to the above symbols (others cannot be fully written due to format issues).

3. Using the Multimeter

(1) Familiarize yourself with the meanings of the symbols on the dial and the main functions of each knob and switch.

(2) Perform mechanical zeroing.

(3) Based on the type and size of the measurement, select the appropriate position and range on the range switch, and find the corresponding scale line.

(4) Choose the position for the probes.

(5) Measuring voltage: When measuring voltage (or current), select the appropriate range. If a small range is used to measure a large voltage, there is a risk of burning the meter; if a large range is used to measure a small voltage, the pointer deflection will be too small to read. The range selection should aim to make the pointer deflect to about 2/3 of the full scale. If the size of the voltage to be measured is unknown, start with the highest range and gradually decrease to an appropriate range.

(a) Measuring AC voltage: Set one range switch to AC or DC voltage, and the other to the appropriate AC voltage range. Connect the two probes in parallel with the circuit or load being measured.

(b) Measuring DC voltage: Set one range switch to AC or DC voltage, and the other to the appropriate DC voltage range, ensuring the “+” probe (red probe) is connected to the high potential and the “-” probe (black probe) to the low potential, allowing current to flow from the “+” probe to the “-” probe. If the probes are reversed, the meter pointer will deflect in the opposite direction, potentially bending the pointer.

(6) Measuring current: When measuring DC current, set one range switch to the DC current position and the other to an appropriate range between 50uA and 500mA. The current range selection and reading method are the same as for voltage. Before measuring, the circuit must be disconnected, and the multimeter must be connected in series with the circuit being measured, allowing current to flow from the red probe to the black probe. If the multimeter is mistakenly connected in parallel with the load, the low internal resistance of the meter head will cause a short circuit, damaging the instrument. The reading method is as follows:

Actual value = Indicated value × Range / Full scale deflection

(7) Measuring resistance: When measuring resistance with a multimeter, follow these steps:

(a) Select the appropriate range. The ohm scale on the multimeter is not uniform, so the range selection should ensure that the pointer stops in the less dense part of the scale, and the closer the pointer is to the middle of the scale, the more accurate the reading. Generally, the pointer should be positioned between 1/3 and 2/3 of the scale.

(b) Zero the ohm setting. Before measuring resistance, short the two probes and adjust the “ohm (electrical) zeroing knob” so that the pointer just points to the zero position on the ohm scale. If the pointer cannot be adjusted to zero, it indicates insufficient battery voltage or an internal problem with the instrument. Additionally, every time the range is changed, the ohm zeroing must be performed again to ensure accurate measurements.

(c) Reading: The reading on the meter head multiplied by the range gives the measured resistance value.

(8) Precautions

(a) Do not change ranges while measuring current or voltage when powered.

(b) When selecting a range, start with a larger range and then select a smaller one, aiming to keep the measured value close to the range.

(c) Do not measure resistance while powered. When measuring resistance, the multimeter is powered by its internal battery, and measuring while powered is equivalent to connecting an additional power source, which may damage the meter head.

(d) After use, set the range switch to the maximum AC voltage position or the off position.

4. Digital Multimeter

Currently, digital measuring instruments have become mainstream and are replacing analog instruments. Compared to analog instruments, digital instruments have higher sensitivity, accuracy, clear display, strong overload capacity, are portable, and are easier to use. Below, we will briefly introduce the usage and precautions of the VC9802 digital multimeter.

(1) Usage

a. Before use, carefully read the relevant user manual and familiarize yourself with the power switch, range switch, probe holes, and special sockets.

b. Set the power switch to the ON position.

c. Measuring AC and DC voltage: Set the range switch to the appropriate range for DCV (DC) or ACV (AC), insert the red probe into the V/Ω hole, the black probe into the COM hole, and connect the probes in parallel with the circuit being measured; the reading will be displayed.

d. Measuring AC and DC current: Set the range switch to the appropriate range for DCA (DC) or ACA (AC), insert the red probe into the mA hole (for <200mA) or the 10A hole (for >200mA), the black probe into the COM hole, and connect the multimeter in series with the circuit being measured. When measuring DC, the digital multimeter can automatically display polarity.

e. Measuring resistance: Set the range switch to the appropriate range for Ω, insert the red probe into the V/Ω hole, the black probe into the COM hole. If the measured resistance exceeds the maximum value of the selected range, the multimeter will display “1”; at this point, a higher range should be selected. When measuring resistance, the red probe is positive, and the black probe is negative, which is the opposite of the analog multimeter. Therefore, when measuring polarized components such as transistors and electrolytic capacitors, the polarity of the probes must be noted.

(2) Usage Precautions

a. If the size of the voltage or current to be measured cannot be estimated in advance, first set to the highest range and measure once, then gradually reduce the range to an appropriate position. After measuring, set the range switch to the highest voltage range and turn off the power.

b. When at full scale, the instrument will only display the digit “1” at the highest position, with other positions disappearing; at this point, a higher range should be selected.

c. When measuring voltage, the digital multimeter should be connected in parallel with the circuit being measured. When measuring current, it should be connected in series with the circuit being measured; when measuring DC, polarity does not need to be considered.

d. If the AC voltage range is mistakenly used to measure DC voltage, or the DC voltage range is mistakenly used to measure AC voltage, the display will show “000” or the digits at the lower position will fluctuate.

e. It is prohibited to change the range while measuring high voltage (above 220V) or large current (above 0.5A) to prevent arcing and burning the switch contacts.

f. When the display shows ” ” or “BATT” or “LOW BAT”, it indicates that the battery voltage is below the operating voltage.

5. Shake Meter

A shake meter, also known as a megohmmeter, is used to measure the insulation resistance and high resistance of the tested equipment. It consists of a hand-cranked generator, a meter head, and three terminals (L: line terminal, E: ground terminal, G: shield terminal).

1) Selection Principles for Shake Meters

(1) Selection of rated voltage levels. Generally, for equipment rated below 500V, a shake meter rated at 500V or 1000V should be selected; for equipment rated above 500V, a shake meter rated at 1000V to 2500V should be selected.

(2) Selection of resistance range. The scale line of the shake meter has two small black dots, and the area between the small dots is the accurate measurement area. Therefore, when selecting a meter, ensure that the insulation resistance value of the tested equipment falls within the accurate measurement area.

2) Using the Shake Meter

(1) Calibration. Before measuring, perform an open-circuit and short-circuit test on the shake meter to check if it is functioning properly. Open the two connection wires, crank the handle, and the pointer should point to “∞”. Then short the two connection wires, and the pointer should point to “0”. If these conditions are met, the meter is good; otherwise, it should not be used.

(2) Disconnect the tested equipment and lines; for large capacitive devices, discharge them.

(3) Select a shake meter with a voltage level that matches.

(4) When measuring insulation resistance, generally only the “L” and “E” terminals are used. However, when measuring the insulation resistance of cables to ground or when the leakage current of the tested equipment is severe, the “G” terminal should be used, connecting it to the shield or outer casing. After connecting the lines, turn the crank clockwise, starting slowly and then increasing speed. When the speed reaches about 120 RPM (for the ZC-25 model), maintain a steady speed, read the value after one minute, and read while cranking; do not stop to read.

(5) Discharge the lines. After reading, slowly crank while disconnecting the lines, then discharge the tested equipment. The discharge method is to remove the ground wire used during measurement from the shake meter and short it to the tested equipment (not discharging the shake meter).

3) Precautions

(1) It is prohibited to measure insulation resistance during thunderstorms or near high-voltage equipment; measurements can only be taken when the equipment is not powered and there is no induced voltage.

(2) During the shaking measurement process, no one should work on the tested equipment.

(3) The shake meter wires should not be twisted together; they should be separated.

(4) Do not touch the shake meter or the tested equipment until the shake meter has stopped turning or the tested equipment has been discharged. When disconnecting the lines, do not touch the metal parts of the leads.

(5) At the end of the measurement, discharge large capacitive devices.

(6) Regularly calibrate its accuracy.

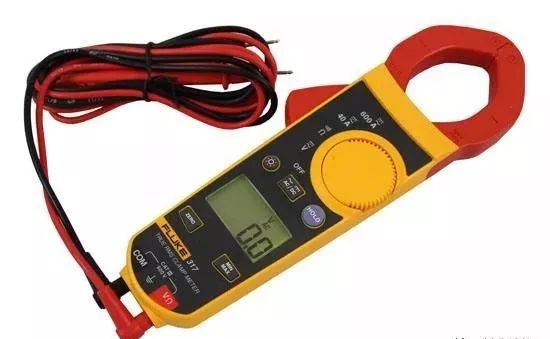

6. Clamp Meter

A clamp meter is an instrument used to measure the current of electrical circuits while they are in operation, allowing current measurement without interrupting the power supply.

1) Structure and Principle

A clamp meter essentially consists of a current transformer, a clamp-type wrench, and a rectifying magnetic electric system with feedback.

2) Usage

(1) Mechanical zeroing must be performed before measurement.

(2) Select the appropriate range, starting with a larger range and then selecting a smaller one or estimating based on the nameplate value.

(3) When using the smallest range for measurement, if the reading is not clear, the tested wire can be looped several times; the number of loops should be based on the number of loops at the center of the clamp, then the reading = indicated value × range / full scale deflection × number of loops.

(4) During measurement, ensure the tested wire is centered in the clamp and that the clamp is tightly closed to reduce errors.

(5) After measurement, set the range switch to the maximum range.

3) Precautions

(1) The voltage of the tested circuit must be lower than the rated voltage of the clamp meter.

(2) When measuring current in high-voltage circuits, wear insulated gloves, insulated shoes, and stand on an insulated mat.

(3) The clamp must be tightly closed; do not change ranges while powered.

Finally, we present a video for further learning.

What do you think about this? Leave your comments below for everyone to discuss.

Mechanical Frontier: jixieqianyan

Mechanical Frontier | Mechanical Technology | Mechanical Videos | Mechanical News