Abstract:The Ankerui precision power distribution system is a multi-loop monitoring device provided by Ankerui to meet the centralized monitoring requirements of data centers, monitoring multiple electrical parameters and providing alarms for various faults.It is mainly suitable for monitoring various types of cabinets, precision power distribution cabinets, power distribution cabinets, UPS output cabinets, and other end distribution equipment.Based on the description of the power distribution target requirements of data center server rooms, this article analyzes the power distribution schemes and issues under traditional distribution models, hoping to provide references for the design and application of new cabinet distribution models, thereby promoting the orderly development of enterprise data center cabinet construction work and ensuring the safety and reliability of data center power distribution.

Keywords:Cabinet; Monitoring System; Touch Screen.

0

Overview

With the rapid development of intelligence and information technology, the construction of information systems has received increasing attention from various organizations, which believe that the construction of information systems can better serve business systems. As a result, the number of information systems continues to grow, and correspondingly, the environmental equipment used to support information systems is also increasing. Environmental equipment in server rooms, such as power distribution equipment, uninterruptible power supplies, precision air conditioning, temperature and humidity control, and fire protection, plays an important role in the safe and reliable operation of server rooms, providing a secure operating environment for various servers, switches, and other devices. As the information hub of enterprises, data centers carry servers that relate to core enterprise information and are complex integrated facilities that include not only computer systems and other associated equipment but also redundant data communication links, environmental control devices, monitoring equipment, and various security devices. The power distribution system is one of the important links in data centers, and power outages or low-quality power supply are major factors causing server downtime. How to optimize the power distribution system of data center server rooms to improve availability and safety, ensuring uninterrupted operation of servers and other hardware, is one of the major challenges faced by data center managers.

1

Intelligent Micro Modules

Micro modules are typically equipped with dynamic environmental monitoring systems that can achieve real-time monitoring of access control, video, temperature and humidity, smoke detection, water immersion, and energy consumption, making management and control easier. The development trend of intelligence in data centers or micro modules can achieve three-dimensional visual management.

2.1 Visualization of Micro Module (Data Center) Environment: ① Virtual simulation of geographical parks; ② Virtual simulation of building exteriors; ③ Three-dimensional modeling based on the actual architectural structure of the building; ④ Horizontal/vertical split display of the structural conditions of each micro module.

2.2 Visualization of Capacity Management: Capacity statistics, real-time statistics of space, load, and power utilization in server rooms and cabinets, allowing for more rational use of server room resources; dynamic space multi-condition query for height, load, and power.

2.3 Visualization of Asset Management: Visual search and positioning, supporting multi-condition search and quick location of equipment; visual information query, integrating scattered management information and automatically generating statistics and equipment lists.

2.4 Visualization of Monitoring Information: Status visualization, intuitively displaying device alarm information and availability status, quickly locating faulty devices, and shortening troubleshooting time; performance visualization, extracting performance data from monitoring subsystems for integrated display, using visual methods to optimize and enhance information interaction efficiency.

Inside the cabinet, a fully functional intelligent monitoring system needs to be integrated, including a monitoring host, touch display screen, sensors, etc., to centrally monitor the power equipment and environmental variables of the data center, promptly identifying faults and alerting maintenance personnel to take necessary actions to resolve issues, providing strong technical support for the automation and intelligent management of the server room.

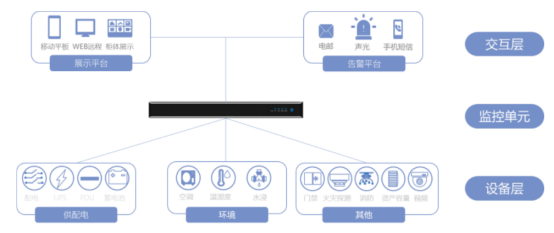

Figure 1 Monitoring System Architecture Diagram

As shown in the figure above, the deployment architecture consists of a data acquisition device processing layer, a centralized monitoring management layer, and a remote browsing interaction layer.

Data Acquisition Device Layer

The monitoring unit collects and processes data and status from facilities and environments within the cabinet, such as UPS, precision air conditioning, temperature and humidity, and water leakage. It has capabilities for data collection, processing, and storage, and presents the operating parameters and status of the cabinet through a touch display screen. Data is uploaded to the centralized monitoring management layer for unified monitoring and management via the network.

Centralized Monitoring Management Layer

Composed of a centralized monitoring management system, responsible for the centralized monitoring and management of all cabinet data. It receives data and alarm information uploaded by the data acquisition processing layer via the network, completing secondary processing and analysis of the data to achieve functions such as data processing analysis, alarm management, report management, asset management, and capacity management.

Remote Browsing Interaction Layer

Provides a unified notification platform for operation and maintenance personnel, data publishing, and interactive operations on the WEB end.

(1) Monitoring Host

A data acquisition monitoring terminal developed for cabinet monitoring needs, equipped with rich device ports, capable of on-site data collection, protocol conversion, intelligent alarm functions, etc. It has a built-in WEB service, allowing users to view and manage the monitoring system through an IE browser.

(2) Touch Display Screen

A capacitive screen supporting multi-touch, embedded in the front door of the cabinet. It can connect to the monitoring management system and can perform real-time monitoring of cabinet environmental parameters.

(3) Sensor Monitoring Module

Facility monitoring functions

The monitoring objects include rack-mounted distribution boxes, rack-mounted UPS, precision air conditioning, sensors, cabinet door status, etc.

(1) Power Distribution Monitoring

Supports detection of voltage, frequency, current, and power of the total input of the mains, as well as input voltage, frequency, and current of the UPS.

(2) Precision Air Conditioning Monitoring

Supports real-time monitoring of supply and return air temperature and humidity, fan speed monitoring display and operational percentage display, and compressor operation status monitoring display.

(3) Sensor Data Monitoring

Monitors temperature and humidity sensor data and battery module within the cabinet.

(4) Security and Fire Protection System Monitoring

The cabinet can manually open skylights and rear doors, and the cabinet status display includes front door, rear door, skylight, water leakage monitoring, and smoke detection status. By monitoring water leakage at the bottom of the cabinet and smoke status, real-time alarm signals are provided.

Alarm Notification Function

The alarm notification module needs to support the following functions.

Supports monitoring of air conditioning, power distribution, environmental status, etc. If there is a fault or parameter anomaly, the system will issue real-time alarms.

Supports record queries for the lifecycle of certain events, including event generation, event handling, alarm sending, etc.

Supports displaying alarm events in list form, providing a real-time alarm window that can quickly filter and display by alarm level and confirmation status, supports customization of alarm window display items, and supports single/batch confirmation of alarms.

Depending on the different alarm levels of alarm events, the monitoring system can provide different alarm methods: email alarms, SMS alarms, phone alarms, and visual/audible alarms.

2.5 Wiring Management Visualization: ① Port management, querying and displaying wiring frame and device front and back panel and port occupancy information in a three-dimensional visual environment; ② Link management, querying and displaying the physical connection relationships between managed devices in a three-dimensional visual environment; ③ Supports import and export of wiring tables; ④ Supports direct operation of link configuration in a visual management environment.

3

Monitoring Requirements for a Micro Module Cabinet in Changshu

The intelligent monitoring board for monitoring multiple loops such as the main and branch circuits of precision distribution cabinets can achieve a visual interface, using a 7-inch LCD color touch screen to display the system simulation diagram, which can show the real-time status of each switch and surge protector, as well as the electrical information of all main and branch circuits. The intelligent monitoring board should support MODBUS or SNMP protocols and be integrable with third-party network management. The intelligent monitoring board must have the following features:

Main Bus Monitoring Parameters

1) Three-phase input voltage, current, frequency, reactive power, active power, power factor, harmonic percentage, electrical quantity, three-phase imbalance, zero-ground voltage, zero-line current, bus temperature.

2) Main circuit switch status, load percentage.

3)Main circuit voltage and current measurement accuracy not lower than0.5%, active/reactive power measurement accuracy not lower than1%, electrical energy measurement accuracy not lower than1%

Branch Circuit Monitoring Parameters

1) Rated current, actual current, branch load percentage, branch switch status, branch temperature measurement.

2) Branch current measurement accuracy not lower than 0.5%, active power measurement accuracy not lower than 2%, electrical energy measurement accuracy not lower than 2%.

Alarm Signals

Supports audible and visual alarms on the LCD display, with a mute function on the touch screen. Alarm information should be categorized into three levels based on importance: prompt alarms, important alarms, and emergency alarms. The intelligent monitoring board must provide the following alarms:

1) Main circuit undervoltage, overvoltage, phase loss, input switch tripping, single circuit power failure alarm, current transformer wiring error alarm.

2) Main circuit current limit and over-limit alarms, main circuit overload alarms, and three-phase imbalance alarms.

3) Main circuit frequency limit alarms, high total harmonic distortion alarms, high total current harmonic distortion alarms.

4) Branch switch status change alarms, overload alarms, high current impact alarms.

5) Two-segment threshold alarm function for branch current, with adjustable alarm thresholds.

6) Monitoring module failure and internal communication failure alarm for the intelligent monitoring board.

Alarm history records must not be less than 2500 entries.

The monitoring module of the intelligent monitoring board supports hot-swapping and has a fault indicator light. When a fault occurs in the detection board module, it can indicate an alarm and supports maintenance without power interruption.

4

Solutions Offered by Ankerui for Cabinet Monitoring

The Ankerui AMC100 series precision power distribution monitoring device is specifically designed for power management of data center servers. This device is compact and can monitor all electrical parameters, input/output switch statuses, and surge protector statuses for two A+B incoming lines and 192 outgoing lines in real-time. The alarm thresholds for all measurement channels can be set individually, and exceeding outgoing limits immediately triggers audible and visual alarms. It can also be paired with insulation detection modules to monitor and manage the insulation status of DC system buses and branches in real-time, achieving a high level of integration of monitoring circuits compared to traditional instruments.

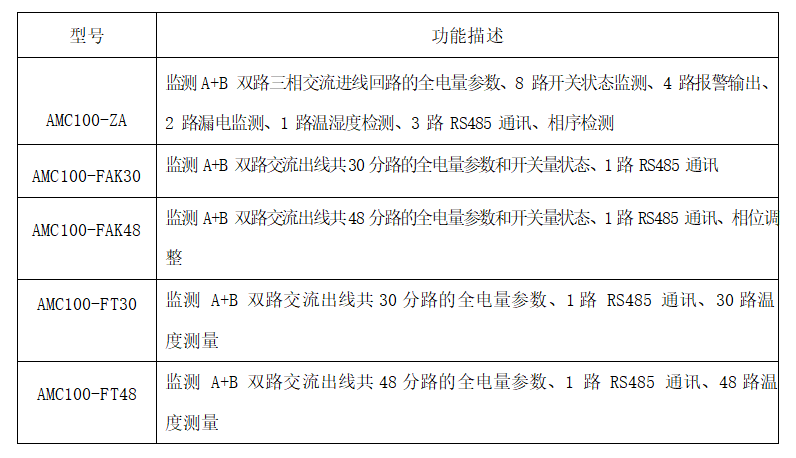

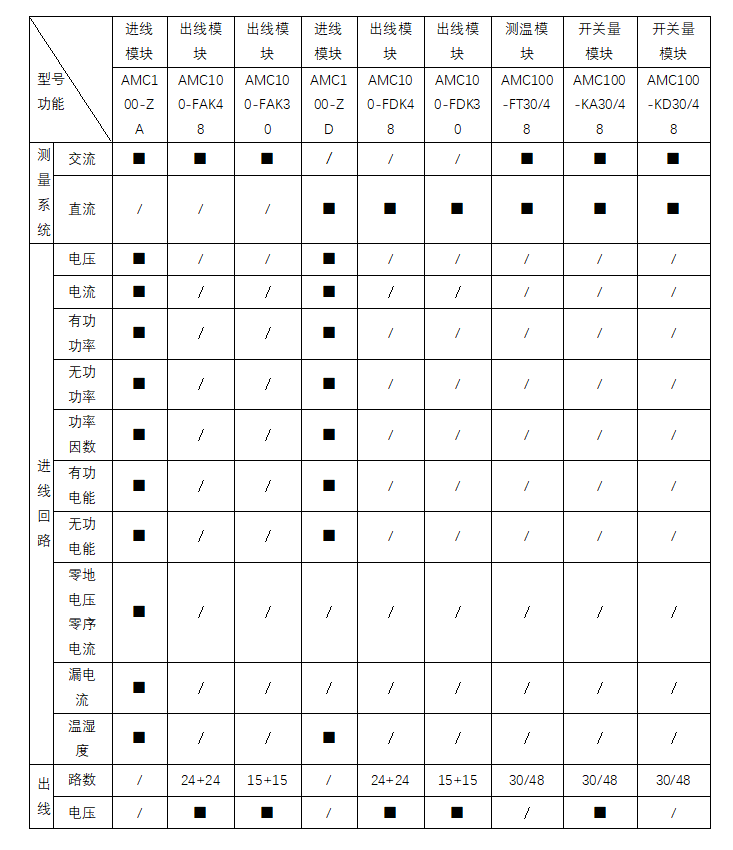

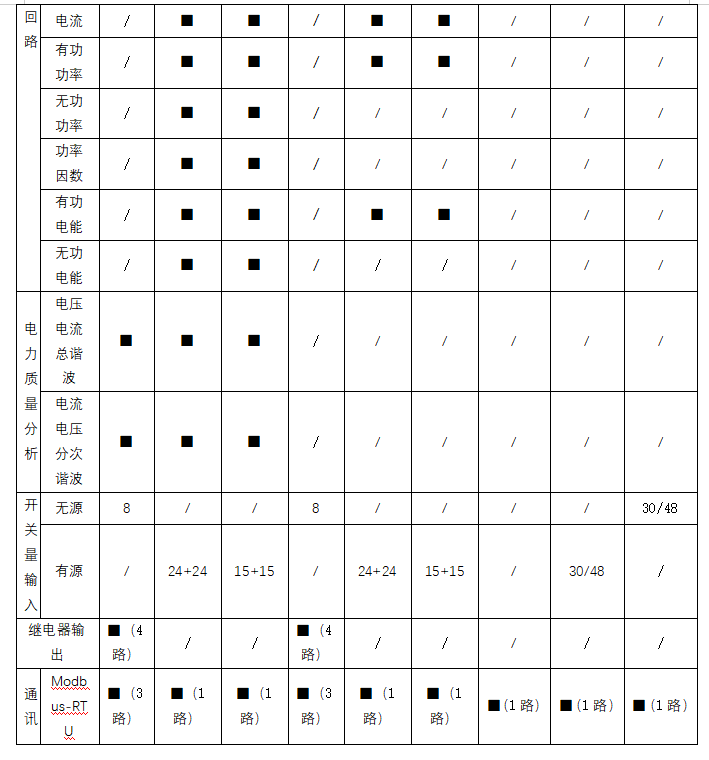

4.1 Product Model

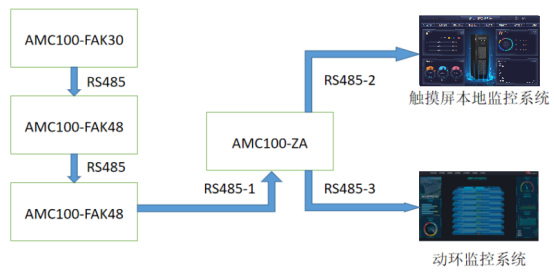

4.2 Networking Scheme

The RS485 port of the main module AMC100-ZA connects to the slave, touch screen system, and dynamic environmental monitoring system.

4.3 Touch Screen Data Presentation

4.4 Recommended Solutions

The AMC100 series products can monitor all electrical parameters, input/output switch statuses, and surge protector statuses for up to 4 incoming lines and 192 outgoing lines in real-time. The alarm thresholds for all measurement channels can be set individually, and exceeding outgoing limits immediately triggers audible and visual alarms, achieving a high level of integration of monitoring circuits compared to traditional instruments.

The entire monitoring system can operate without an external power supply. If any one of the A or B incoming lines of the main incoming line module has power input, it can output DC 24V to power the touch screen and branch outgoing line modules, saving layout space within the precision distribution cabinet, while ensuring that the monitoring system continues to operate normally without power interruption without external relay switching, resulting in lower costs and a better solution compared to competitors.

The single outgoing line module can achieve electrical isolation for A and B outgoing lines. For cabinets with fewer than A24+B24 circuits, only one incoming line module and one outgoing line module are needed to achieve full monitoring, resulting in fewer modules than competitors and lower costs, providing a better solution.

A single monitoring touch screen can collect and display electrical parameters and switch and alarm statuses for 1 to 4 incoming lines, meeting diverse customer needs.

For cabinets with dual power incoming lines, the touch screen can achieve one-click switching between the AABB and ABAB wiring methods for outgoing line modules, facilitating wiring adjustments due to layout installation position reasons, making electrical installations more flexible.

Custom classification and grouping of virtual meters can be achieved, allowing for grouped statistical display of output circuits, with custom group names, such as data statistics and summary display by user.

Value-added service functions can be developed in conjunction with customers, such as locking the touch screen operation, controlling the cabinet ambient light (door/alarm status indication), customizing dedicated operation display interfaces (currently two interface styles), and achieving simultaneous monitoring of AC and DC on the same touch screen.

Available Selection Modules

5

Conclusion

The solutions provided by Ankerui to meet the centralized monitoring requirements of data centers effectively ensure the safety and reliability of power distribution in data center server rooms, while conducting comprehensive internal and external environmental analyses of the data center industry, analyzing national policies, future industry development trends, and predicting future industry directions, while improving various application solutions in the industry and analyzing different customer needs to meet diverse application requirements.