The modular data center mainly consists of cabinets, sealed corridors, power distribution systems, cooling systems, intelligent monitoring systems, integrated wiring, and fire protection systems. A single modular data center is configured according to a maximum of N cabinets (including server cabinets, network cabinets, and integrated wiring cabinets). The module (excluding UPS) occupies an area of 35 m², and with the external maintenance corridor and the PDF cabinet that powers the air conditioning inside the module, the total area does not exceed 55 m², and the total height of the module does not exceed 2.65 m. The number of cabinets can be reduced or increased in pairs according to customer needs.

1. Precision Power Distribution Cabinet

The “KITOZER” series intelligent power distribution cabinets are arguably the best power distribution solution for today’s IT systems, supporting hot-swappable modular design, allowing customers to flexibly configure, upgrade, and manage the power distribution system according to the IT load of the data center and the development needs of the enterprise.

1. Color touch screen operation, simple and direct interface

Using graphical display methods, key parameters can be understood with a light touch on the screen, simplifying maintenance actions and effectively reducing human errors.

2. Intelligent Power Distribution Monitoring System

(1) Full monitoring of main and branch circuit parameters, with comprehensive data and high accuracy.

(2) International brand components

(3) Circuit breakers are all from top international brands such as Schneider and ABB, ensuring high reliability and safety.

(4) Supports hot-swappable, modular design

(5) Modular hot-swappable design for circuit breakers and monitoring modules, eliminating power outages, providing efficient and flexible communication solutions, supporting various communication methods and protocols such as TCP/IP, RS485, MODBUS, SNMP, etc., for quick and efficient integration with backend monitoring platforms.

(6) Supports top/bottom entry

Top/bottom entry can be achieved without additional accessories, easily accommodating various installation needs.

3. Main Circuit Monitoring

Provides a single-line diagram to help customers promptly understand the latest status of power supply lines, main power sources, circuit breakers, and distribution modules, as well as information on voltage, current, power, and harmonics. The status of the power distribution system is fully visible.

4. Branch Circuit Monitoring

Real-time monitoring displays all branch circuit voltage, current, harmonics, power, and other electrical parameter information.

5. Detailed Event Logging

Can log up to 5,000 events, allowing for alarm configurations to prevent system failures due to overload or environmental factors.

2. Aisle Air Conditioning

The modular data center uses row-level horizontal air conditioning for cooling.

1. Overview

(1) In the modular data center, the air conditioning works together with the equipment cabinets to form a sealed cold (hot) aisle, achieving thermal air isolation. The air conditioning used in the modular data center employs a horizontal air supply method, with airflow entering from the back and exiting from the front, sucking in the hot air expelled by the servers, cooling it, and then blowing it out; the cold air is then sucked in and expelled by the servers, repeating this cycle.

(2) The horizontal air conditioning is located close to the heat source, significantly shortening the air supply distance, thereby reducing pressure loss along the airflow path and minimizing cold air leakage, improving the efficiency of cooling capacity utilization.

(3) The standard module of the modular data center is applicable in spaces below 300 m², with a maximum power density of 9 kW per single cabinet, and both the cold and hot aisles have a width of 1.2 m.

(4) The indoor unit of the air conditioning has interfaces for refrigerant piping, power and signal lines, and condensate drainage pipes at the top or bottom.

(5) The appearance of the indoor unit is shown in the figure (actual appearance depends on configuration). The outdoor unit of the air conditioning (T1 condition, maximum ambient temperature 43°C; T3 condition, maximum 55°C can be customized) should have at least 1.5 m of installation and maintenance space reserved around it when determining the installation location.

3. Sealed Corridor

The sealed corridor of the modular data center mainly consists of end doors and skylights.

1: End Doors

(1) The end doors of the sealed corridor are available in two options: sliding doors and double-opening doors, which can be selected according to customer needs.

(2) Sliding door dimensions: height × width × depth = 2050mm × 1200mm × 42mm. The sliding door uses a sliding structure, with the cabinet as the carrier, installing upper and lower tracks to ensure the independence of the sealed corridor system. The door panel is made of 1.5mm cold-rolled steel plate bent, with tempered glass installed in the middle to ensure visibility in the corridor area. The appearance of the sliding door is shown in the figure.

(3) Double-opening door dimensions: height × width × depth = 2050mm × 1200mm × 42mm. The double-opening door is connected to the cabinet with screws, ensuring the independence of the system. The door panel is embedded with tempered glass in the middle to ensure visibility in the corridor, and the tempered glass meets fire emergency requirements well. The lower part of the door panel is equipped with a sealing brush to improve the sealing of the module.

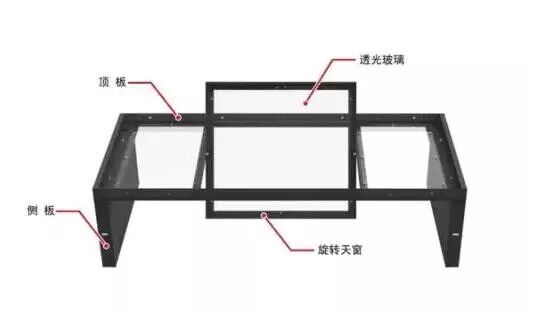

2: Skylights

(1) The sealed corridor adopts a flat-top structure scheme.

(2) Flat-top skylight dimensions: height × width × depth = 350mm × 1200mm × 600mm.

(3) The flat-top skylight consists of side panels, a top panel, and a rotating skylight, serving as an expansion module unit for a single cabinet. The rotating skylight is connected to the top panel by a FuseLink pin, remaining horizontal during normal operation, and automatically opening under gravity when the FuseLink melts in a fire situation, allowing extinguishing gas to enter the corridor. The appearance of the flat-top skylight is shown in the figure.

4. Cabinets

The modular data center can be configured with a maximum of N cabinets, including server cabinets, network cabinets, and integrated wiring cabinets.

The cabinets configured in the modular data center have uniform dimensions, comply with the IEC60297-1 standard, and use front and rear airflow. The appearance of the cabinets is shown in the figure.

Cabinet features: (1) The cabinets meet the following features: (2) Front and rear door ventilation rate of 70%. (3) Two vertical PDUs can be installed at the rear of the cabinet. (4) The vertical mounting columns of the cabinet are marked with the exact position of each “U”. The front door, rear door, and side panels of the cabinet can all be locked and can only be opened with the provided special key. The static load of the cabinet is not less than 1300kg.