From Components to Complete Systems: The Paris Air Show Reveals How 3D Printing is Disrupting the Aerospace Supply Chain

On June 16, the biennial Paris Air Show opened, attracting aerospace manufacturers from around the world. As expected, additive manufacturing became a major highlight of the air show, with numerous additive manufacturing companies exhibiting, and aerospace original equipment manufacturers (OEMs) such as Safran, Airbus, and GKN showcasing their latest innovations in additive manufacturing technology.

The French engine manufacturer Safran Group showcased its largest 3D-printed component to date at the Paris Air Show: a turbine rear frame with a diameter of approximately 90 centimeters, redesigned using additive manufacturing technology, which is one-third lighter than traditionally manufactured components. Additionally, this 3D-printed turbine rear frame was completed in just three weeks, significantly reducing the delivery time compared to the 18 months required by traditional manufacturing methods. Reports indicate that Safran Group aims to shorten the 3D printing delivery cycle to less than one week. The component is made using SLM technology and nickel-based superalloys.

Safran Group’s 3D-printed turbine rear frame

Oerlikon also showcased a range of aerospace solutions, including coatings to protect critical components from corrosion and wear, as well as 3D-printed cooling plates for managing thermal loads in fighter jets. The company recently announced that its facility in Huntersville, North Carolina, has delivered its 25,000th 3D-printed suppressor (using MetcoAdd nickel powder 3D printing).

GKN Aerospace also took the opportunity at the Paris Air Show to announce that its Fan Case Mounting Ring (FCMR) project has successfully achieved industrialization and will reach full-speed production by the end of this year. The FCMR component, made using additive manufacturing, is a key part of the Pratt & Whitney GTF engine, which powers the Airbus A220 and Embraer E195-E2 aircraft.

Integrated components containing the 3D-printed Fan Case Mounting Ring

Pratt & Whitney recently completed testing of the TJ150 turbine rotor, one of the first rotating components manufactured directly using 3D printing. The TJ150 is a turbojet engine with a thrust of 150 pounds (approximately 74 kilograms), making it well-suited for powering autonomous systems and weapons.

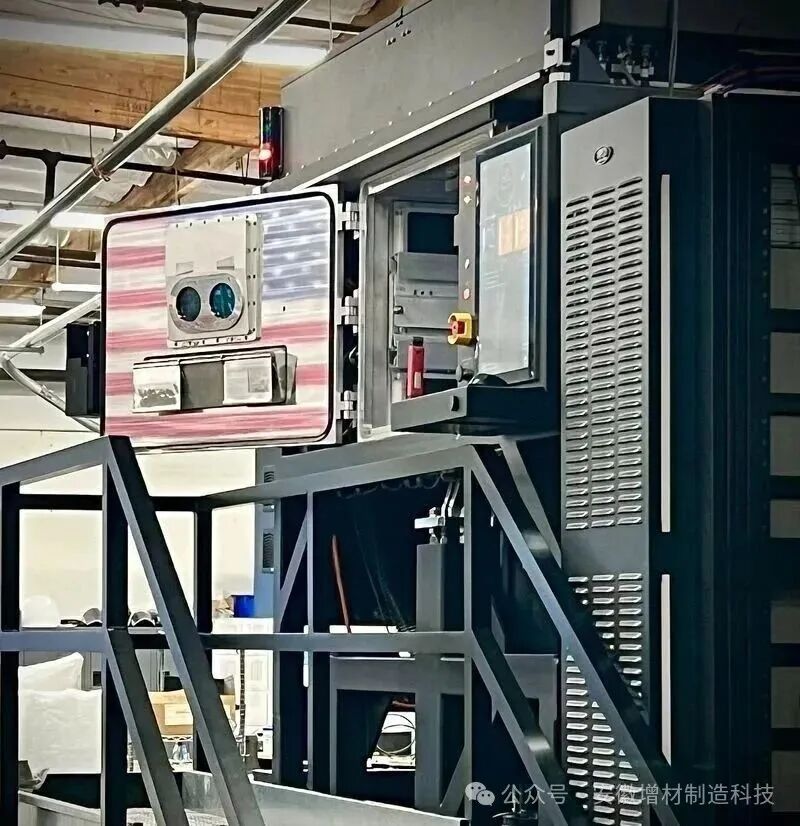

One of the large 3D-printed aerospace components displayed at the Paris Air Show, manufactured using Nikon SLM Solutions’ large-format multi-laser LPBF technology. The component is one meter tall and was produced in collaboration with a French company for the French National Center for Space Studies (CNES) for launcher applications.

A one-meter tall 3D-printed engine launcher

LISI AEROSPACE showcased a 3D-printed metal component with an integrated heater, developed in collaboration with Thales Alenia Space and CSEM under the AHEAD project. This 3D-printed component is designed to heat and monitor mechanical pumping fluid circuits for Thales Alenia Space’s new satellite thermal control system.

3D-printed integrated heater component

The French additive manufacturing expert VOLUM-e presented a series of impressive 3D-printed components at this aerospace industry event, including key parts for the French National Center for Space Studies (CNES) low-temperature engine. The company stated: “CNES commissioned VOLUM-e to produce key components for an innovative propulsion system equipped with electric pumps using oxygen and liquid methane.” VOLUM-e also showcased other components to demonstrate its extensive expertise in additive manufacturing, including an impressive wall of material samples.

Industry events have always been a golden opportunity for companies to announce or sign new cooperation agreements. The 2025 Paris Air Show is no exception, with several additive manufacturing companies signing agreements with new partners or strengthening existing collaborations.

One of the earliest news items from the event was Nikon SLM Solutions signing a memorandum of understanding with Rocket Lab to reserve two upcoming “large-format” NXG metal 3D printers. Rocket Lab is a company that manufactures space systems and provides launch services, having utilized additive manufacturing technology for a decade, including the development of “the world’s first 3D-printed electric pump for orbital rocket engines.”

Nikon SLM Solutions also announced a strategic partnership with the Ariane Group to support the production of components larger than one cubic meter through its metal powder bed fusion solutions. The Ariane Group, co-owned by Airbus and Safran, has extensive experience in the European aerospace industry and is the prime contractor for the European Space Agency’s Ariane 6 launch vehicle and France’s M51 strategic missile.

Another collaboration announcement at the Paris Air Show was GKN Aerospace expanding its partnership with UK-based Archer Aviation to manufacture and supply key fuselage components for Archer’s Midnight eVTOL aircraft. The Midnight aircraft is an electric air taxi capable of carrying up to four passengers, with one of its main selling points being its quiet operation and lower emissions compared to traditional helicopters. The two companies have been collaborating since 2023.

GKN will continue to provide Archer Aviation with 3D-printed key fuselage components

The metal additive manufacturing company Velo3D also signed a master service agreement (MSA) with VayaSpace, which focuses on hybrid rockets and space propulsion systems. The agreement, valued at $4 million, will see VayaSpace use Velo3D’s rapid production solutions (RPS) to accelerate the production of critical components for its hybrid propulsion systems. VayaSpace will utilize Velo3D’s Sapphire XC and XC1MZ printers along with GRCop42 and Inconel718 materials.

Overall, additive manufacturing continues to make strides in the aerospace industry, as evidenced by its growing representation at major events like the Paris Air Show.