Like many other great inventions in history, the printed circuit board (PCB) as we know it today is built on the foundation of progress throughout history. In our little corner of the world, we can trace the history of PCBs back over 130 years to a time when the great industrial machines of the world were just beginning to operate. The blog we will present is not a complete history but rather highlights significant moments that transformed PCBs into what they are today.

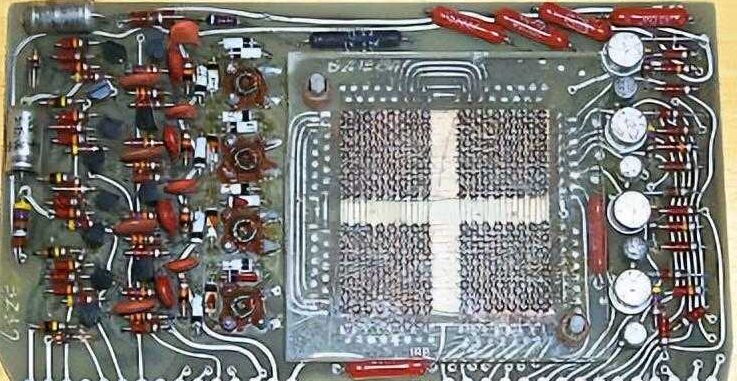

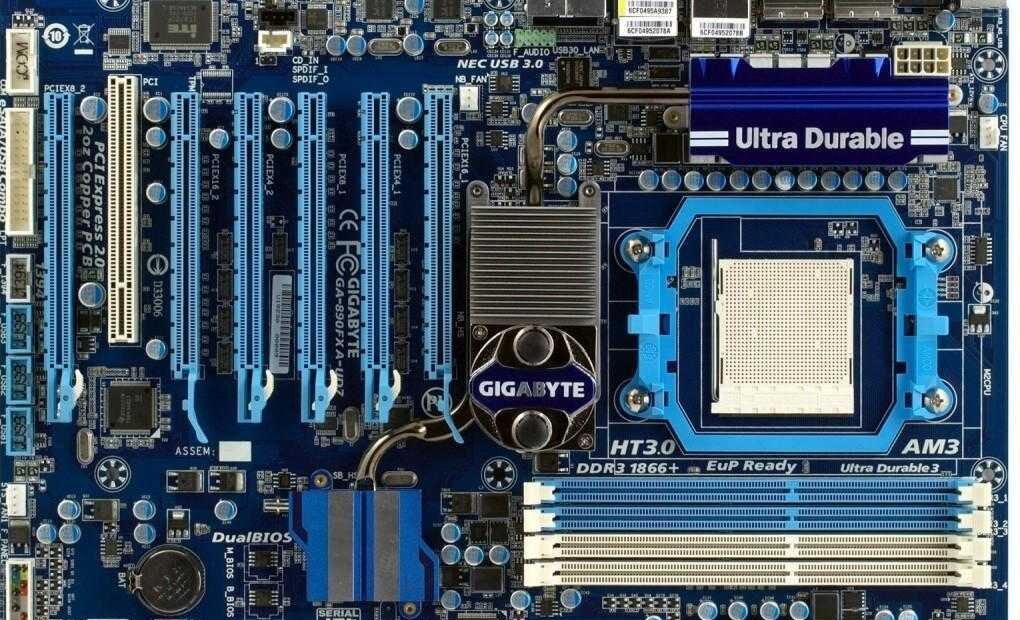

Over time, PCBs have evolved into tools that optimize the manufacturing of electronic products. What was once easy to assemble by hand quickly gave way to microscopic components that require mechanical precision and efficiency. The two circuit boards shown in the following images serve as examples. One is an old board made in the 1960s for calculators, while the other is a typical high-density motherboard you would see in today’s computers.

Comparison of PCBs between calculators from 1968 and modern motherboards.

In calculators, we might have over 30 transistors, but on a single chip on a motherboard, you can find over a million transistors. The pace of advancement in technology and PCB design itself is impressive. Now, everything on a calculator PCB can fit into a single chip designed today. This has led to several notable trends in PCB manufacturing:

-

We are integrating more functions into advanced devices like integrated circuits (ICs) and microprocessors.

-

We are shrinking passive components like resistors and capacitors down to microscopic levels.

-

All of this has resulted in increased component density and complexity on our circuit boards.

All these advances are primarily driven by the increase in the speed and functionality of our products. We want our devices to respond instantly, even a few seconds delay can drive us crazy. For functionality, consider video games. Back in the 80s, you likely played Pac-Man in an arcade. Now we are seeing photo-realistic representations. The progress is simply insane.

Today, the visual effects of video games are nearly realistic.

Clearly, the development of PCBs is a direct response to our expectations of devices. We need faster, cheaper, and more powerful products, and the only way to meet these demands is to miniaturize the manufacturing process and improve efficiency. When did this surge in electronics and PCBs begin? At the dawn of the Gilded Age.

The Gilded Age (1879 – 1900)

We ended the American Civil War in the 60s and now American manufacturing is thriving. During this time, we are doing our best to produce everything from food to clothing, furniture, and railroads. Transportation is booming, and our greatest engineers are studying how to get someone from the East Coast to the West Coast in 5 to 7 days instead of 5 to 7 months.

Railroads made travel from the East Coast to the West Coast take only days instead of months.

During this time, we also introduced electricity into homes, starting first in cities and then spreading to suburbs and rural areas. Electricity has now replaced coal, wood, and oil. Think about living in New York during a harsh winter, trying to cook or heat with dirty coal or stacked firewood. Electricity changed everything.

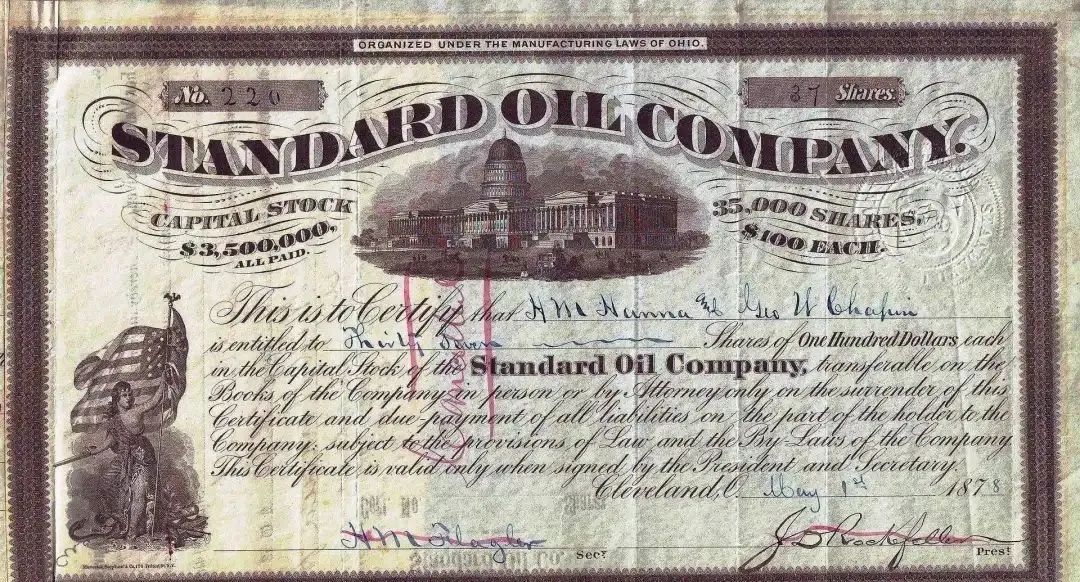

An interesting point is that the Standard Oil Company, which monopolized the oil market, did not supply oil for gasoline. Their market was for oil used in cooking, frying, and lighting. With the advent of electricity, the Standard Oil Company needed to define a new use for oil, which would come with the introduction of cars.

Standard Oil Company issued stock in May 1878, marking the start of the oil monopoly.

During the Gilded Age, we saw some significant discoveries in electromagnetism. We invented the electric motor, which converts electrical energy into mechanical energy. We also saw the generator, which does the opposite by converting mechanical energy into electrical energy.

This was also a time of genius inventors who still influence our electronic world today, including:

-

Thomas Edison invented the light bulb in 1879 and the movie in 1889, along with many other innovations.

-

Nicola Tesla invented the electric motor in 1888 and alternating current in 1895.

-

Alexander Graham Bell invented the telephone in 1876.

-

George Eastman’s Kodak invented the first consumer camera in 1884.

-

Herman Hollerith invented the tabulating machine in 1890, later founding IBM.

During this intense period of innovation, one of the biggest debates was between alternating current and direct current. Tesla’s alternating current eventually became the ideal method for long-distance power transmission. However, interestingly, we are still dealing with AC-DC conversion issues today.

AC may have won this battle, but DC still dominates electronic products.

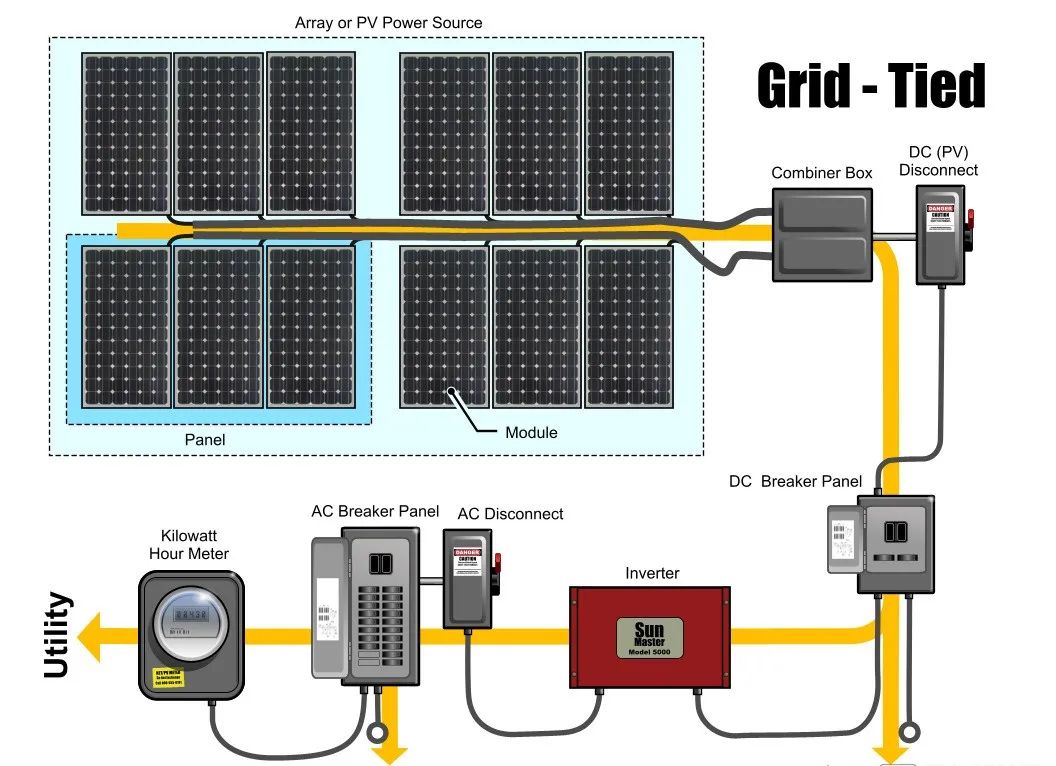

Look at any electronic device you plug into the wall; you need to convert AC into DC. Or, if you look at the infrastructure needed for solar panels, they generate power in DC and must be converted back to AC as a power source and then back to DC for our devices. You could almost say the AC-DC debate has never ended; a balance has just been reached between the two opposing ideas.

There is a lot of back and forth between AC and DC in solar panels.

It is important to note that the original idea of PCB was not invented during the Gilded Age. However, without the manufacturing capabilities of this era and the widespread influence of electricity, PCBs would never have become what they are today.

The Progressive Era (1890 – 1920)

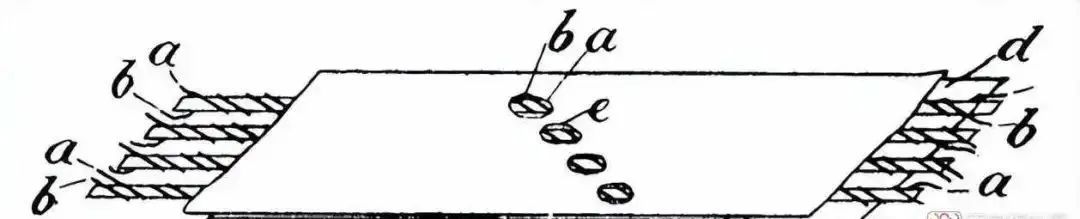

The Progressive Era was marked by a time of social reform, with legislation like the Sherman Antitrust Act breaking the monopoly of Standard Oil. It was also when we saw the first PCB patent. In 1903, German inventor Albert Hanson applied for a British patent for a device described as a flat foil conductor on multilayer insulating boards. Sound familiar?

Drawing depicting the first PCB patent granted to Albert Hanson.

Hanson also described the concept of through-hole applications in his patent. Here, he demonstrated that you could drill a hole between two layers with vertical lines to establish electrical connections.

During this period, we began to see Edison and other business leaders pushing electric devices into everyday homes. The issue with this push was a complete lack of standardization. If you lived in New York or New Jersey and used Edison’s electric inventions for lighting, heating, or cooking, what would happen if you used them in another city? They would not work because each town had its own socket configuration.

Edison not only wanted to sell people a light bulb; he also wanted to sell a service, which made this issue worse. Edison could provide you with electricity service on a monthly basis; then you would buy light bulbs, appliances, etc. Of course, these services were not compatible with other competitive methods.

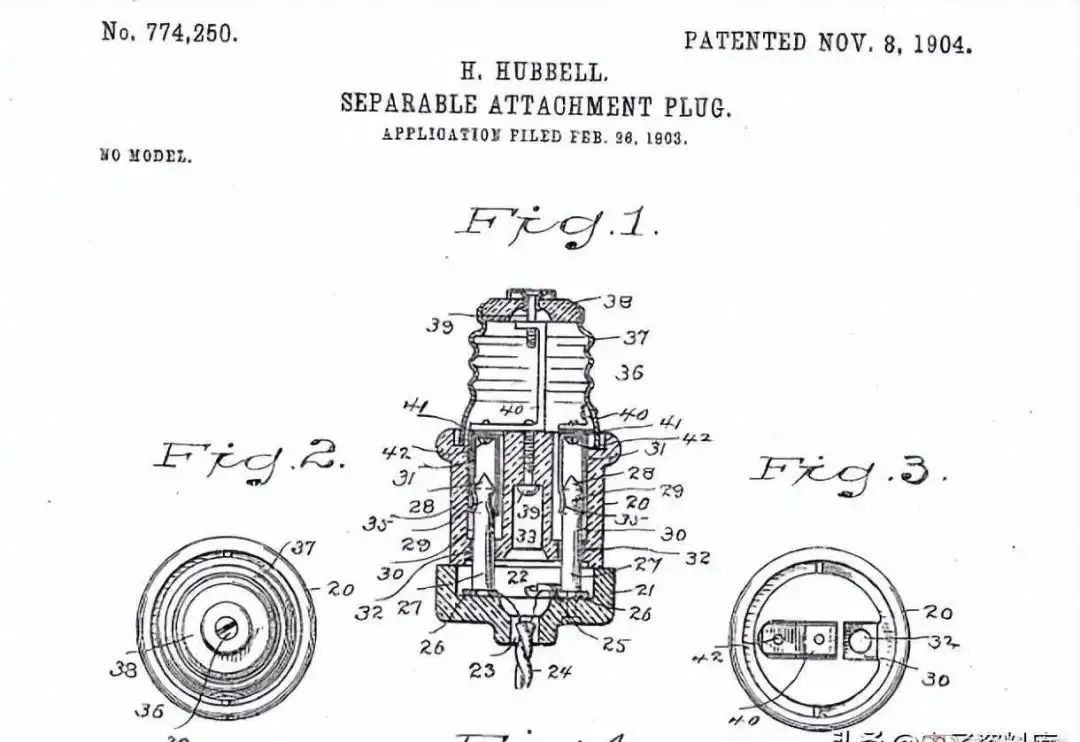

We owe it to Harvey Hubbel for finally ending this chaos. In 1915, he patented the standard wall socket plug that is still in use today. Now we don’t plug toasters or heating pads into light bulb sockets. This was a huge victory for industry standardization.

Thanks to Harvey Hubbel, we now have a standardized wall-mounted socket for all electronic devices.

Lastly, it is important to note that the Progressive Era marked the First World War. This conflict was purely focused on mechanical devices and trench warfare. The concept of PCBs, or even basic electronic products, had not yet been used for military applications, but that would change soon.

The Roaring Twenties (1920s)

With the end of World War I, we are now in the Roaring Twenties, witnessing a tremendous prosperity in the American economy. For the first time in history, more people lived in cities than on farms. We also began to see the introduction of chains and brands across the United States. You might have a family store or two in two different towns, but now we have major brands and stores going nationwide.

The greatest invention of this period was Henry Ford’s automobile and the infrastructure required for it. This situation is similar to the 1990s when we had to build switches, routers, and fiber optic cables to establish a major infrastructure to handle the internet and our information age. The automobile was no exception.

Henry Ford’s first car—the four-wheeler.

Here, we see once muddy roads being paved. People needed gasoline to power their vehicles, leading to the emergence of gas stations. You also had repair shops, parts, etc. Many people’s entire lifestyles stemmed from the invention of the automobile, and still do today.

It was also during this time that we saw the introduction of modern appliances that we still rely on today, such as washing machines, vacuum cleaners, and refrigerators. This was the first time people could buy perishable goods in stores and store them to extend their freshness.

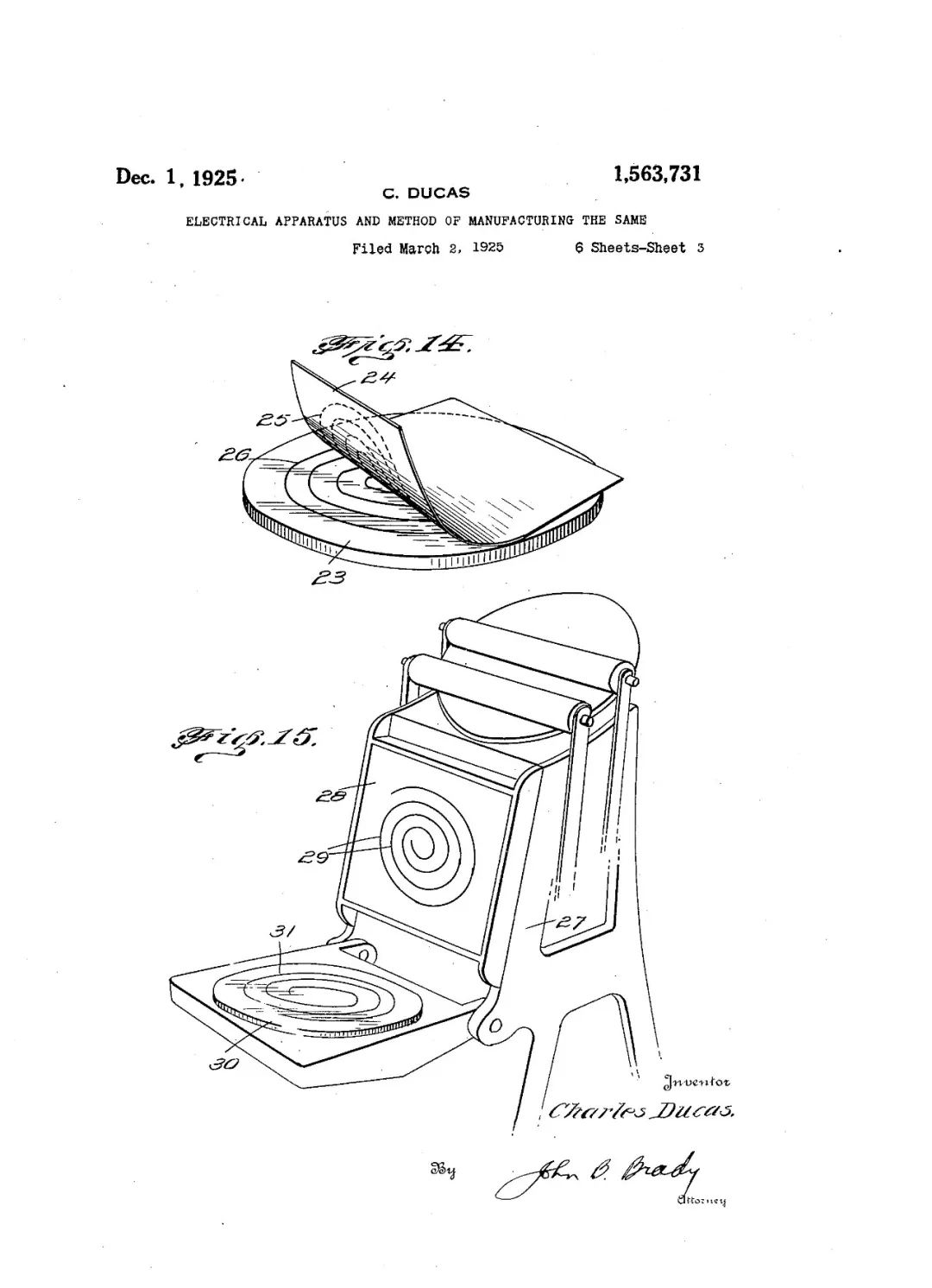

But where are our PCBs? We still do not see them in any appliances or cars launched during this period. However, in 1925, Charles Ducas submitted a patent that described the process of adding conductive ink to insulating materials. This would later lead to the printed wiring board (PWB). This patent was the first practical application similar to PCB, but only used as a flat heating coil. We have not yet achieved any actual electrical connections between circuit boards and components, but we are getting closer.

PCB continued to evolve, this time used as Charles Ducas’s heating coil.

The Great Depression (1930s)

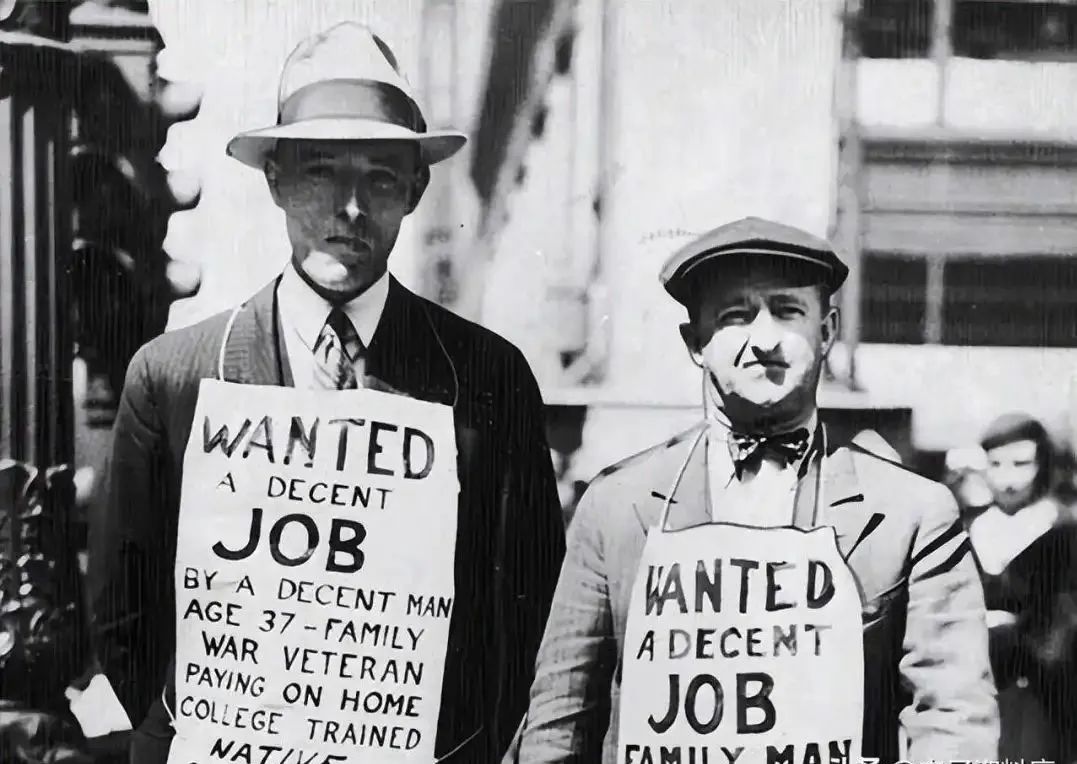

In 1929, the stock market crashed, and all the great innovations of our time plummeted. Here we saw a period with unemployment rates exceeding 25%, 25,000 banks failing, and widespread hardship affecting the globe. This was a tragic time for humanity, paving the way for the rise of Hitler, Mussolini, Stalin, and future world conflicts. Until now, PCBs may have remained silent, but that is about to change.

The Great Depression affected everyone, from banks to common workers.

World War II (1939 – 1945)

World War II is underway, and the United States entered the fight after the Pearl Harbor attack in 1942. The interesting thing about the Pearl Harbor incident was the entire communication failure that led to the attack. The United States had ample evidence that a crisis was imminent, but all contact with their military base in Honolulu was unsuccessful, leaving the island caught off guard.

A battleship lost during the Pearl Harbor attack.

Due to this failure, the U.S. Department of Defense realized they needed a more reliable means of communication. This brought electronics to the forefront as a primary means of communication, replacing Morse code.

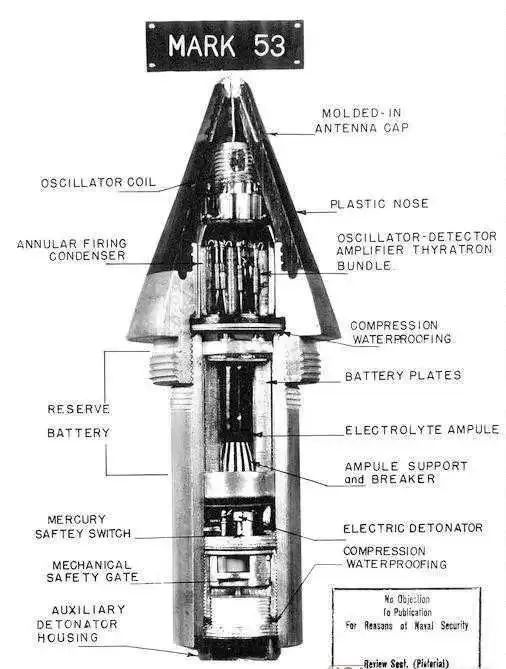

Also during World War II, we saw the first use of PCBs in proximity fuses. This device was used for high-speed projectiles that required long-distance precision firing in the air or on land. Proximity fuses were initially developed by the British to counter the advancing forces of Hitler and later shared with the Americans for perfected design and manufacturing.

One of the earliest military applications using PCB—proximity fuses.

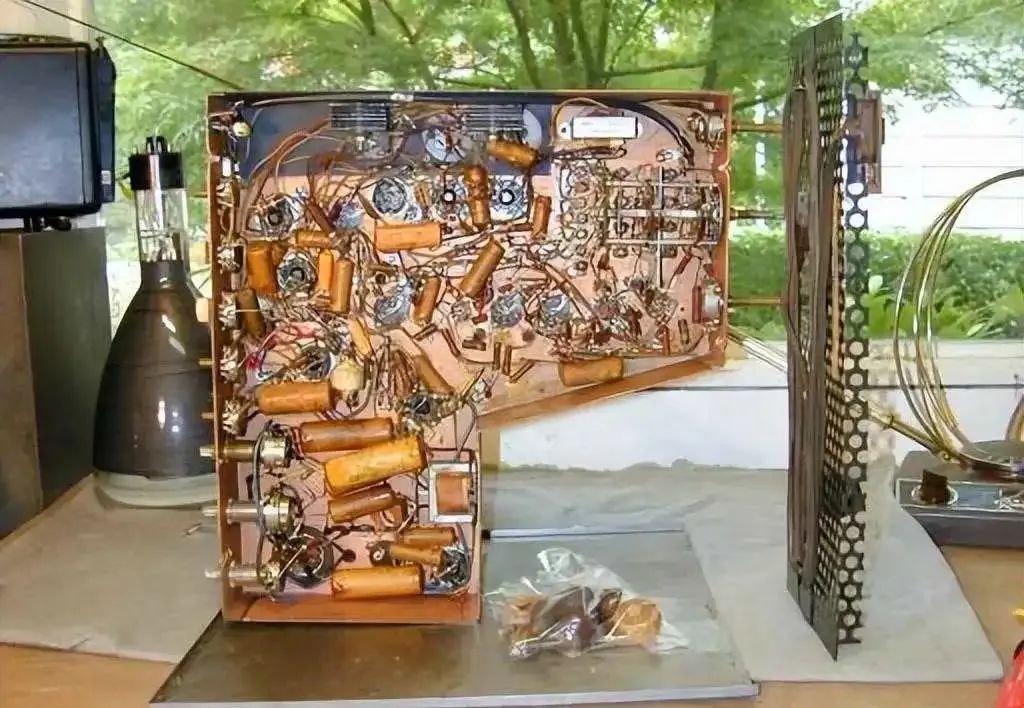

During this period, we also had Austrian Paul Eisler, who resided in the UK, patenting copper foil on a non-conductive glass substrate. Sound familiar? This is the concept we still use today to manufacture PCBs with an insulating layer and copper on the top/bottom. In 1943, Eisler made a radio with his PCB, taking this idea further and paving the way for future military applications.

Radio made with the first printed circuit board (PCB) by Paul Eisler.

Baby Boom Generation (1940s)

As World War II drew to a close, we saw our soldiers returning home, starting families, and giving birth to a bunch of kids. Enter the Baby Boom Generation. It was in the post-war era that we saw significant improvements in existing appliances like vacuum cleaners, washing machines, televisions, and radios. Now that the Great Depression was over, many consumers could finally afford these devices at home.

We still did not see consumer-grade PCBs. Where is Paul Eisler’s work? Look at the old television below, and you will see all the components but no underlying PCB base.

An old Motorola television from 1948, without PCB.

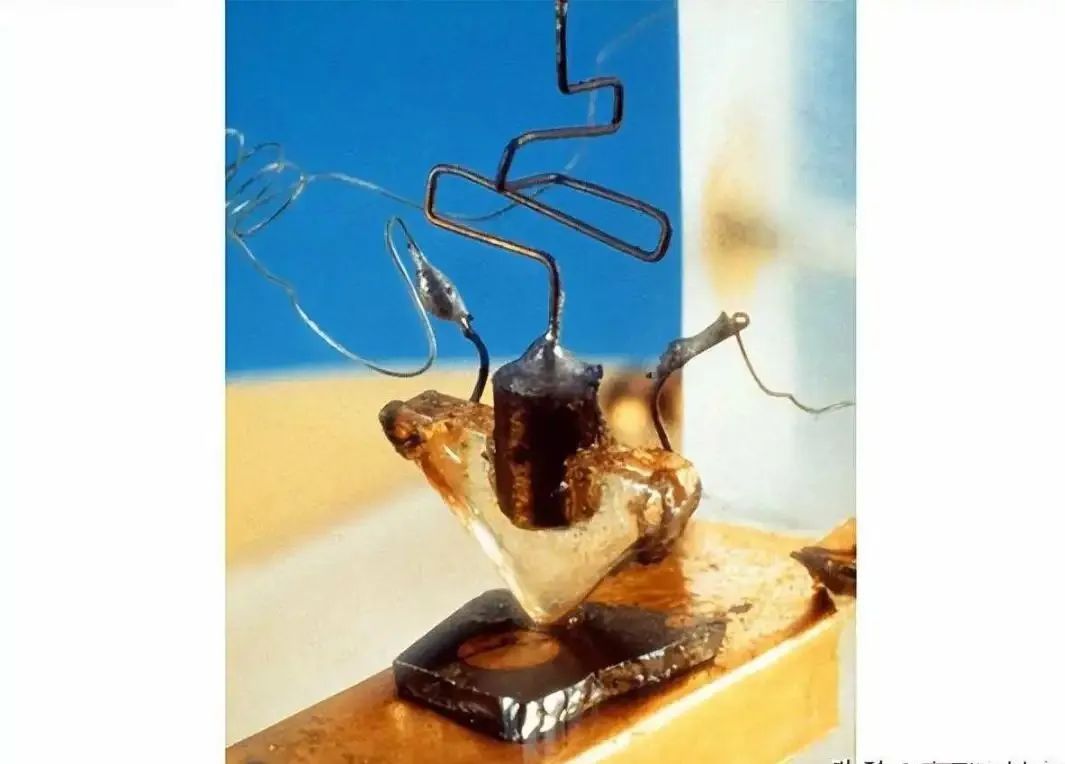

Despite the absence of PCBs, we did see the arrival of the transistor at Bell Labs in 1947. It was another six years before this device was finally used in products, but why did it take so long? In those days, information was spread through journals, conferences, etc. Before the information age, the dissemination of information simply took time.

The first transistor, born in 1947 at Bell Labs.

The Cold War Era (1947 – 1991)

The arrival of the Cold War marked a period of tension between the U.S. and the USSR. Due to the differences between capitalism and communism, these two giants were almost at war with each other, putting the world at risk of nuclear annihilation.

In order to stay ahead in this arms race, both sides had to strengthen their communication capabilities to understand what the enemy was doing. Here, we see PCBs reaching their full potential. In 1956, the U.S. Army published a patent for the “circuit assembly process.” Now manufacturers had a method to both fix electronic products and establish connections between components with copper traces.

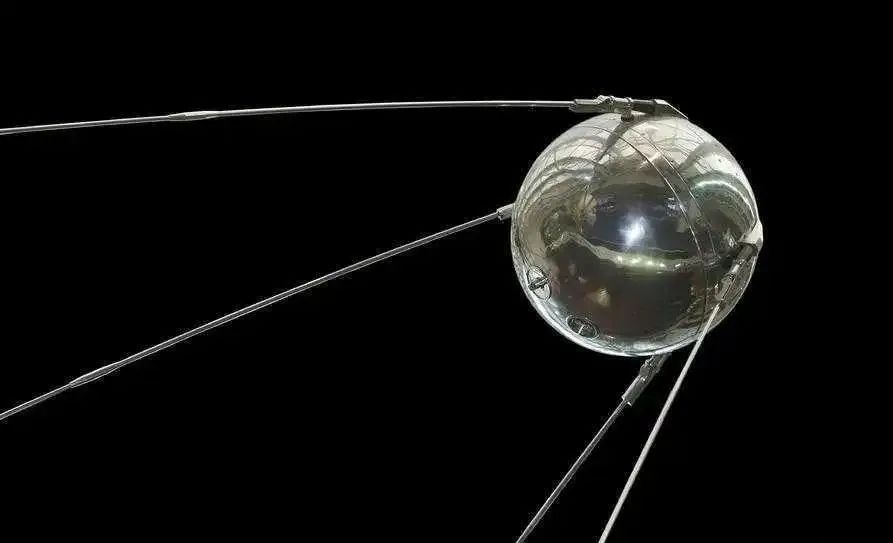

As PCBs began to take off in manufacturing, we found ourselves participating in the world’s first space race. The Russians achieved some astonishing feats during this time, including:

-

Launching the first artificial satellite, Sputnik, in 1957

-

Launching the first spacecraft, Luna 2, to the moon in 1959

-

Sending the first astronaut, Yuri Gagarin, to orbit the Earth in 1961

The first artificial satellite, Sputnik, launched by Russia in 1957.

Where was America in all this? Mostly falling behind, often taking a year or two to develop the same technology. In response to this gap, we saw the U.S. space budget increase fivefold in 1960. We also had the famous speech by President Kennedy in 1962, part of which is worth quoting:

“We choose to go to the moon! We choose to go to the moon in this decade and do the other things, not because they are easy, but because they are hard; because that goal will serve to organize and measure the best of our energies and skills, because that challenge is one that we are willing to accept, one we are unwilling to postpone, and one we intend to win.” — President John F. Kennedy, September 12, 1962

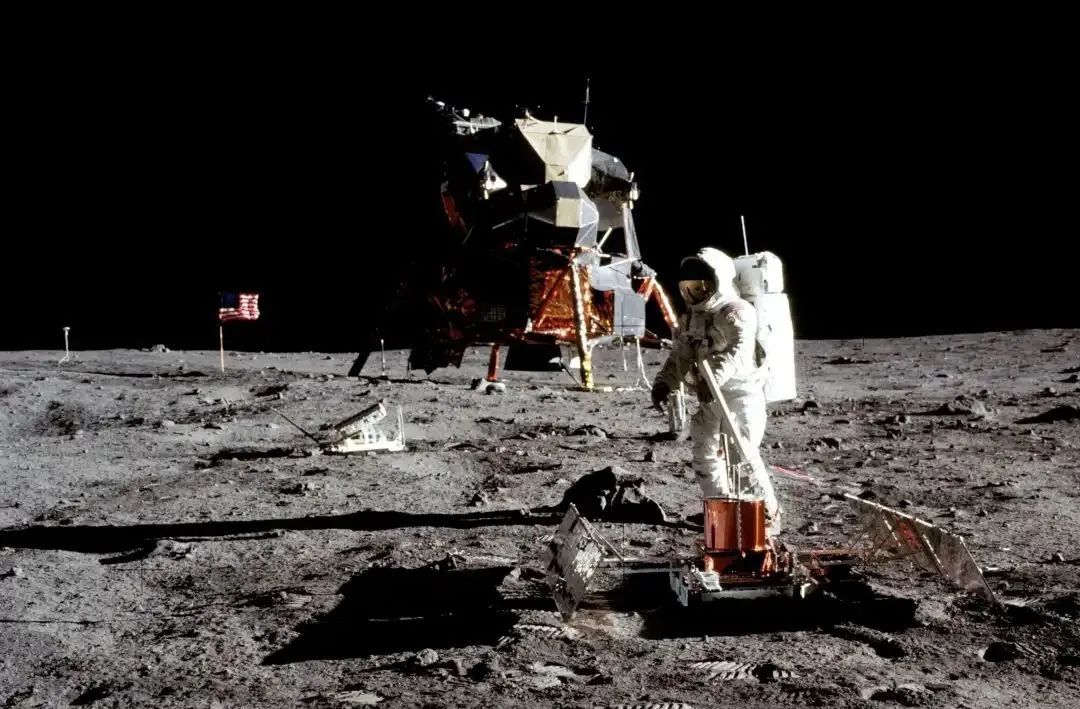

All of this led to a historic milestone. On July 20, 1969, the first human stepped on the moon.

The first person to step on the moon, a historic moment in human history.

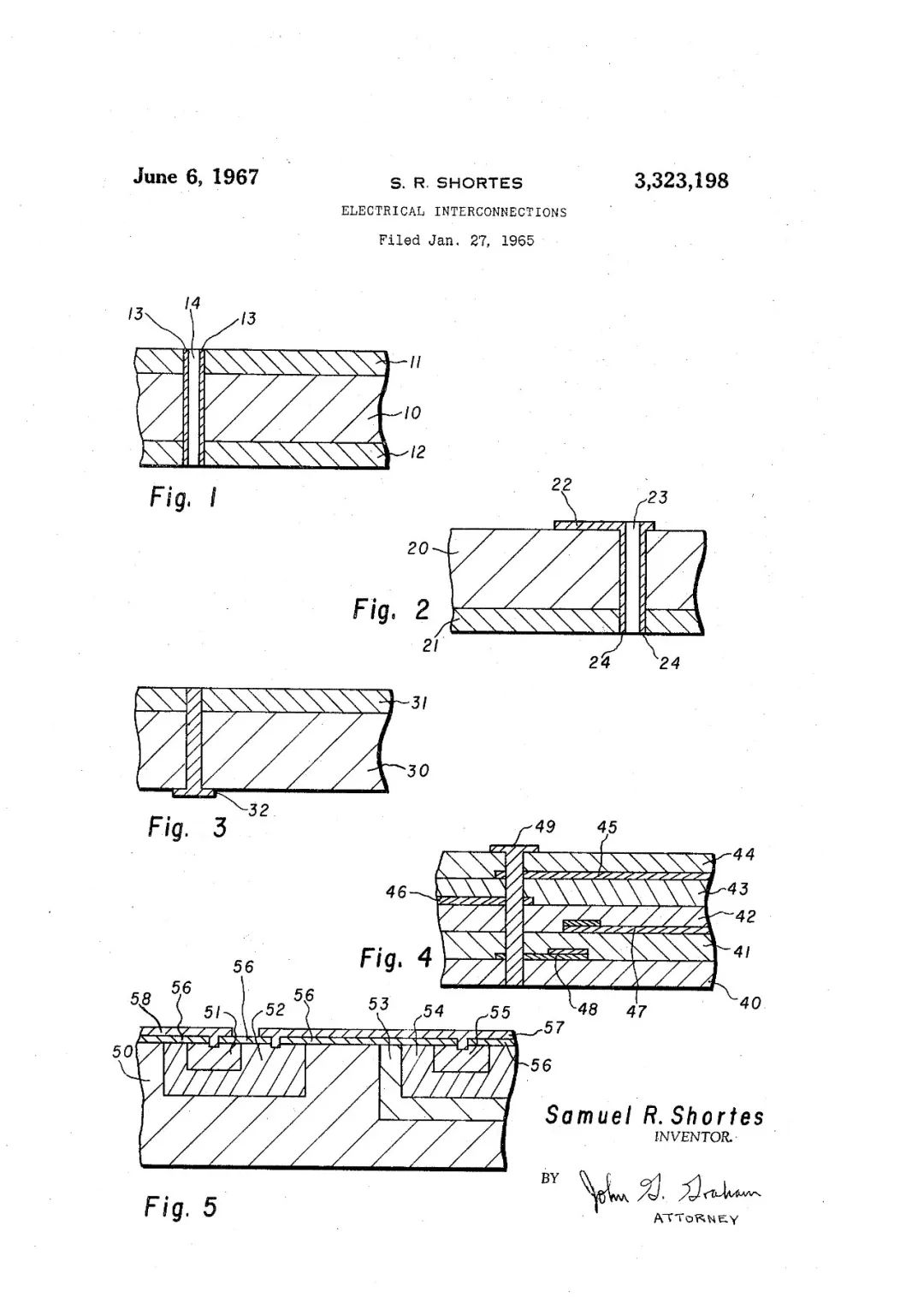

Back to PCBs, in 1963, we had Hazeltyne Corporation apply for the first patent for plated through-hole technology. This would allow components to be closely packed on the PCB without worrying about cross connections. We also saw the introduction of surface mount technology (SMT) developed by IBM. These dense components were first practically applied in the Saturn rocket boosters.

The first through-hole PCB technology patent in 1967.

The Dawn of Microprocessors (1970s)

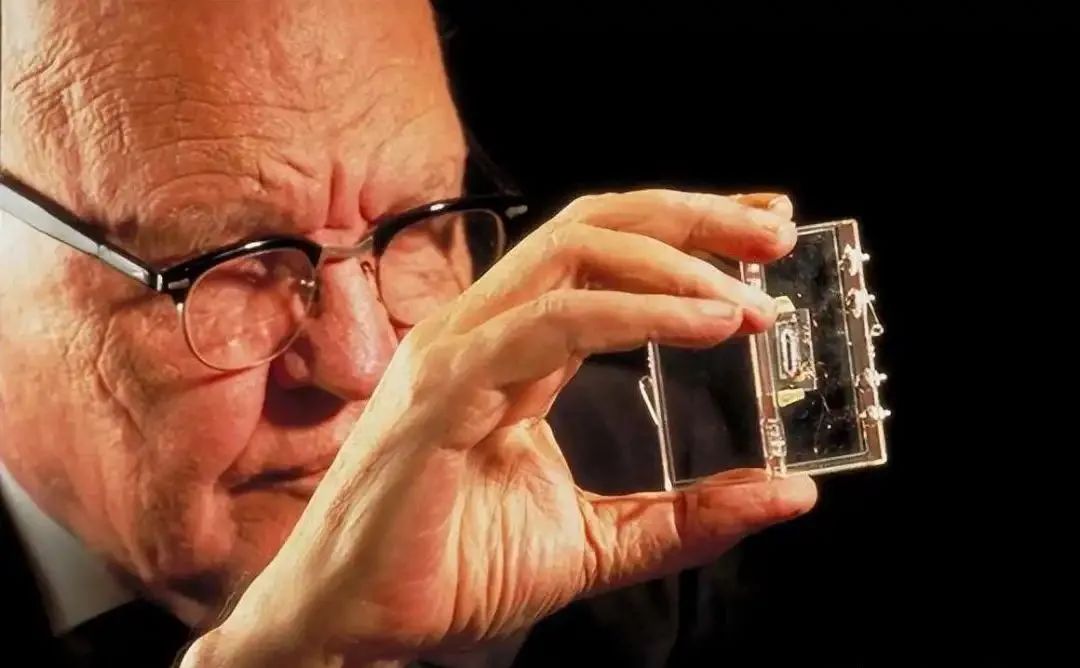

The 1970s brought us the first integrated circuit (IC) in the form of a microprocessor. This was initially developed by Jack Kilby of Texas Instruments in 1958. Kilby was a newcomer at TI, so his innovative ideas for ICs were largely kept secret. However, when TI’s senior engineers were sent to a week-long conference, Kilby stayed behind running with ideas in his mind. Here, he developed the first IC in the TI lab, and the returning engineers loved it.

Jack Kilby holding the first integrated circuit.

In the 1970s, we saw ICs first used in electronic product manufacturing. By this time, if you weren’t using PCBs for connections, you were in trouble.

The Dawn of the Digital Age (1980s)

The digital age brought significant changes to our consumer media, introducing personal devices like CDs, VHS, cameras, gaming consoles, and Walkmans.

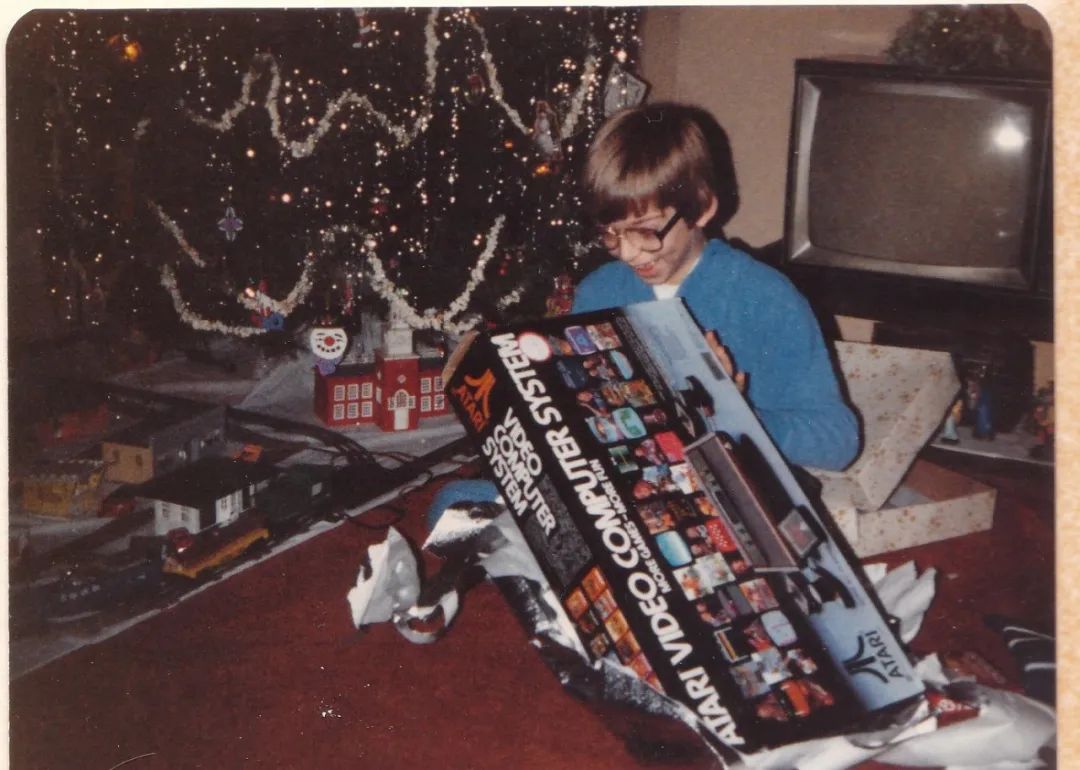

In 1980, the Atari video game console made children’s dreams come true.

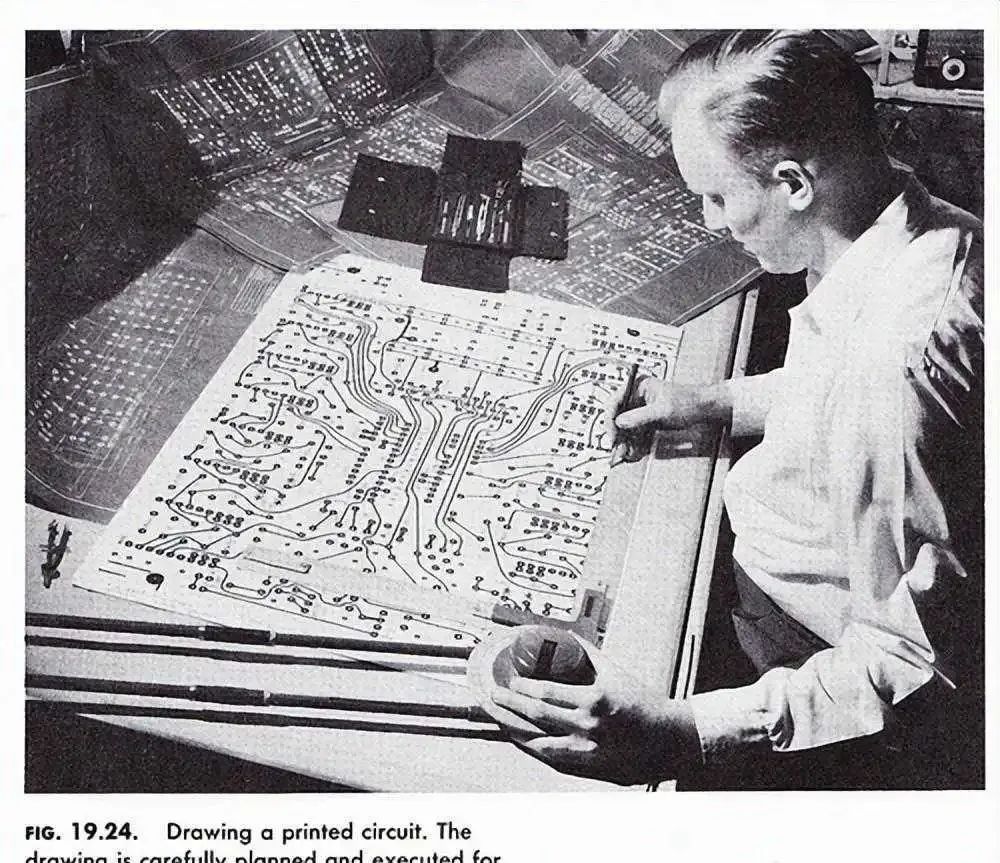

It is important to note that PCBs were still hand-drawn with light boards and templates, but then computers and EDA emerged. Here, we saw EDA software like Protel and EAGLE completely change the way we design and manufacture electronic products. Now we could save designs as Gerber text files instead of photos of PCBs, with coordinates that could be input into manufacturing machinery to produce PCBs.

Drawing printed circuit boards with tape and polyester film before EDA arrived.

In the 1990s, with the introduction of BGA, we saw the full use of silicon. Now we could install more gates on a single chip and began embedding memory and system-on-chip (SoC) together. This was also a period of high miniaturization in electronic products. We did not see any new features added to PCBs, but the entire design process began to change and evolve, shifting towards ICs.

Now designers had to implement design for test (DFT) strategies in their layouts. Popping a component out and adding a blue line was not easy. Engineers had to design their layouts from a future rework perspective. Could all the ways these components were placed be easily removed? This was a huge concern.

This was also an era where smaller component packages like 0402 made hand soldering of circuit boards nearly impossible. Designers now lived in their EDA software, while manufacturers were responsible for physical production and assembly.

Surface mount components from large to small.

The Hybrid Age (2000s and Beyond)

Entering the current era of electronics and PCB design; we call it the Hybrid Age. In the past, we had multiple devices to meet various needs. You needed a calculator; you bought a calculator. You wanted to play video games; you bought a video game console. Now you can buy a smartphone and get 30 different layers of built-in functionality. This may seem very obvious, but when you really see all the things our smartphones can do, it is quite shocking:

We are in an era of device integration, but what will happen next? PCBs have been established, and almost everything we have has processes and procedures. High-speed applications are becoming the norm. We also see that only 25% of PCB designers are under the age of 45, while 75% are preparing for retirement. The industry appears to be in a crisis period.

Will the future of PCB design be robotics? Perhaps in wearable devices with flexible circuits? Or we may see protons replacing electrons with photonics. As for the physical PCBs we know, the future may even change. There may not be a physical medium required for connections between components, but rather the potential of wave technology. This would allow parts to wirelessly send signals without the need for copper.

What Will the Future Hold?

No one really knows the direction PCB design will take in the future, or even the direction of electronic products as a whole. It has been nearly 130 years since our manufacturing muscles began to operate. Since then, with the introduction of major products like automobiles, appliances, computers, and smartphones, the world has changed forever. The days of relying on coal, wood, or oil for our basic livelihood and survival are long gone. Now we have electronic products that can meet our daily needs.

But what will the future hold? It’s a big unknown. It is well known that every invention we face stands on the shoulders of its predecessor. Our ancestors brought PCB design to where it is today, and now we need innovation and a complete overhaul of how we design and interact with technology. The future can be anything. The future depends on you.