A new technology in 3D printing has emerged! Under the illumination of a beam, we can see a printed part “materializing out of thin air,” and the entire process takes only a few minutes.

The animated image is taken from the original paper’s video.

The standout feature of this new technology is that it breaks away from the traditional layer-by-layer printing method of 3D printing, allowing the various parts of the printed object to be formed in one go. This not only speeds up the printing process but also results in smoother printed components.

Printed product. Screenshot source: Nature

Next, let’s compare it in detail with previous 3D printing methods. The two common types of 3D printing previously are: the first one is the most easily seen by everyone: melting the raw material and stacking it layer by layer like squeezing cream.

Image source: prostheticknowledge

The other method is using light to cure liquid resin materials. This method also cures layer by layer.

Image source: Gigaom

The layer-by-layer printing method has some drawbacks, such as the printed items may still show layering marks on the surface, and the printing speed is usually slower.

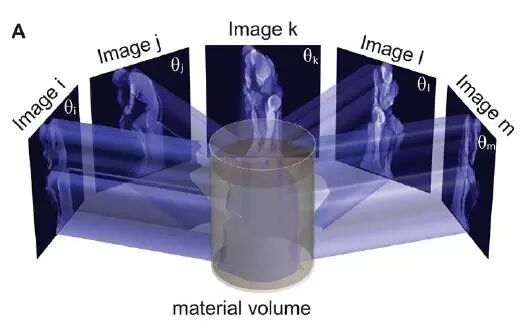

In the video at the beginning, we do not see any such layering. This new technology also utilizes a similar curing principle as mentioned in the second method, where a rotating cylinder contains light-curable resin, and while rotating, it is illuminated by a beam of light that continuously changes shape, with each beam corresponding to a projection of the 3D model from a certain angle (as shown below).

Image source: Original paper

For the resin at a certain position in the cylinder, once the cumulative dose of multi-angle light reaches a certain amount, the energy is sufficient to trigger the curing of the resin. If the light dose is insufficient, the resin remains in a flowable state. The result is that after rotating and illuminating, the light’s accumulation perfectly cures the resin into the desired shape, while the uncured resin can be washed away.

Printed product. Screenshot source: UC Berkeley

The researchers drew design inspiration from CT scans in hospitals. They stated that this 3D printing can be seen as the opposite process of performing a CT scan: a CT scan involves a machine rotating to capture a series of 2D projections from different angles, which are then reconstructed into a 3D image; whereas this 3D printing starts with a 3D model, then transforms it into projections from different angles, and uses a light source to project these 2D images onto the rotating resin.

This method can quickly print smooth, transparent resin small parts, and it can also print directly around other objects, such as adding a resin handle to a metal screwdriver.

Screenshot source: Science Magazine

Because the printing process looks a bit sci-fi, people have also compared this 3D printer to the “replicator” from Star Trek. Of course, while this “replicator” can quickly print a 4 cm tall transparent thinker, it cannot replicate a cup of hot Earl Grey tea…

Original paper: http://science.sciencemag.org/content/early/2019/01/30/science.aau7114

Related reports: https://www.nature.com/articles/d41586-018-07798-9

https://www.sciencemag.org/news/2019/01/star-trek-replicator-creates-entire-objects-minutes

Author: Chuang Qiao Yu

This article is reprinted with permission from

Cool Science (ID: SciencePorn)

Guokr

ID: Guokr42

Guokr, which is always unsure about what to popularize.

I think you should pay attention to it.

Don’t forget to give a thumbs up if you like it↘️