Antarctic Bear Guide: 3D printing is not only revolutionizing manufacturing methods but also driving experimental validation of fundamental scientific principles.

△Video

On April 30, 2025, Antarctic Bear learned that researchers from the AMOLF Institute and ARCNL (Advanced Research Center for Nanolithography in Amsterdam) published a noteworthy paper in the Proceedings of the National Academy of Sciences (PNAS) titled “Exotic mechanical properties enabled by countersnapping instabilities.” In their experiments, they utilized 3D printing molding technology to create flexible silicone components, successfully constructing a seemingly counterintuitive mechanical structure: while a single component normally elongates when stretched, when multiple such components are connected in a specific manner, the entire system unexpectedly “contracts suddenly” when stretched.

This astonishing “countersnapping” phenomenon not only challenges traditional perceptions of force-displacement relationships but also reveals the immense potential of 3D printing technology in experimental mechanics, smart structures, and mechanical metamaterial design. Antarctic Bear notes that the research team employed PolyJet 3D printing technology to create molds and used highly elastic silicone material for molding, demonstrating the critical role of 3D printing in validating nonlinear materials and complex geometries.

From Instability to Functionality: Capturing the “Countersnapping” Phenomenon

In nature and engineering structures, structural instability is often viewed as an uncontrollable source of failure, such as umbrellas flipping in strong winds or columns buckling. However, in recent years, material scientists and mechanical engineers have increasingly recognized that these nonlinear behaviors contain programmable potential, particularly in fields such as variable stiffness structures, soft robotics, and energy-absorbing materials, leading to a wave of research focused on “utilizing instability.”

The “countersnapping” phenomenon proposed by the AMOLF and ARCNL teams was born in this context. Unlike traditional “snapping instability”—which manifests as sudden elongation under tension or sudden contraction under compression—countersnapping is a counterintuitive response: the system suddenly shortens when external tensile forces increase. This anomalous behavior has not only been clearly realized and observed experimentally for the first time but has also been systematically quantified as a distinct self-intersecting feature in the force-displacement curve, holding profound theoretical and practical value.

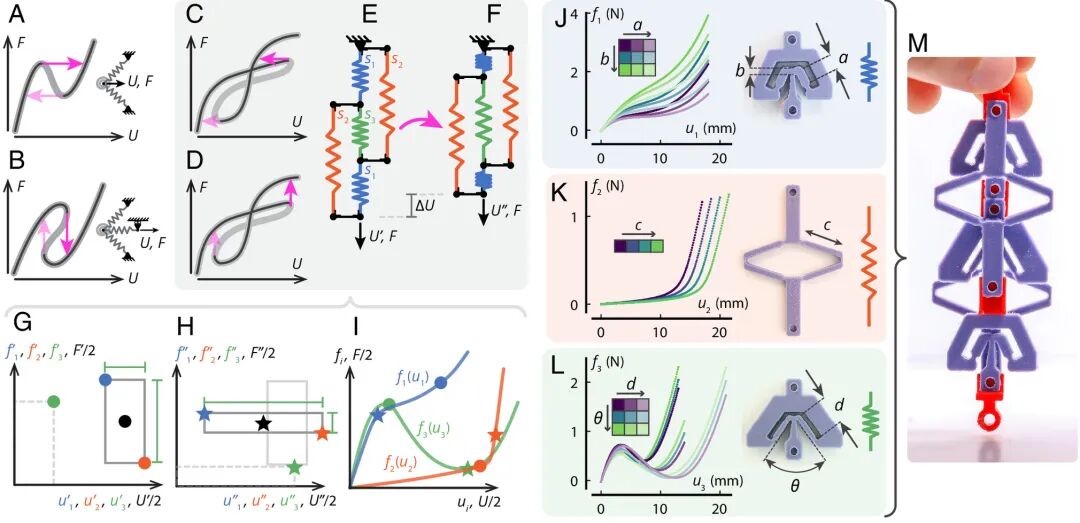

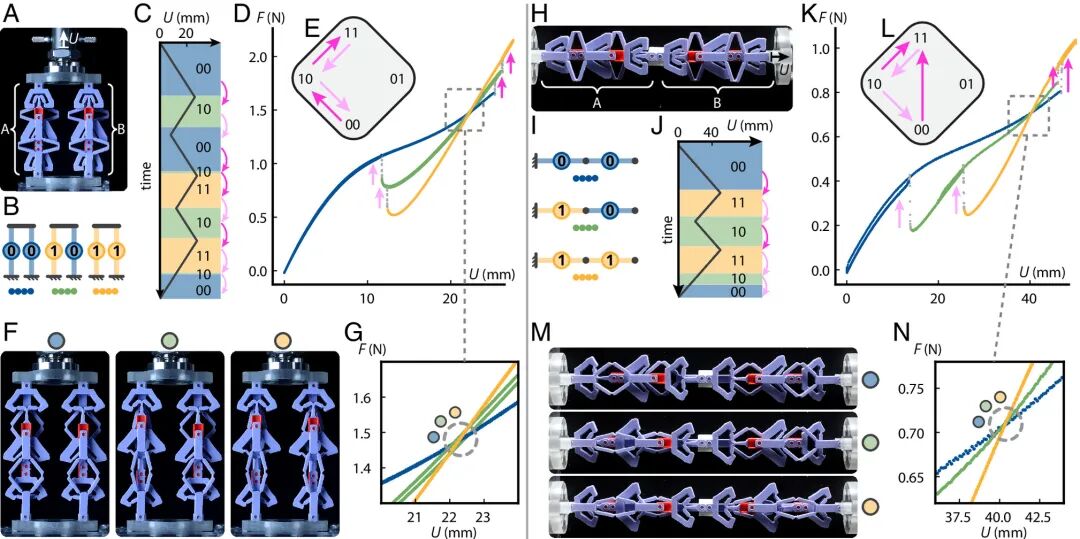

△Combination of nonlinear mechanical components achieving countersnapping instability

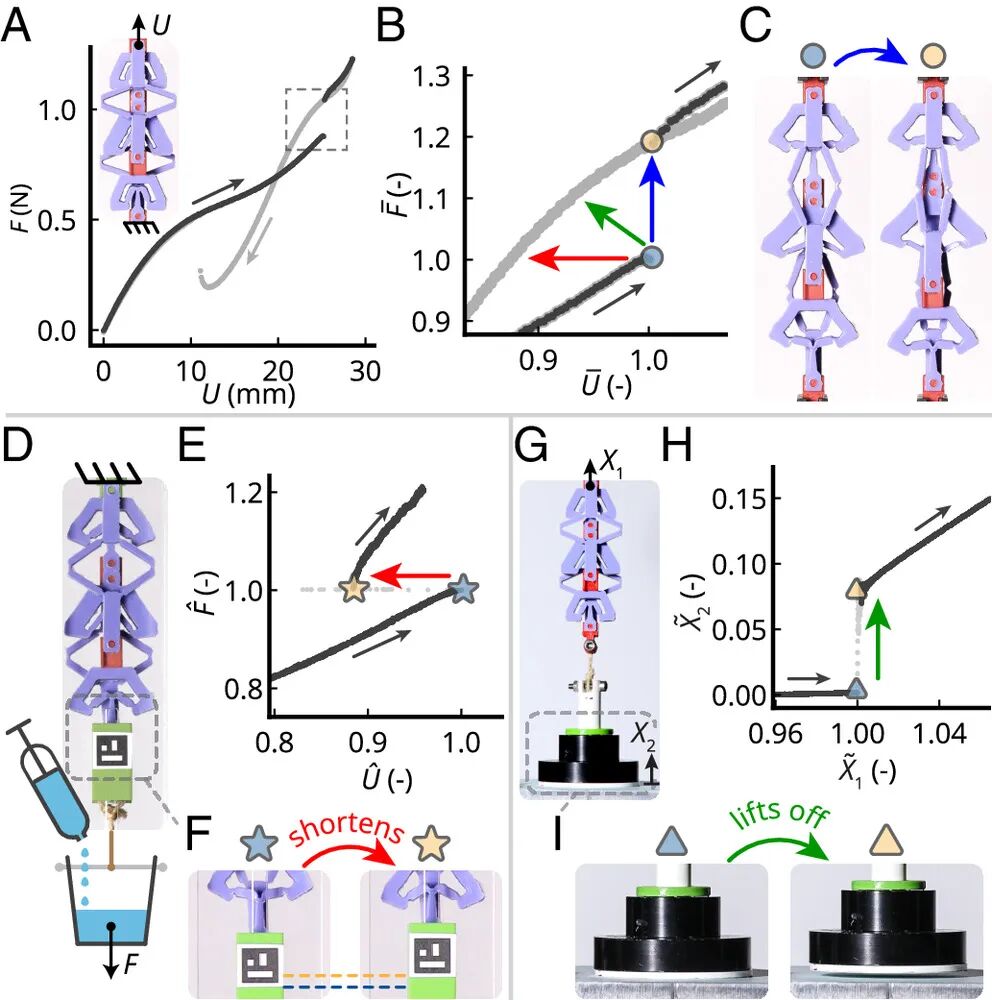

△Experimental observation of countersnapping behavior

Behind the Construction of “Anomalous” Mechanics: 3D Printing + Soft Silicone Materials

Antarctic Bear learned that to achieve this highly precise mechanical structure, the research team adopted a process route of “3D printing molding + multi-module assembly.”

First, they designed three types of building blocks based on nonlinear elastic theory: softening, hardening, and non-monotonic elastic units. These components each possess specific force-displacement response characteristics, with core structures including V-shaped bending beams and rhombic folding beams, all based on geometric nonlinear deformation.

Subsequently, the researchers used a Stratasys Eden260VS PolyJet printer to print high-resolution transparent molds and injected high-flexibility silicone material Smooth-Sil 945 into the molds for curing, resulting in highly consistent elastic components. These components were ultimately assembled into a 5-unit spring network, connected by 3D printed connectors to form the entire “countersnapping structure.”

This approach fully demonstrates the advantages of 3D printing in freeform shapes, microstructure control, and mold manufacturing, providing an experimental foundation for exploring complex mechanical phenomena.

Experimental Validation: The Real Physical Representation of “Shortening When Stretched”

The research team systematically observed and validated the “countersnapping” phenomenon through three types of experimental setups:

1. Displacement control experiment: By slowly stretching the structure on a stretching platform, it was found that when the stretch exceeded a critical value, the system suddenly contracted, and the reaction force rapidly surged. This phenomenon is represented in the force-displacement curve as a typical “self-intersecting mutation” feature, confirming the existence of countersnapping.

2. Force control experiment: By slowly adding water to a suspended device, the structure suddenly shortened at a certain moment, causing the suspended mass to “bounce up,” indirectly proving that a sudden change in mechanical coupling occurred within the structure.

3. Mixed drive experiment: Under composite loading conditions, the structure exhibited a response of “suddenly jumping from rest,” indicating that the countersnapping mechanism has directionally consistent, incremental driving characteristics, which can be used in mechanical logic or soft robotic actuation structures.

Extended Applications: Adhesive Sliding Motion, Programmable Stiffness, and Vibration Suppression

Notably, the research team not only achieved the design and validation of the anomalous structure but also explored its potential applications in functional materials. For example:

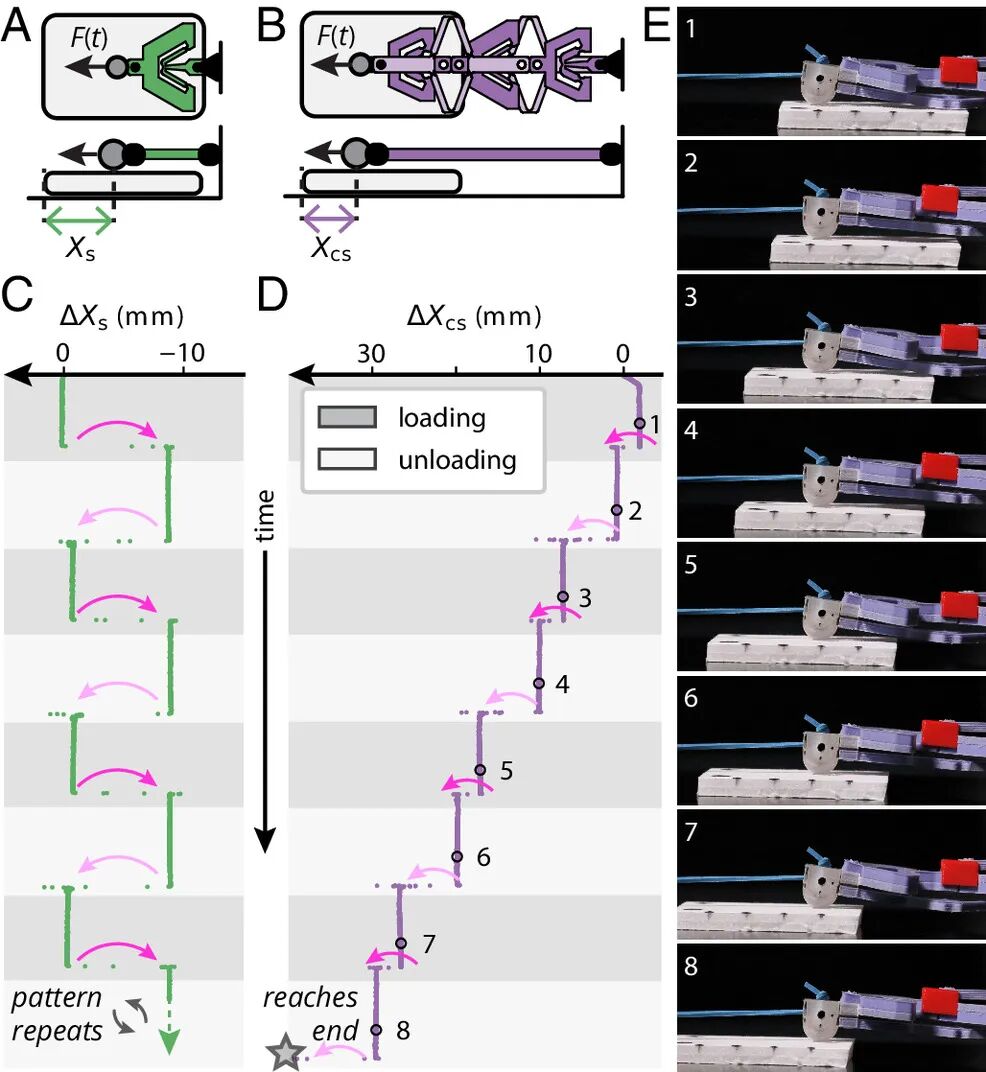

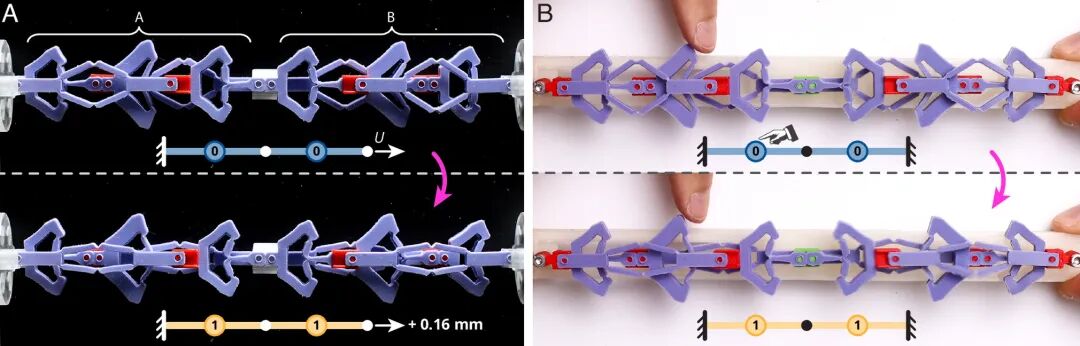

1. Unidirectional adhesive sliding drive: Compared to ordinary snap structures that cancel displacement during back-and-forth stretching, the countersnapping structure undergoes two identical directional deformations within one cycle, allowing the system to achieve directionally consistent incremental displacement without feedback control, potentially applicable to soft robotic micro-propellers or micro-displacement actuators.

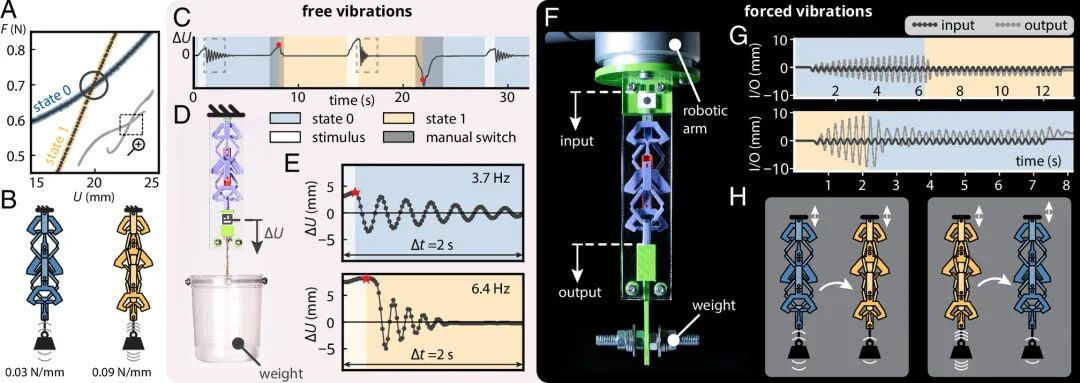

2. Programmable stiffness switching: By controlling the structural state switching, the system can achieve different stiffness adjustments under the same force and displacement conditions. This ability to “switch performance while maintaining state” provides new ideas for tunable filters, passive dampers, and other devices.

3. Resonance self-avoidance and smart materials: The countersnapping structure can “automatically jump” to a non-resonant state under resonance excitation, thereby achieving adaptive protection functions for the system in high-vibration environments. This mechanism has practical significance for structural health monitoring and vibration-resistant design in aerospace structures.

△Experimental observation of unidirectional adhesive sliding behavior

△Demonstration of programmable and self-switching stiffness experiments.

△Collective behavior of observed countersnapping metamaterials

A New Direction for Mechanical Metamaterials: Evolution of Response from Units to Arrays

Furthermore, Antarctic Bear notes that researchers have also designed and tested parallel or series metamaterial structures composed of multiple countersnapping units. In parallel configurations, different units can respond sequentially according to design order, forming programmable variable stiffness materials; in series configurations, the structure can produce an “avalanche response” triggered by unit activation, achieving global state mutation and collective switching.

△Avalanche transition in series countersnapping components

These metamaterials based on countersnapping units not only enhance the diversity of mechanical performance but also lay a new foundation for constructing mechanical logic devices and elastic computing systems.

Antarctic Bear Observation: 3D Printing Empowers the Boundaries of Mechanical Exploration

This research outcome demonstrates that 3D printing is not only an industrial manufacturing tool but also an important platform for fundamental scientific experiments and mechanical theory validation. Whether it is high-precision molds, complex structural designs, or rapid material prototyping and parameter iteration optimization, additive manufacturing plays an irreplaceable role in exploring physical boundaries and constructing future intelligent structures.

All components used in the structure by the research team are based on 3D printing as the “core platform,” further utilizing flexible materials such as silicone for functional realization. This experimental paradigm of cross-disciplinary integration will help promote the deep fusion of structural mechanics, materials science, and intelligent systems.

In the future, nonlinear behaviors like “countersnapping” may find practical applications in fields such as wearable devices, adaptive architecture, and space deployment structures, and 3D printing will undoubtedly continue to serve as a key bridge for exploring “material functionality and geometric logic.”

References:https://doi.org/10.1073/pnas.2423301122

Recent Hot Articles from Antarctic Bear:

“AI-Driven Advances in 3D Printing: Tencent Cloud Collaborates with Antarctic Bear for an Exchange Event”

“I Dreamed of Raising 20 Billion Yuan to Acquire All Foreign 3D Printing Listed Companies and Achieve 290 Billion in A-Share”

“China’s 100-Meter Metal 3D Printer to be Built in Tianjin, Developed by Beijing Institute of Technology, with Ultra-Large Scale Metal Lattice Structure Multi-Arc Parallel 3D Printing Technology and Equipment”

“CCTV Report: Under Tariff Bullying, Delayed US 3D Printing Toy Orders Gradually Return”

Notice to 3D Printing Professionals:

△Scan to open the Antarctic Bear website, set WeChat to Star Mark☆, or open it in your mobile browser and set it to your phone’s desktop