|

Absolute Content |

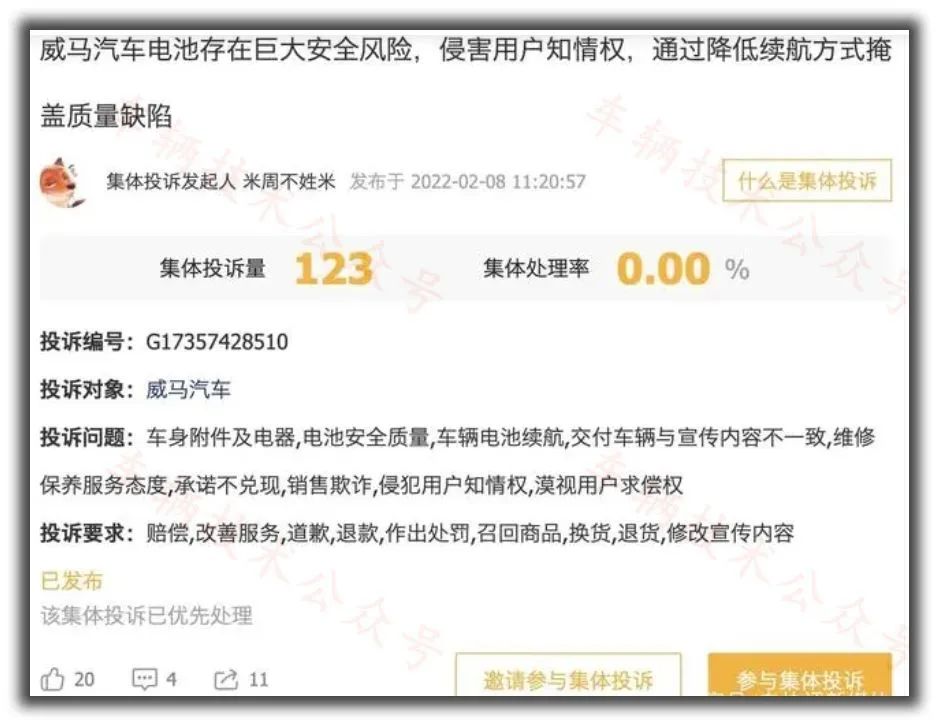

Tesla officially stated that through OTA upgrades, the rear seat heating function of the owner’s car can be activated remotely, thus enhancing the configuration experience, but the owner needs to pay 2400 yuan for the feature activation. So the question arises, when users purchase a car, the hardware facilities are all installed in the car, but users actually do not know that there is such a function in the car. If it weren’t for the OTA upgrade, users might never know that there is a seat heating function.

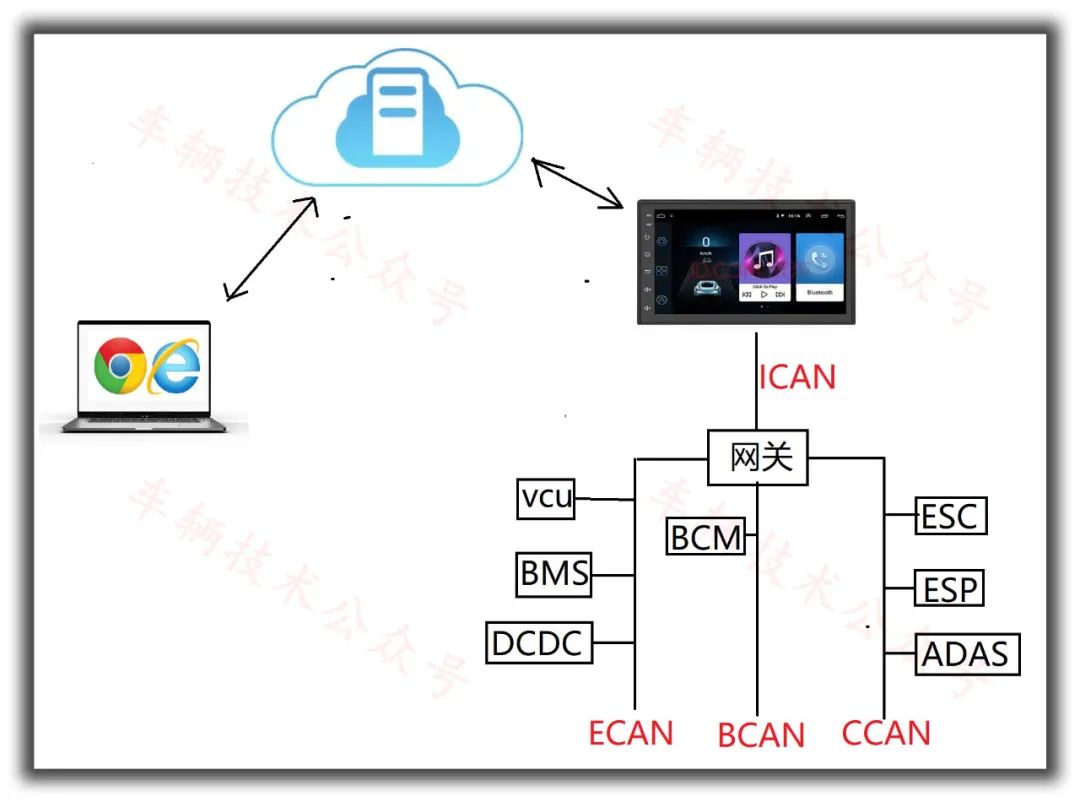

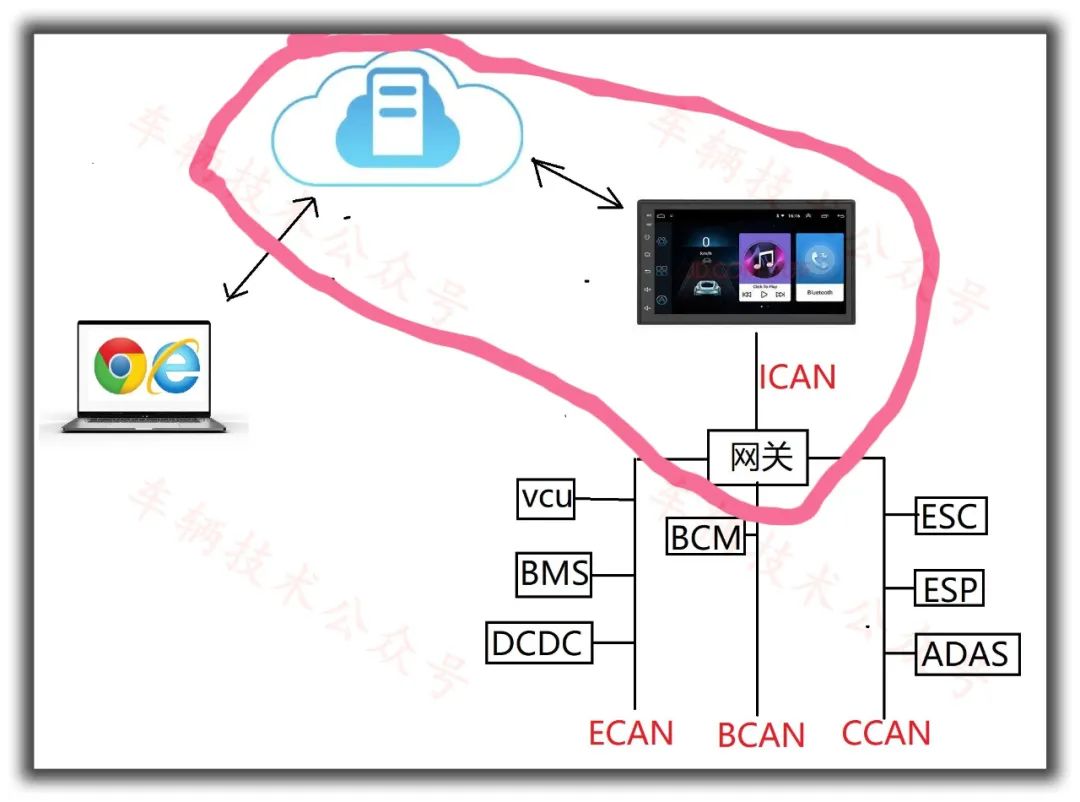

Principle of OTA Technology

Feasibility of Automated Testing

Common Issues in the Testing Process

Real Vehicle Testing

Further Communication