This article is dedicated to those who are overwhelmed by too many messy wires and don’t know what to do…

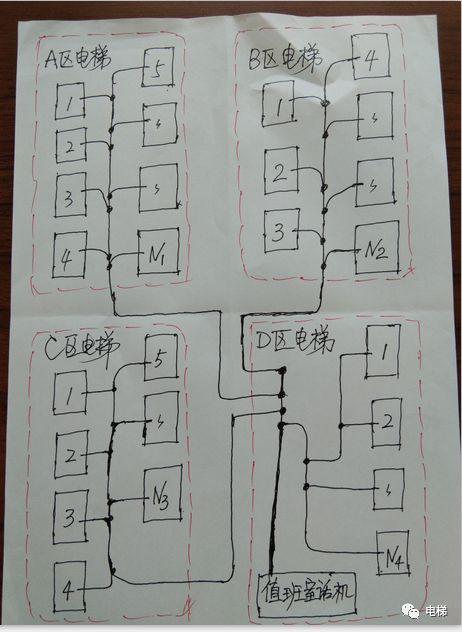

The five-party intercom is one of the emergency rescue features of elevators, and it is a mandatory inspection item during elevator installation acceptance and annual inspections. In our community, the intercom between the car and the user duty room uses the bus-type control system from Shanghai Xinling. Two years ago, there were 5 buildings in Area A, with 12 elevators installed in each building. Last year, 2 new buildings were constructed in Area B, with 12 elevators installed. This year, 3 new buildings are being constructed in Area C, with 18 elevators installed. These areas are spaced between 200 to 500 meters apart. These 42 elevators are interconnected via a bus, allowing any elevator’s call to be answered in the duty room.

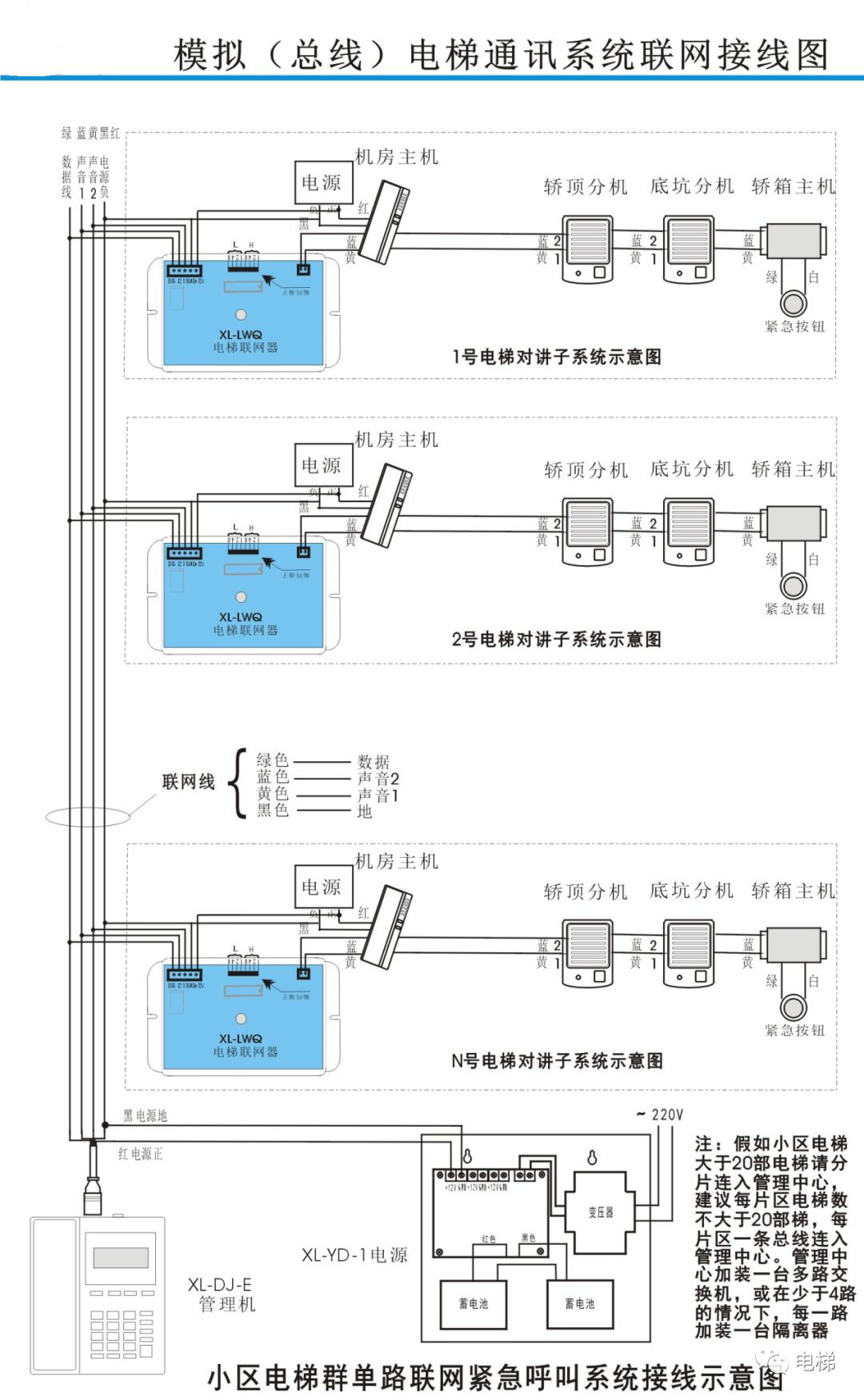

Below is a brief introduction to the wiring and connection process between the elevator and the property duty room phone. The elevator and property duty room phone system uses bus-type communication, with each elevator having a networking device installed in its control cabinet. Each elevator’s code is set on the networking device, which connects the elevator’s power and communication lines to the input terminals, and the output connects to the duty room’s management machine. The output signals include one address line, two voice lines, and one shared ground line. All elevators’ address lines, voice lines, and ground lines are connected separately. Please imagine how many cables are needed for this duty room phone? How many joints are there between the elevator’s output and the duty room phone? If one cable is damaged, how do you check it?

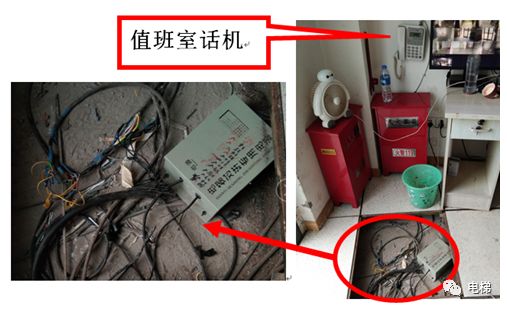

The overall wiring diagram is as follows; the wiring was not completed in the same period. The phone lines were laid to wherever new buildings were constructed. The construction team often changes, and the specifications and colors of the cables vary from period to period, making it feel overwhelming during wiring.

The cable wiring process is roughly as follows:

1) Use 4-core cable to wire from the elevator control cabinet encoder through the shaft to the basement level of the building; this cable is referred to as the branch line.

2) In the basement of the building, connect a thicker cable with each elevator’s branch line and wire it to the property duty room. This cable is referred to as the trunk line.

3) When a new building is completed, if you want to network the new building’s phone with the previous duty room phone, new cables need to be laid, and the duty room phone needs to be relocated, which also involves re-routing. The difficulty in this process is that the colors of the branch lines, trunk lines, and the lines laid earlier and later are inconsistent, making it inevitable to connect the wires incorrectly at the joints. Subsequent construction may break or compress the lines together, causing a short circuit. Since it is a bus type, all lines are connected together, and when a problem occurs, the maintenance workload is large.

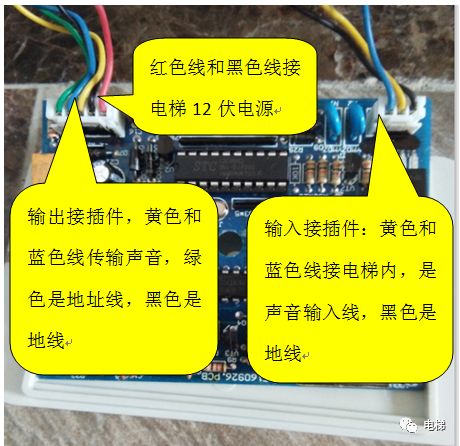

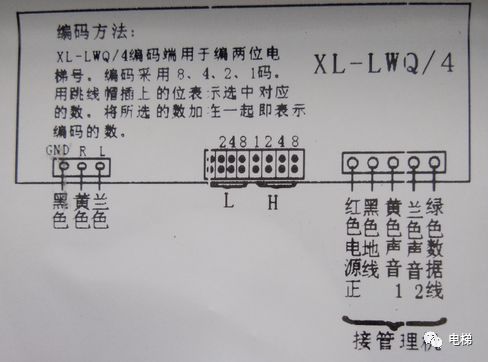

The following diagram shows the wiring schematic of the encoder installed in the elevator:

The following diagram is the wiring diagram on the encoder cover. When encoding the elevator, the low position L corresponds to the unit digit, and the high position H corresponds to the tens digit. For example, if the elevator code is 13, you need to short-circuit the tens digit 1 and the unit digit 1,2. For another example, if the code is 62, you need to short-circuit tens digits 2,4 and unit digit 2.

The following content is very critical, please read it carefully if needed.

1. After the elevator installation is completed, the client temporarily finds a room as the phone duty room for quick acceptance. The cable from the elevator to the duty room is also temporary, laid nearby without being placed in a cable trough, and at that time, no cable trough was installed. In the subsequent building construction, the cables may get torn. Therefore, after the elevator acceptance is completed, the output connector J2 on the encoder must be unplugged to prevent short-circuiting and damaging the encoder.

2. Wiring method for the new building’s elevator when networking. First, check whether there is a short circuit or open circuit in the cable. Measure the terminal of the cable; if there is a short circuit, notify the client to handle it. The method to measure for an open circuit is to short-circuit the four wires at the terminal of the cable, and then measure the output connector J2 of the encoder in the control cabinet. If there is no continuity, it indicates that there is a break in the cable, and notify the client for repair. When wiring, do not rely on the images of the trunk lines and branch lines taken by the wiring construction personnel, as the colors of the wires may be confused, leading to errors. A good practice is to refer to the wiring diagram inside the cover of the networking device, first find the output connector J2 in the control cabinet, short-circuit the ground line and address signal line, then go to the duty room and measure the two lines on the trunk cable with a multimeter and mark them. After that, go back to the elevator control cabinet and short-circuit the ground line and voice 1 signal line, then measure the two lines that are connected in the duty room. This way, through these two short circuits, the ground line, elevator coding address line, and voice signal line can be identified. Return to the machine room to remove the short-circuit wires, restore the connector on the encoder, and finally connect the already identified wires in the duty room.

Maintenance Case 1: The client notified that the cables are ready for connection. The wiring is the responsibility of the client, while connecting the phone is the responsibility of the elevator installation or maintenance personnel. When measuring the cables in the new building, it was found that the cable for building 5 had a short circuit. After notifying the client, two wiring personnel carried a ladder, continuously looking for joints, climbing the ladder to disassemble joints, measuring the continuity of the lines, and it took them 2 hours to find the problematic cable, which was damaged in the elevator shaft of unit one during construction. The exact fault point of the cable still needs further inspection.

Maintenance Case 2: During the annual inspection of the elevator, it was found that the communication between the elevators in building 12, unit 3 and the duty room was abnormal. The phenomenon was that the duty room personnel could hear the voices of the car personnel, but the car personnel could not hear the response from the duty room. Following the method of checking from easy to difficult, after replacing the encoder, communication was normal, indicating that the encoder was faulty. If communication was still abnormal after replacement, it would only require checking the cables.

PS: This article is sourced from exclusive contributions, and all appreciation belongs to the author.

Long press the QR code to follow this platform

For business cooperation, please call: 135-8595-9424