On automotive forums, it is often seen that car enthusiasts mention piston damage after ECU tuning. There has been much discussion about the pros and cons of ECU tuning, primarily focusing on methods (canned tunes, custom tunes, whether to use a dyno, etc.) and pricing.

This article will discuss the technical reasons behind why some vehicles experience engine damage after ECU tuning, specifically focusing on why it is always the pistons that fail!

If you want to upgrade your power, how should you choose a reliable power upgrade plan?

First, let’s look at some images to understand what a piston is! The image below shows a normal piston and connecting rod assembly:

The next image shows a piston and connecting rod assembly that has bent due to water entering the engine under pressure. The piston is intact, but the connecting rod is bent! Note: Because water is incompressible, once water enters the engine, the rotating engine will be forced to stop immediately and cannot be restarted!

From the comparison above, we can see that the piston has a strong ability to withstand pressure, strong enough to bend the connecting rod.

So what kind of pressure can cause piston damage?

The image below shows a damaged piston after ECU tuning. From the image, we can observe that the area of the piston directly bearing the combustion pressure is intact, but the damage occurs between the two weakest compression rings.

The vibrational pressure wave directly penetrates the thick piston top and fractures the layer between the two compression rings! This is typical damage caused by severe knocking!

Why does the engine experience such intense knocking?

Next, we will analyze which part of the program is responsible for piston damage, and whether it is possible to increase power without damaging the pistons.

The power output of an engine is mainly affected by five factors: displacement, engine speed, air quality entering the engine, mixture (LAMDA value), and ignition timing.

The main relationships are as follows:

1. The larger the displacement, the higher the power.

2. The higher the speed, the higher the power.

3. The better the air quality entering the engine, the higher the power.

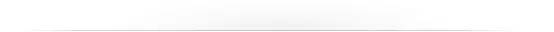

4. The concentration of the mixture, as shown in the image below: the mixture (LAMDA value) is higher when between 0.8-0.9, while LAMDA values between 1.1-1.2 are more fuel-efficient.

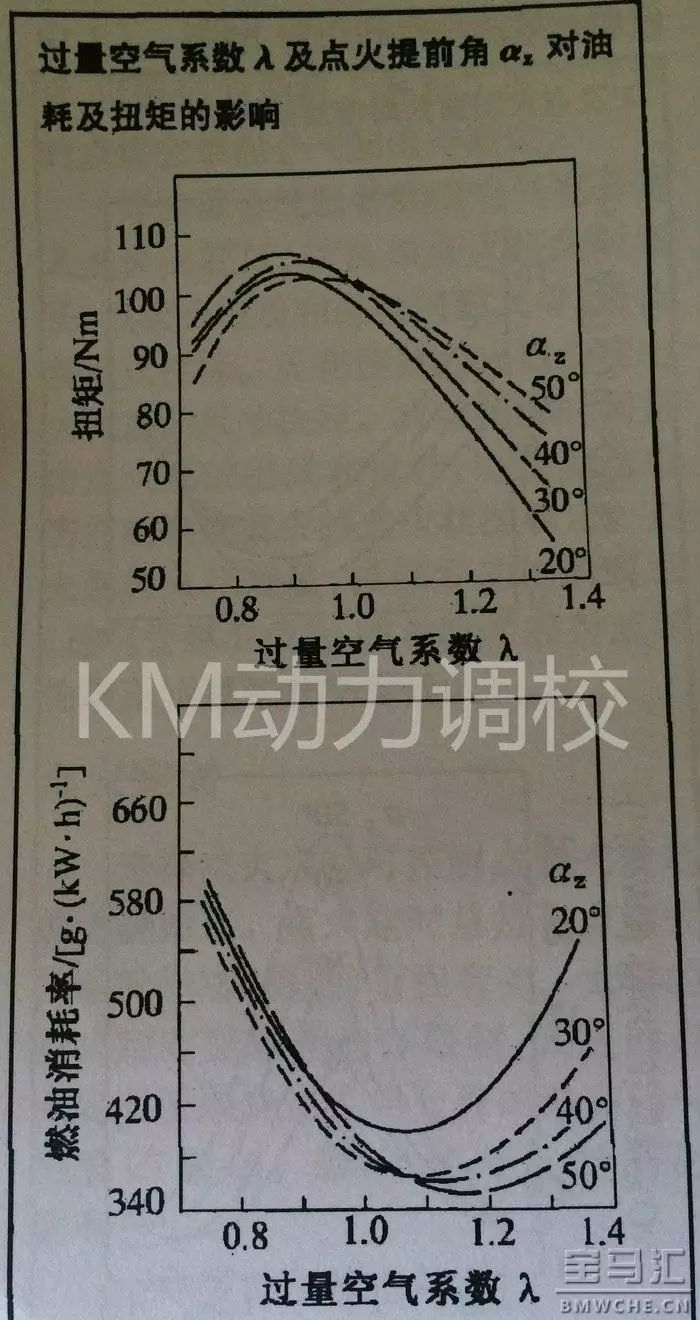

5. Ignition timing. As shown in the image below: the combustion pressure generated at 40 degrees before OT (top dead center) is twice that generated at 30 degrees before OT! An earlier ignition timing generates higher combustion pressure, but if it is too early, it can cause knocking.

Based on the above analysis, we can conclude that for an engine with a fixed displacement, to upgrade power, we can only adjust the quality of the intake air, LAMDA value, ignition timing, and engine speed.

Among these, increasing the pre-boost pressure (which is the air quality) is the main method for increasing power. (Currently, mainstream external computers and ECU flashing use this method.) However, the boost pressure of the engine is limited by knocking. Therefore, the boost pressure cannot be increased indefinitely.

For the BMW N20 engine, the factory peak boost pressure for the 320 is 0.6 Bar, while the peak pressure for the 328 is 0.96 Bar. This 0.96 Bar boost pressure is also the highest pressure currently used on all BMW cast piston assemblies!

By analyzing several key data sets from a well-known canned tune that has previously caused piston failures, we can understand how this tuned software increases engine power.

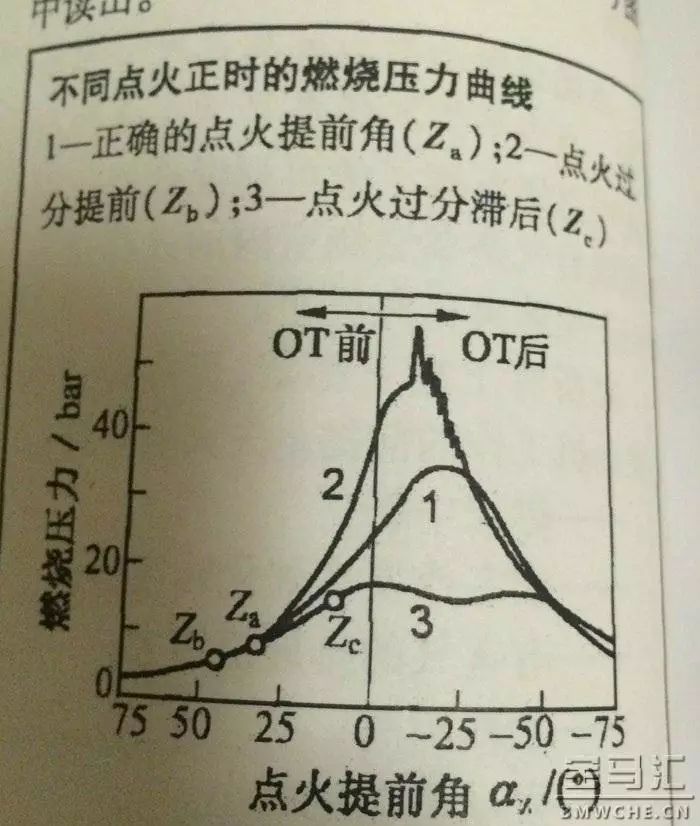

The image below shows the ignition timing curve at 5000 RPM. From the image, we can observe that the software tuner has advanced the ignition timing at the end of the load.

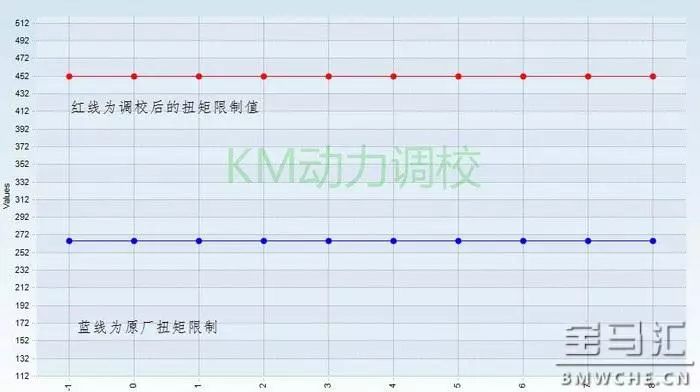

The next image shows the engine torque limit; the software tuning has increased the limit from the factory 250 N.M to 450 N.M.

This indicates that the engine will work hard in various gears and modes until it reaches 450 N.M! For an engine with a displacement of 2.0L and cast pistons, this is a somewhat extreme number.

The 6-cylinder turbocharged engine equipped in the BMW M2, which has forged piston and connecting rod assemblies, has a maximum torque limit of only 465 N.M. The ZF 8HP45Z eight-speed transmission can also only handle a maximum torque of 450 N.M.

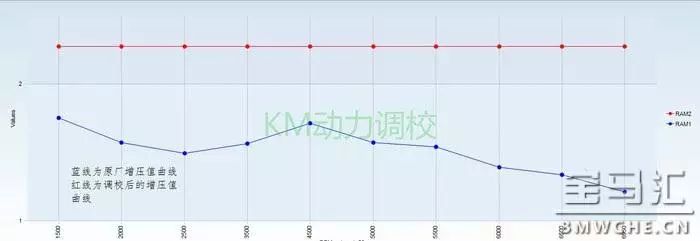

The next image shows the boost pressure; the software tuner has directly set the pressure across the entire load range to 2.2 Bar.

According to this value, plus the engine control tolerances, the actual maximum boost pressure peak during engine operation could reach an absolute pressure of 2.6 Bar. The relative pressure would be at 1.6 Bar.

Note: The boost value for the S55B30 engine equipped in the all-new BMW M3 is 1.5 Bar.

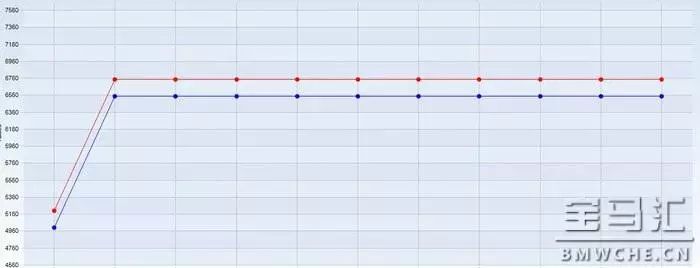

The next image shows the engine speed limit. The limits have been raised by 200 RPM in all working conditions.

Based on the above data analysis, we can see that the goal of this software tuner is to pursue maximum power across all engine operating conditions. Such tuning can still be managed if combined with high-quality oil, good engine cooling, and brief high load and high RPM conditions. However, if the engine is subjected to poor oil quality, inadequate cooling, or prolonged high load and high RPM conditions, piston rupture due to knocking impact becomes understandable!

Many brands of tuning programs on the market adjust the boost pressure to 1.5-1.7 BAR to differentiate the tuned power from the factory power, along with lower LAMDA values and aggressive ignition timing. This causes the engine to experience spontaneous combustion during high load periods, resulting in huge pressure peaks in the combustion chamber that strike indiscriminately and ultimately destroy the weak points of the pistons!

The damaged piston in the image above is likely a result of this type of damage.

Therefore, it is recommended that car enthusiasts who wish to increase engine power communicate thoroughly with the tuning engineer before adjusting the program. Develop the most suitable power upgrade plan according to your actual needs. Do not blindly trust big brands or high-end automotive engineers from the UK, USA, or Italy.

Only through sufficient communication can a tuning engineer who understands the true needs of the car enthusiast and the actual condition of the vehicle produce the best and most suitable software!

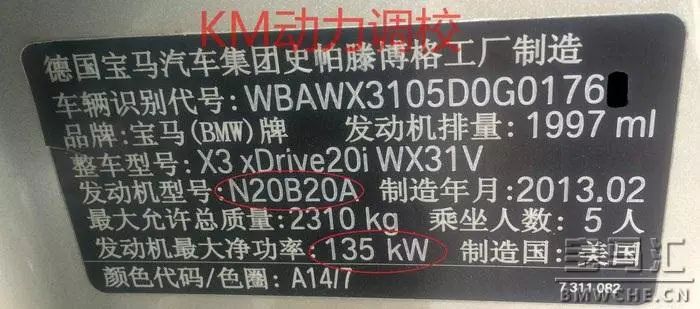

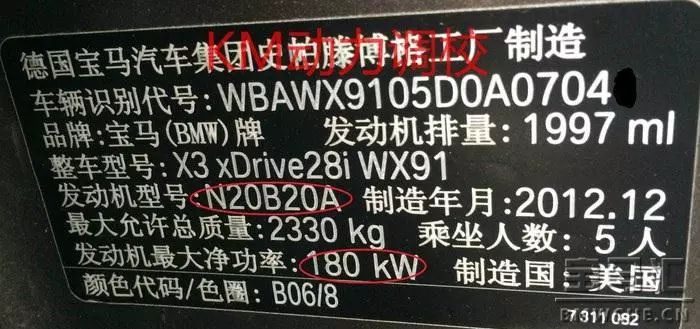

For ordinary low-power engine upgrades, tuning the power to match that of the high-power version of the same engine is a very stable and cost-effective choice. As shown in the image below, the MINI COOPER and COOPER S, as well as the BMW X3 20 and 28. After writing the factory 28 program, stable high power output can be achieved!

The low-power engine of the BMW 320 can also refer to the control methods of the high-power engine of the 328, but limitations should be made in high load and high RPM ranges!

MINI COOPER S

N18B16A/140KW

The engine is the same model as the one with only 90KW!

MINI COOPER

N18B16A/90KW

BMW X3 20

N20B20A/130KW

BMW X3 28

N20B20A/180KW

For engines that are already high-power versions of the same model, replacing the internal components with forged parts as shown in the image below and then making corresponding adjustments to the program is an excellent choice!

Forged piston and connecting rod assembly

Forged crankshaft

The content of this article is shared by “FZ_keep_moving”. BMW Hui is only responsible for summarizing and organizing it. If there are copyright issues, please inform us for removal!