When testing the CAN bus in vehicles, we find that the resistance between the CAN buses in the vehicle is around 60 ohms. When testing a specific ECU CAN bus on a test bench, we may find that some ECUs have a resistance of 120 ohms, while others do not have any. Why does this phenomenon occur?

-

1. Origin of CAN Bus Termination Resistors

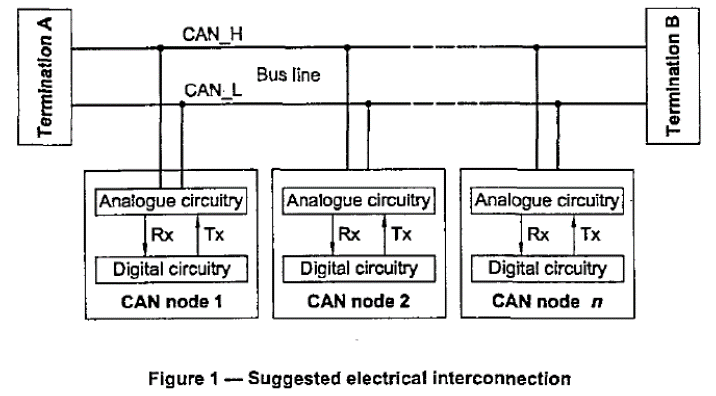

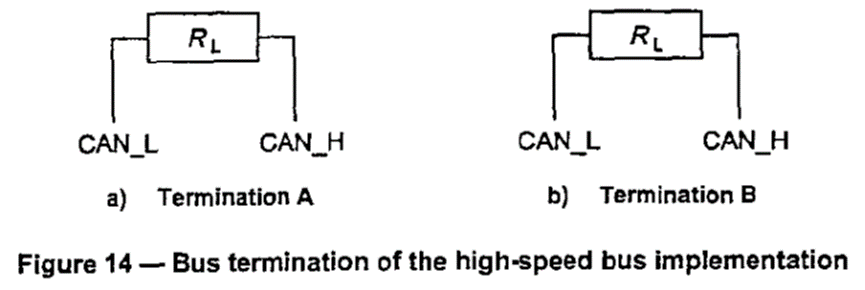

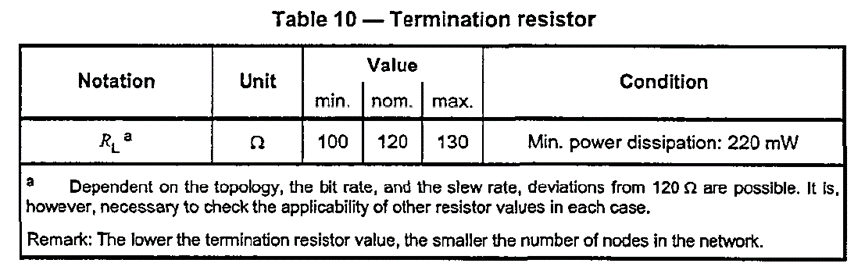

The requirement for termination resistors on the CAN bus network originates from the CAN specification. The international standard ISO11898-2 for CAN bus, titled “High-Speed Medium Access Unit,” specifies the need for termination resistors, stating that the CAN bus network should have Termination A and Termination B as two endpoints.

The specification further states that for a twisted pair differential bus with a speed of less than 1 Mbit/s, termination resistors RL should be placed at both Termination A and B.

Additionally, the electrical specification further stipulates that the nominal resistance value RL is 120 ohms, with a range of 100 to 130 ohms. This is the origin of the CAN termination resistor.

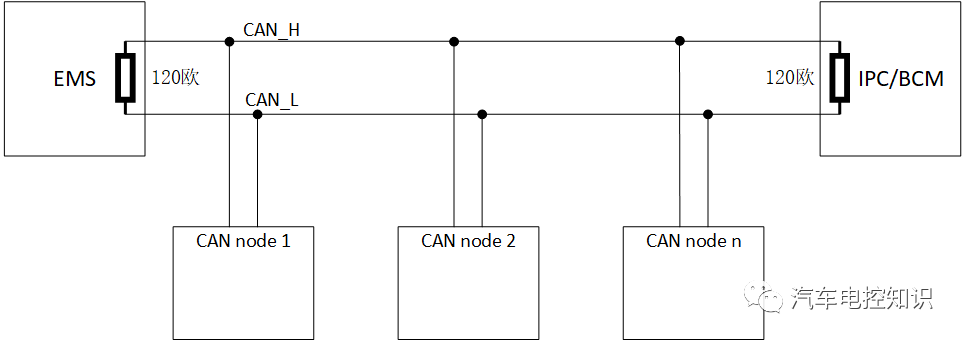

Although the specification does not recommend integrating termination resistors within the ECU, in actual vehicles, due to space constraints, wiring layout, and characteristics of the controllers, these two termination resistors are often integrated into the ECU.

Common layout of CAN network termination resistors

Therefore, when testing in the vehicle environment, the parallel value of the two termination resistors is 60 ohms, while during individual testing on the test bench, if it is an ECU with integrated termination, it is 120 ohms, while other ECUs may not be 120 ohms.

2. Function of CAN Termination Resistors

Why does the ISO specification require the installation of termination resistors?

Firstly, the main function of the CAN termination resistor is to suppress reflections!

During high-speed communication, when the signal edge energy encounters impedance mismatches, signal reflections occur. When the geometric structure of the transmission line cable changes, the characteristic impedance of the cable also changes, causing reflections.

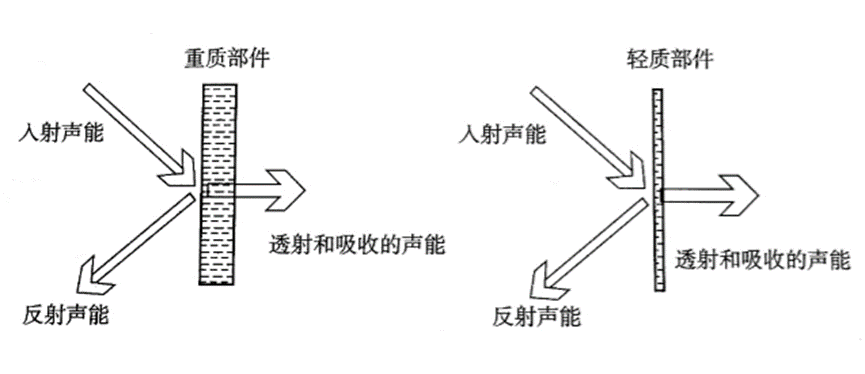

The principle of signal reflection is similar to that of sound wave reflection. Sound waves do not reflect when propagating in uniform air, but when they encounter a medium with a higher acoustic impedance, reflections occur, producing echoes.

Sound wave reflection

The cables at the two endpoints of the CAN bus network are most prone to reflections, which is why termination resistors must be placed at both ends. Reflected signals superimposed on normal signals cause interference, affecting the correctness of the CAN signal.Installing termination resistors on the CAN bus can suppress signal reflections and improve signal quality.

Secondly, CAN termination resistors can also enhance anti-interference capability!

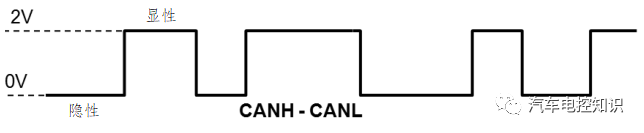

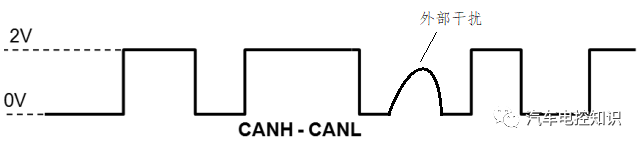

In a CAN bus network, when all CAN node bus drivers are turned off, the bus is in a “dominant” state, and in this case, the average bus voltage is generated by the high impedance of the network terminals and the receiving circuits of each CAN node.

When one of the CAN nodes has its bus driver turned on, a “recessive” bit is sent to the bus, creating a current on the bus that flows through the termination resistor, resulting in a voltage difference on the bus. The receiving circuit of the bus detects the levels and voltage differences on the CAN bus to determine the “dominant” and “recessive” states.

If termination resistors are not installed on the bus, the average bus voltage in the “recessive” state is only generated by the high impedance of the CAN nodes. Due to the high internal resistance, and since voltage = resistance * current, external interference requires very little energy (current) to cause significant fluctuations in bus voltage.

At this point, if differential mode interference occurs, it can create a “dominant” bit on the bus, causing the CAN network to mistakenly enter the “dominant” state.

With termination resistors

Without termination resistors

Termination resistors can absorb fluctuations caused by external interference, greatly enhancing the anti-interference capability in the “recessive” state. Finally, termination resistors ensure that the CAN bus quickly transitions from “dominant” to “recessive” state!

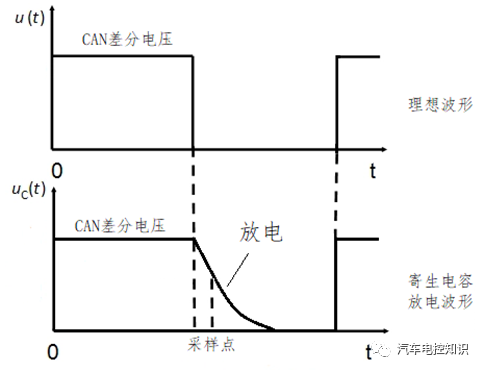

The ideal differential voltage waveform of the bus should be a square wave, but during the “dominant” state of the CAN bus, the parasitic capacitance in the bus gets charged, and when the bus changes to the “recessive” state, these capacitors need to discharge. Without termination resistors, the parasitic capacitance can only discharge through the internal differential resistance of the transceiver, which is quite large. According to the characteristics of the RC filter circuit, the time constant τ=RC, meaning that the larger the resistance, the longer the discharge time. The longer discharge time affects the differential voltage of the bus, preventing it from quickly transitioning from “high” to “low,” resulting in a gradual decrease instead of a sharp drop.

The result of this waveform is that if the sampling point of the CAN signal is set too early, such as at 30%, it will lead to sampling errors, interpreting low levels as high levels, mistakenly judging “recessive” as “dominant,” resulting in incorrect data received by the CAN.

3. Conclusion

1) The faster the speed of the CAN bus, the more necessary it is to install termination resistors. Without them, the network can experience severe errors and fail to transmit and receive normally.

2) When conducting CAN tests on the entire vehicle, the CAN testing equipment (such as CANoe, SPY3, USBCAN, etc.) does not need to connect to termination resistors.

3) When testing a specific ECU controller on a test bench, the CAN testing equipment must connect to a 120-ohm termination resistor.

4) In embedded software, the setting of the CAN sampling point should be as late as possible, preferably between 75% and 85%.