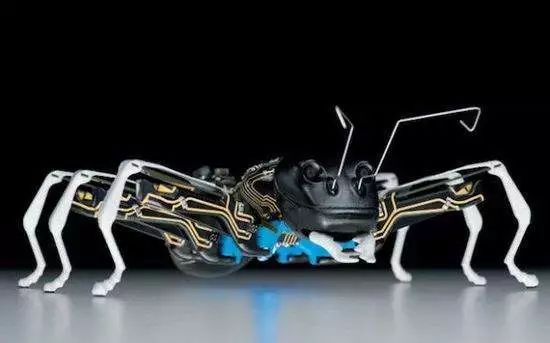

Robotics technology is a high-tech field that integrates multiple disciplines such as computer science, control theory, mechanics, information and sensing technology, artificial intelligence, and bionics. It is an area of active research and increasingly widespread application in contemporary society. The application of robotics is an important indicator of a country’s industrial automation level.

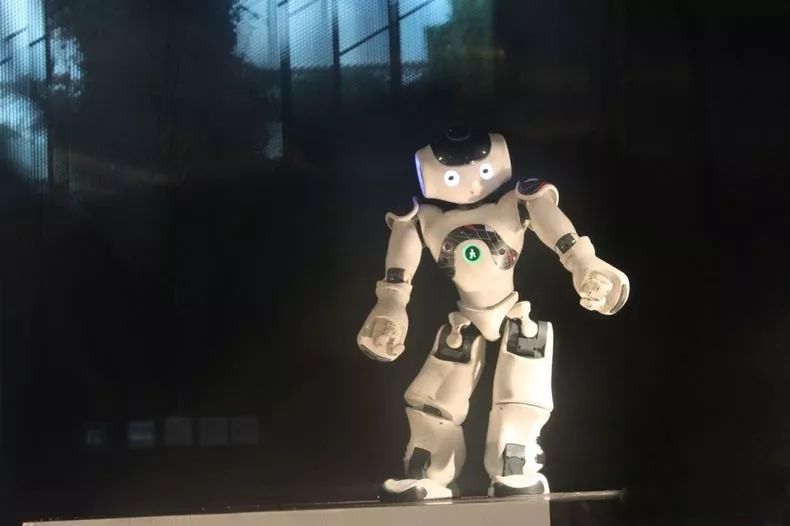

Robots do not simply replace human labor in a simplistic sense; rather, they are anthropomorphic electronic mechanical devices that integrate human strengths and machine capabilities. They possess the rapid response and analytical judgment abilities of humans, as well as the capacity for long-lasting work, high precision, and resistance to harsh environments that machines have. In a certain sense, they are also products of the evolutionary process of machines. They are important production and service equipment in both industrial and non-industrial sectors, and are indispensable automation devices in advanced manufacturing technology.

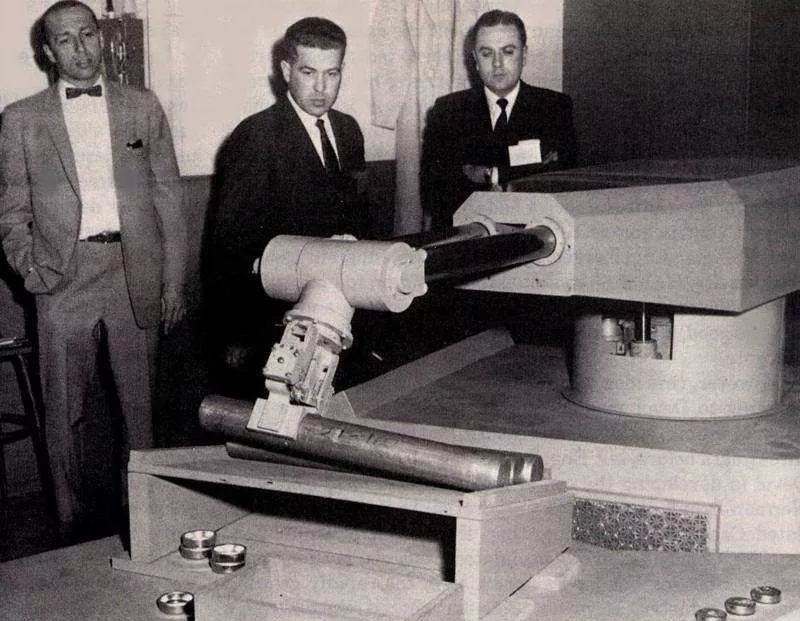

According to conventional methods, robots can generally be divided into three generations based on their development process: the first generation of robots is a type of “remote-controlled device”; the second generation of robots is controlled by pre-programmed instructions set by humans, enabling them to automatically repeat certain operations; the third generation of robots is intelligent robots, which utilize various sensors and measuring devices to gather information about the environment, and then employ intelligent technology for recognition, understanding, reasoning, and ultimately decision-making, allowing them to act autonomously to achieve predetermined goals.

This brief overview cannot adequately convey the arduous journey of robotics technology development. To detail this journey, we must start from the development of robots in various countries. While the development processes of robots in different countries are interconnected, they are also distinct from one another. Different historical and social backgrounds have led to varying perceptions of robotics technology, resulting in different policies and outcomes, which in turn influence people’s thoughts and the development of social history.

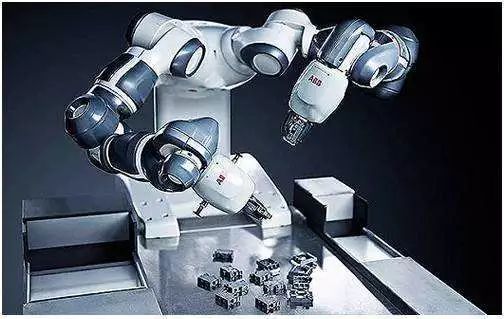

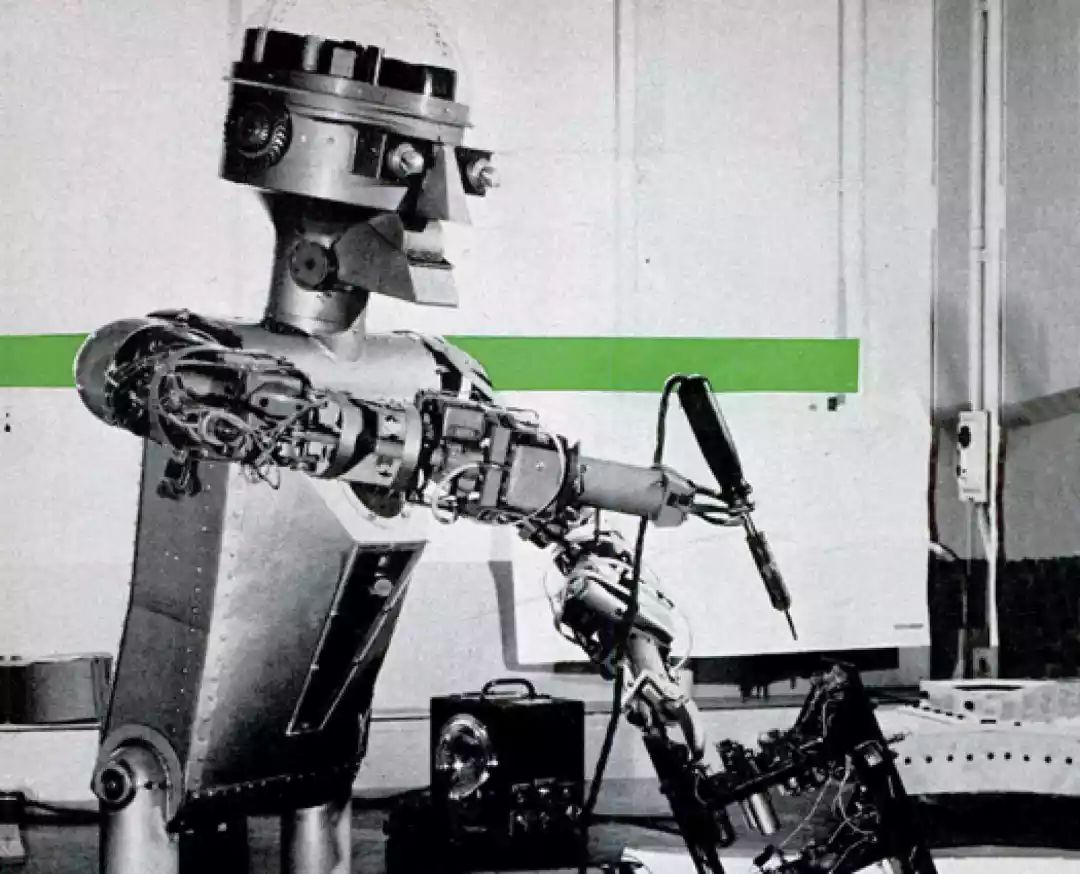

The birthplace of robots is the United States, where the world’s first industrial robot was developed in 1962. After more than 30 years of development, the U.S. has become one of the world’s leading robotics powers, with a solid foundation and advanced technology. Looking back at its history, the path has been winding and uneven.

During the period from the 1960s to the mid-1970s, the U.S. government did not prioritize the development of industrial robots as a key project, only conducting some research work in a few universities and companies. For enterprises, seeing only immediate benefits and lacking government financial support, they preferred to miss good opportunities and stick to rigid automation devices rather than risk applying or manufacturing robots. Additionally, with the unemployment rate in the U.S. reaching as high as 6.65%, the government feared that developing robots would lead to more job losses, resulting in a lack of investment and organization in robot research. This can be seen as a strategic decision error by the U.S. government. In the late 1970s, although the government and business sectors began to pay attention, they still focused on researching robot software and developing advanced robots for special fields such as military, space, ocean, and nuclear engineering, allowing Japanese industrial robots to catch up and quickly surpass the U.S. in industrial production applications and the robotics manufacturing industry, establishing strong competitiveness in the international market.

In the 1980s, the U.S. finally felt the urgency of the situation, and both the government and business sectors began to take robotics seriously, as reflected in their policies. On one hand, they encouraged the industrial sector to develop and apply robots; on the other hand, they formulated plans, increased investments, and raised research funding for robots, viewing robotics as a characteristic of America’s re-industrialization, leading to rapid advancements in U.S. robotics.

By the mid to late 1980s, as major manufacturers’ robotics technology matured, the technological performance of the first generation of robots increasingly failed to meet practical needs. The U.S. began producing second-generation robots equipped with vision and force sensing, quickly capturing 60% of the U.S. robot market.

Despite the winding path of emphasizing theoretical research while neglecting applied development, U.S. robotics technology has remained at the forefront internationally. Its technology is comprehensive, advanced, and highly adaptable.

In contrast, the development in the UK has been remarkably different. Although Hall Automation in the UK developed its own robot, RAMP, in 1967, the British government’s Scientific Research Council issued the Lighthall Report in the early 1970s, which denied artificial intelligence and robotics, imposing strict limitations on the development of industrial robots. Consequently, the robotics industry in the UK stagnated, placing it near the bottom in Western Europe.

However, the global boom in robotics soon made the UK government realize that its technological lag led to a significant decline in the competitiveness of its products in the international market. Therefore, starting from the late 1970s, the UK government adopted a supportive stance, implementing a series of policies and measures to promote robotics development, such as widely publicizing the importance of using robots, providing financial subsidies to companies purchasing robots, and actively facilitating collaboration between robotics research institutions and enterprises, ushering in a prosperous era of extensive application and vigorous development of robotics in the UK.

This illustrates that the development of new technologies is not subject to human will; those who adapt to and actively develop them will achieve progress, while those who isolate themselves and restrict their development will fall behind due to failure to keep pace with the times.

In contrast to the lessons learned by the UK, France has made significant advancements by embracing artificial intelligence technology early on. France ranks among the world’s leaders in the quantity of robots and is at the forefront in terms of application levels and ranges. This is mainly attributed to the French government’s early emphasis on robotics technology, particularly focusing on applied research in robotics. The development of robotics in France has been relatively smooth, primarily due to the establishment of a comprehensive scientific and technological system supported by government-backed research programs. The government organizes research projects in foundational robotics technology while the industry supports applications and development, allowing for rapid development and widespread adoption of robotics in French enterprises.

Germany, its neighbor, ranks third in the world in terms of the total number of industrial robots, following Japan and the U.S. However, it introduced robots about five to six years later than the UK and Sweden. This delay was due to the economic downturn faced by Germany’s robotics industry at its inception. Nevertheless, the social environment in Germany has been favorable for the development of the robotics industry. Factors such as labor shortages due to war and a high national technical level have created favorable conditions for the adoption of robotics.

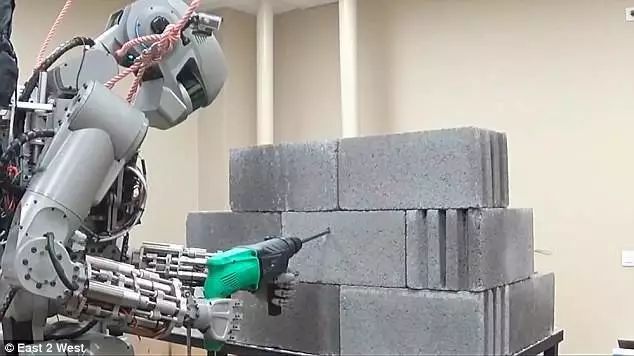

By the late 1970s, the government adopted administrative measures to promote the use of robots. The “Improving Labor Conditions Plan” mandated that for certain dangerous, toxic, or harmful jobs, robots must replace ordinary human labor. This plan opened up a wide market for the application of robots and promoted the development of industrial robotics technology.

The German people are practical, consistently adhering to the principle of combining technology application with social needs. Besides applying robots mainly in the automotive industry like most countries, Germany has notably modernized its textile industry by replacing old machines with modern automated equipment, electronic computers, and robots, significantly reducing costs, improving quality, and enhancing the variety of products. By 1984, this revitalized what was dubbed a “dying industry.” Meanwhile, Germany recognized the role of advanced automation technologies such as robotics in industrial production and set a goal to transition to advanced, sensory intelligent robots after 1985. After nearly a decade of effort, Germany has achieved a recognized leading position in the research and application of intelligent robots worldwide.

In contrast to Western countries, the former Soviet Union (mainly Russia) was also advanced in robotics technology. The exploration of robotics technology in the Soviet Union began in the late 1950s. By the late 1950s, research on robot prototypes commenced. In 1968, a deep-sea robot was successfully developed. In 1971, a versatile robot for factory use was developed.

As early as the ninth five-year plan of the Soviet Union (1970-1975), the development of robotics was included in the national science and technology development program. By 1975, 120 robots of 30 different models had been developed, and after 20 years of effort, the Soviet Union’s robotics technology was among the best in the world in both quantity and quality. The government systematically organized research, production, application, promotion, and enhancement of robotics technology as a means to drive social production development.

Although the Soviet Union’s technology was advanced, it operated under a planned economy. A common issue with planned economies is their disconnection from the market, which prevented their technology applications from achieving the leaps seen in other Western capitalist countries. In stark contrast, our neighbor Japan achieved tremendous success.

Japan was in a period of rapid economic growth in the late 1960s, with an annual growth rate of 11%. After World War II, Japan already faced labor shortages, and the rapid economic development exacerbated this issue. To address this, in 1967, Kawasaki Heavy Industries imported robots and technology from Unimation in the U.S. and established a production workshop, successfully trial-producing the first Kawasaki “Unimate” robot in 1968.

Due to the significant labor shortage at that time, robots were welcomed in enterprises as a “savior.” The Japanese government adopted an actively supportive economic policy, encouraging the development and application of robots, further stimulating entrepreneurs’ enthusiasm for the robotics industry. Particularly, a series of economic incentives for small and medium-sized enterprises, such as low-interest financing provided by government banks, encouraged the establishment of “robot long-term leasing companies.” After purchasing robots, these companies would lease them to users at a low monthly fee, significantly alleviating the financial burden of acquiring robots. The government also designated computer-controlled teaching replay robots as specially discounted products, allowing enterprises to enjoy a typical 40% discount on new equipment, along with an additional 13% price subsidy. Furthermore, the state funded specialized knowledge and technical guidance for small enterprises in applying robots. This series of supportive policies led to the rapid development of Japan’s robotics industry, which by the mid-1980s had ascended to the status of the “robot kingdom,” with production and installations of robots leading internationally.

According to Kanji Yonemoto, an executive director of the Japan Industrial Robot Association, “The development of robotics in Japan has gone through a cradle period in the 1960s, a practical period in the 1970s, and has entered a popularization and enhancement period in the 1980s.” The year 1980 was officially designated as the “Year of Popularization of Industrial Robots,” marking the beginning of widespread promotion and application of robots across various fields.

The Japanese government and enterprises placed great trust in robots and boldly employed them. Robots have not disappointed expectations, significantly contributing to alleviating labor shortages, improving productivity, enhancing product quality, and reducing production costs, becoming an indispensable force for Japan’s sustained economic growth and product competitiveness.

Japan’s extensive use of robots in the automotive and electronics industries has led to a dramatic increase in production, improved quality, and significantly reduced manufacturing costs. This enabled Japanese cars to enter the so-called “automobile kingdom” of the U.S. market with a price advantage, and Japan also exported practical robots to the birthplace of robotics. At this time, affordable and high-quality household appliances from Japan flooded the U.S. market, much to the regret of “Uncle Sam.” Japan’s manufacturing and use of robots enhanced its national strength and brought immense benefits, forcing many countries like the U.S., UK, and France to take measures to catch up. In the 1980s and 1990s, Japan was referred to as the world’s factory, largely due to its advancements in robotics technology.

With the opening up and reform, China also entered an era of rapid economic development. However, we must recognize that the competitiveness of our products today is due to China’s cheap labor, which cannot solve everything. The inevitable increase in living standards will lead to higher wages, which is a trend that cannot be reversed. If we continue to “exploit” workers without developing new technologies to enhance labor capabilities, China’s labor resources may soon be depleted, leading to economic stagnation, potentially causing a regression like Japan’s today. Therefore, China must focus on the future and emphasize the development of robotics technology.

In recent years, several trends have emerged in the field of robotics both domestically and internationally:

1. The performance of industrial robots continues to improve (high speed, high precision, high reliability, easy operation and maintenance), while the price per unit continues to decline.

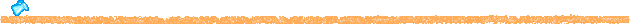

2. Mechanical structures are evolving towards modular and reconfigurable designs. For example, the integration of servo motors, reducers, and detection systems in joint modules; constructing the entire robot using reconfigured joint and link modules.

3. Industrial robot control systems are developing towards open controllers based on PC architecture, facilitating standardization and networking; the integration level of components is increasing, leading to more compact control cabinets with modular structures; significantly enhancing system reliability, operability, and maintainability.

4. The role of sensors in robots is becoming increasingly important. In addition to traditional position, speed, and acceleration sensors, assembly and welding robots are also utilizing vision and force sensors, while remote-controlled robots are employing multi-sensor fusion technology, integrating vision, sound, force, and touch for environmental modeling and decision control; multi-sensor fusion configuration technology has already seen mature applications in productized systems.

5. The role of virtual reality technology in robotics has evolved from simulation and rehearsal to process control, enabling remote-controlled robot operators to experience the sensation of being in a distant operational environment.

6. The development characteristics of contemporary remote-controlled robot systems do not pursue fully autonomous systems but focus on human-robot interaction control, integrating remote control with partial autonomy to form a complete monitoring and control operation system. The “Sojourner” robot launched by the U.S. to Mars is the most famous example of this system’s successful application.

In China, intelligent and special robots have also achieved significant results under the support of the “863” program. Among them, underwater robots, capable of operating at depths of 6000 meters without cables, are at the world-leading level. Various types of robots, such as directly controlled robots, dual-arm coordinated control robots, wall-climbing robots, and pipeline robots, have also been developed; significant work has been done in the development and application of foundational technologies such as robot vision, force, touch, and sound, establishing a certain development foundation. However, in areas like multi-sensor information fusion control technology, remote-controlled robots with partial autonomy, intelligent assembly robots, and robotic machinery, we are just beginning and lagging significantly behind advanced international levels. We need to systematically tackle these areas based on our existing achievements to develop practical technologies and products.

Yangzhou Yuanzhi Automation specializes in leasing, integrating, and selling second-hand industrial robots, providing a one-stop service for second-hand robot brands.Currently, most of Yangzhou Yuanzhi Automation’s robotic products are applied in small and medium-sized enterprises, accumulating rich experience in various industrial robot applications across sectors such as automotive, electronics, machinery, building materials, food, daily chemicals, rail vehicles, construction machinery, and shipbuilding, with functionalities including arc welding, spot welding, gluing, handling, casting, forging, machine tool loading and unloading, stamping automation, and assembly.Yangzhou Yuanzhi Automation emphasizes product and functionality development, focusing on improving production efficiency while also listening to user feedback and collaboratively developing specialized application functions tailored to customer needs, assisting enterprises in upgrading their intelligent manufacturing.

Recently, Everyone Is Watching

1. Development Trends of Automotive Image Sensors

2. Global TOP30 Advanced Packaging Companies

3. Global Top 10 Dedicated Wafer Foundries

4. Academician Gao Wen: AI Will Bring Revolutionary Changes to Chip Design

5. Nvidia in a Predicament: Further is Flowers, Retreat is a Cliff

6. Tesla AI Day Ignites Market Enthusiasm for Humanoid Robots

7. China Achieves Significant Breakthroughs in Next-Generation Optoelectronic Chip Manufacturing

8. By the End of the Year, All Prefectural Cities Nationwide Will Promote! Will Biodegradable Plastics Explode? These Companies Are Stepping Up Their Layouts!

9. “Flying Bicycles” Are Here! Using a Lot of Carbon Fiber! Sinopec, Jilin Chemical Fiber… Actively Expanding Production

10. Related to You and Me! Starting in October, These New Regulations Will Be Implemented

1. Development Trends of Automotive Image Sensors

2. Global TOP30 Advanced Packaging Companies

3. Global Top 10 Dedicated Wafer Foundries

4. Academician Gao Wen: AI Will Bring Revolutionary Changes to Chip Design

5. Nvidia in a Predicament: Further is Flowers, Retreat is a Cliff

6. Tesla AI Day Ignites Market Enthusiasm for Humanoid Robots

7. China Achieves Significant Breakthroughs in Next-Generation Optoelectronic Chip Manufacturing

8. By the End of the Year, All Prefectural Cities Nationwide Will Promote! Will Biodegradable Plastics Explode? These Companies Are Stepping Up Their Layouts!

9. “Flying Bicycles” Are Here! Using a Lot of Carbon Fiber! Sinopec, Jilin Chemical Fiber… Actively Expanding Production

10. Related to You and Me! Starting in October, These New Regulations Will Be Implemented