This article is sourced from: Smart Driving Frontier

/ Introduction/

Advanced Driver Assistant System (ADAS) refers to the use of various sensors installed in vehicles to collect environmental data both inside and outside the vehicle at the earliest possible moment. This technology processes the identification, detection, and tracking of static and dynamic objects, allowing drivers to quickly become aware of potential dangers, thereby enhancing attention and improving safety through proactive safety technology.

The purpose of automotive sensor equipment varies, which can be divided into two main categories: traditional Micro-Electro-Mechanical Systems (MEMS) that enhance the information level of a single vehicle and intelligent sensors that support autonomous driving. MEMS provide feedback in various system control processes in vehicles, enabling automatic control, and serve as the “neurons” of the vehicle. Intelligent sensors, on the other hand, collect information directly from the outside world, acting as the “eyes” of autonomous vehicles.

The Foundation of Automotive Intelligence—Sensors

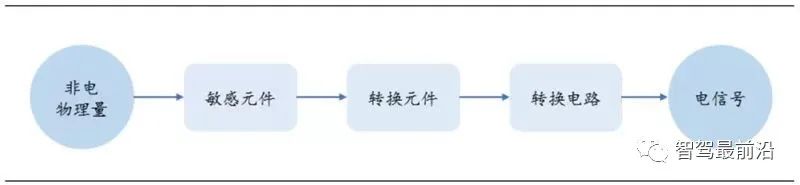

Sensors are the source of information for automotive electronic control systems and are fundamental components of vehicle electronic control systems. Sensors typically consist of sensitive elements, conversion elements, and conversion circuits. The sensitive element refers to the part of the sensor that can directly sense or respond to the measured quantity, while the conversion element converts the aforementioned non-electrical quantities into electrical parameters. The function of the conversion circuit is to process the electrical signals output by the conversion element into forms that are convenient for processing, displaying, recording, and controlling. Based on the different purposes of current automotive sensor equipment, they can be categorized into traditional MEMS sensors that enhance the information level of a single vehicle and intelligent sensors that support autonomous driving.

Composition of Automotive Sensors

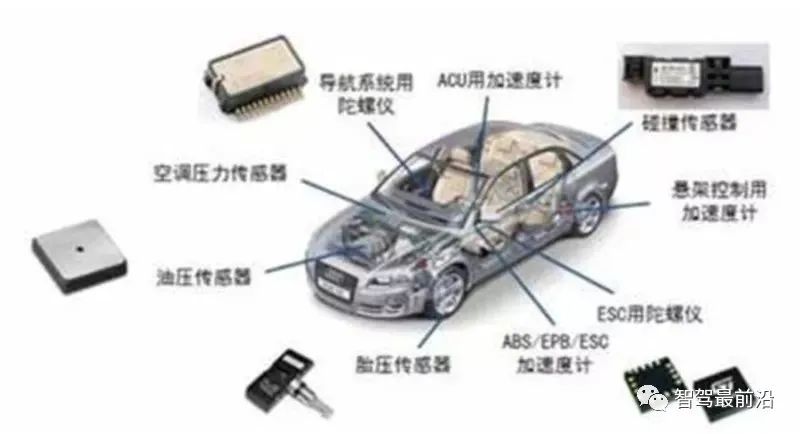

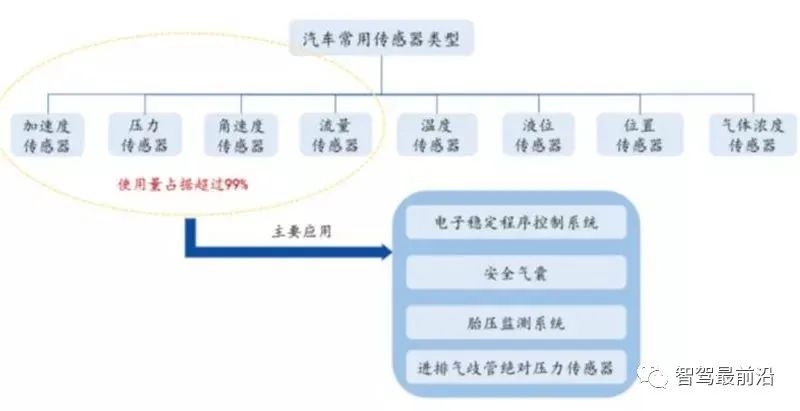

Traditional Sensors: Various system control processes rely on sensors for feedback, achieving automatic control functions and serving as the “neurons” of the vehicle. Traditional automotive sensors can be classified into eight categories based on functionality: pressure sensors, position sensors, temperature sensors, acceleration sensors, angular velocity sensors, flow sensors, gas concentration sensors, and liquid level sensors. Automotive sensors are primarily used in powertrain systems, body control systems, and chassis systems. In these systems, automotive sensors are responsible for information collection and transmission, with the information collected processed by the electronic control unit to issue commands to actuators, completing electronic control.

Classification of Traditional Sensors

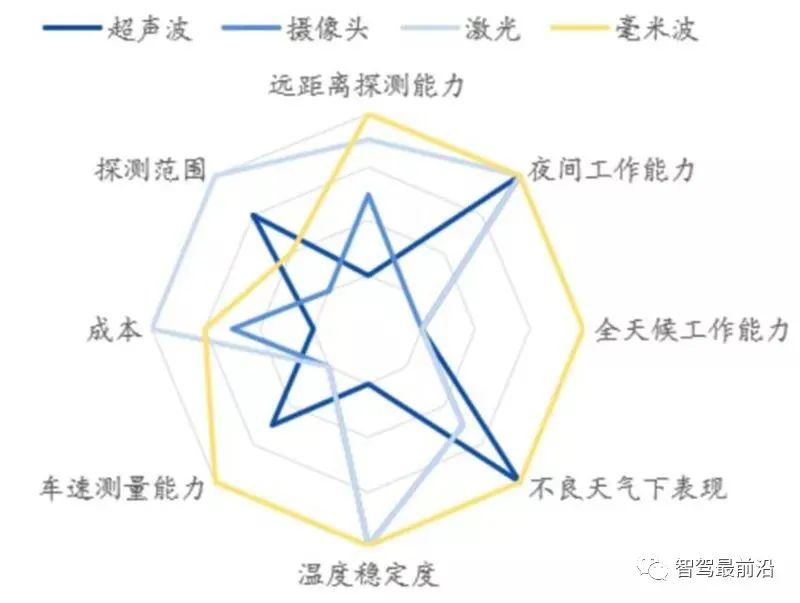

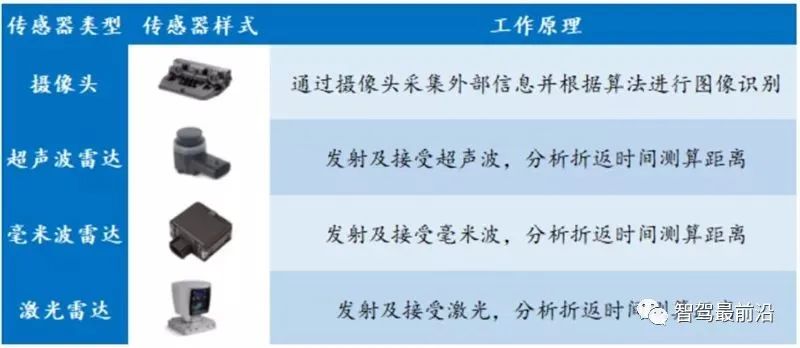

Intelligent Sensors: Intelligent sensors are the “eyes” of autonomous vehicles. Vehicles are rapidly evolving into safe, connected autonomous driving robots that perform environmental perception and planning decisions to ultimately achieve safe arrival at destinations. Currently, mainstream sensor products used for environmental perception mainly include four categories: LiDAR, millimeter-wave radar, ultrasonic radar, and cameras.

Classification of Intelligent Sensors

MEMS Sensors: The Micro-Sensors of Vehicles

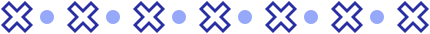

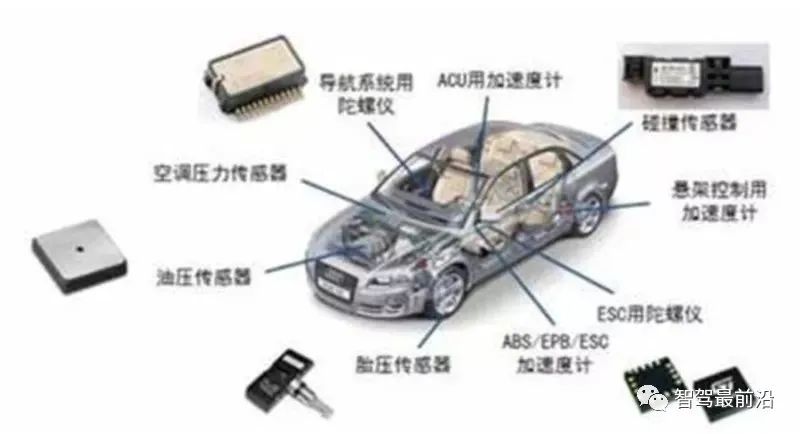

MEMS sensors are developed based onsemiconductor manufacturing technology and are new types of sensors manufactured using microelectronics and micromechanical processing technology. MEMS sensors are widely used in electronic stability programs (ESP), anti-lock braking systems (ABS), electronic control suspensions (ECS), tire pressure monitoring systems (TPMS), and other systems. Among these, pressure sensors, accelerometers, gyroscopes, and flow sensors are the most commonly used MEMS sensors in vehicles, accounting for 99% of automotive MEMS systems.

MEMS Applications Are Extensive

MEMS Applications Are Extensive

MEMS Sensor Value Is Concentrated

MEMS hasobvious advantages and is one of the main choices for building the perception layer of the Internet of Things in the future. Its advantages mainly include: 1) Miniaturization, 2) Silicon-based processing technology, 3) Mass production, 4) Integration.

1. Miniaturization: MEMS devices are small in size, with individual dimensions measured in millimeters or even micrometers, lightweight, and low in energy consumption. The higher surface-to-volume ratio (surface area to volume ratio) of MEMS can enhance the sensitivity of surface sensors.

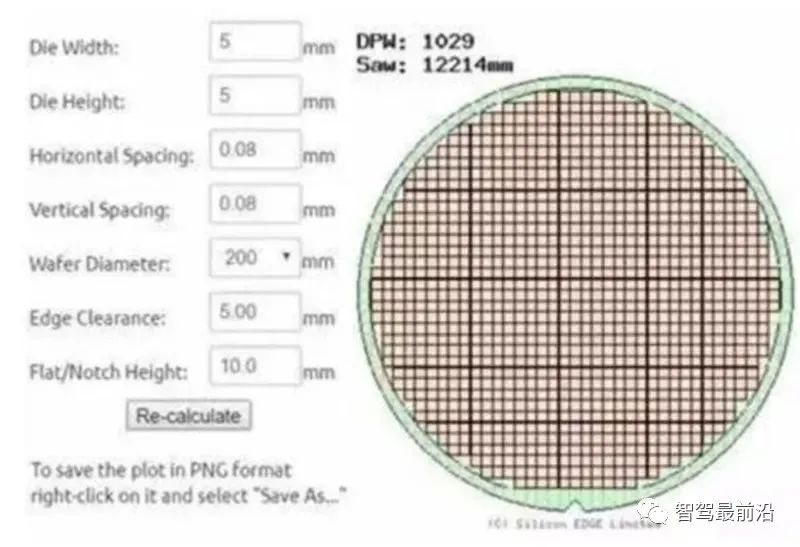

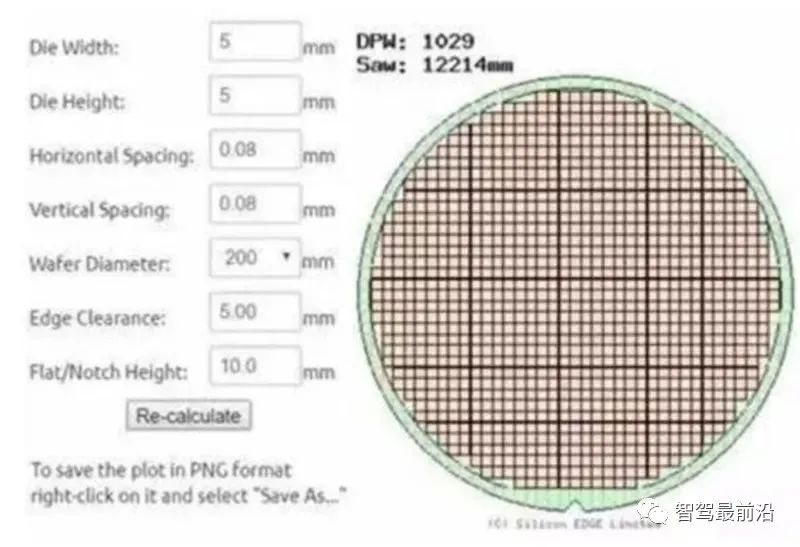

2. Mass Production: Taking a single 5mm x 5mm MEMS sensor as an example, using silicon micromachining technology, approximately 1000 MEMS chips can be simultaneously cut from an 8-inch silicon wafer, significantly reducing the production cost of a single MEMS.

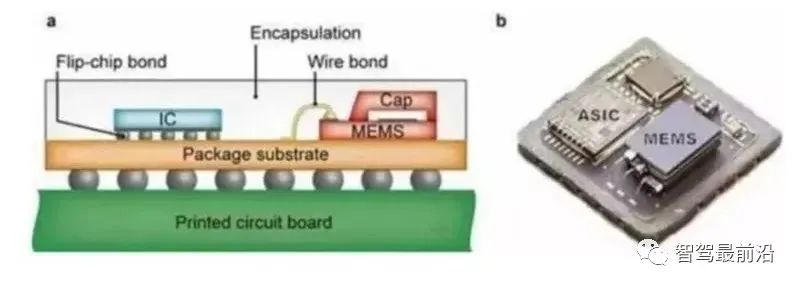

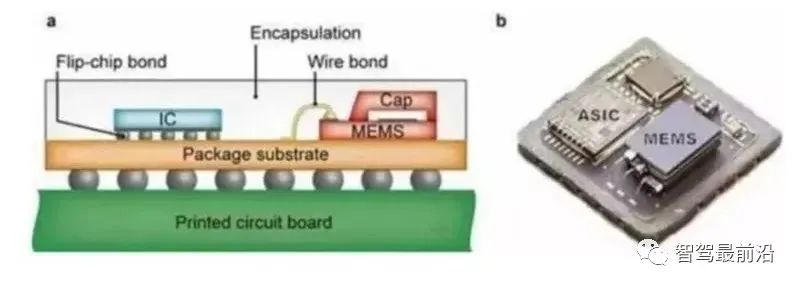

3. Integration: Generally, a single MEMS often integrates an ASIC chip while packaging mechanical sensors, controlling the MEMS chip and converting analog signals to digital outputs.

MEMS Sensor Value Is Concentrated

MEMS hasobvious advantages and is one of the main choices for building the perception layer of the Internet of Things in the future. Its advantages mainly include: 1) Miniaturization, 2) Silicon-based processing technology, 3) Mass production, 4) Integration.

1. Miniaturization: MEMS devices are small in size, with individual dimensions measured in millimeters or even micrometers, lightweight, and low in energy consumption. The higher surface-to-volume ratio (surface area to volume ratio) of MEMS can enhance the sensitivity of surface sensors.

2. Mass Production: Taking a single 5mm x 5mm MEMS sensor as an example, using silicon micromachining technology, approximately 1000 MEMS chips can be simultaneously cut from an 8-inch silicon wafer, significantly reducing the production cost of a single MEMS.

3. Integration: Generally, a single MEMS often integrates an ASIC chip while packaging mechanical sensors, controlling the MEMS chip and converting analog signals to digital outputs.

MEMS Integrated Packaging with ASIC Chips

MEMS Integrated Packaging with ASIC Chips

MEMS Mass Production Reduces Manufacturing Costs

Foreign Giants Dominate the MEMS Sensor Market, with a high market concentration. According to HIS Automotive statistics, the top three global MEMS suppliers in 2017 (Bosch, Sensata, NXP) accounted for 57% of the market share, with Bosch at the forefront, achieving a market share of 33.62%, Sensata at 12.34%, and NXP at 11.91%. Denso (8.94%), Analog Devices (8.51%), Panasonic (7.45%), and Infineon (7.23%) also hold significant shares.

Foreign companies have a wide product line, advanced technology, numerous customers, and a high barrier to entry. The difficulty of R&D and the complexity of manufacturing processes for MEMS sensors are the main reasons for formingindustry barriers. Companies like Invensense and Infineon have 2 to 3 product lines, while Bosch, Denso, and STMicroelectronics have over 4 product lines. In contrast, small suppliers find it difficult to achieve mass production in a short time, so the market share of leading suppliers remains relatively stable, with high market concentration.

The assembly quantity and value of MEMS sensors are proportional to the price level of the vehicles they are installed in. Currently, an average vehicle contains 24 MEMS sensors, while high-end vehicles may use 25-40 MEMS sensors. For example, high-end BMW models can use 20-40 sensors just for the engine, while entry-level models only use about 5. The value of commonly used MEMS sensors in aftermarket vehicles ranges from 2000 to 20000 yuan; joint venture vehicles typically do not fall below 4000 yuan, while domestic brands are around 2000 yuan, and high-end models are about 10000-20000 yuan. It is expected that by 2019, the MEMS sensor market size could reach 42.013 billion yuan; with the enhancement of intelligence and electrification, the market size could reach 44.621 billion yuan and 47.227 billion yuan in 2020 and 2021, respectively, with a compound annual growth rate of 6.5% from 2015 to 2021.

Intelligent Sensors: The Core of Autonomous Driving

Millimeter-Wave Radar: The Core Sensor of ADAS Systems

Millimeter-wave radar refers to the use of waves with wavelengths of 1-10 mm and frequencies of 30GHz-300GHz, measuring the time difference of the echo to calculate distance. Millimeter-wave radar was initially used in military applications and has gradually been applied in the automotive field as technology has advanced.

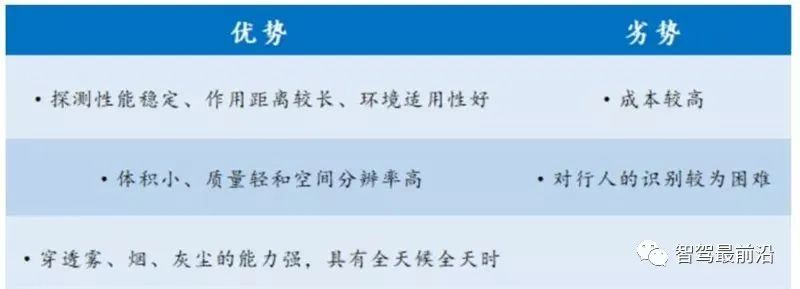

Theadvantages of millimeter-wave radar are primarily threefold: 1) Stable detection performance, long range, and good environmental adaptability. 2) Compared to ultrasonic radar, it is smaller, lighter, and has higher spatial resolution. 3) Compared to optical sensors, millimeter-wave radar has strong capabilities to penetrate fog, smoke, and dust, making it suitable for all-weather and all-time use. However, it also has drawbacks, such as high costs and difficulties in recognizing pedestrians.

Advantages and Disadvantages of Millimeter-Wave Radar

77 GHz has advantages in both performance and size. Currently, vehicle-mounted radar frequencies are mainly divided into 24GHz and 77GHz bands. Compared to 24GHz millimeter-wave radar, 77GHz has higher distance resolution and is one-third smaller in size. In 2018, China’s New Car Assessment Program (C-NCAP) included the Automatic Emergency Braking System (AEBS) in the scoring system, which is expected to drive market demand for 77GHz millimeter-wave radar in the future. In the long term, the smaller size and longer detection range of 77GHz millimeter-wave radar will provide it with greater market potential compared to 24GHz millimeter-wave radar.

Comparison of 24GHz and 77GHz Millimeter-Wave Radar

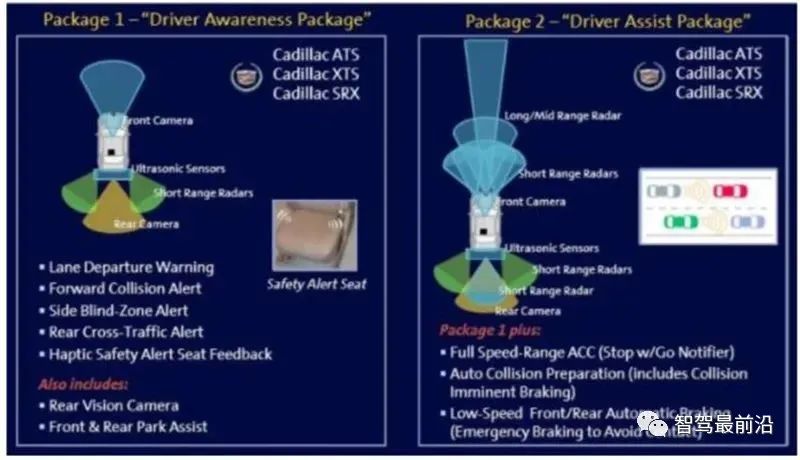

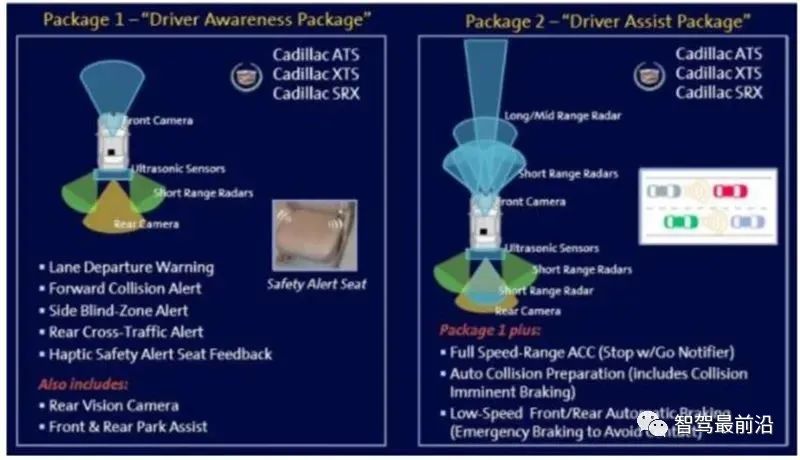

Both 24GHz and 77GHz millimeter-wave radars are used for long and short-range detection in ADAS. Millimeter-wave radar is widely used in ADAS systems due to its small hardware size and immunity to adverse weather conditions. Currently, 24GHz is extensively used in blind spot monitoring and lane change assistance in vehicles. The radar is installed in the rear bumper to monitor whether there are vehicles in the lanes on both sides of the vehicle, allowing for safe lane changes. The 77GHz radar excels in detection accuracy and distance compared to 24GHz radar, primarily installed in the front bumper of vehicles to measure the distance and speed of the vehicle in front, enabling functions such as emergency braking and adaptive cruise control in active safety. To fully implement all ADAS functions, typically “1 long-range + 4 short-range” millimeter-wave radars are required. For instance, the Audi A8 is equipped with 5 millimeter-wave radars (1LRR + 4MRR), while the Mercedes-Benz S-Class is equipped with 6 millimeter-wave radars (1LRR + 6SRR). Currently, the unit price of 77GHz millimeter-wave radar systems is around 1000 yuan, while the price for 24GHz millimeter-wave radar systems is around 500 yuan.

MEMS Mass Production Reduces Manufacturing Costs

Foreign Giants Dominate the MEMS Sensor Market, with a high market concentration. According to HIS Automotive statistics, the top three global MEMS suppliers in 2017 (Bosch, Sensata, NXP) accounted for 57% of the market share, with Bosch at the forefront, achieving a market share of 33.62%, Sensata at 12.34%, and NXP at 11.91%. Denso (8.94%), Analog Devices (8.51%), Panasonic (7.45%), and Infineon (7.23%) also hold significant shares.

Foreign companies have a wide product line, advanced technology, numerous customers, and a high barrier to entry. The difficulty of R&D and the complexity of manufacturing processes for MEMS sensors are the main reasons for formingindustry barriers. Companies like Invensense and Infineon have 2 to 3 product lines, while Bosch, Denso, and STMicroelectronics have over 4 product lines. In contrast, small suppliers find it difficult to achieve mass production in a short time, so the market share of leading suppliers remains relatively stable, with high market concentration.

The assembly quantity and value of MEMS sensors are proportional to the price level of the vehicles they are installed in. Currently, an average vehicle contains 24 MEMS sensors, while high-end vehicles may use 25-40 MEMS sensors. For example, high-end BMW models can use 20-40 sensors just for the engine, while entry-level models only use about 5. The value of commonly used MEMS sensors in aftermarket vehicles ranges from 2000 to 20000 yuan; joint venture vehicles typically do not fall below 4000 yuan, while domestic brands are around 2000 yuan, and high-end models are about 10000-20000 yuan. It is expected that by 2019, the MEMS sensor market size could reach 42.013 billion yuan; with the enhancement of intelligence and electrification, the market size could reach 44.621 billion yuan and 47.227 billion yuan in 2020 and 2021, respectively, with a compound annual growth rate of 6.5% from 2015 to 2021.

Intelligent Sensors: The Core of Autonomous Driving

Millimeter-Wave Radar: The Core Sensor of ADAS Systems

Millimeter-wave radar refers to the use of waves with wavelengths of 1-10 mm and frequencies of 30GHz-300GHz, measuring the time difference of the echo to calculate distance. Millimeter-wave radar was initially used in military applications and has gradually been applied in the automotive field as technology has advanced.

Theadvantages of millimeter-wave radar are primarily threefold: 1) Stable detection performance, long range, and good environmental adaptability. 2) Compared to ultrasonic radar, it is smaller, lighter, and has higher spatial resolution. 3) Compared to optical sensors, millimeter-wave radar has strong capabilities to penetrate fog, smoke, and dust, making it suitable for all-weather and all-time use. However, it also has drawbacks, such as high costs and difficulties in recognizing pedestrians.

Advantages and Disadvantages of Millimeter-Wave Radar

77 GHz has advantages in both performance and size. Currently, vehicle-mounted radar frequencies are mainly divided into 24GHz and 77GHz bands. Compared to 24GHz millimeter-wave radar, 77GHz has higher distance resolution and is one-third smaller in size. In 2018, China’s New Car Assessment Program (C-NCAP) included the Automatic Emergency Braking System (AEBS) in the scoring system, which is expected to drive market demand for 77GHz millimeter-wave radar in the future. In the long term, the smaller size and longer detection range of 77GHz millimeter-wave radar will provide it with greater market potential compared to 24GHz millimeter-wave radar.

Comparison of 24GHz and 77GHz Millimeter-Wave Radar

Both 24GHz and 77GHz millimeter-wave radars are used for long and short-range detection in ADAS. Millimeter-wave radar is widely used in ADAS systems due to its small hardware size and immunity to adverse weather conditions. Currently, 24GHz is extensively used in blind spot monitoring and lane change assistance in vehicles. The radar is installed in the rear bumper to monitor whether there are vehicles in the lanes on both sides of the vehicle, allowing for safe lane changes. The 77GHz radar excels in detection accuracy and distance compared to 24GHz radar, primarily installed in the front bumper of vehicles to measure the distance and speed of the vehicle in front, enabling functions such as emergency braking and adaptive cruise control in active safety. To fully implement all ADAS functions, typically “1 long-range + 4 short-range” millimeter-wave radars are required. For instance, the Audi A8 is equipped with 5 millimeter-wave radars (1LRR + 4MRR), while the Mercedes-Benz S-Class is equipped with 6 millimeter-wave radars (1LRR + 6SRR). Currently, the unit price of 77GHz millimeter-wave radar systems is around 1000 yuan, while the price for 24GHz millimeter-wave radar systems is around 500 yuan.

Application of Millimeter-Wave Radar in ADAS Systems

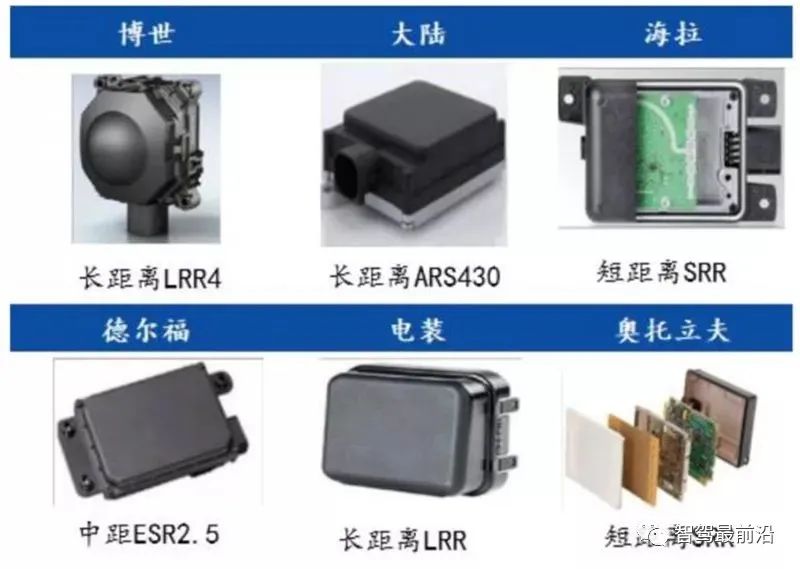

Millimeter-wave radar key technology is dominated by foreign companies, with high market concentration. In the global millimeter-wave radar market, countries such as Germany, the United States, and Japan dominate. Currently, millimeter-wave radar technology is mainly monopolized by traditional automotive giants such as Continental, Bosch, Denso, Autoliv, and Delphi; among them, 77GHz millimeter-wave radar technology is monopolized by Bosch, Continental, Delphi, Denso, TRW, Fujitsu, and Hitachi. In 2016, Bosch and Continental each held a 17% share of the global millimeter-wave radar market, ranking first; Denso and Hella ranked second with an 11% share, ZF held 8%, and Delphi held 6%, while Autoliv held 4%. The top seven suppliers accounted for 73% of the market share.

Major Foreign Suppliers and Products of Millimeter-Wave Radar

Domestic millimeter-wave radar relies on imports,limited by foreign technology blockades, with 24GHz millimeter-wave radar being the mainstream direction. Currently, all millimeter-wave radar sensors installed in mid-to-high-end vehicles in the Chinese market rely on imports, with the market being monopolized by American, Japanese, and German companies, which are expensive and have implemented technology blockades, making domestic control urgent. Overall, domestic vehicle-mounted millimeter-wave radar products are still in the development stage. Considering the R&D costs and the limitations of 77GHz development technology, domestic manufacturers are focusing their R&D on 24GHz. In the domestic market, the product system for 24GHz millimeter-wave radar is relatively mature, and the supply chain is relatively stable. The core chips for 24GHz can be sourced from suppliers like Infineon and Freescale. According to market research, in 2016, the number of pre-installed millimeter-wave radars in Chinese automobiles reached 1.05 million, with 63.8% being 24GHz radar and 36.2% being 77GHz radar.

According to estimates, the market size for millimeter-wave radar in 2019, 2020, and 2025 is expected to reach 470 million yuan, 3.6 billion yuan, and 8 billion yuan, respectively. The compound annual growth rate from 2017 to 2025 is expected to be around 58%.

LiDAR: Key in L3-L5 Autonomous Driving

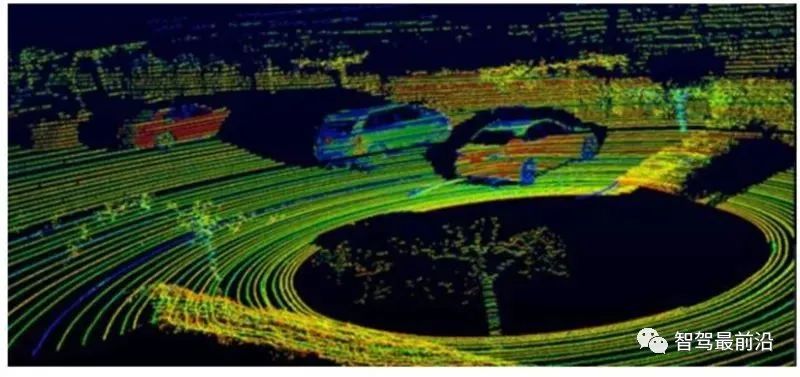

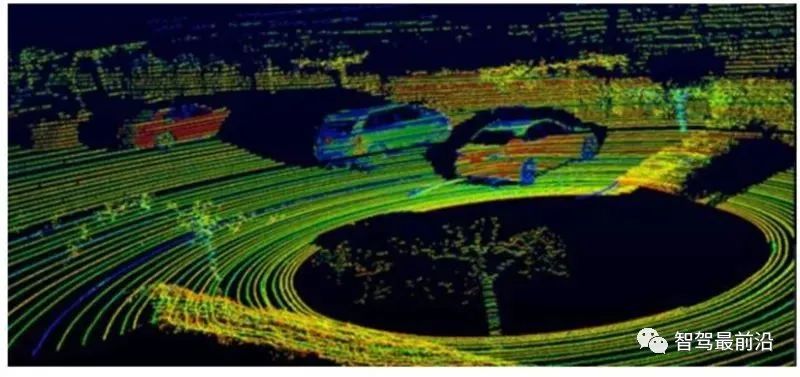

LiDAR is a comprehensive optical detection and ranging system that emits and receives laser beams, analyzing the time it takes for the laser to return after hitting a target to calculate the relative distance to the target object. Common types include 8-line, 16-line, and 32-line LiDAR. The more lines the LiDAR has, the higher the measurement precision and safety. LiDAR is not a new technology; it has been applied in aerospace, surveying, and other fields for a long time. With the development of automotive intelligence, LiDAR has begun to be used in L3-level autonomous driving due to its high precision and real-time 3D environmental modeling capabilities, making it the most critical sensor in the L3-L5 stages of autonomous driving.

Working Principle of LiDAR

Application of Millimeter-Wave Radar in ADAS Systems

Millimeter-wave radar key technology is dominated by foreign companies, with high market concentration. In the global millimeter-wave radar market, countries such as Germany, the United States, and Japan dominate. Currently, millimeter-wave radar technology is mainly monopolized by traditional automotive giants such as Continental, Bosch, Denso, Autoliv, and Delphi; among them, 77GHz millimeter-wave radar technology is monopolized by Bosch, Continental, Delphi, Denso, TRW, Fujitsu, and Hitachi. In 2016, Bosch and Continental each held a 17% share of the global millimeter-wave radar market, ranking first; Denso and Hella ranked second with an 11% share, ZF held 8%, and Delphi held 6%, while Autoliv held 4%. The top seven suppliers accounted for 73% of the market share.

Major Foreign Suppliers and Products of Millimeter-Wave Radar

Domestic millimeter-wave radar relies on imports,limited by foreign technology blockades, with 24GHz millimeter-wave radar being the mainstream direction. Currently, all millimeter-wave radar sensors installed in mid-to-high-end vehicles in the Chinese market rely on imports, with the market being monopolized by American, Japanese, and German companies, which are expensive and have implemented technology blockades, making domestic control urgent. Overall, domestic vehicle-mounted millimeter-wave radar products are still in the development stage. Considering the R&D costs and the limitations of 77GHz development technology, domestic manufacturers are focusing their R&D on 24GHz. In the domestic market, the product system for 24GHz millimeter-wave radar is relatively mature, and the supply chain is relatively stable. The core chips for 24GHz can be sourced from suppliers like Infineon and Freescale. According to market research, in 2016, the number of pre-installed millimeter-wave radars in Chinese automobiles reached 1.05 million, with 63.8% being 24GHz radar and 36.2% being 77GHz radar.

According to estimates, the market size for millimeter-wave radar in 2019, 2020, and 2025 is expected to reach 470 million yuan, 3.6 billion yuan, and 8 billion yuan, respectively. The compound annual growth rate from 2017 to 2025 is expected to be around 58%.

LiDAR: Key in L3-L5 Autonomous Driving

LiDAR is a comprehensive optical detection and ranging system that emits and receives laser beams, analyzing the time it takes for the laser to return after hitting a target to calculate the relative distance to the target object. Common types include 8-line, 16-line, and 32-line LiDAR. The more lines the LiDAR has, the higher the measurement precision and safety. LiDAR is not a new technology; it has been applied in aerospace, surveying, and other fields for a long time. With the development of automotive intelligence, LiDAR has begun to be used in L3-level autonomous driving due to its high precision and real-time 3D environmental modeling capabilities, making it the most critical sensor in the L3-L5 stages of autonomous driving.

Working Principle of LiDAR

Velodyne HDL-64E LiDAR 3D Imaging

The Solid-State Development of LiDAR Is a Future Trend, with advantages in miniaturization and low cost. The industry is primarily reducing LiDAR costs in two ways: 1) Eliminating mechanical rotating structures and adopting solid-state technology fundamentally reduces the cost of LiDAR. Solid-state LiDAR is smaller, easier to integrate, and has improved system reliability; thus, LiDAR is trending toward solid-state development. 2) Reducing the number of LiDAR lines and using multiple low-line LiDARs in combination. Transitioning from mechanical rotating to hybrid solid-state and then to pure solid-state LiDAR, with expanding production scales and technological iterations, costs continue to decline, and LiDAR is consistently moving towards miniaturization, low power consumption, and integration.

Thecore technologies of LiDAR are mainly held by three companies: Velodyne, Ibeo, and Quanergy. Velodyne’s mechanical LiDAR was developed earlier and is technologically advanced; it recently launched the 128-line prototype product VLS-128 and has established partnerships with global autonomous driving leaders like Google, General Motors, Ford, Uber, and Baidu, capturing a significant portion of the vehicle-mounted LiDAR market.

Companies like Google, Baidu, Ford, Audi, and BMW have successively adopted LiDAR-based perception solutions. BMW has announced a partnership with the LiDAR startup Innoviz to develop autonomous vehicles, expected to launch in 2021. According to various company websites, the price of a single vehicle LiDAR sensor ranges from $30,000 to $80,000.

In the short term, LiDAR will not be widely applied in the automotive field. Although the rapid development of autonomous driving creates a favorable application prospect for the LiDAR industry, numerous pain points in LiDAR developmentlimit its application in autonomous vehicles. The limiting factors mainly involve three aspects: 1) High costs. Velodyne’s 16-line product costs $8,000, the 32-line product costs $40,000, and the 64-line product costs about $80,000.

High Product Prices also suppress the application of LiDAR in autonomous vehicles. 2) Difficulty in mass production and long delivery cycles. The production cycle for Velodyne’s 64-line products is 4-8 weeks, while the 32-line and 16-line products take 2-4 weeks. To ensure the accuracy of the signals transmitted and received by LiDAR, the complex assembly and calibration processes extend the delivery cycle. 3) Lack of relevant automotive regulations. Currently, autonomous driving is still a forward-looking concept without practical implementation, and there are no corresponding mandatory policy regulations, which somewhat limits the popularization of LiDAR in the autonomous driving field.

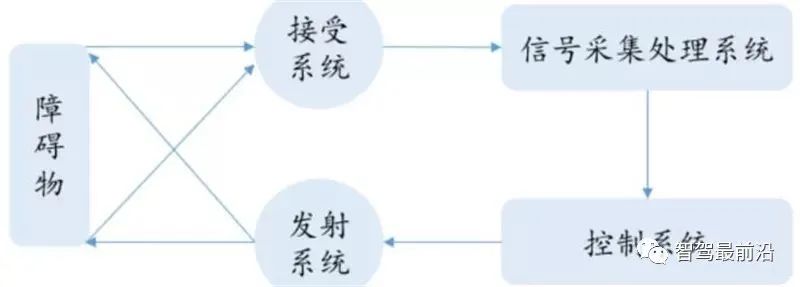

Ultrasonic Radar: The Mainstream Sensor for Automatic Parking Systems

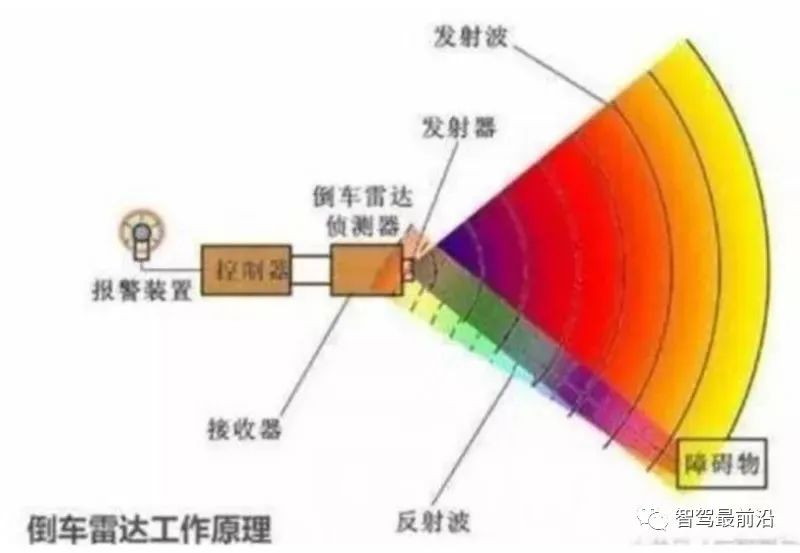

The working principle of ultrasonic radar is to emit ultrasonic waves through a transmitter and measure the time difference when the receiver receives the reflected ultrasonic waves to calculate distance. In autonomous driving, the basic applications of ultrasonic radar include parking assistance warnings and collision warnings in blind spots. Ultrasonic radar is cost-effective and has advantages in short-distance measurements, with a detection range between 0.1 to 3 meters, and it is relatively accurate, making it very suitable for parking applications. However, its measurement distance is limited and is easily affected by adverse weather conditions.

Working Principle of Ultrasonic Radar

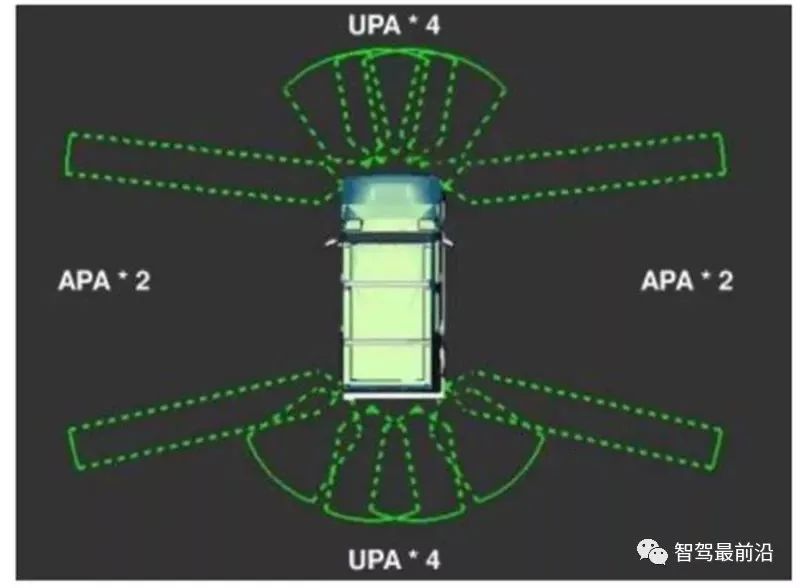

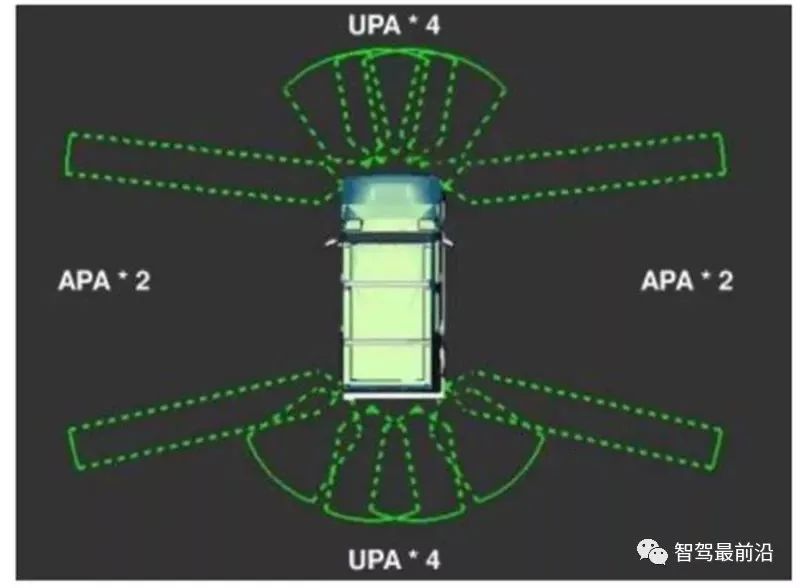

The Popularization of Automatic Parking Stimulates Demand for Ultrasonic Radar. Ultrasonic radar is generally installed in the vehicle’s bumpers or sides; the former is called UPA, mainly used to measure obstacles in front of and behind the vehicle, while the latter is called APA, used to measure side obstacles. APA ultrasonic sensors are core components of automatic parking assistance systems, with longer detection distances, used to measure parking space width and obtain parking space dimensions and vehicle position information. Ultrasonic radar is mainly applied in reverse radar and automatic parking systems for near-distance obstacle monitoring. Reverse radar has already penetrated from high-end models to mid- and low-end models, with an installation rate of about 80%. Reverse radar systems typically require 4 UPA ultrasonic radars, while automatic parking radar systems require 6-12 ultrasonic radars, with a typical configuration of 8 UPA + 4 APA.

Velodyne HDL-64E LiDAR 3D Imaging

The Solid-State Development of LiDAR Is a Future Trend, with advantages in miniaturization and low cost. The industry is primarily reducing LiDAR costs in two ways: 1) Eliminating mechanical rotating structures and adopting solid-state technology fundamentally reduces the cost of LiDAR. Solid-state LiDAR is smaller, easier to integrate, and has improved system reliability; thus, LiDAR is trending toward solid-state development. 2) Reducing the number of LiDAR lines and using multiple low-line LiDARs in combination. Transitioning from mechanical rotating to hybrid solid-state and then to pure solid-state LiDAR, with expanding production scales and technological iterations, costs continue to decline, and LiDAR is consistently moving towards miniaturization, low power consumption, and integration.

Thecore technologies of LiDAR are mainly held by three companies: Velodyne, Ibeo, and Quanergy. Velodyne’s mechanical LiDAR was developed earlier and is technologically advanced; it recently launched the 128-line prototype product VLS-128 and has established partnerships with global autonomous driving leaders like Google, General Motors, Ford, Uber, and Baidu, capturing a significant portion of the vehicle-mounted LiDAR market.

Companies like Google, Baidu, Ford, Audi, and BMW have successively adopted LiDAR-based perception solutions. BMW has announced a partnership with the LiDAR startup Innoviz to develop autonomous vehicles, expected to launch in 2021. According to various company websites, the price of a single vehicle LiDAR sensor ranges from $30,000 to $80,000.

In the short term, LiDAR will not be widely applied in the automotive field. Although the rapid development of autonomous driving creates a favorable application prospect for the LiDAR industry, numerous pain points in LiDAR developmentlimit its application in autonomous vehicles. The limiting factors mainly involve three aspects: 1) High costs. Velodyne’s 16-line product costs $8,000, the 32-line product costs $40,000, and the 64-line product costs about $80,000.

High Product Prices also suppress the application of LiDAR in autonomous vehicles. 2) Difficulty in mass production and long delivery cycles. The production cycle for Velodyne’s 64-line products is 4-8 weeks, while the 32-line and 16-line products take 2-4 weeks. To ensure the accuracy of the signals transmitted and received by LiDAR, the complex assembly and calibration processes extend the delivery cycle. 3) Lack of relevant automotive regulations. Currently, autonomous driving is still a forward-looking concept without practical implementation, and there are no corresponding mandatory policy regulations, which somewhat limits the popularization of LiDAR in the autonomous driving field.

Ultrasonic Radar: The Mainstream Sensor for Automatic Parking Systems

The working principle of ultrasonic radar is to emit ultrasonic waves through a transmitter and measure the time difference when the receiver receives the reflected ultrasonic waves to calculate distance. In autonomous driving, the basic applications of ultrasonic radar include parking assistance warnings and collision warnings in blind spots. Ultrasonic radar is cost-effective and has advantages in short-distance measurements, with a detection range between 0.1 to 3 meters, and it is relatively accurate, making it very suitable for parking applications. However, its measurement distance is limited and is easily affected by adverse weather conditions.

Working Principle of Ultrasonic Radar

The Popularization of Automatic Parking Stimulates Demand for Ultrasonic Radar. Ultrasonic radar is generally installed in the vehicle’s bumpers or sides; the former is called UPA, mainly used to measure obstacles in front of and behind the vehicle, while the latter is called APA, used to measure side obstacles. APA ultrasonic sensors are core components of automatic parking assistance systems, with longer detection distances, used to measure parking space width and obtain parking space dimensions and vehicle position information. Ultrasonic radar is mainly applied in reverse radar and automatic parking systems for near-distance obstacle monitoring. Reverse radar has already penetrated from high-end models to mid- and low-end models, with an installation rate of about 80%. Reverse radar systems typically require 4 UPA ultrasonic radars, while automatic parking radar systems require 6-12 ultrasonic radars, with a typical configuration of 8 UPA + 4 APA.

Application of Ultrasonic Radar in Vehicles

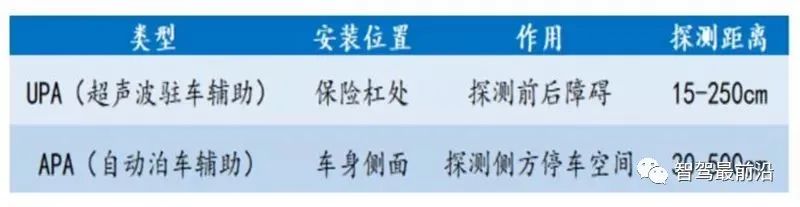

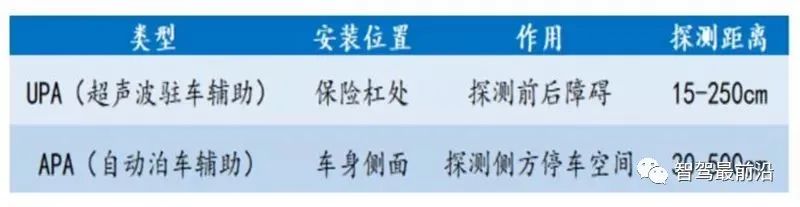

Comparison of UPA and APA Ultrasonic Radar

Comparison of UPA and APA Ultrasonic Radar

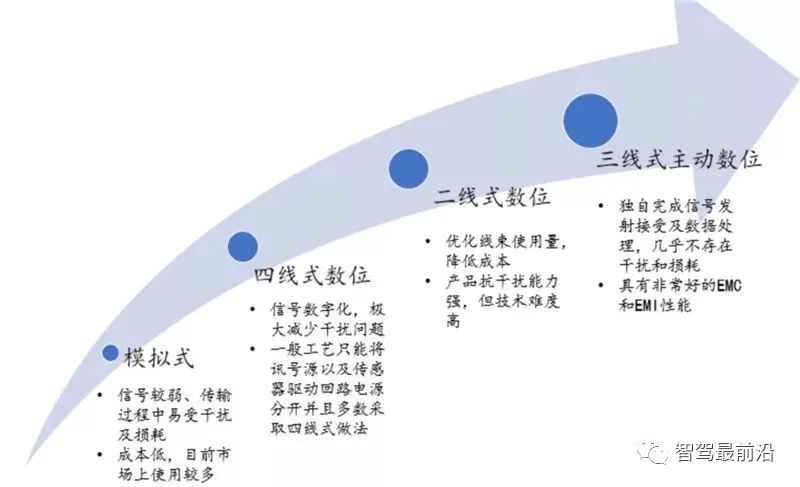

Ultrasonic Radar Technical Solutions Each Have Their Advantages and Disadvantages, with analog radar occupying the main market. The technical solutions for ultrasonic radar generally include analog, four-wire digital, two-wire digital, and three-wire active digital types, with each progressively improving in handling signal interference. Currently, the most widely used technology route in the market is the “analog” technology route, which is cost-effective but easily interfered with by external environments. In the future, under the trend of intelligentization, the “digital” technology route will become more popular. Under the “digital” technology route, the digitization of signals can greatly enhance the radar’s anti-interference capability, but it is more costly and technically challenging, leading to the current manufacturing process primarily adopting the four-wire approach.

Four Technical Solution Routes for Ultrasonic Radar

The ultrasonic radar market is mainly occupied by Bosch, Japan’s Murata, and Japan’s Nicera, with domestic companies like Audiwei and Tongzhi Electronics being highly competitive. Audiwei is a leading domestic manufacturer of ultrasonic sensors, with sales of 26.27 million vehicle-mounted ultrasonic sensors in 2016, while the global market capacity for vehicle-mounted ultrasonic sensors is approximately 27.4 million units, with Audiwei holding a 9% share of the global passenger vehicle market. Audiwei’s largest customer is Taiwan’s Tongzhi Electronics, whose core product is reverse radar, and in 2016, it ranked first in market share in Asia.

The Ultrasonic Radar Market Is Expected to Continue to Grow in the Short to Medium Term, but in the long term, it may face replacement pressure from other radar sensors. Currently, the installation rate of rear ultrasonic radar is the highest, reaching 45.2%, while the installation rate of “front + rear radar” is 28.3%, and the non-installation rate is 26.5%. With the development of automated driving, “front + rear” radar is expected to become the standard configuration. Therefore, it is expected that the market penetration of ultrasonic radar will continue to rise in the short to medium term, but in the long term, some or all ultrasonic radars in high-level autonomous vehicles may be replaced by millimeter-wave radar, LiDAR, and other sensors with better overall performance.

According to estimates, the market size for ultrasonic radar in 2019, 2020, and 2025 is expected to reach 4.2 billion yuan, 8.7 billion yuan, and 19.2 billion yuan, respectively, with a compound annual growth rate of around 38% from 2016 to 2025.

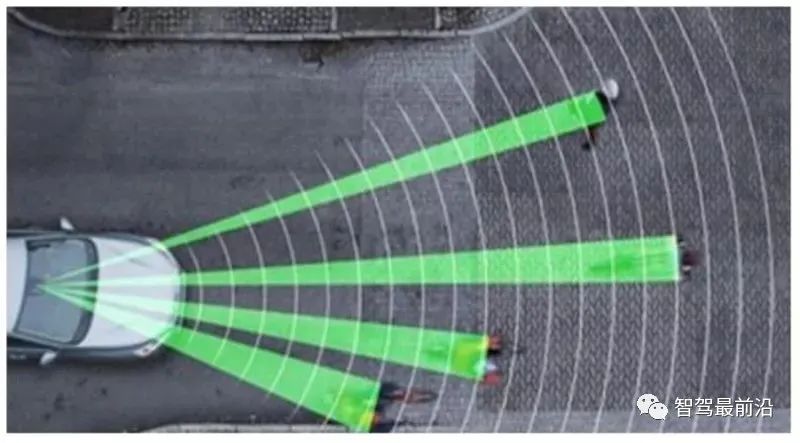

Cameras: Major Visual Sensors in ADAS Systems

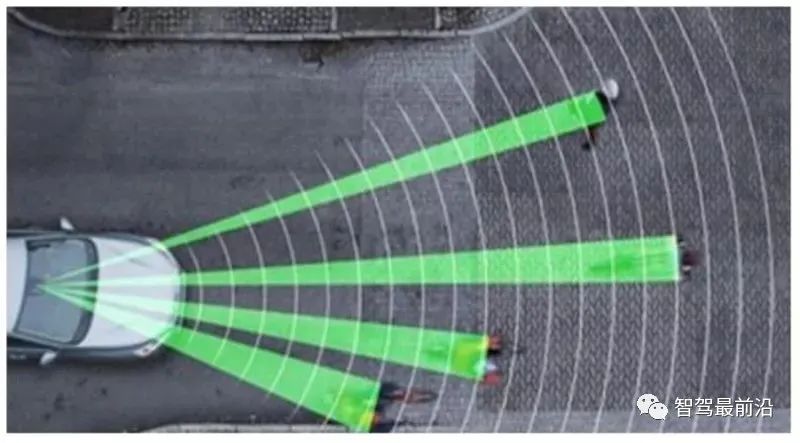

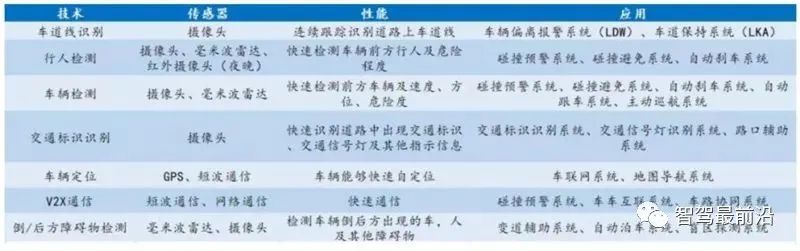

Vehicle-mounted cameras are the main visual sensors in ADAS systems and are among the most mature vehicle-mounted sensors. By capturing images through lenses, the light-sensitive components and control components within the camera process the images and convert them into digital signals that can be processed by computers, enabling the perception of road conditions surrounding the vehicle. Cameras are primarily used in 360-degree panoramic imaging, forward collision warning, lane departure warning, and pedestrian detection in ADAS functionalities.

Camera Detecting Road Pedestrians

Application of Cameras in Panoramic Parking Systems

ADAS systems typically require more than six cameras. Depending on the needs of different ADAS functions, the installation positions of cameras vary. They are mainly divided into front, rear, side, and internal cameras. To realize the full set of ADAS functions for autonomous driving, more than six cameras must be installed. The front camera, due to the need for complex algorithms and chips, typically costs around 1500 yuan, while rear, side, and internal cameras cost around 200 yuan each. The widespread application of ADAS has created significant market space for vehicle-mounted camera sensors.

Camera Installation Positions and Characteristics

In the short term monocular cameras will be the mainstream technology route. Front cameras in ADAS systems can be divided into those equipped with monocular and binocular cameras. Compared to monocular cameras, binocular cameras have more powerful functions and higher measurement precision, but they are more costly, hence are more commonly found in high-end vehicles. The binocular camera scheme faces challenges in cost, manufacturing processes, reliability, and precision, making it difficult to promote in the market. Therefore, under the current market environment, monocular camera solutions will remain mainstream.

Cameras primarily serve as supplementary sensors to radar. Although cameras have high resolution and can detect the texture and color of objects, their visual performance is poor in backlighting or complex lighting conditions and is easily affected by adverse weather. Therefore, the image information obtained by cameras is mainly responsible for traffic sign recognition and other specific fields, serving as a complement to LiDAR and millimeter-wave radar.

The Camera Industry Chain can be roughly divided into three parts: upstream component production, midstream module packaging and integration, and downstream product applications. 1) Upstream components mainly include CMOS sensors, lens groups, DSPs, etc. In the upstream market, CMOS sensors and DSPs are mainly monopolized by foreign companies such as Sony, Samsung, TI, and ON Semiconductor, while domestic companies have advantages in lens group production, with local brands like Sunny Optical being highly competitive; 2) Midstream packaging and integration include module packaging and system integration. The packaging and integration processes are complex and are dominated by foreign companies, with major manufacturers including Panasonic, Sony, and Valeo. 3) Downstream product applications are directed towards vehicle manufacturers and 4S stores.

The Vehicle-Mounted Camera Industry requires high production standards and long certification cycles. Compared to mobile phone cameras, vehicle-mounted cameras face harsher operating conditions and must meet multiple requirements such as high-temperature resistance, shock resistance, magnetic resistance, and stability. Especially for front cameras used in ADAS systems, which relate to driving safety, the reliability requirements must be extremely high. As a result, the production standards for vehicle-mounted cameras are very high. Before becoming a first-tier supplier to vehicle manufacturers, companies must undergo various rigorous tests. Once they enter a vehicle manufacturer’s supply system, it creates high barriers to entry, making it difficult to be replaced, and the replacement costs are also very high. For example, the foreign visual sensor leader Mobileye took 8 years to transition from R&D to the front-mounted market.

According to estimates, the market size for camera sensors is expected to reach 15 billion yuan in 2019, with the camera market size reaching 20.5 billion yuan in 2020 and 31.5 billion yuan in 2025, with a compound annual growth rate of around 17% from 2016 to 2025.

Multi-Sensor Fusion Is an Inevitable Trend

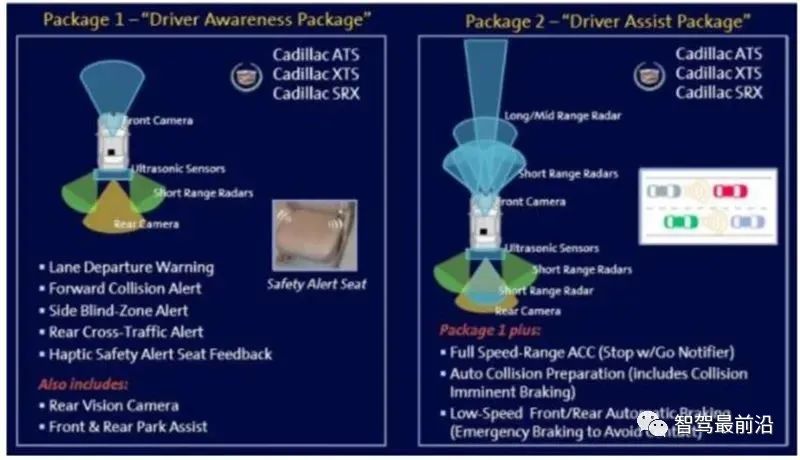

ADAS Integrates Multiple Sensors, driving the development of the sensor market. As the proportion of intelligent vehicles increases in the future, the ADAS market will accelerate its growth. According to research by Goldman Sachs’ global investment research department, the current global ADAS penetration rate is generally low, with penetration rates in Europe, America, and Japan only at 8%-12%. According to estimates by the Gaishi Automotive Research Institute, the ADAS penetration rate in China is around 2%-5%; from a lifecycle perspective, ADAS has already transitioned from the introduction phase to the growth phase. Overall, under the wave of intelligent driving and autonomous driving, the level of automotive electrification and intelligence continues to rise, and ADAS has significant growth potential. Environmental perception, as the hardware foundation of ADAS, is indispensable, and the improvement in ADAS penetration rates will significantly increase the demand for vehicle-mounted sensors, leading to further expansion of the sensor market size in the future.

ADAS Integrates Multiple Sensors

Environmental Perception Sensors are the eyes of the vehicle, with millimeter-wave radar showcasing outstanding comprehensive advantages. In the context of the intelligent era, environmental perception is particularly important. Different sensors have different principles and functions, each playing its advantages in various scenarios, making it difficult to replace one another. Millimeter-wave radar exhibits outstanding comprehensive advantages and is expected to become the main sensor in ADAS systems first.

Comparison of Advantages and Disadvantages of Various Sensors

Millimeter-Wave Radar Shows Outstanding Comprehensive Advantages

Single Sensor Characteristics Are Prominent, but none can provide complete information coverage, making multi-sensor fusion an inevitable future trend. It also provides the necessary technical reserves for achieving Level 3 to Level 5 autonomous driving solutions. Currently, the main technical routes for autonomous driving environmental perception are mainly two: one is the multi-sensor fusion scheme led by vision, represented by Tesla, and the other is the low-cost LiDAR-led scheme, with Google Waymo as a typical representative. Leading foreign automotive companies like Tesla, Audi, and General Motors have released their multi-sensor plans for autonomous vehicles. Multi-sensor fusion is crucial for ensuring the vehicle’s global positioning and understanding of its surrounding environment.

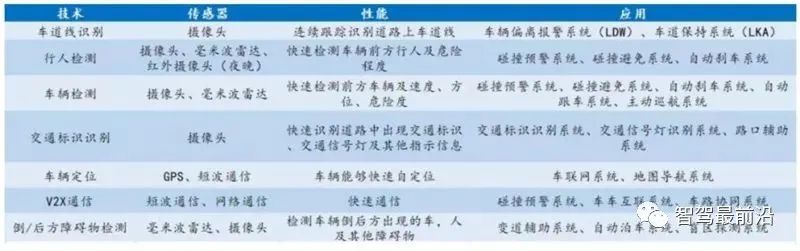

In summary, the sensors used in ADAS mainly include cameras, radars, LiDAR, and ultrasonic sensors, which can detect light, heat, pressure, or other variables used to monitor the state of the vehicle. These sensors are typically located on the front and rear bumpers, side mirrors, inside the steering column, or on the windshield. Each subsystem within ADAS operates through the collection, processing, and judgment of information, and after the judgment is completed, the system issues commands to the vehicle to perform various actions. In this process, sensors such as radars and cameras, along with processors like MCUs or image processing ICs, become the primary components used. On the road to achieving Level 5 autonomous driving,the maturity and perfection of ADAS systems are fundamental guarantees.

ADAS Integrates Multiple Sensors

Environmental Perception Sensors are the eyes of the vehicle, with millimeter-wave radar showcasing outstanding comprehensive advantages. In the context of the intelligent era, environmental perception is particularly important. Different sensors have different principles and functions, each playing its advantages in various scenarios, making it difficult to replace one another. Millimeter-wave radar exhibits outstanding comprehensive advantages and is expected to become the main sensor in ADAS systems first.

Comparison of Advantages and Disadvantages of Various Sensors

Millimeter-Wave Radar Shows Outstanding Comprehensive Advantages

Single Sensor Characteristics Are Prominent, but none can provide complete information coverage, making multi-sensor fusion an inevitable future trend. It also provides the necessary technical reserves for achieving Level 3 to Level 5 autonomous driving solutions. Currently, the main technical routes for autonomous driving environmental perception are mainly two: one is the multi-sensor fusion scheme led by vision, represented by Tesla, and the other is the low-cost LiDAR-led scheme, with Google Waymo as a typical representative. Leading foreign automotive companies like Tesla, Audi, and General Motors have released their multi-sensor plans for autonomous vehicles. Multi-sensor fusion is crucial for ensuring the vehicle’s global positioning and understanding of its surrounding environment.

In summary, the sensors used in ADAS mainly include cameras, radars, LiDAR, and ultrasonic sensors, which can detect light, heat, pressure, or other variables used to monitor the state of the vehicle. These sensors are typically located on the front and rear bumpers, side mirrors, inside the steering column, or on the windshield. Each subsystem within ADAS operates through the collection, processing, and judgment of information, and after the judgment is completed, the system issues commands to the vehicle to perform various actions. In this process, sensors such as radars and cameras, along with processors like MCUs or image processing ICs, become the primary components used. On the road to achieving Level 5 autonomous driving,the maturity and perfection of ADAS systems are fundamental guarantees.

Business Cooperation: mufengjixie2016

Copyright Notice: Thank you to every author for their hard work and creativity. Except for a large number of articles without traceable sources, we have noted the source in the articles. If copyright issues arise from reprinting, please contact us for deletion or payment of manuscript fees. Thank you very much!

Click to Share

Click to Like

Click to View

MEMS Applications Are Extensive

MEMS Applications Are Extensive MEMS Sensor Value Is Concentrated

MEMS Sensor Value Is Concentrated MEMS Integrated Packaging with ASIC Chips

MEMS Integrated Packaging with ASIC Chips MEMS Mass Production Reduces Manufacturing Costs

MEMS Mass Production Reduces Manufacturing Costs

Velodyne HDL-64E LiDAR 3D Imaging

Velodyne HDL-64E LiDAR 3D Imaging

Comparison of UPA and APA Ultrasonic Radar

Comparison of UPA and APA Ultrasonic Radar

ADAS Integrates Multiple Sensors

ADAS Integrates Multiple Sensors