When it comes to sensors, everyone is likely familiar with them. So how much do you really know about sensors?

Sensors are like the “five senses” of devices, essential components for communication between humans and machines. Why is this said? The five senses of humans are natural sensors that perceive external information through sight, hearing, smell, taste, and touch. Our brain processes information received through these senses. Similarly, a sensor acts like a biological organ that can detect or sense external signals (such as light, heat, humidity, smoke, etc.) and transmit the detected information to other organs or devices.

A sensor is a detection device, typically composed of a sensitive element and a conversion element, which can sense specified measurements and convert them into usable signals according to certain rules. Sensors can perceive the information being measured and transform the detected information into electrical signals or other required forms for transmission, processing, storage, display, recording, and control. Different types of sensors serve different functions and are classified into thermal sensitive elements, optical sensitive elements, gas sensitive elements, force sensitive elements, magnetic sensitive elements, humidity sensitive elements, sound sensitive elements, radiation sensitive elements, color sensitive elements, and taste sensitive elements, among others.

There are many types of sensors. To better differentiate them, here is a classification:

1. Classification by Purpose

Pressure sensitive and force sensitive sensors, position sensors, liquid level sensors, energy consumption sensors, speed sensors, acceleration sensors, radiation sensors, thermal sensitive sensors.

2. Classification by Output Signal

Analog sensors: Convert non-electrical quantities into analog electrical signals.

Digital sensors: Convert non-electrical quantities into digital output signals (including direct and indirect conversion).

Switch sensors: When a measured signal reaches a specific threshold, the sensor outputs a preset low or high-level signal accordingly.

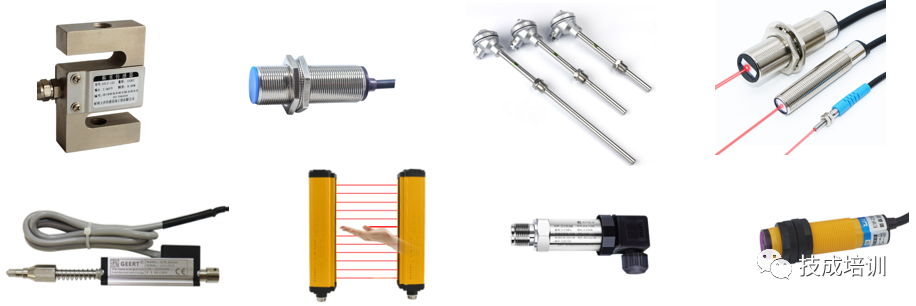

Common sensors include proximity switch sensors, photoelectric switch sensors, load sensors, thermistors, Hall sensors, temperature sensors, light-sensitive sensors, laser sensors, displacement sensors, grating sensors, pressure sensors, infrared sensors, etc. Below, I will introduce the most commonly used proximity switch, photoelectric switch sensors, and pressure sensors.

Proximity Switch Sensor:When the switch approaches an object, it emits a control signal. The proximity switch, also known as a non-contact limit switch, not only completes travel control and limit protection but also serves as a non-contact monitoring device for detecting part sizes and speed measurement.

Photoelectric Switch Sensor:This sensor converts the input current into a light signal at the transmitter, and the receiver detects the target object based on the strength and quantity of the received light. In simple terms, it uses the obstruction or reflection of a light beam by the detected object to determine the presence of an object, which can include any object that reflects light, not limited to metals.

1. Different methods of detecting objects: The emission tube of the photoelectric switch emits modulated light, and the receiving tube detects whether it has received this light to judge the presence of an object; while the proximity switch relies on the sensing of its detection head to determine the presence of an object.

2. When it is inconvenient for the detection switch to approach the detected object or when the detected object is easily damaged, or when space is limited and the detected object is small, a photoelectric switch can be used, as it can detect both metallic and non-metallic objects. When the detection switch can easily approach the detected object and is not easily damaged, an inductive proximity switch is used for metal objects, while a capacitive proximity switch is used for non-metallic objects.

3. Proximity switches can only sense metals and cannot sense plastics or other materials, generally with a shorter distance, while photoelectric switches can sense all materials, but their sensing ability depends on the reflective capacity of the object to light; for example, white objects can be sensed from a greater distance than black objects.

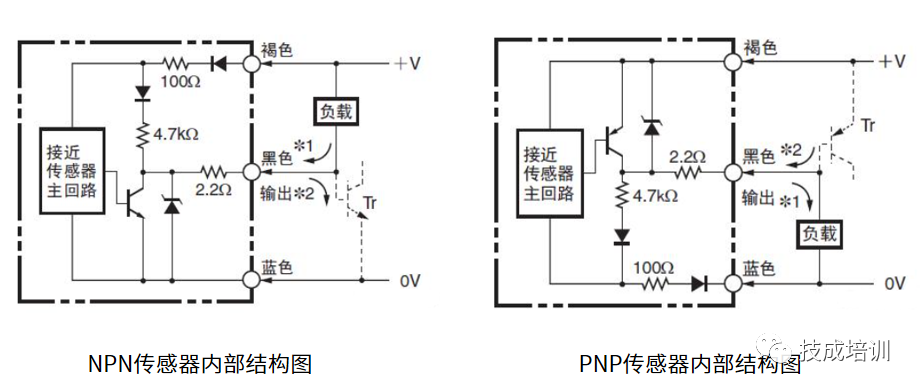

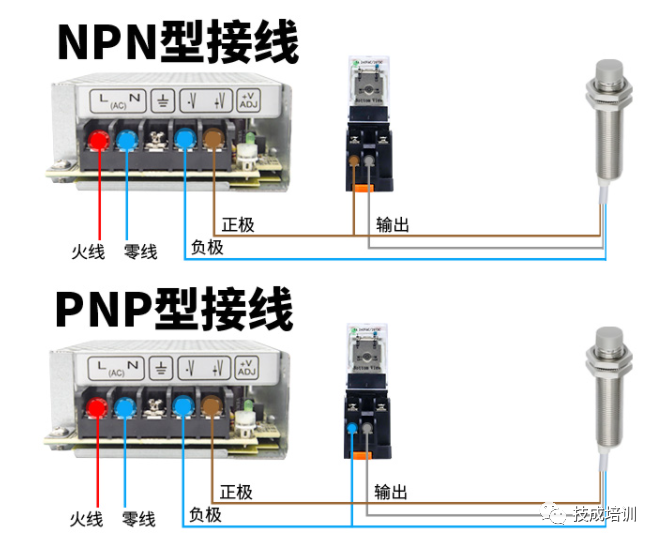

Of course, proximity switches and photoelectric switches also have similarities. Typically, based on the form of the output circuit, both proximity switches and photoelectric switches can be divided into NPN and PNP types. Below, I will also briefly introduce the differences between NPN and PNP. The principle of NPN and PNP sensors utilizes the saturation and cutoff of transistors, outputting two states, which are switch-type sensors, but the output signals are completely opposite, namely high level and low level. NPN and PNP sensors generally have three lead wires: the power supply line Vcc, 0V line, and out signal output line.

NPN Sensor:When a signal is triggered, the output signal line out connects to the 0V line, equivalent to outputting a low level, 0V. For NPN-NO type, when no signal is triggered, the output line is floating, meaning the 0V line and out line are disconnected.

PNP Sensor:When a signal is triggered, the output signal line out connects to the power supply line Vcc, equivalent to outputting a high level, Vcc. For PNP-NO type, when no signal is triggered, the output line is floating, meaning the VCC power supply line and out line are disconnected.

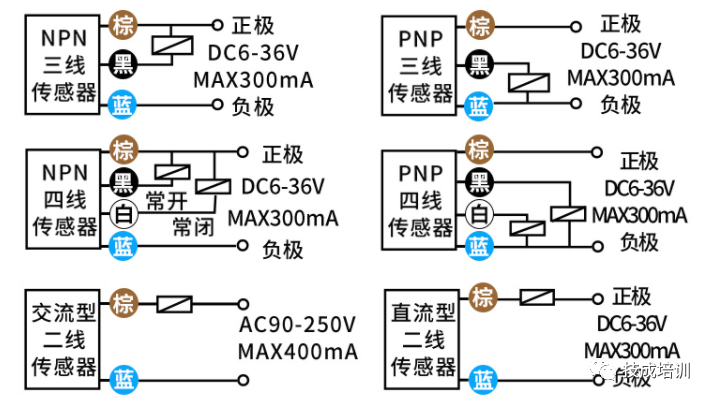

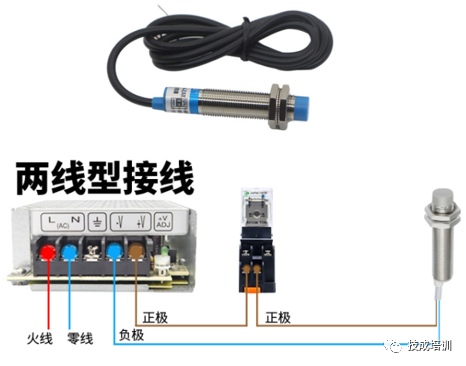

Common sensors are generally three-wire, but there are also two-wire DC, two-wire AC, four-wire, and even five-wire sensors. The wiring schematic is shown below.

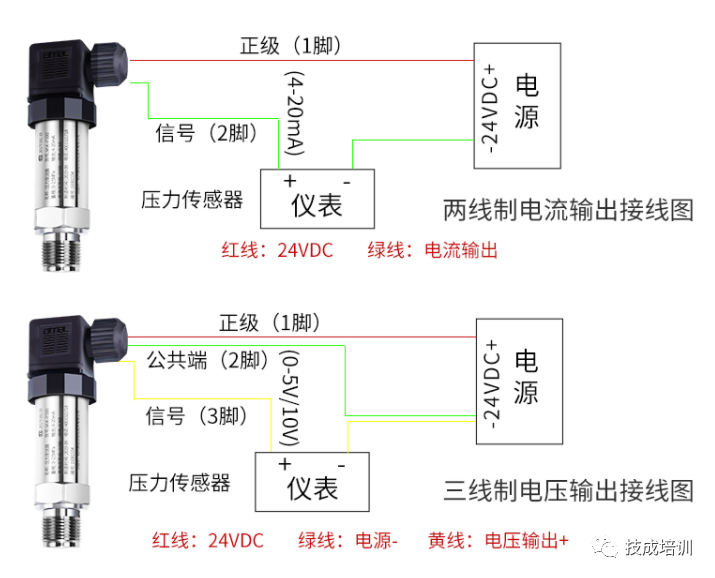

Earlier, we discussed that both proximity switches and photoelectric switches are types of switch sensors. Now, let’s look at analog sensors, with pressure sensors being a typical example. Pressure sensors can sense pressure signals and convert them into usable output electrical signals according to certain rules. Generally, ordinary pressure sensors output analog signals, or over a continuous time interval, output digital signals.

Pressure sensors are one of the most commonly used sensors in industrial control and instrumentation. They come in various types, including piezoresistive, inductive, capacitive, resistive strain gauge, semiconductor strain gauge, resonant types, etc. The most commonly used piezoresistive pressure sensors are typically made using the piezoelectric effect.

Pressure sensors generally have two-wire, three-wire, and four-wire configurations. The two-wire pressure sensor is relatively simple, with one wire connected to the positive power supply and the other wire (the signal wire) connecting to the negative power supply through the instrument. This is the simplest configuration. The three-wire pressure sensor adds one more wire to the two-wire configuration, which directly connects to the negative power supply. The four-wire pressure sensor has two power input terminals and two signal output terminals. Generally, four-wire pressure sensors mostly output voltage rather than 4~20mA output. The 4~20mA type is called a pressure transmitter, and most are made as two-wire configurations. The wiring for two-wire and three-wire pressure sensors is shown below.

The above is a detailed introduction to the functions, roles, principles, and wiring of commonly used sensors. Sensors are frequently used components in industrial control, so remember to save this for future reference!

Complete Question Bank for Beginner Electricians in 2021 (Includes Answers)

Is troubleshooting frequency converter failures difficult? Just one click is enough!

Can you browse all electrical exam questions with just one click? Don’t you have this amazing tool yet?

Which of the five major electrical drawing software (CAD, Eplan, CADe_simu…) do you pick?

Latest Electrical CAD Drawing Software with Detailed Installation Tutorial!

Latest Electrical Drawing Software EPLAN with Detailed Installation Tutorial!

Common Problems for Beginners Using S7-200 SMART Programming Software (Includes Download Links)

Comprehensive Electrical Calculation EXCEL Sheets Automatically Generated! No Need to Ask for Electrical Calculations!

Bluetooth Headphones, Electrician/PLC Introductory Books Given Away? Come and claim your electrical gift!

Basic Skills of PLC Programming: Ladder Diagrams and Control Circuits (Includes 1164 Practical Cases for Mitsubishi PLC)

Still can’t understand electrical diagrams? Take away the basics of electrician diagram reading and simulation software to quickly get started!

12 Free Electrician Video Courses, 10GB Software/E-book Materials, and 30 Days of Free Live Electrician Courses!