▲ Click the blue text to set as a star to prevent losing contact

Exclusive original video every dayIn the past five years, Professor Xu Weiguo from Tsinghua University and his team have used “robotic 3D concrete printing” technology to successively “print” a bridge, a reading room, several parks, and even built a house for a couple from the 1970s—the entire “printing” process took only 160 hours, costing just over 200,000 yuan,

Exclusive original video every dayIn the past five years, Professor Xu Weiguo from Tsinghua University and his team have used “robotic 3D concrete printing” technology to successively “print” a bridge, a reading room, several parks, and even built a house for a couple from the 1970s—the entire “printing” process took only 160 hours, costing just over 200,000 yuan,

the only one in the country.

▲

▲

Interior and exterior of the 3D printed farmhouse in Wujiazhuang

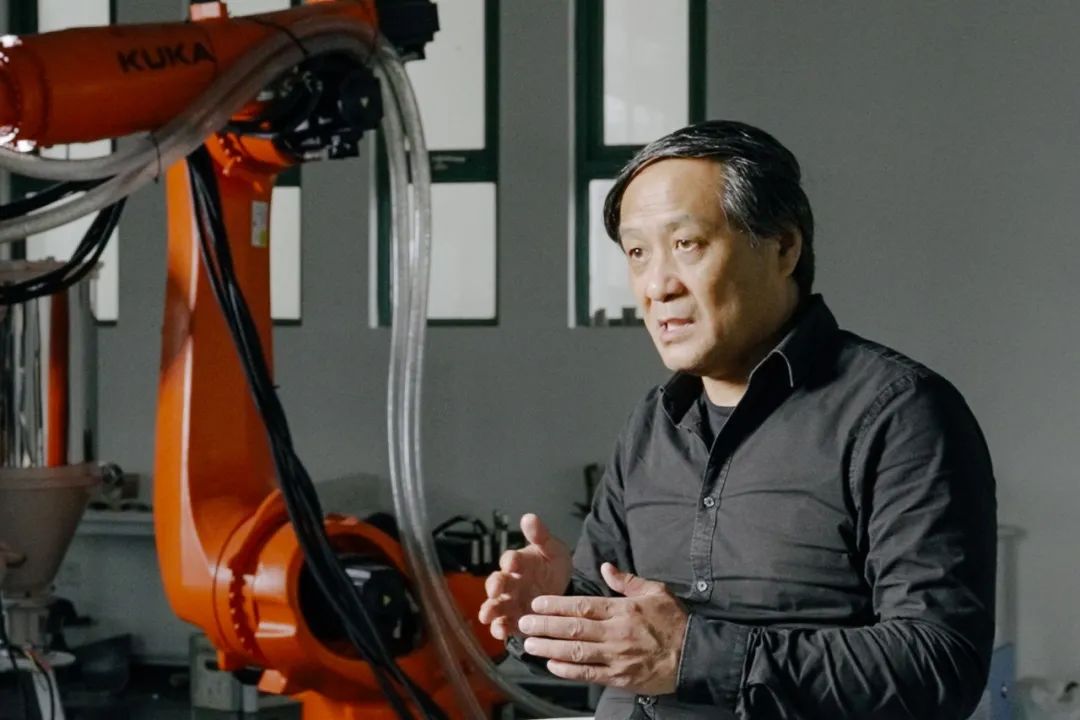

Xu Weiguo is a first-generation student of Tsinghua after the reform and opening up,who stayed on to teach after graduation and later obtained a doctorate in Japan.Since 2003, he has been rooted in the field of intelligent construction,developing his own theoretical and technical system from learning from the West.

For 20 years, he has been a pioneer in cutting-edge architecture in China.

▲Professor Xu Weiguo during an interviewAt the end of January,an interview team visited the Future Habitat Laboratory at Tsinghua University,to explore the printing site and interview Xu Weiguo.He confidently predicts that in 5 to 8 years,3D printed buildings will gradually become popular,and will definitely become the most common construction method,

quickly and cheaply improving the daily living conditions of ordinary people.

Written by: Ye Li

Editor: Chen Ziwen

▲

▲

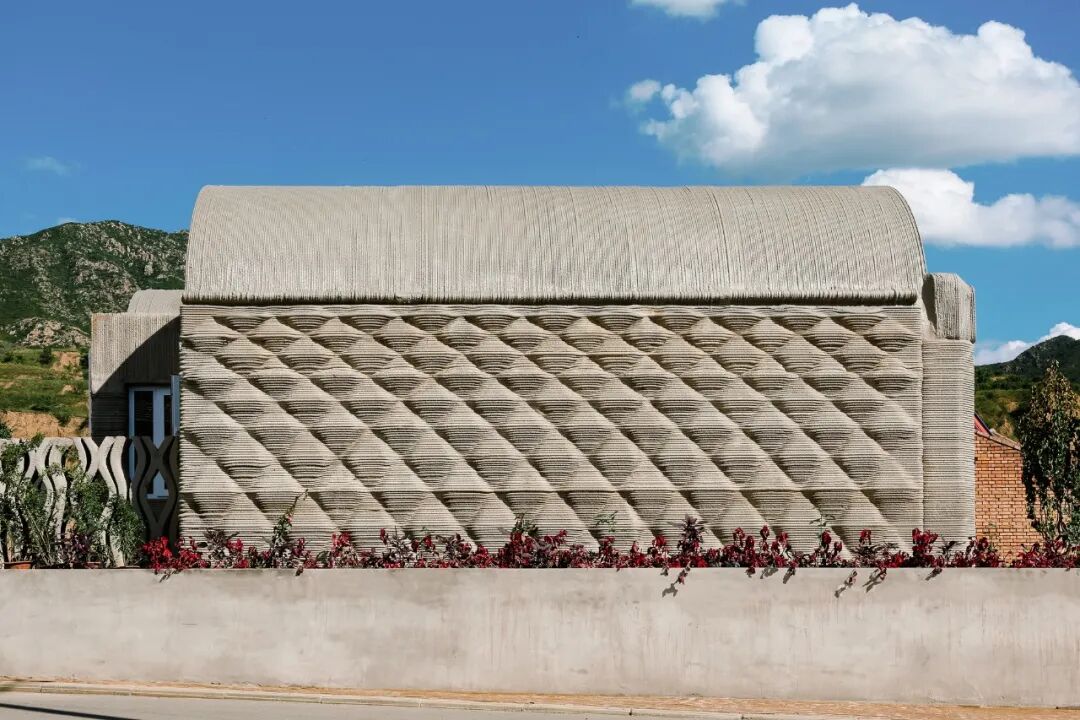

Wujiazhuang 3D printed farmhouse

On the eve of this year’s Spring Festival, in Wujiazhuang village, Hebei, Juanzi’s home was rated as one of the province’s “Top Ten Beautiful Homes”; she immediately informed the architect Xu Weiguo of the news.

The farmhouse where Juanzi lives, 106㎡, is the first house in the country completely built using “3D concrete printing” technology.

The residence is located on the village road in Wujiazhuang, with an arched roof and gray walls, standing out among the many simple earthen houses.

On this ancestral land, the original old house was built with bricks and had a wooden roof. One year during the Spring Festival, Xu Weiguo entered the village for research, “The wind blew directly into the house through the gaps in the windows and walls, making the indoor temperature extremely low.”

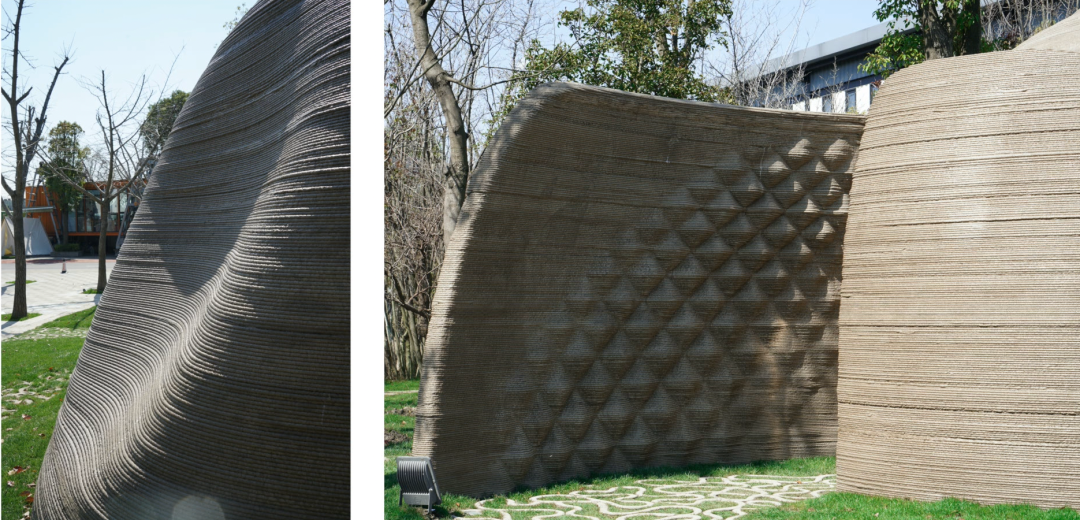

▲

Above: West facade of the 3D printed farmhouse

Below: Details of the courtyard wall

To address this, when building a house for Juanzi’s family, the walls of the building were carefully designed. The outer wall used a woven texture as decoration, integrated with the structural wall during printing. The inner side of the wall has a hollow space filled with foam insulation material, meeting energy-saving requirements.

The entire building is very sturdy, keeping cool in summer and warm in winter, and has passed seismic tests.

▲Bedroom of the 3D printed farmhouse

▲Bedroom of the 3D printed farmhouse

The interior has 5 rooms, including two bedrooms, a living room, a bathroom, and a kitchen, and the family is very satisfied. The interior is particularly bright due to the arched ceiling.

The new home has been completed for less than a year, but many people have already lined up to visit Juanzi’s house, “Some even ask if I want to turn it into a guesthouse.”

Juanzi and her husband are both from Wujiazhuang, born in the 1970s, and have worked outside for many years. Now Juanzi has returned to work at the village committee. Why were they willing to try a 3D printed house, which has no precedent in the country? Would they feel the house is too conspicuous?

Juanzi mentioned a detail: once, when Xu Weiguo and his wife came to the village, they showed her a bridge they had printed in Shanghai, and she felt reassured, “I have the land, he has the idea, we hit it off immediately! Our family is eager to try new things.”

▲

▲

Bird’s eye view of the 3D printed farmhouse, much sturdier than surrounding houses

▲

Robotic concrete 3D printing process

▲

▲

3D printed woven texture wall

During construction, due to the narrow roads in the village, large trucks could not enter, so the team invented a small vehicle with a robotic arm mounted on it, which was used to transport materials into the farmhouse.

With just two people operating, one robotic arm can start printing, and three robotic arms can work simultaneously.

The nozzle at the front of the robotic arm extrudes fiber concrete material, layering it from the foundation to the walls, with the entire construction process completed on-site, attracting the attention of the entire village.

The construction period for the house is very short, with the entire “printing” process taking 160 hours, and it can be completed in about two weeks. In the future, if built in batches, two houses can be constructed in a month.

The cost is also very low, including simple interior decoration, costing about 2000 to 2500 yuan per square meter, with a 100㎡ house costing only around 200,000 yuan, cheaper than steel structure prefabricated buildings.

Xu Weiguo remarked, “This technology is very worthy of promotion in the construction of rural houses across the country.”

▲

▲

Concrete 3D printed bridge

The first completed project of Xu Weiguo’s team was quite “explosive”: they built a bridge.

This pedestrian bridge is located in Baoshan District, Shanghai, measuring 26.3 meters long and 3.6 meters wide, resembling a gray ribbon floating on the river, with a steep slope. The bridge railings are streamlined and integrated.

Two 3D printing robotic arms completed all concrete components in 450 hours. The components were then transported to the site for assembly. The cost was only two-thirds of that of a conventional bridge.

▲

The printing material is mainly polyethylene fiber concrete, along with additives, which is a new composite material independently developed by the team.

▲

3D printed bridge deck, assembled on-site

This bridge is inspired by the single-arch structure of the ancient Chinese “first bridge”, the Zhaozhou Bridge, and has undergone destructive testing to ensure it can support a full load of pedestrians.

The intelligence of this pedestrian bridge also lies in the fact that it is embedded with a real-time monitoring system, capable of collecting data on the bridge’s stress and deformation status, aiding in future tracking.

In 2020, the news column of the journal “Nature” published an article discussing the latest developments in 3D printing technology, highlighting the goals of printing “larger, faster, and stronger”, which included this “world’s largest 3D concrete printed bridge”.

▲

3D printed reading roomNear the 3D printed bridge, in 2021, the team also attempted to build a public reading room of less than 30 square meters, which can accommodate 15 people. Two robotic arms worked continuously and completed it in 5 days.

▲

Shenzhen 3D Printing Park

▲

3D printed landscape features

Various shaped landscape features have a significant advantage with 3D printing.

In 2022, the Shenzhen 3D Printing Park was completed, with undulating terrain and streamlined seating that appears to have “grown” directly from the ground. Groups of curves simulate natural forms like valleys and streams.

▲

3D printing landscape feature process

Today, Xu Weiguo leads a team of over 20 people, many of whom are post-90s. In addition to architects, there are structural designers, mechanical designers, PhDs specializing in robotics, software engineers, and materials engineers…

The team is dispersed across three locations: R&D in Shenzhen, production in Wuxi, and part of the design team in Beijing.

The workflow involves the team first building the house in the computer, then planning the robotic arm’s path, converting the path into code, and inputting it into the robotic arm’s control system. This way, only one or two people are needed at the printing site.

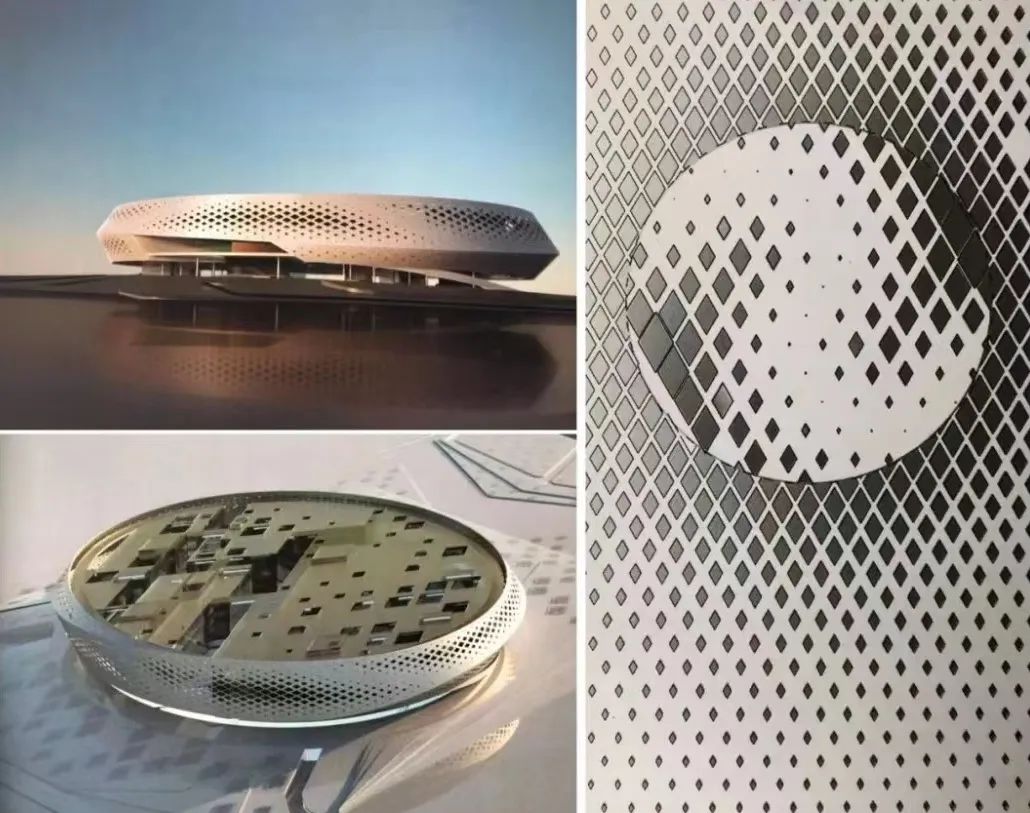

▲

Early digital architectural design works

Xu Weiguo is one of the first university students after the reform and opening up, having entered Tsinghua University to study architecture in 1978. On one hand, he studied, taught, and wrote at Tsinghua; on the other hand, he obtained his doctorate in Japan, and has also taught at the Southern California Institute of Architecture and the University of Southern California.

In 2003, he was one of the curators of the China Architecture Art Biennale and went abroad for research. While visiting the Pompidou Center in Paris, he was deeply moved by an exhibition called “Non-standard Architecture”.

12 pioneering architects from around the world showcased future buildings designed with digital technology, all of which were irregular, non-standard geometric forms, some resembling organic shapes, more like sculptures or art, “very different from traditional architecture”.

He was already very interested in the latest architectural trends and had a strong premonition at that time, “This will be a new direction for architectural exploration”.

▲

Some works by young architects at the China Architecture Art Biennale curated by Xu Weiguo in 2006

Upon returning to China, Xu Weiguo immediately began inviting leading architects and scholars in this field to hold exhibitions and lectures in China.

Since 2004, he has hosted five China Architecture Biennales, each with around 50 young firms participating, and invited over 20 of the world’s most avant-garde architectural schools to showcase student works in Beijing.

A British scholar who was invited to collaborate once told him that currently, he might be the only person in China who knows what digital design and algorithmic design are.

“Once I understood this field and delved into it, I never came out,” Xu Weiguo describes his experience over the past 20 years.

In the first 10 years, he mainly focused on research in intelligent construction, gradually forming his own theoretical and structural system.

In 2017, two of his early students returned to China and joined his team, starting to industrialize the technology. The past five years have focused on applying “robotic 3D concrete printing” technology to practical construction.

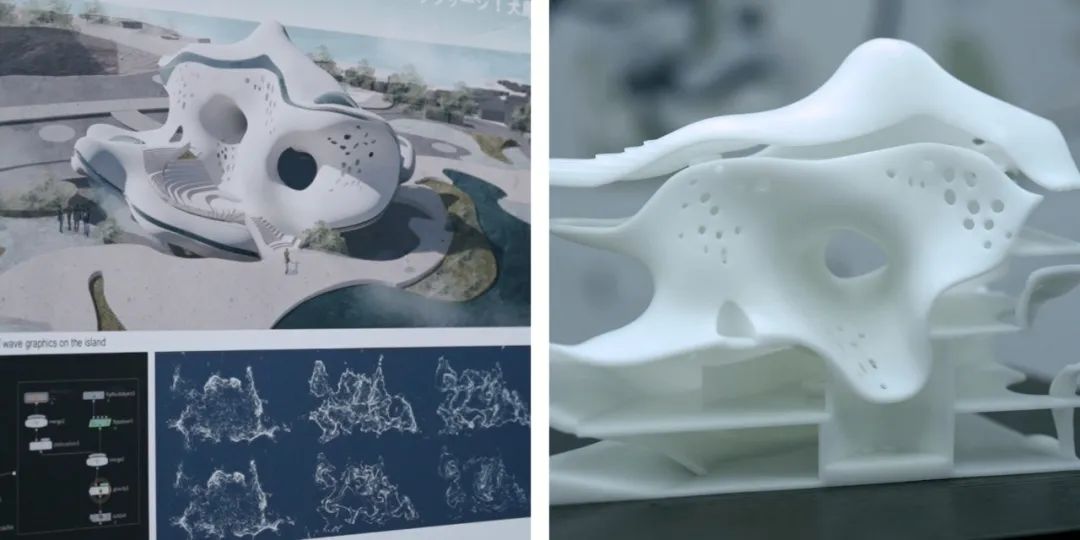

▲

Xu Weiguo at work

▲

Student design works guided by Xu Weiguo

In the past three years, Xu Weiguo has established the “Future Habitat Research Institute” at Tsinghua University’s Shenzhen International Graduate School, with students mostly from the post-95 and post-00 generations.

He gives students alternative design assignments, such as: building houses on Mars.

“Reflecting on how humans originally built homes using natural materials, the primary goal was economic and practical, which is similar to our current design for Martian habitats. Using intelligent 3D printing methods to create the building shell along with the interior in one go should be a visible future for us.”

▲

Developing 3D printed housing for low-income families in Africa

Will houses built by computers and robots feel cold and lack a human touch?

In Xu Weiguo’s view, machines are more friendly and understanding than humans.

“Machine intelligence gathers different types of human intelligence together, just like AlphaGo was able to defeat its opponents because it concentrated the wisdom of many people.”

“Machines may seem cold, but they also condense the warmth of different people, forming a new sense of warmth that is more nuanced and comprehensive than a single-dimensional human perspective.”

▲

Visitors experience concrete 3D printing works at this year’s “Shenzhen Biennale”

What is the future of 3D printed architecture?

When answering this question, Xu Weiguo’s tone is firm, and his eyes shine, “In the future, it will definitely become the most common construction method,” he pauses and adds, “This is undoubtedly our firm belief after years of contemplation.”

“Currently, the development stage of ‘robotic 3D concrete printing’ technology can be likened to a 400-meter race, and we are about 150 meters in. The technology is still being developed. It will take some time to fully mature to the level of brick-wood structures, brick-concrete structures, or reinforced concrete structures.”

▲

Can work continuously in different scenarios and time periods

Why is there such optimism?

He believes that on one hand, we are gradually bidding farewell to the industrial society and moving towards an intelligent society. The production and construction modes of 3D printed architecture match the intelligent society, possessing strong vitality, and can be tailored to each person’s life, just like wearable devices.

On the other hand, construction workers are becoming increasingly scarce. If robots can replace some of the construction work, leaving only a small number of people for programming and control operations, it will liberate people from heavy physical labor.

In Xu Weiguo’s view, architects do not necessarily have to create famous landmarks or viral buildings, or win awards, “Meeting the living needs of the vast majority of ordinary people—that is the core purpose of our technology development.”

In the past three years, 3D printed architecture has been sweeping the globe, with some cities already starting to publicly sell 3D printed houses. The number of floors is no longer limited to single-story; two-story and multi-story 3D printed houses have become a reality.

Let’s dream a little more wildly: avant-garde architects around the world are beginning to experiment with various new and old materials, combining them with 3D printing technology to create uniquely designed small buildings, responding to the post-pandemic era’s desire for more comfortable, nature-friendly, and energy-efficient living.

1. Spherical 3D printed house

Location: Japan

▲

▲

Image source: Serendix

Last year, a startup in Hyogo Prefecture, Japan, printed a spherical 3D printed house in less than 23 hours and 12 minutes, making it Japan’s first 3D printed house completed within 24 hours.The 10-square-meter house is priced at 3.3 million yen (about 170,000 yuan), and six spherical houses have been sold out.This year, the company plans to launch another “luxury version” of the 3D printed house, covering 49 square meters, equipped with electricity, water, and gas, as well as a bathroom, making it convenient for immediate occupancy, with an estimated price of 5 million yen (about 250,000 yuan).

“Our goal is to make buying a house as easy as buying a car, freeing everyone from mortgages.”

2. East 17th Street Residential AreaLocation: USA

▲

Image source: ICON

The East 17th Street Residential Area is the first 3D printed residential area for sale in the USA, consisting of four houses, each with two to four rooms. The houses are built using ICON’s proprietary 3D printing technology, combined with advanced new materials, and are expected to have a longer lifespan than traditional building materials.

The printing construction of this area took only 7 days. Since completion, these concrete printed houses have withstood the tests of a 7.4 magnitude earthquake and severe storms.

3. 3D printed rental houseLocation: Netherlands

▲Image source: Houben & Van MierloThis giant stone-shaped residence was designed by the Houben & Van Mierlo studio, in collaboration with the 3D printed housing research team from Eindhoven University of Technology in the Netherlands.

▲Image source: Houben & Van MierloThis giant stone-shaped residence was designed by the Houben & Van Mierlo studio, in collaboration with the 3D printed housing research team from Eindhoven University of Technology in the Netherlands.

This project is the world’s first 3D printed rental housing development and also the first long-term 3D printed residence in Europe.

4. Two-story houseLocation: Germany

▲

▲

Image source: PeriThis two-story detached house is Germany’s first completed 3D printed house, with each floor having about 80 square meters of living space.

The uniqueness of this project lies in the use of a new type of 3D printer called BOD2, developed by Danish manufacturer COBOD, which adds pipes and other internal components during the printing of the building structure, achieving high printing efficiency, with 1 square meter of double walls printed in just 5 minutes.

5. Curved houseLocation: USA ▲

▲

Image source: WATGThis house, named “Curved Attraction”, is built from 3D printed plastic, carbon fiber panels, and glass walls. The dynamically curved exterior walls not only have aesthetic appeal but also provide optimal structural stability, making it the world’s first free-form 3D printed residence.

The house covers an area of about 90㎡, and the architectural design is by the WATG team, an international team with over 70 years of experience. The building structure uses a free-form printing process developed by Branch Technology, which represents a breakthrough innovation in building technology. At the same time, the entire structure achieves net-zero energy consumption.

6. Summer HouseLocation: Netherlands ▲

▲

Image source: DUS ArchitectsThis independent micro house occupies only 8㎡, with a volume of just 25m³. The core structure is made from black sustainable bioplastics 3D printed, with geometric walls. The printed patterns at the porch extend outside the house.

The interior is equipped with a foldable sofa and modular decorations that can be pulled out to become a sofa bed when needed, making it a very suitable “mini dwelling” for urban seclusion, with a 3D printed bathtub outside.

The materials used for printing can be fully recycled and reprinted, meaning the entire small house can be completely crushed and 100% reused.

7. Casa CovidaLocation: USA

▲Photography: Elliot Ross, Emerging Objects

Image source: Emerging Objects

Casa Covida consists of three cylindrical structures, located in the desert of Colorado. The earthen walls of the residence are 3D printed by robotic arms, using a traditional mixture commonly used in local masonry, made of sand, silt, clay, water, and straw, and then sun-dried.The interior space includes a double bedroom, a bathroom, and a central living area with a fireplace, with the cooking utensils also 3D printed using local clay.

This small residence was born out of the need for social distancing during the COVID-19 pandemic, suitable for two occupants.

Some images provided by Xu Weiguo’s studio

▼