Can Microcontrollers Replace PLCs?

Microcontrollers cannot completely replace PLCs. Although microcontrollers can achieve similar functions through programming, they are relatively less reliable and stable compared to PLCs.

PLCs are widely used in industrial control and automation due to their excellent programmability, real-time performance, and stability.

PLCs have several advantages over microcontrollers, which make them irreplaceable in certain applications:

1. High Reliability

PLCs use industrial-grade components, ensuring reliable and stable performance. Their internal mechanisms are complex and precise, running stably, which rarely results in issues like crashes or blue screens, and they have a long lifespan.

2. Strong Anti-Interference Capability

PLCs typically have stronger anti-interference capabilities and higher stability, allowing them to operate in harsher environments, such as high temperatures, high humidity, and strong electromagnetic interference.

3. Modular and Distributed Control

PLCs can build complex systems through modular and distributed control, supporting multitasking and multi-device coordinated control.

4. Simple Programming

PLC programming is relatively simple, often using graphical programming languages such as Ladder Diagram, Sequential Function Chart (SFC), and Structured Text (ST). This shortens the development cycle and reduces development difficulty.

5. Flexible Input and Output Interfaces

PLCs usually have a larger number of input and output interfaces for easy expansion, and they also have good multi-channel control capabilities for direct input and output operations.

6. Strong Expandability

PLCs can increase functionality through module expansion without modifying the PLC itself.

7. High Safety

PLCs typically have high safety features, ensuring system security through safety modules and protocols.

What Are the Differences Between PLCs and Microcontrollers?

1

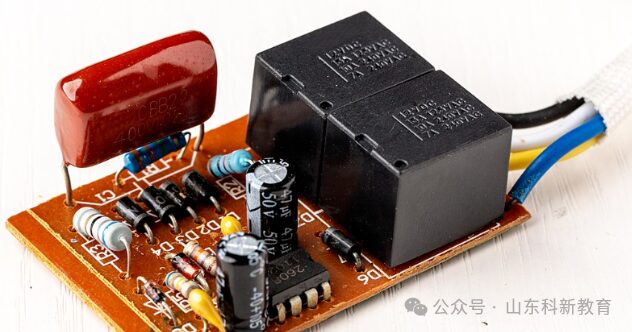

PLC is a mature control system composed of microcontrollers, representing a product of a stable and mature application system of microcontrollers. It has strong versatility.

2

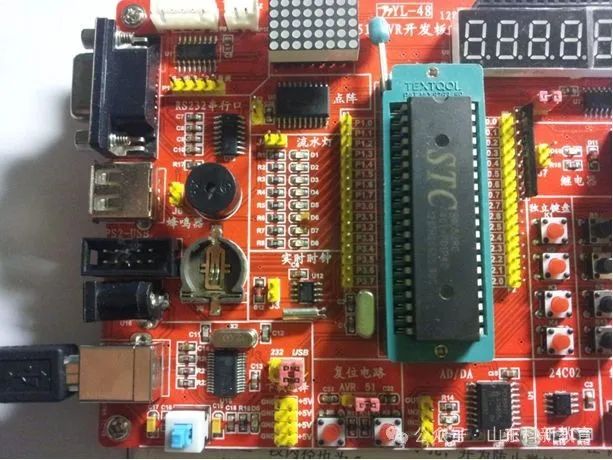

In contrast, microcontrollers can form a wide variety of application systems and have a broader range of use. By itself, a “microcontroller” is just an integrated circuit and must be combined with other components and software to form a system for application.

3

From the engineering perspective, for single projects or projects with very few repetitions, using PLCs is quick and convenient, with high success rates and reliability, though at a higher cost.

4

Essentially, a PLC is a complete microcontroller system

that has been developed with supporting programming software, using simple programming languages to replace the basic languages of computers, greatly simplifying application programming.

PLCs widely use Ladder Diagrams, Statement Lists, Function Blocks, etc., to replace computer languages, providing a certain advantage in programming. You can think of Ladder Diagrams as a programming language similar to assembly language; the only difference is the scope of use! Typically, PLC software converts your Ladder Diagram into C or assembly language, which is then compiled into machine code using an assembler or C compiler! What PLCs actually run is just machine code. Ladder Diagrams make usage easier, lowering the requirements for users and shortening the development cycle.

Of course, you can also develop control systems directly with microcontrollers, but this requires a high level of expertise (not something that just anyone can handle). First, a certain language foundation in C or assembly language is needed, and second, familiarity with electronic circuits and hardware is essential, along with a significant amount of programming experience. Even an experienced engineer will need to go through designing circuits, writing programs, testing, and then starting mass production, followed by modifications and maintenance based on feedback from industrial sites to stabilize the system, resulting in a long development cycle and high costs.

Therefore, to learn PLC programming, one only needs to systematically study PLC programming instructions and advanced functions such as interrupts, high-speed counting, high-speed pulses, communication, and analog applications, along with some on-site experience, to quickly complete the design of small projects independently. For those looking to engage in industrial automation programming, learning PLC is the best choice.

In summary, microcontrollers and PLCs differ in applications, methods of function realization, structure, interfaces, reliability, stability, costs, and programming debugging. In practical applications, it is essential to choose the appropriate control system based on specific needs and conditions.

Source: This article is reprinted from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us for removal. Thank you!

Scan to Follow

WeChat ID|13615417996

Follow the QR code on the left to get

【Siemens Data Collection】