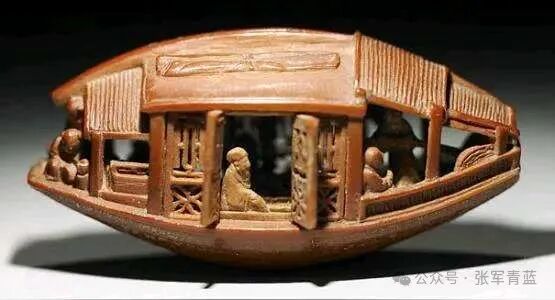

In a middle school eighth-grade Chinese textbook, there is an article about Wang Shuyuan, a craftsman from Jiangnan during the Ming Dynasty, who carved a painting of Su Dongpo’s night tour of Chibi on a jujube pit.

The eight carved windows can be opened and closed, with inscriptions on the window frames reading “The mountain is high, the moon is small” and “The water recedes, the rocks emerge”; inside the cabin, there are tea cups and incense burners, with five characters each displaying different expressions—Su Dongpo is reading intently, Huang Tingjian is whispering over the table, and the beads of the monk are surprisingly able to turn one by one.

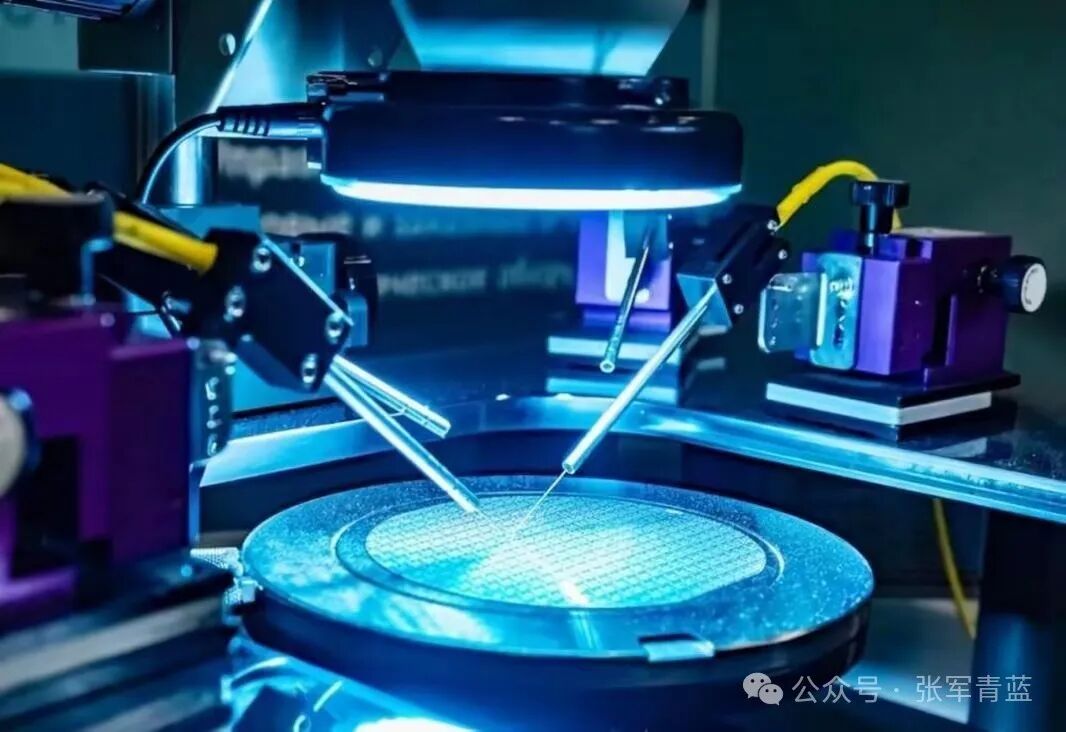

This legendary tale from “The Core Boat” has transformed into a circuit wonder on silicon chips four hundred years later: when the Dutch lithography machine focuses 1980 beams of extreme ultraviolet light into a spot of 0.000000001 meters, etching transistors smaller than bacteria onto a 12-nanometer thick photoresist, humanity has finally reproduced the meticulous philosophy of Eastern civilization in the silicon-based world.

1. The Nanotechnology Carved in DNA

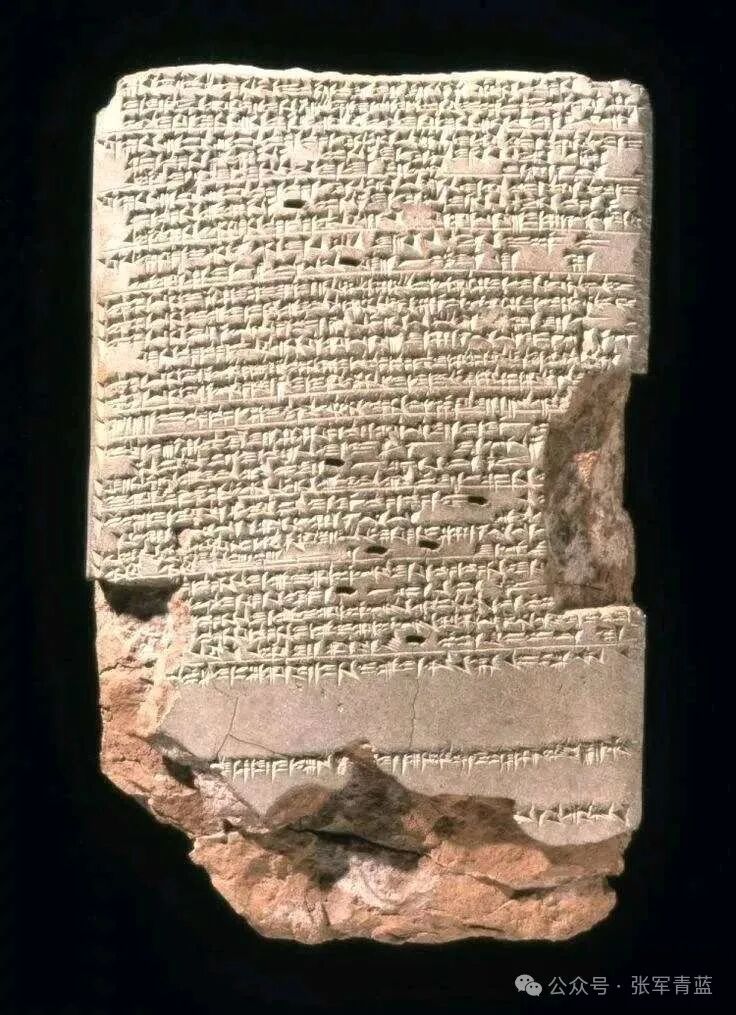

Among the top ten chip giants globally, eight CEOs, including Jensen Huang of NVIDIA, Lisa Su of AMD, and Hock Tan of Broadcom, are of Chinese descent. This is no coincidence, but a transmission of craftsmanship spanning millennia. When Mesopotamia inscribed cuneiform on clay tablets,

the ancient Egyptians were painting sacred images on papyrus, while the Chinese were already carving 0.1 millimeter micro-sculptures on oracle bones and casting millimeter-level mortise and tenon joints on bronze ice basins. The movable type printing technology recorded by Shen Kuo in the Northern Song Dynasty,

is essentially the earliest form of “chip manufacturing”—carving type molds (designing chips), arranging and combining (wafer testing), and ink printing (mass production). This pursuit of “extreme precision” reached its peak in the Ming Dynasty’s core boat and the Qing Dynasty’s snuff bottles, ultimately transforming into the core competitiveness of the semiconductor industry by the end of the 20th century.

(The ice basin of Zeng Houyi from the early Warring States period)

In the 1980s, in a Boston Chinese restaurant, future chip giants were engineering Chinese who debugged ion implanters in MIT laboratories during the day and discussed CMOS processes while serving plates at night. They were the real characters from “Beijinger in New York”: Chen Liwu integrated the precise control thinking of nuclear reactors into chip yield management when transitioning from nuclear industry to semiconductors; Huang Renxun sketched the prototype architecture of the GPU after cleaning toilets at AMD during the night shift. These overseas students, carrying the “core boat gene,” discovered in the clean rooms of Intel and TI that etching one billion transistors on a silicon wafer is not much different from carving five characters on a jujube pit—the material changes from fruit pit to single crystal silicon, the carving tool changes from a chisel to an electron beam, but the craftsman’s spirit of “a hair’s breadth off leads to a thousand miles of error” remains unchanged.

2. The Chinese Resurgence in the Silicon-based World

The decline of Intel is akin to a “negative textbook” of missed opportunities. In 2005, when Jobs knocked on Intel’s door with the design of the first iPhone, this PC era giant was immersed in its “Tick-Tock” strategy—two years for process upgrades and two years for architecture optimization, completely dismissing the “small-scale” mobile chip market. They did not realize that they were not only rejecting Apple’s orders but also missing the ticket to the mobile internet. When the ARM architecture captured 95% of the market share in the smartphone era, and NVIDIA ignited the AI revolution with GPUs, Intel finally realized: three strategic missteps (missing mobile chips, missing GPU acquisitions, delaying advanced processes) stemmed from losing the original intention of “precision manufacturing”—they spent seven years refining the 14nm node, with yield rates consistently below TSMC’s 90%, just like the core boat craftsman trembling on the last cut, causing the entire boat to shatter instantly.

In contrast, companies led by Chinese have forged “precision” and “innovation” into sharp blades. When Lisa Su took over AMD, she achieved performance surpassing Intel’s 10nm on 14nm with the “Zen architecture,” akin to carving a more complex image on a smaller jujube pit; the CUDA architecture invented by Huang Renxun transformed GPUs from graphics accelerators into the heart of AI computing, just like developing the single boat model of the core boat into a fleet formation. The success of these Chinese CEOs is essentially a victory of Eastern wisdom of “broad and meticulous”—capable of strategically laying out grand architectures while also tackling nanometer-level challenges in processes.

3. The Eastern Awakening of Silicon Civilization

Today, China’s chip industry is undergoing a “core boat-style” transformation. When SMIC’s 14nm process yield exceeds 95%, and Huawei achieves “heterogeneous integration” in 3D packaging technology, we see a modern interpretation of millennia of meticulous craftsmanship. Just as Wang Shuyuan’s core boat underwent over forty processes of selecting the pit, sketching, carving, and polishing, chip manufacturing also requires hundreds of processes such as lithography, etching, and ion implantation—each step demands a focus as if walking on thin ice, and every link tests the patience of “pursuing perfection.”

Some question: why are so many top Chinese CEOs in American companies? Look at the three fires ignited by Chen Liwu after taking over Intel to understand the answer: cutting 15,000 redundant positions, focusing on 1.8nm ultra-fine processes, selling non-core assets to go all-in on chip manufacturing—this is a reflection of the Chinese wisdom of “cutting and letting go.” Meanwhile, thousands of chip companies in mainland China are staging a real-life version of “Hua Shan’s Swordplay”: Liang Mengsong’s team at SMIC breaks through the 10nm bottleneck, Yangtze Memory Technology stacks 12 layers of “silicon-based towers” with 3D NAND, and Huawei HiSilicon builds a self-sufficient ecosystem on EDA tools. These scenes are reminiscent of the core boat craftsman opening up new worlds in a limited space, seeking possibilities in extremes.

From jujube pits to silicon wafers, what changes is the carrier, but what remains unchanged is the pursuit of precision engraved in the genes. As the beams of the Dutch lithography machine cross the Pacific, and Chinese engineers build a technological bridge between Silicon Valley and Zhongguancun, we finally understand: the chip war is not only a competition of technology but also a dialogue of civilizations—those who can carve thousands of troops and horses on a jujube pit will eventually inscribe their own civilizational code in the silicon-based world. As the last sentence of “The Core Boat” states: “Ah, the skill is indeed miraculous!” When this exclamation transcends four hundred years and lands in the clean rooms of the 21st century’s chips, it becomes the strongest annotation of China’s chip rise—precision in soul, what fear of high mountains and long roads?