In the laboratory of Professor Zhang Yihui at Tsinghua University, a robot weighing only 25 grams and the size of a palm is performing a “transformation”: one moment it hovers like a drone in the air, and the next moment it retracts its rotors and transforms into a “small car” speeding on the ground.What kind of cutting-edge technology is hidden in this world’s smallest wireless amphibious robot?

Professor Zhang Yihui is a tenured professor in the Department of Engineering Mechanics at the School of Aerospace Engineering, Tsinghua University. He holds multiple positions in organizations such as the Chinese Society of Mechanics and the Chinese Institute of Electronics, and has received the National Outstanding Youth Science Fund and the Science Exploration Award.

What untold stories lie behind the research efforts of Professor Zhang Yihui’s team? Why has he repeatedly achieved cutting-edge international scientific results? In this episode of “Research Scene,” we listen to the innovative thoughts of this post-80s scientist.

Rewriting the Rules of Multimodal Microrobots

Creating a robot that is both small and light, wirelessly controlled, and capable of complex shape-shifting is extremely challenging.

In terms of form, previously reported amphibious robots typically weigh over 450 grams, while our developed robot is particularly small, measuring only 9 centimeters in length and weighing 25 grams, fully wirelessly controlled, making it the smallest and lightest known micro wireless amphibious robot in the world.

Functionally, compared to traditional small drones, it possesses both land and air movement modes and can change its form, flexibly switching modes according to the environment, demonstrating stronger environmental adaptability and longer endurance.

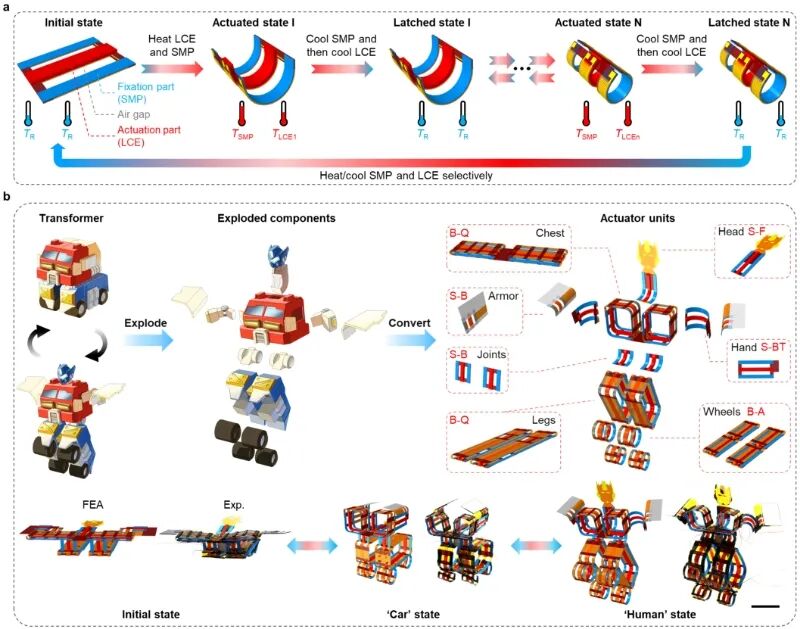

The realization of these features primarily stems from a core original technology: a small actuator with continuous deformation and locking capabilities. This is the “heart” of the microrobot and represents our innovative achievements in the collaborative design of materials and structures.

This film-like micro actuator, measuring only a few millimeters at its smallest, can be controlled electrically to allow the microrobot to achieve continuous shape changes like a “Transformers” character, and can also “lock” its specific action forms, enhancing its environmental adaptability—something that was previously difficult for small-scale actuators to achieve.

Based on this actuator, we have achieved on-demand switching of the robot’s form, enabling both ground travel and aerial flight capabilities, while maintaining lightweight and compact design, and adapting to complex terrains such as rugged ground, narrow passages, or tree holes.

The image shows the small-scale actuator with continuous deformation and locking capabilities. (a) is a schematic diagram of the actuator’s deformation and locking; (b) is a “Transformers” actuator based on a “building block” design strategy. (Scale: 10mm)

From an application perspective, this technology greatly expands the application space of robots. For example, it can be used in equipment fault diagnosis and repair, geological and cultural relic exploration, replacing humans in performing various tasks in complex and hazardous environments. In the field of medical devices, such as implantable devices, electronic stents can enter the body in a folded state and then expand. In the future, we also plan to apply this technology to tactile feedback or virtual reality fields, enriching human-machine interaction modes.

Trade-offs and Innovations: From “Land, Sea, and Air” to “Land and Air”

Looking back at the entire project, from the initial concept to experimental success, the team invested more than two years of effort.

In fact, since 2017, our research group has been engaged in the field of microrobots. Early on, we successfully developed a micro soft-bodied wall-climbing robot that can climb on various complex surfaces such as cylindrical, spherical, and wavy walls, and even perform impressively on leaves or bamboo joints.

Additionally, we collaborated with partners to develop a passive micro aerial vehicle inspired by wind-dispersed seeds. This flying device is lightweight and can spin stably in the air while descending at a very low speed, achieving ultra-long hovering time.

In our early research, we accumulated rich experience in developing soft actuators and deeply recognized the importance of shape reconstruction capabilities for microrobots, which can endow robots with diverse movement modes and enhance their environmental adaptability.

Initially, our goal was to develop a tri-modal robot capable of operating in land, sea, and air. We spent more than half a year attempting this, and while we initially achieved surface movement on water, the results were not ideal. After in-depth discussions and careful consideration, we decided to focus first on amphibious functionality, achieving it step by step before pursuing greater breakthroughs.

While researching amphibious robots, another challenge arose: how to reduce the size and weight of the motor while enabling it to have complex deformation capabilities? Existing actuators struggle to achieve both continuous shape change and configuration locking at small scales (e.g., less than 5 centimeters), and it is also difficult to achieve decoupled deformation and locking control, which severely hinders the miniaturization and wireless development of multi-modal robots.

My doctoral student Xu Shiwei is the main person responsible for this work. In the early research, he had already mastered the processes and application characteristics of smart materials (liquid crystal elastomers and shape memory polymer materials with controllable deformation capabilities).

Professor Zhang Yihui (right) guides students in experiments.

However, merely understanding material properties is far from sufficient; another challenge lay ahead: how to organically integrate these two materials so that they do not interfere with each other during the electrical control process, allowing them to work independently while also cooperating.

Thus, we boldly innovated in structural design, fully leveraging the team’s strengths in mechanics and structural design, introducing cavity designs to achieve thermal isolation using air. This way, the same power source can control both deformation and locking functions without interference, while allowing for close cooperation.

Through the clever integration of innovative materials and structural collaborative design, we successfully solved the problem of continuous deformation and locking in small-scale actuators.

In terms of process, achieving seamless integration of the actuator with the robot system was also challenging. To enable the robot to switch forms controllably and move flexibly on the ground and in the air, we meticulously optimized the actuator’s size, thickness, and other parameters.

Ultimately, through the hard work and efficient collaboration of team members, we successfully overcame the challenges. In fact, many of our research projects have long cycles, and the fact that this project was completed in just over two years is largely due to the students’ efforts.

At the International Forefront, Delving into Key Mechanical Challenges

In 2015, I returned to China from Northwestern University to join Tsinghua University.For over a decade, our research group has consistently kept pace with the forefront of global technology, actively responding to the country’s major needs in the field of science and technology, and delving into key mechanical challenges in the design and manufacturing of three-dimensional micro-nano structures and micro-nano electronic devices, providing theoretical foundations and manufacturing pathways for innovations at the device or system level.

We conduct comprehensive and in-depth research, extending from fundamental mechanical design methods and theories to device structures, processing techniques, and application levels, advancing layer by layer from technical breakthroughs to innovative applications.

In device and structure manufacturing, three-dimensional assembly manufacturing technology is our research group’s original “secret weapon.”

We innovatively proposed using buckling mechanics to assemble three-dimensional micro-nano structures. Simply put, we first create easily formable two-dimensional micro-nano structures or devices under mature semiconductor two-dimensional planar processing techniques, and then use mechanical loading to transform them into three-dimensional structures. With this technology, we were the first in the world to complete the assembly and reconstruction of complex three-dimensional structures of single-crystal silicon on soft substrates.

Nature is our source of inspiration. The porous microstructures of many plants are crucial for their formation and morphological development. Inspired by this, we proposed the concept of micro-lattice design, established theoretical models and machine learning design methods, and achieved customized design and fabrication of over 30 types of three-dimensional complex curved surfaces at micro and even nano scales.

This achievement has broad application prospects. For example, we have developed breathable three-dimensional electronic devices that can conform to the surface of the heart, and three-dimensional electronic cell scaffolds that mimic the retina.

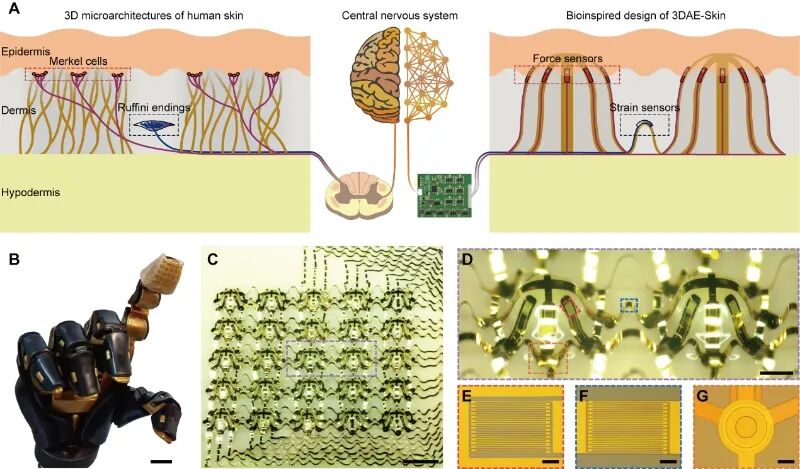

We have also created a bionic three-dimensional architecture for electronic skin devices, achieving decoupled measurement of pressure, shear force, and strain at the physical level. Combined with deep learning algorithms, we developed an advanced tactile system that can measure both the modulus and local principal curvature of an object through touch alone.

The electronic skin with a three-dimensional architecture: bionic design concept and real device images.

This achievement has enormous potential in the field of robotics, enabling robots to have tactile perception and effectively interact with the external environment. For instance, a robot equipped with this electronic skin can sense the hardness and surface curvature of fruit upon touch, determining whether it has spoiled. This work has been praised by top experts in the field of electronic skin technology as a “significant advancement in electronic skin technology,” with the proposed “innovative path” endowing electronic skin with “sensory capabilities never before possessed.”

In recent years, we have made some important progress in scientific research, which I believe is mainly due to the research group’s long-term emphasis on interdisciplinary integration, focusing on cutting-edge technological issues, and using mechanical principles and interdisciplinary approaches to tackle key problems.

The original technologies we developed not only addressed long-standing pain points in the field but also contributed a small part to the country’s technological development. This makes me feel a great sense of responsibility and understand the extraordinary significance of this work.

Actions Speak Louder Than Words: Breakthroughs by an Interdisciplinary Team

As a teacher, I am often moved by the growth of my students during my years of teaching.

Watching them continuously hone themselves on the path of overcoming challenges and solving problems, maturing from naivety to sophistication, and significantly improving their research capabilities as they successfully cross one hurdle after another fills me with joy and pride.

The path of scientific research is by no means smooth. Many research problems have long cycles, and there are numerous difficulties in the exploration process. However, the students have never given up, working with me to explore new knowledge, learning to proactively identify and solve problems, significantly enhancing their research capabilities.

Take our micro-lattice design project as an example; from initiation to completion, it took five years, during which we experienced countless failures and stagnations.

The concept of micro-lattice design originated in 2018. In the early stages of the project, I assigned a postdoctoral researcher and an undergraduate student to work together. However, as we progressed, challenges arose one after another. On one hand, we lacked preparation experience; on the other hand, the preparation conditions were not perfect, leading to slow project progress. After nearly two years, we still had not achieved significant breakthroughs.

Later, I realized that to make the design not only theoretically feasible but also effective in experimental preparation, we needed to validate the theory. Therefore, I arranged for a doctoral student with strong hands-on and experimental skills to join the team, primarily responsible for experiments and process exploration. After he joined, the project began to show progress. Subsequently, the rise of artificial intelligence and machine learning technologies also provided opportunities for our technological expansion.

With the support of new technologies, we achieved remarkable results in some very complex curved surfaces we designed, including a surface that closely resembles the shape of an ant. This surface, made from electronic device materials, is realistic in shape and comparable in size to a real ant.

Throughout this process, I deeply realized the importance of teamwork, as well as the critical role of experimental and manufacturing processes. Although these foundational works may be briefly mentioned in papers, their importance should not be underestimated.

The entire project lasted five years, during which doctoral students graduated, and postdoctoral researchers completed their tenure. However, we overcame the pandemic and spatial distances, maintaining close contact and continuously advancing our research.

This project illustrates that the success of a long-term project requires a spirit of inquiry and the perseverance to “sit on the cold bench.”

In fact, my research group is not large, but the members have diverse professional backgrounds. Most doctoral students have a background in mechanics, while the postdoctoral team covers multiple disciplines, including electronics, materials, mechanics, and chemistry. This diversity provides strong support for solving complex and comprehensive problems, especially in areas such as electronic devices and microrobots, where talents from different professional backgrounds can showcase their strengths and collaborate effectively to solve problems.

Professor Zhang Yihui (front row, first from the left) with team members.

In our teamwork, we particularly emphasize innovation, unity, and a spirit of hard work. Everyone engages in in-depth discussions, exchanges ideas, inspires each other, and progresses together. It is this sincere cooperation that allows us to continuously break through on the path of scientific research.

I want to say to my colleagues who are striving together on the path of scientific research that we are living in a particularly good era, where technology plays a crucial role in the development of various national undertakings. We must dare to strive, work hard, and not waste this era or our youth.

The motto of Tsinghua University, “Actions Speak Louder Than Words,” has greatly influenced me. It inspires me to keep moving forward on the path of scientific research and constantly reminds me to conduct research with practical actions.

Editor: Chen JinmeiReviewed by:Zhang JingyiEditorial Committee on Duty:Song Yurong

Editor: Chen JinmeiReviewed by:Zhang JingyiEditorial Committee on Duty:Song Yurong

A researcher’s exploration of “human-machine symbiosis” across disciplines

A researcher’s exploration of “human-machine symbiosis” across disciplines

Encountering the Two Sessions on International Women’s Day: How These Four Female Scientists Shine with “Her Power”

We welcome your submissions. Submission email:[email protected]

We welcome your submissions. Submission email:[email protected]

Reprint with acknowledgmentSource: Voice of the China Association for Science and TechnologyWeChat Official Account