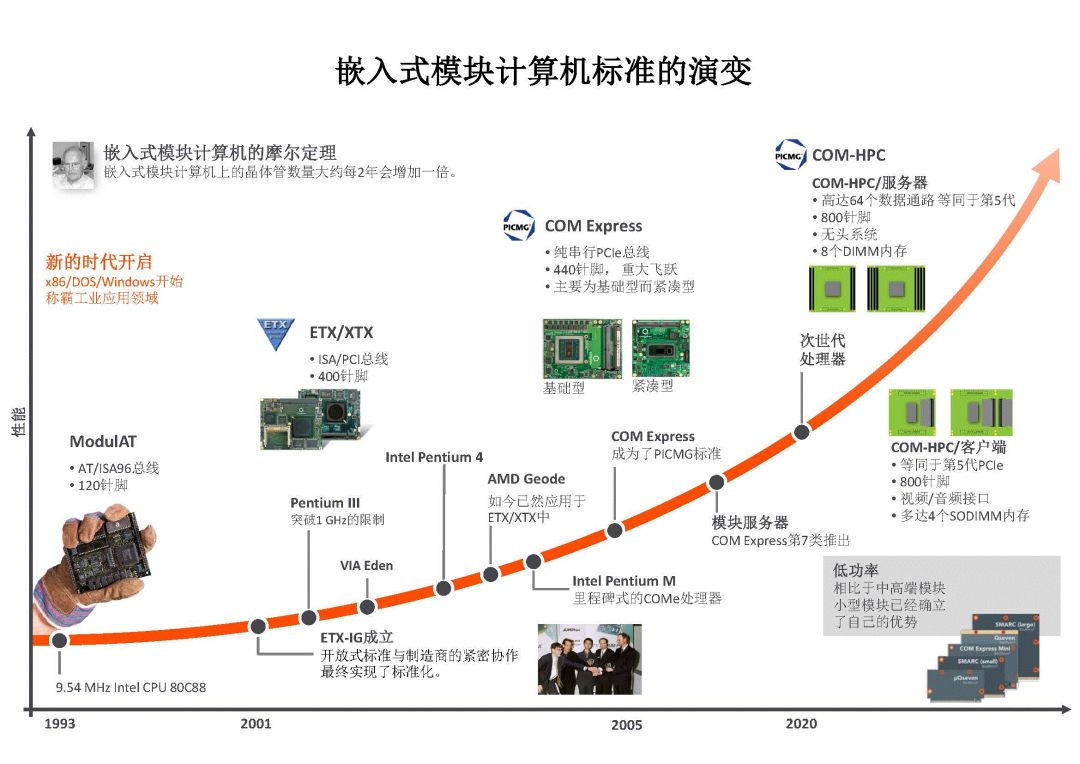

Following ETX/XTX and COM Express, the embedded computer module industry has introduced a product lifecycle that sets a new performance level. This new design standard is known as COM-HPC and has been certified by PICMG, which includes companies like Kontron. With the advancement of 5G networks, ultra-fast real-time data exchange will become a major application area. However, current users of the COM standard need not worry about their solutions becoming obsolete, as the transition will take time, and products based on the current standards will remain on the market for many years to come.

Figure 1

The ETX and its evolution into the COM Express standard are two technical specifications for embedded computer modules that have been standardized through the efforts of multiple independent groups as technology has advanced. Now, the third standard, COM-HPC, is about to be launched to meet the high-performance requirements of broadband, 5G-connected devices, machines, and systems.Since the concept of embedded computer modules (Computer-On-Module, hereinafter referred to as COM) was born, modular computers have become the most important design principle in embedded computer systems.Research by IHS Markit indicates that by 2020, 38% of global sales of embedded computer motherboards, modules, and systems will come from COMs. The first embedded computer module was introduced in the early 1990s by Hans Mühlbauer, the owner of the German company JUMPtec, which is still active today. Based on the then-common AT/ISA96 bus, the first ModulAT module was launched, featuring a 9.54 MHz Intel CPU 80C88 and DRAM memory of up to 640KB.The goal was to make office computer technology more suitable for industrial use, which was unprecedented in the embedded computer field.At that time, industrial computers primarily used 19-inch rack systems, and industrial-grade computers with 100 x 160 mm motherboards were virtually unheard of. The module had 120 pins mounted on the same side as the CPU and components, and at that time, processors did not require complex thermal management considerations.

Figure 2

JUMPtec launched the first ModulAT module based on the then-common AT/ISA96 bus, equipped with a 9.54 MHz Intel CPU 80C88 and DRAM memory of up to 640KB.

The goal of the first module was to avoid concentrating all functions on a single card to reduce the impact of rapid CPU upgrades.In the past, Intel and AMD could release a new CPU every six months. Due to uncertainty about how long older CPUs would remain on the market, modularization was necessary to ensure long-term availability. Of course, the scalability it offered also brought various performance variants. Another focus was to reduce the complexity of I/O board design.When the demand for I/O boards significantly decreased, the cost of PCB design also dropped.At that time, how to reduce power consumption and heat generation with new modules was also a concern.Finally, customers always wanted the latest CPU models, a fact that remains unchanged to this day. Modules can also ensure this advantage.

Modules can also solve cable tangling issues.

However, compared to the AT/ISA96 bus, the ModulAT module was launched later, as embedded computers for industrial use were just beginning to emerge. For example, x86 and Windows had not yet made their mark in the industry, and the battle against blue screen issues was still fierce. In this regard, modules were more like early “pirated” products of a new industry rather than unique products within established module standards.Nevertheless, JUMPtec pioneered the global module business and established standard specifications. In hindsight, this was a significant success.In the mid-1990s, the PC/104 single-board computer (SBC) specification left insufficient space for connectors, making it difficult to install on the same side as the CPU and chipset, further proving the importance of modules. As customers began to demand higher connectivity capabilities, connectors were custom-installed on the opposite side of the PCB to connect more external devices.The design principles of PC/104 also meant that cables had to route I/O to the chassis, exacerbating cable tangling issues and making systems more prone to errors. At that time, good system design meant clean and tidy cable connections.By using dedicated carrier boards, external I/O can be directly connected to the chassis without the need for cables, effectively solving cable tangling issues, which became a major highlight of the module concept.The first ETX module developed by JUMPtec was successfully launched, marking a significant breakthrough in the embedded computer module market.

Intense Competition for the Best Module Concept

However, although JUMPtec established standard specifications, the ETX design, based on ISA/PCI with 400-pin connectors, did not have a smooth journey.Many companies and competing module concepts began to request original equipment manufacturers to provide similar solutions, most of which are now only remembered by loyal fans. Although the scale of embedded computer suppliers at that time was far from what it is today, fierce competition ensued.In November 2001, JUMPtec and Advantech jointly founded the ETX Industrial Group (ETX-IG), launching the first open, manufacturer-independent module standard specification, one version of which is still valid today.Mühlbauer explained at the time: “For example, Advantech, I-Base, IBR, and PCISystems all developed different ETX motherboards and quickly reached market maturity. To ensure the unified development of the global ETX standard, we needed to establish an open ETX alliance.” Within months, other key ETX supporters recognized the outstanding benefits of open standards and joined the alliance. Subsequently, ETX-IG became increasingly significant through mergers and acquisitions, and the variety of module design types gradually decreased. Ultimately, the differences in module design were nearly eliminated. As a result, in the next technology cycle, the embedded computer module industry successfully established new standard specifications, avoiding excessive competition and conflict.

Figure 3

Advantech and JUMPtec established ETX-IG at the SPS/IPC/Drives in Nuremberg.

COM Express Became an Official PICMG Standard in 2005

In 2004, with the widespread adoption of the newly launched PCI Express bus, new processors and chipsets no longer supported ISA, and the industry needed a completely new design concept: COM Express. Although the specification was relatively easy to establish, it was not without challenges.The PICMG, which hosted the standard specification, had to combat various internal obstacles and delays.Ultimately, in July 2005, the embedded computer industry reached a consensus on the PICMG COM Express standard.The concept was proposed in collaboration with Intel in the fall of 2003 and took 18 months to standardize. From the 2010 Rev2.0 to the 2017 Rev3.0, the drafter Christian Eder led the standard’s formulation. He initially worked at Mühlbauer’s JUMPtec, then joined Kontron, and is now serving Kontron in Germany.

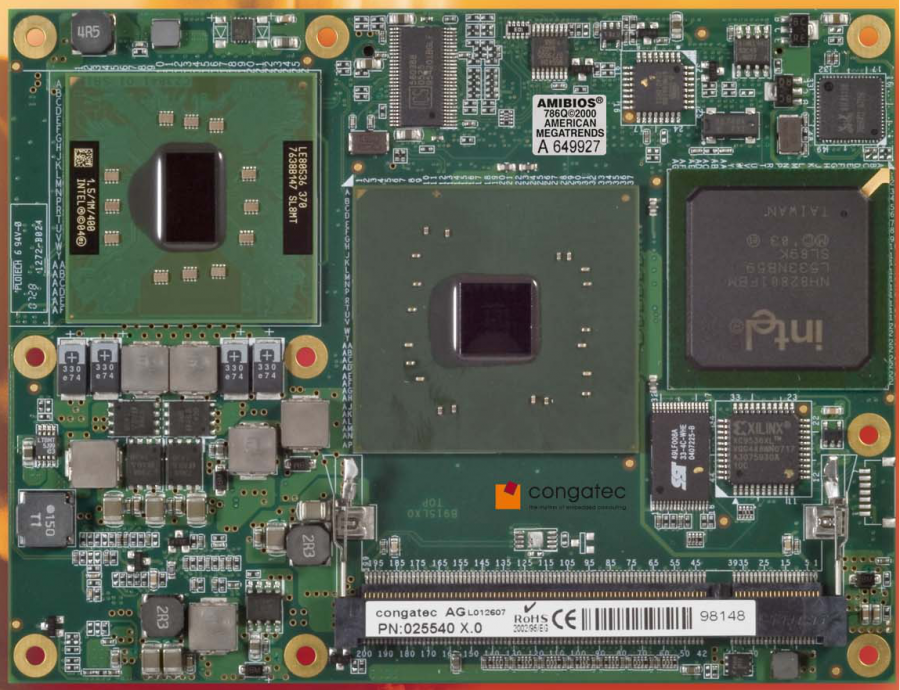

Figure 4

The first COM Express module began mass production in 2005, using the Intel Pentium M processor, marking a true milestone in embedded computer processors.Today, 14 years after PICMG launched COM Express, the embedded computer module market has become the largest and most significant sub-market for embedded computers, with all embedded computer manufacturers able to offer a variety of COM Express modules.Despite this, ETX/XTX modules have not disappeared, indicating that the first computer module (COM) cycle has not yet ended.COM Express took many years to catch up with ETX/XTX, finally surpassing the latter in quantity in 2012. It seems that the saying “if it works, don’t change it” is not only popular in the embedded computer market.

COM Express Modules Remain Unmatched

Today, for mid-to-high-end performance new embedded carrier boards, COM Express remains the undisputed standard specification.It seems that no other standard can compete with it. This standard has undergone several low-profile revisions, with the current version 3.0 released in May 2017, which is one of the benefits of the standard. In the relatively new Type 7 specification, COM Express is designed for embedded edge server applications and can even serve as a benchmark for VITA specifications under extreme conditions. Other module standards, such as Qseven and SMARC 2.0, while both supporting ARM-based application processors, are limited to low-power or small designs.The latest COM-HPC module standard has learned from past lessons: from the outset, this high-performance embedded computer module standard has been developed by PICMG to avoid intense competition between modules as much as possible. For the third-generation module standard, a manufacturer-independent alliance is the ideal ecosystem.

Figure 5

The most powerful COM Express Type 7 embedded server module to date, equipped with an AMD EPYC processor.

The Third Generation of High-Performance COM is Here

Since October 2018, the PICMG working group, chaired by Christian Eder, Marketing Director of Kontron, has been researching the latest COM-HPC module standard. This standard is urgently needed because all new IoT/5G-connected devices require high-bandwidth, high-frequency communication buses, which the COM Express interconnectors cannot support.It means that the embedded computer module standard, conceived and implemented globally for decades, will be established by the same German COM alliance. Currently, the main driving force behind this alliance is Kontron, which was founded in 2005 as a pure computer module supplier to avoid competing with its customers in the system solution market.The company is also the creator of Qseven and SMARC 2.0.

Broadband Networks Require Broadband Computers

As the industry gradually transitions from ETX to COM Express, the introduction of new bus technologies will naturally lead to new standards.The COM-HPC standard aims to set a new embedded computer module standard suitable for PCI Express generations 3 to 5 high-frequency signals in broadband networks.However, just as COM Express did not replace ETX, COM-HPC should not be seen as a replacement for COM Express. As I mentioned earlier, ETX/XTX modules are still usable today, and users can still apply the same design principles even 20 years later. Therefore, the COM-HPC module standard can also ensure that the fundamental concepts that were effective in the past remain valid today. Additionally, the design of new processors is more complex, necessitating the export of I/O from the CPU module through specific carrier boards.

But why not continue developing COM Express? The new COM-HPC standard requires not just new connectors, but many functions in traditional COM Express are no longer needed and need to be removed. This is because the new standard targets application methods that demand much higher performance than the current top COM Express can support.However, its purpose remains to enable original equipment manufacturers to benefit from a large ecosystem and the reputation of PICMG and its standards, thus particularly emphasizing that users can easily complete system migrations. The extensive experience gained from migrating from ETX to COM Express should serve as a reference.For these reasons, there will be two new performance levels above the COM Express Type 7 and Type 6 standards.One category is primarily aimed at edge server technology, which requires more communication interfaces rather than powerful integrated graphics, and features multi-core for workload consolidation. The other category will expand existing high-end embedded computer standards, adding new performance options that COM Express cannot accommodate, including graphics cards, USB 3.2 (20 Gbit/s), USB 4.0 (40 Gbit/s), 4th and 5th generation PCIe with x2/x4 port configurations and retimers, 100/200 Gb Ethernet, NVMe, and other options.

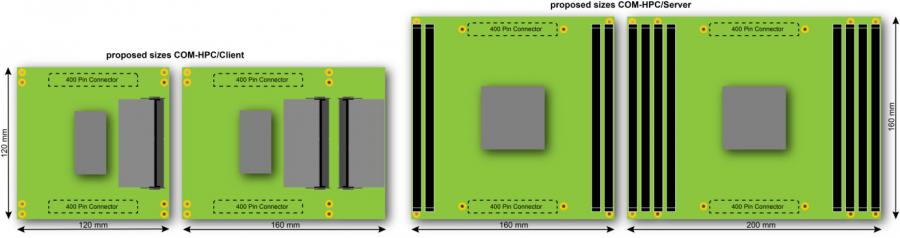

Double the Pins, Up to 8 DIMM Slots

Connectors are a very important part of the new standard. COM Express is limited to transmission speeds of 8 Gb/s and clock frequencies of 5.0 GHz for third-generation PCIe. The new connector can support transmission speeds exceeding 32 Gb/s, equivalent to fifth-generation PCIe. Additionally, it supports up to 65 PCI Express lanes, sufficient to connect many powerful GPGPUs for machine learning. In contrast, COM Express can support a maximum of only 32 PCI Express lanes.COM Express’s performance is currently limited to 10 Gb Ethernet per signal pair, which will also be upgraded to at least 25 Gb Ethernet, making support for 100 Gb Ethernet possible.The new generation of processors for edge computers also requires more interconnects and more space for DIMM slots. The new standard can support up to 8 DIMM slots and 800 pins, while COM Express only has 440 pins.

Figures 7-8

Kontron’s COM-HPC module has two performance categories, similar to today’s COM Express Type 6 and Type 7, divided into Client and Server classes. From the outset, the design area of these two types means that large high-end COM-HPC modules can accommodate up to 8 DIMM slots. The illustrations also clearly show the same layout of inter-board connectors in different sizes.

Some may think that establishing a new standard is easy, but the reality is quite different. Simply increasing signal frequency brings many complex issues.For example, to support modules up to 300W, Kontron and Samtec have been collaborating for two years on the requirements and testing for COM-HPC connectors. However, the PICMG working group was not established until October 2018, meaning much foundational work had already been completed, thus accelerating the decision-making speed of the working group.

When Will COM-HPC Modules Be Released?

Companies involved in the standard-setting process are currently eagerly awaiting, hoping the process does not stall again in PICMG as it did with COM Express. Its success largely depends on whether companies can work together rather than pursuing individual initiatives.Therefore, the entire industry is quite cautious about releasing public statements. Semiconductor manufacturers like Intel have already shared their latest processor technologies through early experience programs, and development teams are fully engaged in research for the initial design.Kontron’s first COM-HPC module may be launched this year, marking the beginning of a new generation of embedded computers, which is expected to take a similar amount of time as COM Express did, making it quite feasible.

PICMG – A Powerful Team

The PCI Industrial Computer Manufacturers Group (PICMG) is an alliance of over 140 companies aimed at jointly developing patent-free standards for high-performance telecommunications and industrial applications. The alliance’s members are mostly pioneers in the technology field, with many years of development experience in their respective industries. Currently, the organization is developing the COM-HPC standard to provide an open architecture for the next generation of embedded computer modules. Companies involved in the development of the COM-HPC standard include the founding members of the working group, Kontron, Advantech, and others, as well as companies like AAEON, Amphenol, Bielefeld University, Elma Electronic, Emerson Machine Automation Solutions, ept, Fastwell Group, Heitec, Intel, MEN Mikro Elektronik, MSC Technologies, N.A.T., Samtec, SECO, TE Connectivity, Trenz Electronic, and VersaLogic, with Christian Eder from Kontron serving as the chairman.