Skip to content

In recent years, China’s marine fisheries have achieved significant progress. With the continuous development of marine engineering equipment technology and the enhancement of digital capabilities in the marine engineering field, large-scale, digital, and intelligent solutions have become important development directions for deep-sea aquaculture facilities. Hardware-in-the-loop simulation testing technology is an efficient simulation testing technique used to detect and verify the reliability of control system software. It simulates the operational state of controlled objects by running simulation models on real-time processors, offering advantages of low cost and low risk, which helps improve product quality and shorten development cycles. As digitalization and intelligence continue to advance, the safe operation of marine aquaculture equipment increasingly relies on complex and critical control systems. Therefore, hardware-in-the-loop testing technology plays a very important role in the comprehensive and thorough testing of control systems, making research into the inspection and certification technology of deep-sea aquaculture equipment testing systems highly significant.

Introduction to Deep-Sea Aquaculture Equipment

Deep-sea aquaculture facilities refer to marine engineering facilities directly used for fish farming in deep and distant waters or primarily for fish farming while also serving recreational fishing purposes. They are also known as aquaculture workboats or aquaculture vessels. Typically, they have a steel structure as the main framework, including column-stabilized, frame-type, and ship-type structures, with netting made from fiber or metal alloys. Deep-sea aquaculture equipment consists of independent functional units on these facilities, mainly including feed processing units, feed feeding units, fishing devices, net cleaning devices, monitoring systems (underwater monitoring devices, environmental monitoring devices, fish density monitoring devices, CCTV/camera units, wastewater treatment and freshwater treatment control/monitoring units, underwater lighting systems, radar optical sea area monitoring systems), and netting materials.

1. Feed Processing Equipment

Common feed processing equipment includes feed medication mixing machines. These machines are used to mix fish feed and fish medication, with common structural forms including vertical and horizontal types. The motor reducer is generally located at the end face of the main equipment, ensuring stable operation and minimal damage to the feed. During operation, materials remain in motion, requiring high power. Liquid medication is injected during the mixing of feed and fish medication, with the feed in a solid particle state throughout the mixing process. The feed is ultimately discharged through the bottom feeder or valve and pipeline of the mixer.

2. Feed Feeding Equipment

Common feed feeding equipment includes remote pneumatic automatic feeding devices. These devices are an efficient aquaculture support system that can disperse feed to cages using gas. They generally consist of a feeding system, power system, distribution system, spraying system, and control system. They typically use diesel generators for power, driving a Roots blower to generate high-speed air that transports feed through pipelines, then distributing the feed to multiple cages or different positions within a single cage. The spraying system allows for even dispersion of feed on the water surface, and the control system achieves overall logical control, enabling timing, quantification, and automation functions.

Common fishing equipment includes vacuum fish pumps. These pumps are specialized devices for grading and transporting live fish. They utilize the principle of vacuum negative pressure extraction to remove live fish without damage, significantly reducing fish loss. A vacuum fish pump mainly consists of a vacuum pressure tank, water ring vacuum pump, cooling water system, intake and discharge pipelines, and control devices. The vacuum pressure tank connects to the intake and discharge pipelines, enabling the storage and transportation of live fish; the water ring vacuum pump provides power to the system, connecting the pump’s intake and discharge ports to the vacuum pressure tank to create negative and positive pressure for fish intake and discharge functions. The cooling water system supplies cooling water to the water ring pump to prevent overheating during operation, typically installing pneumatic ball valves and flow regulating valves on the cooling pipeline to control the water supply.

Introduction to Hardware-in-the-Loop Testing Technology

Hardware-in-the-loop (HIL) is a technology used for the development and testing of complex equipment control systems. Through HIL testing, the physical parts of a machine or system are replaced by simulators, and it is widely used in the development of control systems. A hardware-in-the-loop simulation system is a set of software and hardware systems with high real-time requirements, relying on advances in microelectronics and computer technology. During the software development process for deep-sea aquaculture equipment control systems, a simulation model is built based on the physical structure of the equipment, and HIL simulation testing is conducted to verify the system’s functionality, reliability, and redundancy earlier, avoiding risks of offshore tests and saving costs.

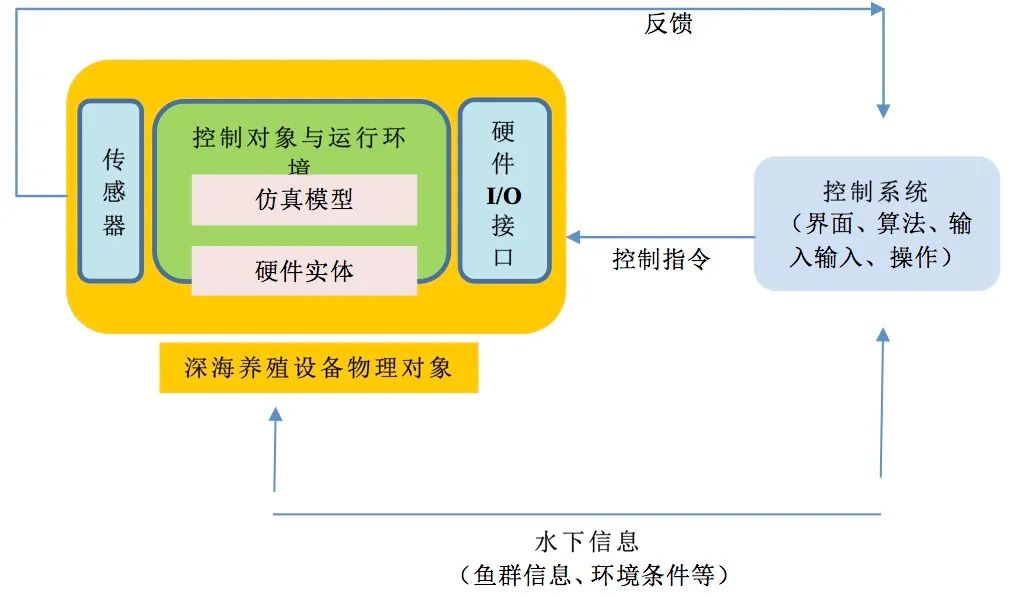

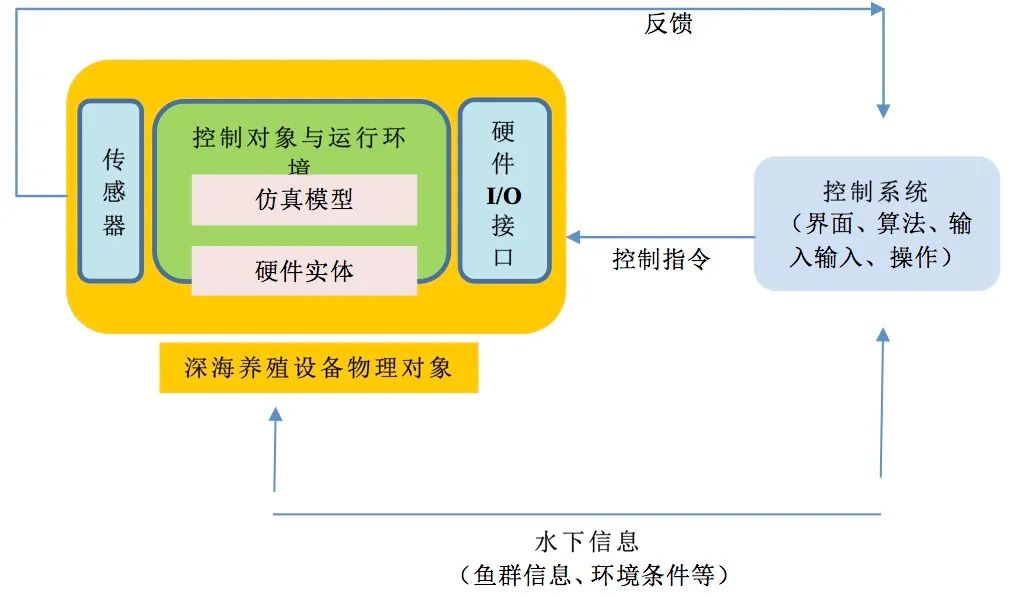

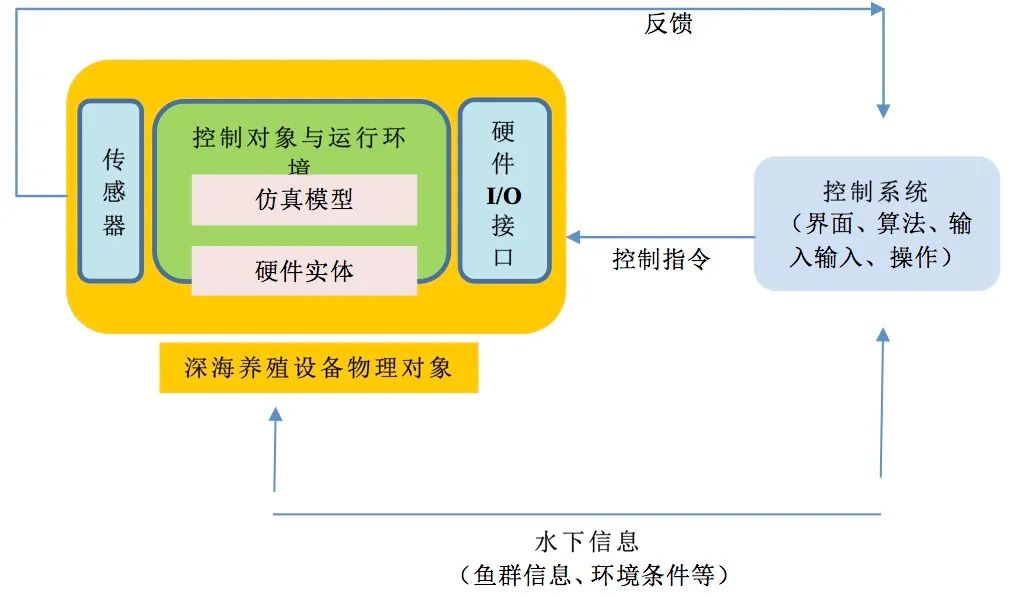

1. Components of HIL Testing Systems

HIL equipment generally consists of controlled object simulation models, real-time processors, I/O interfaces, and user interfaces. The controlled object simulation model establishes an accurate model to simulate the physical object being controlled and sends out correct status information, such as hardware device dynamics models, sensor models, battery models, etc.; the real-time processor runs the simulation model in real-time, ensuring communication and data processing; hardware I/O interfaces are responsible for data exchange and signal transmission between the control system and the controlled object; the user interface provides a visual interface for system operation and management. The principle diagram of the deep-sea aquaculture equipment HIL testing system is shown in Figure 1.

Figure 1: Principle Diagram of the Deep-Sea Aquaculture Equipment HIL Testing System

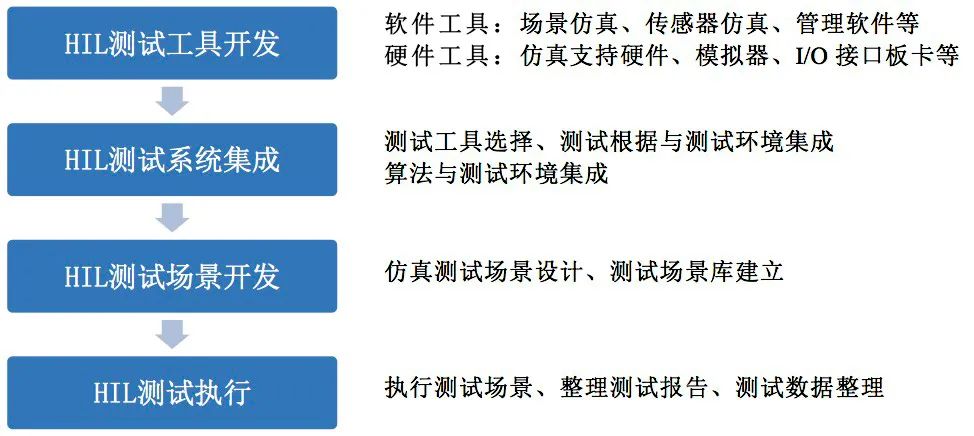

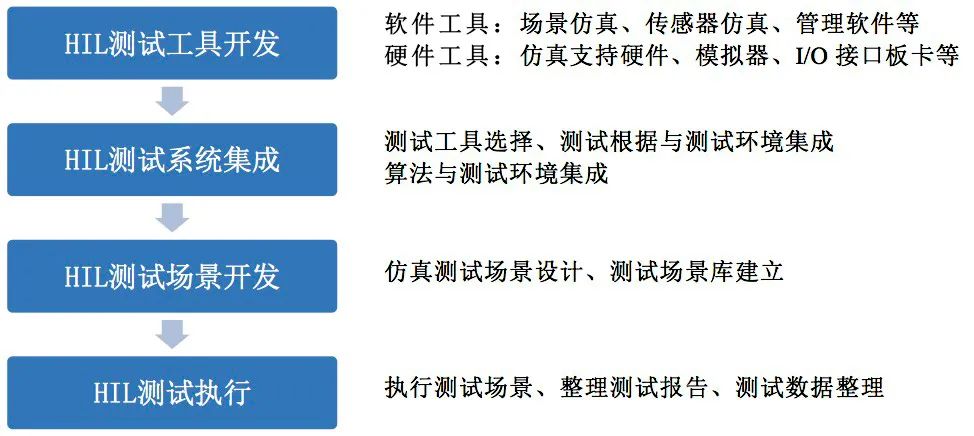

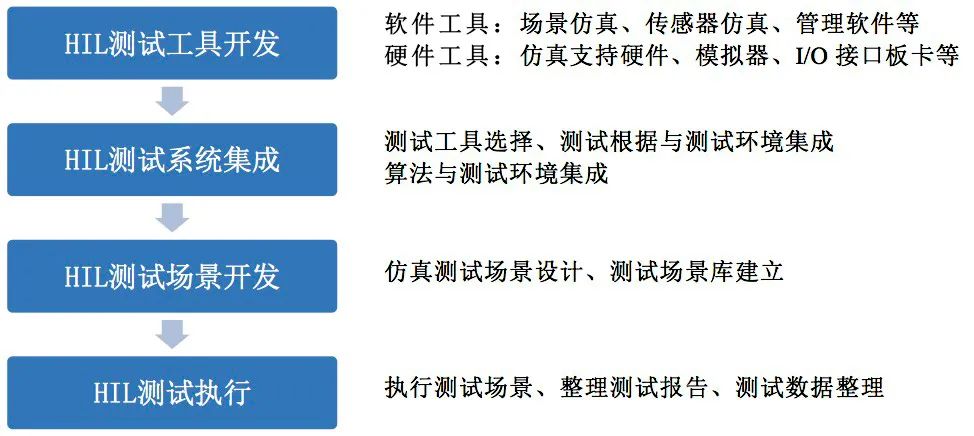

HIL testing includes four steps: HIL testing tool development, HIL testing system integration, HIL testing scenario development, and HIL testing execution (as shown in Figure 2).

Figure 1: Principle Diagram of the Deep-Sea Aquaculture Equipment HIL Testing System

HIL testing includes four steps: HIL testing tool development, HIL testing system integration, HIL testing scenario development, and HIL testing execution (as shown in Figure 2).

Figure 2: HIL Testing Process

Inspection of Deep-Sea Aquaculture Equipment HIL Testing Systems

The performance and safe operation of deep-sea aquaculture equipment are crucial for the healthy development of the deep-sea aquaculture industry. The control systems of equipment are becoming increasingly complex, posing high challenges for the comprehensiveness and coverage of testing. HIL testing technology can effectively help verify the performance level and safety grade of aquaculture equipment control systems. With the continuous development of HIL testing technology in the deep-sea aquaculture field, it is necessary to propose HIL testing system inspection requirements and standards suitable for deep-sea aquaculture equipment to guide the HIL testing process.

1. Requirements for HIL Software

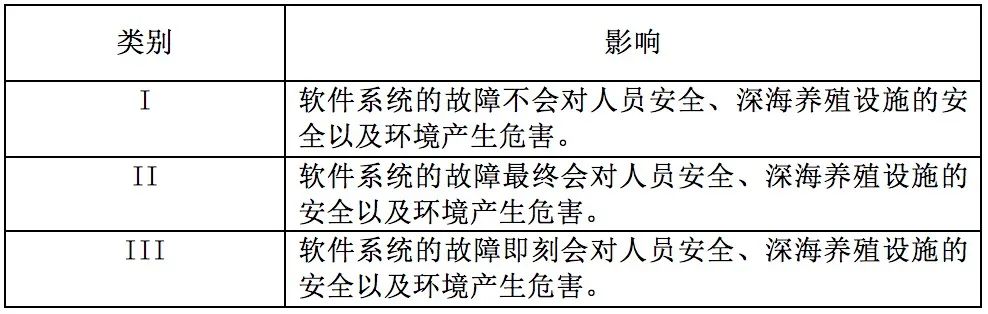

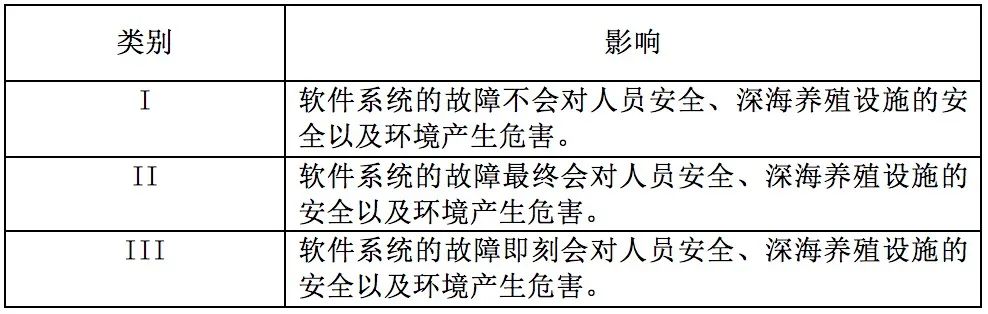

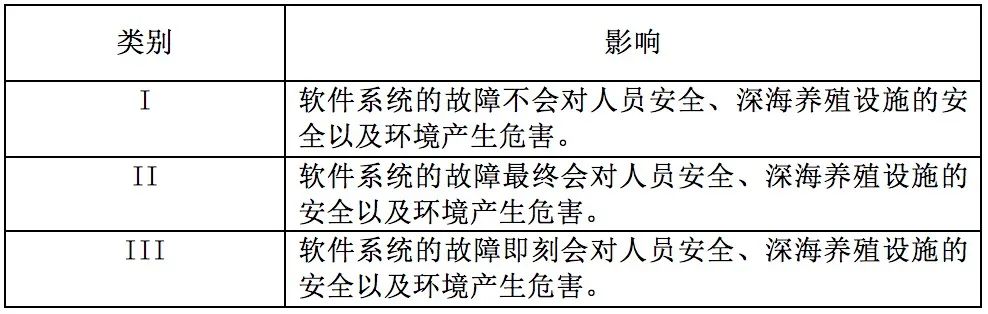

Based on the failure impact of HIL software, it is classified into three categories: I, II, and III (refer to Table 1).

Table 1: Classification of HIL Software

Figure 2: HIL Testing Process

Inspection of Deep-Sea Aquaculture Equipment HIL Testing Systems

The performance and safe operation of deep-sea aquaculture equipment are crucial for the healthy development of the deep-sea aquaculture industry. The control systems of equipment are becoming increasingly complex, posing high challenges for the comprehensiveness and coverage of testing. HIL testing technology can effectively help verify the performance level and safety grade of aquaculture equipment control systems. With the continuous development of HIL testing technology in the deep-sea aquaculture field, it is necessary to propose HIL testing system inspection requirements and standards suitable for deep-sea aquaculture equipment to guide the HIL testing process.

1. Requirements for HIL Software

Based on the failure impact of HIL software, it is classified into three categories: I, II, and III (refer to Table 1).

Table 1: Classification of HIL Software HIL software manufacturers should formulate quality assurance measures for the entire lifecycle of HIL software in accordance with IEEE 730 requirements and submit relevant documents to inspection agencies. These include:

(1) Software Quality Plan;

(2) Software Requirements Specification;

(3) Software Overview/ Detailed Design Report;

(4) Software Test Outline;

(5) Software Test Report;

(6) System Risk Analysis/ Assessment Report;

(7) Software Installation and User Manual/ Operation Manual;

(8) Model List and Model Description Documents.

The testing scope of HIL software should include aspects such as system functionality, performance, reliability, and availability. For II and III category HIL software, relevant measures to ensure safety functions should also be developed and tested.

2. Requirements for HIL Hardware

For hardware-in-the-loop testing, ensuring the integrity and smoothness of communication throughout the loop is the most basic requirement. For the control system and simulation equipment, real-time communication capabilities between the two must be guaranteed.

The HIL simulator replaces the real I/O interfaces with real-time simulated I/O interfaces for data exchange with the control system, providing the necessary information and processing signals from the control system. The HIL simulator must ensure that the simulated data it provides is consistent with real data to guarantee comprehensive testing and verification of various scenarios for the control system.

According to the inspection party’s needs, a hardware list of the HIL system should also be provided, including configuration information, models, and specifications for each piece of hardware, such as cabinets, simulators, real-time processors, I/O boards, fault injection units (if any), and host computers.

The acceptance testing of HIL system hardware includes three levels: excitation testing, open-loop testing, and closed-loop testing. Excitation testing is conducted without connecting to the controller, testing the hardware devices; open-loop testing involves connecting the target controller, calibrating simulated sensor signals, and collecting actuator drive signals to prepare for closed-loop testing; closed-loop testing incorporates the real-time model of the controlled object to test various operating conditions and scenarios. All test results should be compiled into a report and submitted to the inspection agency for confirmation.

This is an exclusive article from China Classification Society. Please indicate the source “China Classification Society or International Shipping Media” when forwarding. Violators will be prosecuted!

HIL software manufacturers should formulate quality assurance measures for the entire lifecycle of HIL software in accordance with IEEE 730 requirements and submit relevant documents to inspection agencies. These include:

(1) Software Quality Plan;

(2) Software Requirements Specification;

(3) Software Overview/ Detailed Design Report;

(4) Software Test Outline;

(5) Software Test Report;

(6) System Risk Analysis/ Assessment Report;

(7) Software Installation and User Manual/ Operation Manual;

(8) Model List and Model Description Documents.

The testing scope of HIL software should include aspects such as system functionality, performance, reliability, and availability. For II and III category HIL software, relevant measures to ensure safety functions should also be developed and tested.

2. Requirements for HIL Hardware

For hardware-in-the-loop testing, ensuring the integrity and smoothness of communication throughout the loop is the most basic requirement. For the control system and simulation equipment, real-time communication capabilities between the two must be guaranteed.

The HIL simulator replaces the real I/O interfaces with real-time simulated I/O interfaces for data exchange with the control system, providing the necessary information and processing signals from the control system. The HIL simulator must ensure that the simulated data it provides is consistent with real data to guarantee comprehensive testing and verification of various scenarios for the control system.

According to the inspection party’s needs, a hardware list of the HIL system should also be provided, including configuration information, models, and specifications for each piece of hardware, such as cabinets, simulators, real-time processors, I/O boards, fault injection units (if any), and host computers.

The acceptance testing of HIL system hardware includes three levels: excitation testing, open-loop testing, and closed-loop testing. Excitation testing is conducted without connecting to the controller, testing the hardware devices; open-loop testing involves connecting the target controller, calibrating simulated sensor signals, and collecting actuator drive signals to prepare for closed-loop testing; closed-loop testing incorporates the real-time model of the controlled object to test various operating conditions and scenarios. All test results should be compiled into a report and submitted to the inspection agency for confirmation.

This is an exclusive article from China Classification Society. Please indicate the source “China Classification Society or International Shipping Media” when forwarding. Violators will be prosecuted!

Figure 1: Principle Diagram of the Deep-Sea Aquaculture Equipment HIL Testing System

Figure 1: Principle Diagram of the Deep-Sea Aquaculture Equipment HIL Testing System Figure 2: HIL Testing Process

Figure 2: HIL Testing Process

Figure 1: Principle Diagram of the Deep-Sea Aquaculture Equipment HIL Testing System

Figure 1: Principle Diagram of the Deep-Sea Aquaculture Equipment HIL Testing System Figure 2: HIL Testing Process

Figure 2: HIL Testing Process