The design of embedded products directly determines the performance, cost, reliability, and time-to-market of the entire device. Faced with a plethora of core board products in the market, how can engineers identify the most suitable “core” for their projects?“

Today, we will deeply analyze the key considerations behind this to help you clear the fog and make informed decisions.

1. Technical Specifications:This is thefoundation of performance, a non-negotiable hard metric.

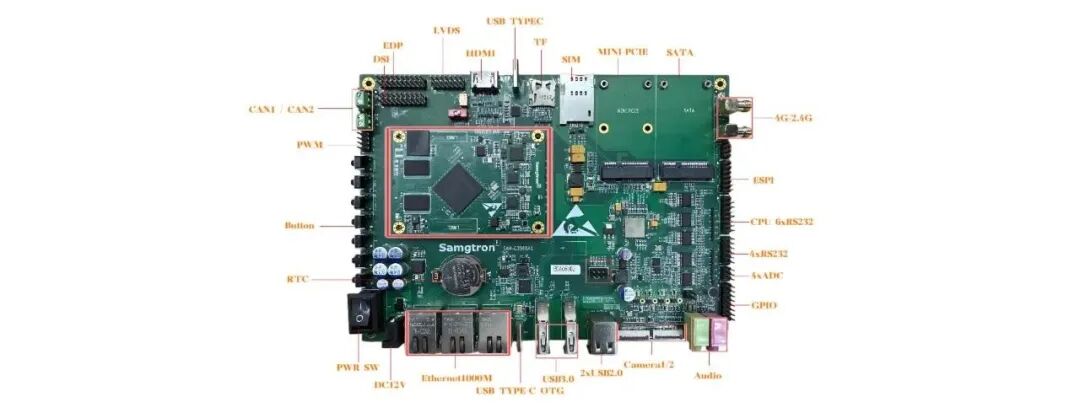

If the basic performance of the core board (such as processing core, clock frequency, memory bandwidth, storage capacity, and key peripheral interface types and quantities) cannot meet application requirements, all subsequent efforts will be futile.

Engineers need to think deeply about:

Computational Power Requirements: ARM Cortex-A / Cortex-M / RISC-V? What are the frequency requirements? Is hardware acceleration units (such as NPU, GPU, DSP) needed?

Memory and Storage: What is the size of RAM (LPDDR4/5)? What type and capacity of Flash (eMMC, SPI NOR/NAND, QSPI)? Is high-speed storage interface (such as PCIe NVMe) required?

Key Peripherals: What high-speed interfaces are needed (USB 3.x, GbE, MIPI-CSI/DSI)? How many low-speed interfaces (UART, I2C, SPI, CAN FD) are required? What are the requirements for ADC/DAC accuracy and speed?

Expansion Capabilities: How many PCIe lanes? Availability of high-speed serial buses (such as SerDes)? Is the number of reserved GPIO sufficient?

Remember: On the specification sheet, “just right” may mean future “constraints everywhere”; be sure to leave reasonable performance headroom for the technical evolution and functional iteration of the project.

2. Product Pricing: Beyond the “Low Price” Trap, Focus on the Optimal “Value” Solution

The core of commercial products is profitability, and cost control is crucial. However, the wisdom of engineers lies in precise cost-benefit analysis rather than simply chasing low prices. Behind the price differences of core boards often lie key differences in chip platform levels, component selection quality, PCB layer count and process complexity, and testing coverage.

“You get what you pay for” is a hard truth: Excessively low-priced core boards may compromise component lifespan, long-term stability, and anti-interference capabilities, leading to high maintenance costs and damage to brand reputation later on.

TCO (Total Cost of Ownership) Perspective: When evaluating prices, consider potential development and debugging time costs, risks of secondary hardware revisions, and complexities of after-sales maintenance. A “slightly more expensive” but mature and reliable core board may have a much lower overall project TCO than a “cheap” but problematic solution.

Selection Strategy: Within the budget framework, prioritize core board solutions that provide the best long-term value and lowest overall risk.

3. Packaging Form: The Art of Balancing Connection and Maintenance

The physical connection method of the core board (packaging form) directly affects product design, production yield, and subsequent maintenance costs.

Common forms each have their pros and cons:

Pin Headers (DIP/SMT Header): Intuitive connection, easy for manual soldering and replacement, making it the preferred choice for prototype development and small to medium batch flexibility. However, they are larger in size, relatively weak in shock resistance, and pose significant challenges for high-speed signal integrity design.

Castellated Holes: Lower cost, compact size. However, manual soldering is extremely difficult, rework is very challenging, and production process requirements are strict, generally only suitable for large-scale, highly automated production with expected maintenance-free scenarios.

Board-to-Board Connectors: Excellent maintainability, easy to plug and replace. However, they increase connector costs (both the connector itself and the mating socket), require high PCB flatness and connector reliability, and may have certain contact resistance issues.

LGA/BGA: Extremely compact, good electrical performance, cost-effective. However, the biggest pain point is: almost impossible to perform on-board rework or replacement! Any core board failure usually means scrapping the entire board (unless equipped with expensive BGA rework stations and technology), which poses significant pressure on after-sales costs post-mass production.

Engineers’ Choice: A comprehensive evaluation must closely revolve around the product’s final application scenarios, expected production volume, production process capabilities, and after-sales maintenance strategies. For example, in fields such as industrial control and medical devices that require high reliability, the maintainability of board-to-board connectors is often a key advantage; while consumer electronics and IoT modules that pursue extreme cost and size in large-scale products may lean towards castellated holes or LGA/BGA, but must ensure good production control and quality assurance.

4. Service Support: The Invisible Engine for Project Acceleration

Embedded development is complex and fraught with pitfalls; choosing the wrong core board can lead teams to spend months on underlying drivers, BSP adaptation, and hardware compatibility issues. Therefore, the technical support and ecosystem maturity of core board suppliers are key variables for whether a project can be launched quickly.

Quality service is reflected in: A responsive technical support team, high-quality and continuously maintained BSP/Linux SDK, detailed hardware reference designs (schematics & PCB), and rich development documentation, etc.

Avoiding “Island” Solutions: Choosing suppliers with mature ecosystems, a broad user base, and ongoing R&D investment can effectively reduce the risk of pitfalls and accelerate problem resolution.

Evaluating “Hidden Costs”: A core board lacking support may save procurement costs, but the hours spent by engineers filling in the gaps can multiply those savings, even delaying the product launch window.

Remember: Excellent service support is an “invisible accelerator” for rapid project implementation and seizing market opportunities, and its value should not be underestimated.

5. Supply and Quality: The Cornerstone of Building the Product Lifeline

A stable supply chain and reliable product quality are the foundation of the product lifeline.

Supply Assurance: Is the supply chain for the core board’s main control chip and key components mature and redundant? Does the supplier have stable sourcing channels and transparent supply plans? Are there contingency plans to address supply shortages?

Quality Reliability: How is the supplier’s quality control system (such as ISO certification)? Has the core board undergone rigorous environmental testing? How is the consistency of mass production batches? What is the average time between failures (MTBF) data?

The Power of Reputation: Feedback from long-term customers of the supplier; stable supply and excellent quality are core elements in building a good reputation.

Core Principle: Choosing partners with a good track record and commitment to supply reliability and product quality is the only way to mitigate risks in projects, gain the trust of end customers, and shape brand reputation.

Choosing a core board is not merely a simple comparison of parameters or prices, but a systematic engineering process that integrates technical insight, cost analysis, risk anticipation, and supply chain management capabilities. Accurately grasping the above five dimensions (specifications, pricing, packaging, support, supply quality) is essential to lock in the “core engine” that drives product success amidst the complex market.

Experienced engineers, what other “pits” or unique considerations have you encountered during the actual selection process? Feel free to share your insights in the comments section and let’s spark a collision of wisdom!