1. Determine the Plan and Purpose

1. Determine the Plan and Purpose

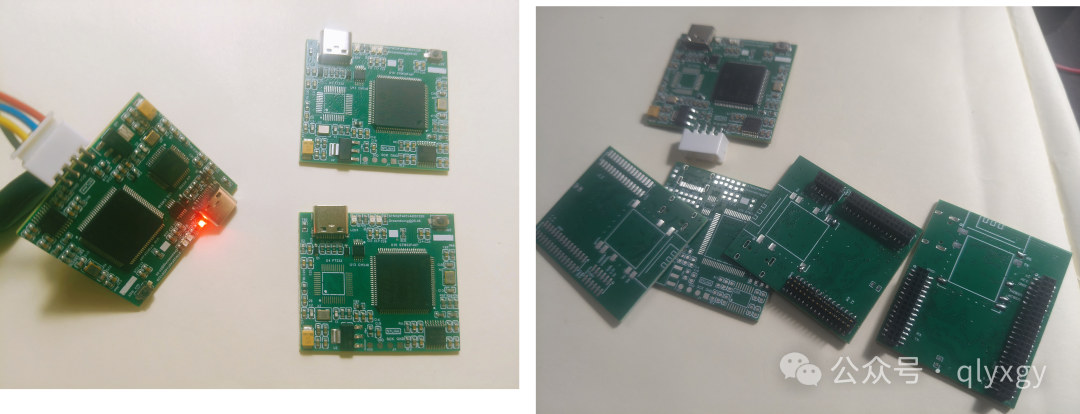

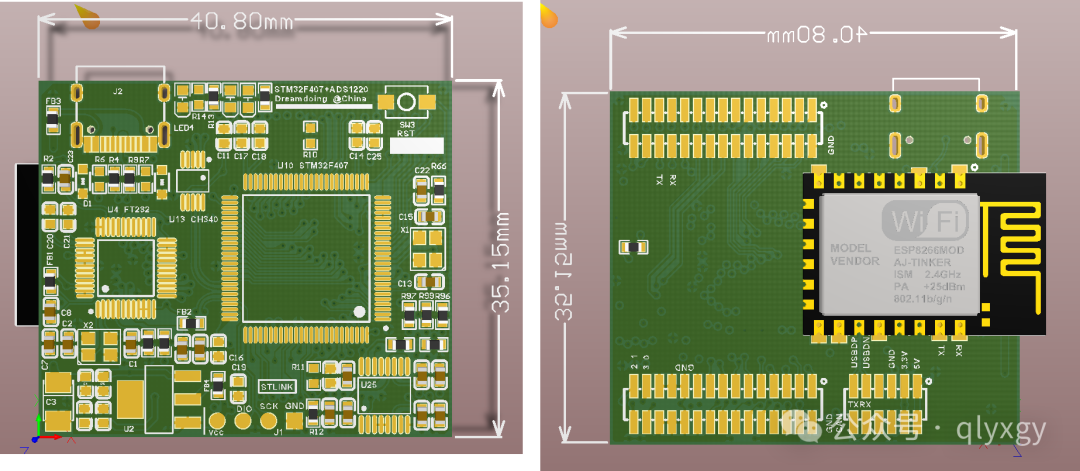

Hello everyone, today the miniaturized development board has arrived, and we are starting the arrival inspection task. The requirements are as follows:

[Notes] STM32F4 + FT232H High-Speed Acquisition Development Board Design Draft

Objective: STM32F4 Development Board 01. High-speed transmission testing, and reliable verification; 02. ADS1220 driver verification and debugging; Keywords: PCB, STM32F4 Note: High-definition images can be viewed via WeChat on mobile phones. 2. Basic Testing Content

2. Basic Testing Content

01. The FT232H chip needs to be configured for high-speed FIFO mode. After configuring the mode, send the AC3 clock, then switch the data via the parallel port;

02. Load data at high level with AC3, then trigger a low level to complete one FIFO load;

03. The FIFO function generates a cache after enabling reading in the DLL file, and after completion, the API interface outputs and releases the cache;

04. There may be a persistent waiting phenomenon when calling the DLL interface, which needs subsequent optimization to resolve;

06. The FT232H chip has internal and external power configurations, and there will be heating phenomena in high-speed FIFO mode. It is recommended to add heat dissipation measures under high conditions;

07. The STM32 writes a test program to drive, outputs the clock, then switches the parallel port for testing;

08. The parallel port function needs to meet the requirements for fast transmission, and under controllable speed, single IO operations can be used;

3. Communication Testing Content

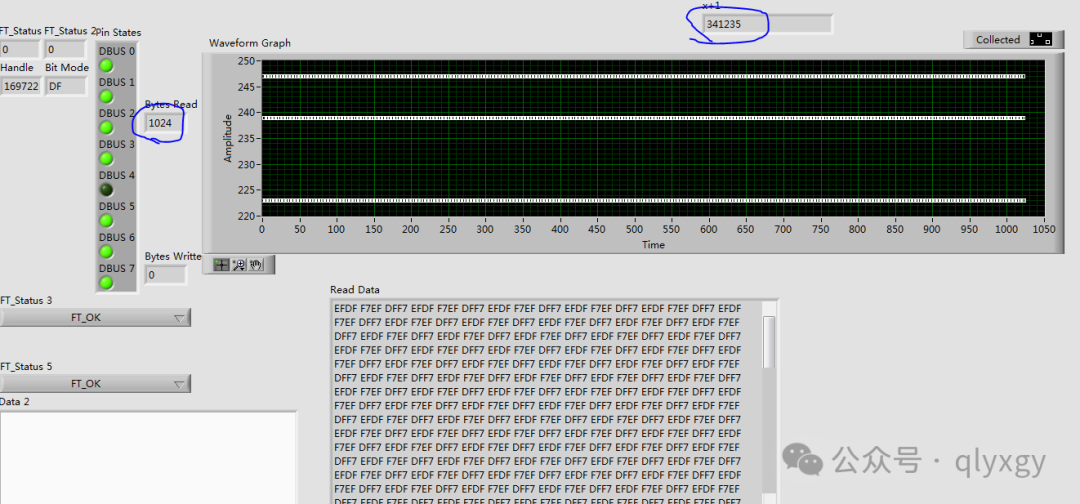

3. Communication Testing Content 01. Write a program to receive data on the computer, receiving 1024 data points each time, with a 20ms interval, testing 342,000 times;02. Total time spent: 342,000/50/3600=1.9 hours;;03. Total data volume =342,000*1024=35020.8 million=350 million data points, tested successfully;04. Verification result: It can meet the requirements for high-speed transmission and different rate transmission needs;05. During high-speed transmission, the system consumes about 50mA under 3.3V power supply, and the chip exhibits heating phenomena;06. The function of the STM32 program is: output three pulses to send three values, sending in a loop;07. Configure the transmission chip to FIFO mode, then download and save parameters;

01. Write a program to receive data on the computer, receiving 1024 data points each time, with a 20ms interval, testing 342,000 times;02. Total time spent: 342,000/50/3600=1.9 hours;;03. Total data volume =342,000*1024=35020.8 million=350 million data points, tested successfully;04. Verification result: It can meet the requirements for high-speed transmission and different rate transmission needs;05. During high-speed transmission, the system consumes about 50mA under 3.3V power supply, and the chip exhibits heating phenomena;06. The function of the STM32 program is: output three pulses to send three values, sending in a loop;07. Configure the transmission chip to FIFO mode, then download and save parameters; 4. ADS1220 Chip Testing

4. ADS1220 Chip Testing

Description of Phenomenon: Unable to operate the register

01. After writing to the register with 0x43, reading the register with the 0x23 instruction responds, but all values are default 0x00;

02. The 0x06 instruction works normally, and the RDATA instruction can also read data;

Solution:

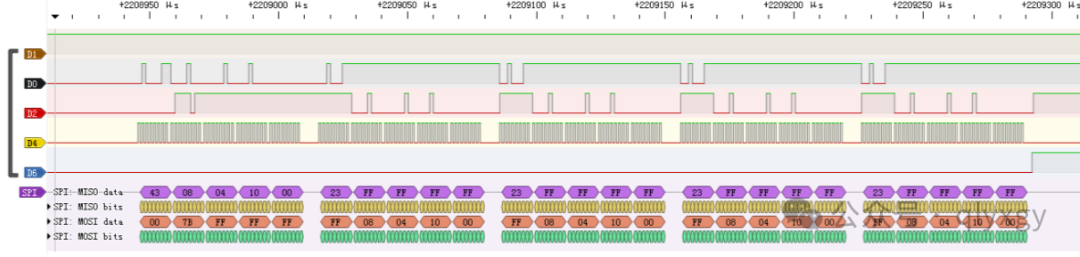

01. Suspect that the SPI bus level is mismatched; the oscilloscope verifies that the levels are normal, and data feedback is also normal;

02. Suspect that the CS and ready signals are not ready before operating the register; added delay and analyzed with a logic analyzer, signals are normal;

03. Suspect hardware chip damage, or bus interference or disconnection; RDATA has data feedback, indicating the chip is normal, and circuit routing is normal;

04. Suspect GPIO conflicts and configuration issues; determined through a logic analyzer that the configuration is normal and without conflicts;

05. Suspect SPI bus configuration issues; discovered through a logic analyzer that the clock phase was incorrect; checked SPI configuration and changed the first edge to the second edge, which worked normally; retested data with a logic analyzer, and it was normal;

5. Schematic and PCB

5. Schematic and PCB

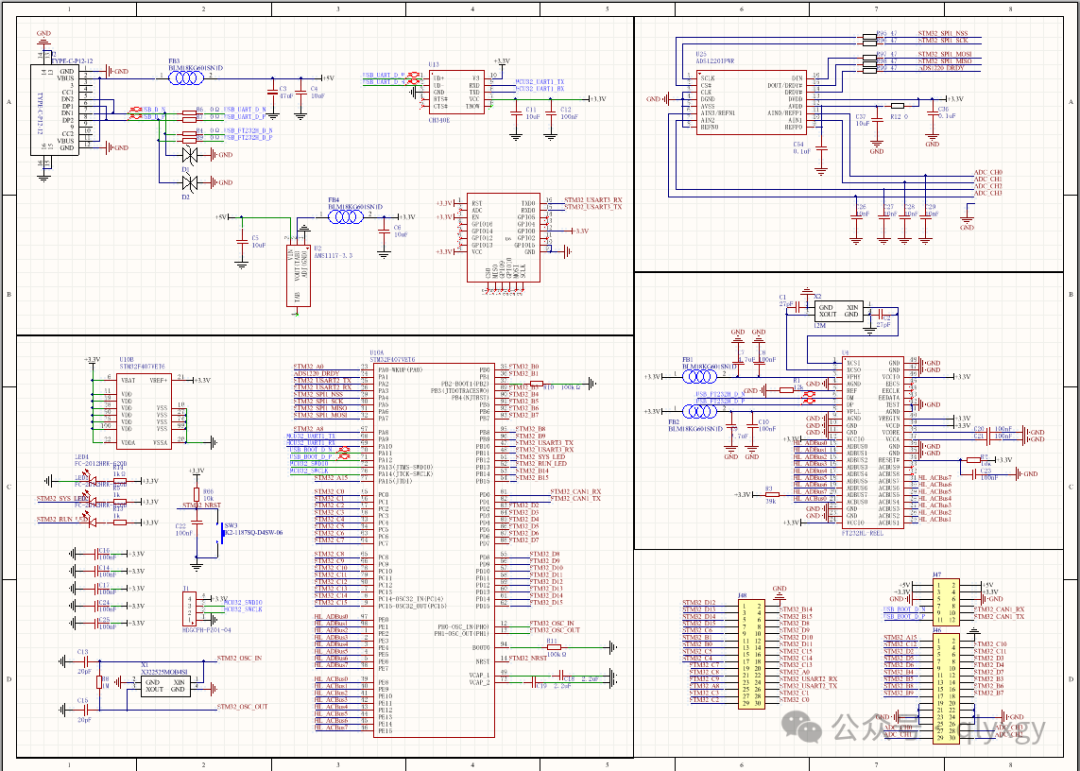

01. Power supply voltage regulator chip with magnetic beads + filter capacitor design; USB adds ESD/TVS protection bidirectional diode devices to protect against static interference;03. Circuit power consumption calculation: STM32F4 + FT232H + ADS1220 + CH340 + ESP8266, calculated under normal maximum load will not exceed 0.6A;04. The 3.3V voltage regulator chip has heating phenomena; attempts to solve this with a heat sink; need to check installation height;05. Four-layer board design verifies that signal transmission is normal, downloads normally, serial port is normal, SPI bus is normal;06. [Planning 01] Design acquisition carrier board, enabling ADS1220 low-speed high-precision 24-bit analog acquisition branch;07. [Planning 02] Design acquisition carrier board, enabling AD7606 high-speed 8-channel acquisition branch;08. [Planning 03] Design control carrier board; exit the core board product;6. Statement01. All codes, images, and text in this tutorial are original, and the copyright belongs to Qianli Youxuan Teaching Base;02. This tutorial is for technical sharing, applied in the teaching field; related codes and technical discussions are for reference only;03.Note: High-definition images can be viewed via the mobile WeChat client.;

01. Power supply voltage regulator chip with magnetic beads + filter capacitor design; USB adds ESD/TVS protection bidirectional diode devices to protect against static interference;03. Circuit power consumption calculation: STM32F4 + FT232H + ADS1220 + CH340 + ESP8266, calculated under normal maximum load will not exceed 0.6A;04. The 3.3V voltage regulator chip has heating phenomena; attempts to solve this with a heat sink; need to check installation height;05. Four-layer board design verifies that signal transmission is normal, downloads normally, serial port is normal, SPI bus is normal;06. [Planning 01] Design acquisition carrier board, enabling ADS1220 low-speed high-precision 24-bit analog acquisition branch;07. [Planning 02] Design acquisition carrier board, enabling AD7606 high-speed 8-channel acquisition branch;08. [Planning 03] Design control carrier board; exit the core board product;6. Statement01. All codes, images, and text in this tutorial are original, and the copyright belongs to Qianli Youxuan Teaching Base;02. This tutorial is for technical sharing, applied in the teaching field; related codes and technical discussions are for reference only;03.Note: High-definition images can be viewed via the mobile WeChat client.;