As a series of high-speed trains glide like silver dragons

through the Changqing Yellow River Railway Bridge,

passengers on board may not realize

that this bridge, spanning the chasm,

is undergoing a special “health management“

634 “neurons”

monitoring its health 24 hours a day

23 pairs of “eagle eyes”

capturing subtle changes in real-time

……

The Jinan Railway Bureau Group Co., Ltd.

and the Liaocheng Engineering Section provide

a dual guarantee of technology and tradition,

jointly safeguarding the safety of this steel artery.

634 Sensors: The Bridge’s “Smart Bracelet”

Just as people use bracelets to monitor heart rates and steps,

this bridge has also donned its own “health bracelet.”

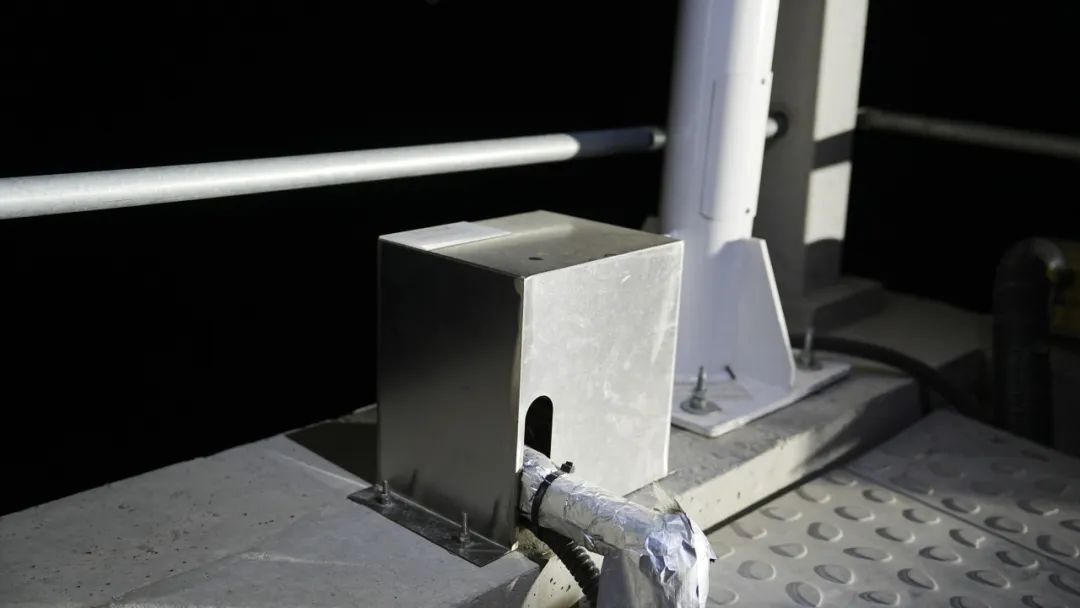

634 sensors installed at critical points of the bridge

act like nerve endings in the human body,

capable of sensing displacement changes of 0.5 millimeters,

which is equivalent to detecting a rolling sesame seed on a 100-meter track.

When trains pass,

the sensors can collect hundreds of data sets per second.

If the system detects anomalies,

the warning information will be immediately sent to the staff’s mobile phones.

Based on the specific location and millimeter-level anomalies,

maintenance personnel can accurately identify the cause on-site.

23 Cameras: Performing a “CT Scan” of the Bridge

The bridge’s “health records” go far beyond numerical data.

A monitoring network composed of 23 high-definition cameras

is like giving the bridge “eyes” that can think.

“With the system’s early warning,

inspection work has transformed from

‘finding a needle in a haystack’ to ‘precision targeting.’

Our role has shifted from ‘emergency doctor’

to ‘health consultant,’”

said Wang Zhiben, the foreman.

The previous 9-person team working overnight to inspect the stay cables

has now been replaced by sensors.

Smart Hub: Equipping the Bridge with the “Strongest Brain”

At the monitoring center of the Liaocheng Engineering Section,

colorful waveforms dance on the electronic screen.

This is like the “nerve center” of the bridge,

where all the data transmitted back is gathered.

The “nerve center” can process over 1000 data points per second,

equivalent to the data volume of watching 30 4K movies simultaneously.

It can not only predict the fatigue cycle of steel beams

but also intelligently calculate the optimal time for bolt replacement.

“Look at this curve, it’s like reading an ECG,”

said Hou Jiachen, the deputy foreman of the bridge section, pointing at the screen.

“A sharp rise in temperature indicates a risk of rail expansion,

and abnormal vibration frequency

may indicate a loose bolt hazard.”

The model of “human + intelligence”

plays a safety symphony over the Yellow River.

The intelligent system significantly reduces the frequency of annual inspections,

and the accuracy of manual inspections has increased threefold.

From manual climbing to cloud monitoring,

from experience-based judgment to data-driven decision-making,

the health management of the Changqing Yellow River Railway Bridge

is a microcosm of China’s intelligent maintenance and repair.

Source: Shandong Correspondent Station of the People’s Railway Newspaper Co., Ltd. (Jinan Bureau Group Media Center)

Text and images: Li Xibing, Duan Xiuxian, Li Yuanlu, Kou Chunka, Guo Yan

Editor: Jin Huanmei

Proofreader: Gao Shan