University

Project

Introduction

High

Technology

Achievement

#Technology Transfer#

2024

In recent years, significant opportunities have arisen in the areas of digitization, networking, and intelligence, leading to remarkable achievements in the development of electronic information and advanced manufacturing automation in China. The innovation capability has continuously improved, and the ecosystem has been further refined, playing a supportive and leading role in national economic and social development. At the same time, in the face of severe and complex domestic and international situations and numerous risks and challenges, only by adhering to the path of independent innovation, enhancing core competitiveness, and building a more closely related industrial chain system can we seize opportunities, strengthen advantages, and achieve breakthroughs.

The Shanghai Higher Education Technology Development Center, relying on the high-quality scientific research resources of Shanghai universities, actively promotes the transformation of scientific and technological achievements in Shanghai universities. This time, we will recommend two projects in the field of electronic information and advanced manufacturing automation.

The projects have broad application value. If you would like to learn more about the projects and communicate with the project team experts, please contact our center.

Contact Person:

Teacher Sun 56627214

Teacher Lu 56635819

Email: [email protected]

01 / Fudan University

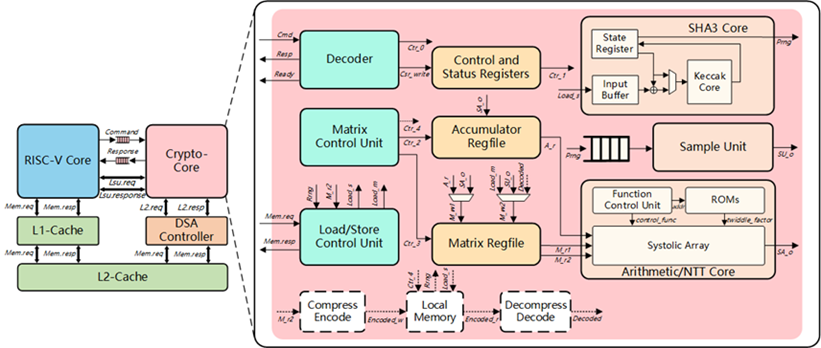

Design of Domain-Specific Architecture Based on RISC-V—XPU Chip for Intelligence and Security

Project Overview

This project focuses on high-performance domain-specific processor chip technology for edge intelligence and security. The research team designs a specialized architecture XPU based on the open-source instruction set architecture RISC-V, with a focus on applications in artificial intelligence and post-quantum cryptography. To unify the XPU design paradigm from the perspective of instruction set architecture, the research team has developed a custom instruction interface with strong flexibility and high performance, facilitating agile development for different application scenarios. To accelerate post-quantum cryptographic algorithms, the research team has proposed a high-performance vector and matrix-based post-quantum cryptographic computing architecture for the first time, designing a custom computing engine coupled with general-purpose processors based on the proposed RISC-V cryptographic extension, forming a high-performance heterogeneous computing system. This high-performance post-quantum cryptography processor can flexibly support all post-quantum cryptographic standard algorithms issued by the U.S. National Institute of Standards and Technology (NIST) and various mainstream domestic post-quantum cryptographic algorithms, achieving an average performance of over six times that of the ARM Cortex-A75+Neon architecture. To meet the application requirements for high image quality, high energy efficiency, and low inference latency, the research team has fully utilized the advantages of RISC-V extended instructions to propose a high-energy-efficiency AI super-resolution system, whose algorithm features high scene adaptability and strong hardware friendliness, with a hardware architecture that boasts low bandwidth, high computing power, and high energy efficiency. This super-resolution system can support image super-resolution tasks of X2, X3, and X4, achieving a throughput of 1080P@60fps, and the research results have been published in IEEE flagship journals.

Commercialization Prospects

Currently, the evolution of traditional general-purpose processors has encountered bottlenecks. Meanwhile, artificial intelligence technology (AI) is rapidly integrating into various smart terminals such as mobile phones, computers, headsets, smart homes, automobiles, and robots, with the exponential growth of application types and computing power demands far exceeding the capabilities of general CPU architectures. On the other hand, the development of 5G/6G communication technology has driven the widespread deployment of various high-bandwidth, high-computing-power, low-latency applications in the integrated cloud-edge-end network space, thus creating an urgent demand for building high-performance security services. Therefore, to achieve high-performance application scenarios in the post-5G era, there is an urgent need to focus on domain-specific chips for intelligence and security, conducting cutting-edge explorations of their computing, storage, and interconnection architectures.

Project Intellectual Property Status

This project holds multiple authorized invention patents.

Cooperation Method

Cooperative development.

Team Introduction

The research team led by Researcher Han Jun from the School of Microelectronics at Fudan University aims at human-machine integrated intelligent systems and high-performance chip architecture, while conducting cooperation on open-source chip technologies such as RISC-V for intelligent and secure applications in 5G edge computing. The main research directions include human-machine integrated intelligent systems, high-performance chip architecture design methodology, and open-source chip technology. The team has published over 100 papers in important domestic and international academic journals and conferences, and has been granted over 30 Chinese invention patents.

02 / Shanghai University

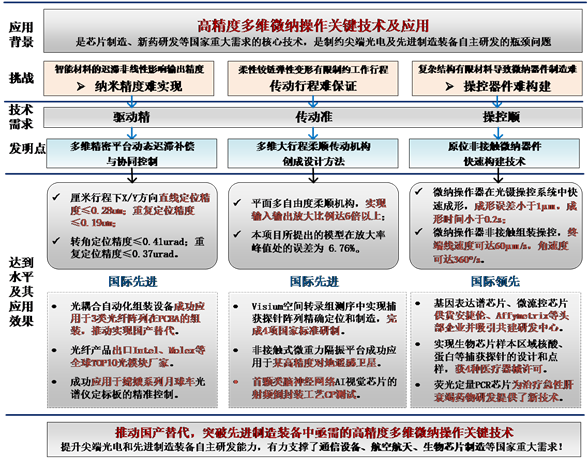

Key Technologies and Applications for High-Precision Multi-Dimensional Micro-Nano Manipulation

Project Overview

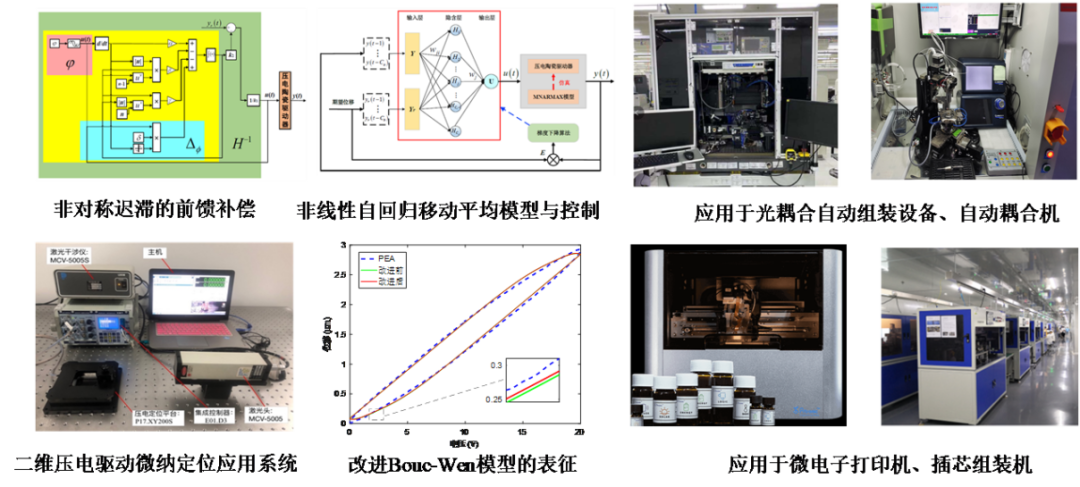

High-precision multi-dimensional micro-nano positioning and manipulation is a core technology in major national demand areas such as communication equipment, aerospace, and biochip manufacturing. It is a bottleneck issue that restricts the independent research and development of cutting-edge optoelectronic and advanced manufacturing equipment. In response to the challenges faced by cutting-edge optoelectronic and advanced manufacturing equipment in complex and harsh environments, such as “difficulty in achieving nanometer precision,” “difficulty in ensuring transmission stroke,” and “difficulty in constructing manipulative devices,” Shanghai University, in collaboration with Shanghai Biochip Co., Ltd. and Shenzhen Huifukang Optical Communication Co., Ltd., has made breakthroughs in key technologies for high-precision multi-dimensional micro-nano manipulation after eight years of technical research, supporting cutting-edge optoelectronic and advanced manufacturing equipment to achieve “precise driving,” “accurate transmission,” and “smooth manipulation” at the micro-nano scale. The main innovations are as follows: a dynamic hysteresis compensation and collaborative control technology for multi-dimensional precision platforms has been invented, and a non-symmetric hysteresis characterization and compensation method based on a phenomenological model has been proposed, achieving hysteresis cross-decoupling of multi-dimensional precision platforms, reducing the root mean square error of dynamic hysteresis identification by 11.28% and the coupling displacement error by more than four times. A design method for multi-dimensional large-stroke compliant transmission mechanisms has been invented, proposing a design theory for multi-degree-of-freedom compliant mechanisms that combines topology optimization and pseudo-rigid body methods, establishing a motion model for compliant mechanisms based on the second theorem of Kinematics and elastic beam theory, achieving a linear repeat positioning accuracy of ≤0.19μm and an angular repeat positioning accuracy of ≤0.37μrad for multi-degree-of-freedom positioning platforms. A rapid construction technology for in-situ non-contact micro-nano devices has been invented, proposing an in-situ micro-forming technology based on optical tweezers and optical shaping, establishing a non-contact assembly and manipulation method for micro-nano manipulators based on different surface characteristics, achieving end manipulative device feature sizes smaller than 5μm, forming errors less than 1μm, and manipulation and forming times less than 0.2s.

Overall Project Approach

Core Technology One

Dynamic Hysteresis Compensation and Collaborative Control for Multi-Dimensional Precision Platforms

Implementation Effect: Based on this technology, optical coupling automation assembly equipment has been developed, achieving core indicators with a travel range of 180 mm x 100 mm x 50 mm, with a moving resolution of 50nm, repeat accuracy of less than 1um, and rotation resolution of 0.05° for the X/Y/Z axes. The technical indicators have reached the level of similar products from Germany’s FICON-TEC and Korea’s ADS-TEC, successfully applied to the assembly of three types of fiber optic array PCBA, promoting domestic substitution. The fully automatic fiber threading machine and fully automatic plug assembly machine developed or improved have achieved serial applications, and fiber optic products have passed Cisco wiggle tests, North American GR326 tests, etc., supplying Intel, Molex, and other global top 10 optical module manufacturers, maintaining long-term and stable batch delivery cooperation. It has been applied to improve the control accuracy of ultrasonic motors, supporting the opening and closing and angle control of the internal calibration board of the infrared imaging spectrometer on the Chang’e series lunar rover; applied in the precise control of micro-droplet nozzles in the power square technology MP1100 microelectronic printer and MF3D-200 structure and circuit hybrid 3D printer, with related products purchased by Tsinghua University, Zhejiang University, and others.

▲ Dynamic Hysteresis Compensation and Collaborative Control for Multi-Dimensional Precision Platforms

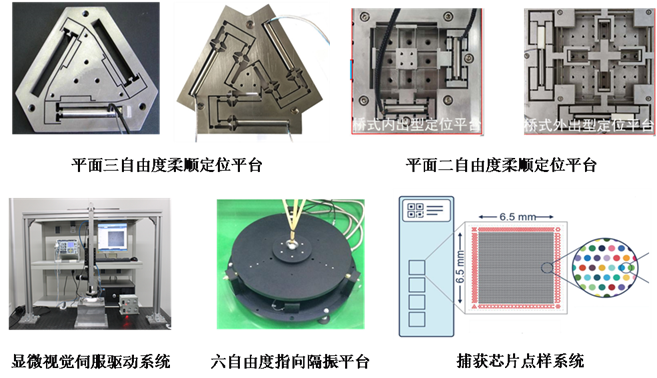

Core Technology Two

Design Method for Multi-Dimensional Large-Stroke Compliant Transmission Mechanisms

Implementation Effect: Based on this technology, a six-degree-of-freedom microgravity pointing isolation platform has been designed, achieving displacement pointing accuracy of 5um, steering accuracy of 20urad, and a low-frequency vibration displacement amplitude attenuation rate of over 95%. It has been successfully applied to key technology breakthroughs for high-precision earth observation satellite models and micro-vibration suppression of star-mounted control moment gyroscope equipment. This technology has been successfully used in the RF flip-chip packaging process CP testing of the AI visual recognition chip from Daoyuan Technology Co., Ltd., supporting the development of the industry’s first fully asynchronous data flow architecture brain-like neural network AI visual chip; successfully applied in the development of precision molds for aviation, achieving precision casting of the CJ1000A large aircraft engine blades from Commercial Aircraft Corporation of China; successfully applied in the precise preparation of gene expression profile chip capture areas, achieving step accuracy of 2.5 microns, probe spacing of 100 microns, and positioning errors of less than 2.5 microns, with products supplied to Agilent, Affymetrix, and other well-known companies, and achieving the formulation of four important national standards for nucleic acid biotechnology.

▲ Design Method for Multi-Dimensional Large-Stroke Compliant Transmission Mechanisms

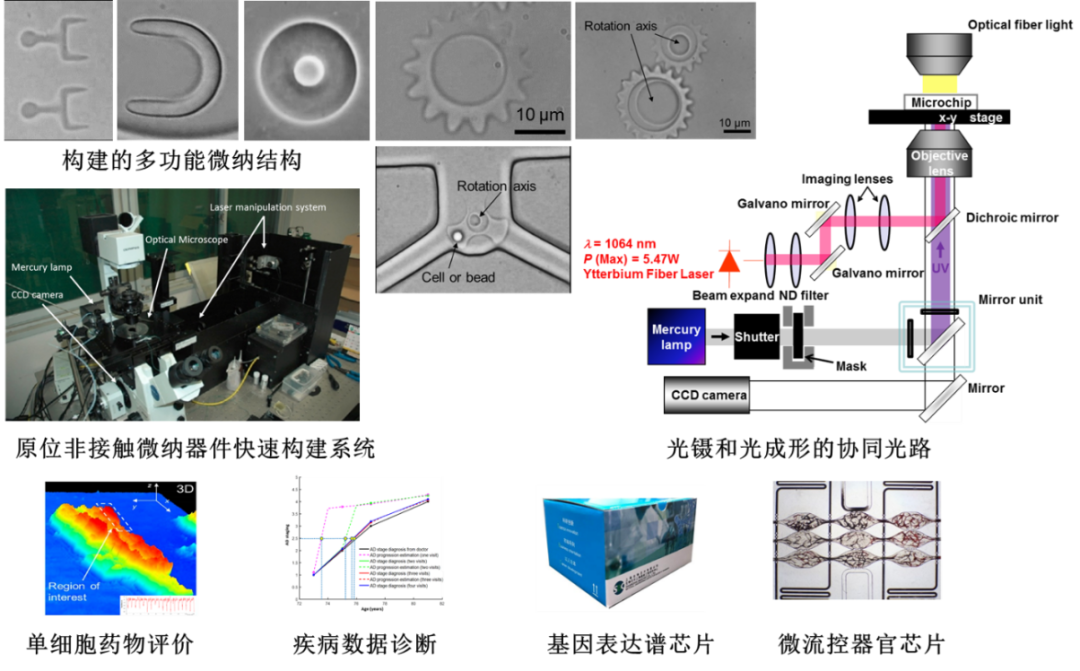

Core Technology Three

Rapid Construction Technology for In-Situ Non-Contact Micro-Nano Devices

Implementation Effect: Based on this technology, production equipment and processes for various biochip products have been developed, achieving the completion of 48 needle points on 50 slides (4000 points/slide) within one hour, with high point-making efficiency and stable manufacturing processes. It has achieved the design and point sampling of various functional capture probes for nucleic acids, proteins, and exosomes in the biochip sample area, with four products successfully approved for medical device registration. It has been applied in the core component manufacturing of gene expression profile chips, microfluidic chips, spatial transcriptomics, etc., with the developed chip products playing an important role in studying the mechanism of bone marrow mesenchymal stem cells in improving acute liver failure, providing new technologies for drug development for treating acute liver failure, and co-establishing research centers with well-known companies such as Agilent and Affymetrix.

▲ Rapid Construction Technology for In-Situ Non-Contact Micro-Nano Devices

Commercialization Prospects

This project has broken through key technologies for high-precision multi-dimensional micro-nano manipulation, supporting cutting-edge optoelectronic and advanced manufacturing equipment to achieve “precise driving,” “accurate transmission,” and “smooth manipulation” at the micro-nano scale, serving major national demands in communication equipment, aerospace, and biochip manufacturing. Communication Equipment: Optical coupling automation assembly equipment has been successfully applied to the assembly of three types of fiber optic arrays in PCBA, achieving international advanced levels and promoting domestic substitution. Products have passed North American GR326 tests, supplying Intel and other global top 10 optical module manufacturers. Applied in RF flip-chip packaging process CP testing, promoting the development of the industry’s first brain-like neural network AI visual chip. Aerospace: Applied in the laser communication pointing tracking system of high-precision earth observation satellites; applied in the development of precision molds for aviation, achieving precision casting of the CJ1000A large aircraft engine blades; applied in precise driving of ultrasonic motors, successfully mounted on the Chang’e series lunar rover. Biochips: Fluorescent quantitative PCR platforms and gene expression profile chip products are used to reveal the processes of angiogenesis and osteogenic differentiation, and stem cell therapy for acute liver failure, with great application prospects, attracting leading international companies such as Agilent to co-establish research centers, creating good social and economic benefits.

Project Intellectual Property Status

This project holds multiple authorized invention patents.

Cooperation Method

Pilot scale verification, cooperative development, and technology transfer.

Team Introduction

Yue Tao, Associate Researcher and PhD supervisor at the School of Mechanical and Electrical Engineering, Shanghai University. A young scholar of the Shanghai Eastern Scholar program and a young technology star of Shanghai. Currently serves as the director of the Micro-Nano Manipulation Technology Research Center at Shanghai University, mainly engaged in research on micro-nano robots, microfluidic chips, bioinformatics, and bio-intelligence, achieving a series of results in micro-nano manipulation and detection: overcoming key technologies such as non-contact micro-manipulation and closed micro-scale environment control, achieving precise control of micro-nano structures and detection, and high-speed and efficient systems. Zhang Quan, Professor and PhD supervisor at the School of Mechanical and Electrical Engineering, Shanghai University. Research direction is driving and sensing technology based on smart materials. Li Long, Associate Professor and PhD supervisor at the School of Mechanical and Electrical Engineering, Shanghai University. Long-term research on intelligent structures and sensing, flexible/soft robots, etc. Achieved a series of results in innovative configurations, driving sensing, and intelligent control of flexible/soft robots, overcoming key technologies such as frictional electric-based soft sensing, decoupled configurations of line-driven continuum robots, flexible origami modular robots, and variable stiffness control, supporting multiple key development directions in aerospace pre-research.

■ Source: Innovation Integration Promotion Office