Aerospace components are evolving towards digitalization, intelligence, sustainability, efficiency, and high quality from development to mass production. This industrial upgrade process continuously drives technological innovation, significantly accelerating the penetration and application of metal 3D printing technology in the aerospace field. Relying on its efficient production model, integrated forming capability for complex components, and intelligent process system, metal 3D printing technology increasingly highlights its technical advantages and industrial value in key dimensions such as performance optimization, cost control, and efficiency improvement in development.

01

Innovative Advantages: Reshaping Development Methods

With over a decade of technical accumulation and industrial layout in the field of metal 3D printing technology, Platinum has established an integrated innovation service system covering equipment manufacturing, material research and development, process innovation, and optimization design, providing customers in high-end equipment fields such as aerospace with a full lifecycle additive manufacturing solution from R&D to mass production and remanufacturing, helping customers achieve technological upgrades and value enhancement.

01Rapid R&D and Personalized Manufacturing

Faced with the need for multiple rounds of physical trial iterations in design verification in aerospace, metal 3D printing technology can adapt to the rapid upgrade iterations and personalized customization needs of components, compressing the component development cycle from months to days, better aligning with the flexibility requirements of manufacturing cycles.

02Integrated Forming of Complex Configurations

In traditional manufacturing, complex structural components often require several parts to be assembled, while metal 3D printing technology can achieve moldless production and near-net shaping, reducing machining allowances, the number and complexity of part assemblies, and shortening manufacturing processes, eliminating welding seam risks from the manufacturing end, achieving a precise balance between functional integration and manufacturing efficiency.

03High-Performance Parts Cost Reduction and Efficiency Increase

By utilizing unique structural innovations such as thin-walled ribs, hollow lattice, and built-in honeycomb in metal 3D printing technology, it achieves high-strength lightweight integrated forming, reducing material consumption, R&D, and manufacturing costs, while ensuring that mechanical performance meets standards, achieving the “performance-cost-process” goals.

02

Application Practice: Helping Leaders Solve Problems

Metal 3D printing technology is accelerating to become a strategic competitive advantage for high-end equipment manufacturing enterprises. Platinum fully leverages its full industrial chain advantages, collaborating with customers to overcome technical challenges in integrated forming of complex structural parts, manufacturing cost optimization, and key component performance enhancement, ensuring product quality stability and delivery reliability:

“Fast Boat 11 Solid Launch Vehicle

-

Customer Demand: Shorten product development cycle, effectively control costs, and achieve the lightweight goal of the entire rocket structure.

-

Cooperation Results:Integrated forming shortened the design modification testing time and manufacturing time of parts, improved manufacturing efficiency, avoided issues such as cracking at welding points during service, effectively improving the quality and lifespan of parts; while ensuring the strength of parts, lightweight was achieved, with better performance indicators.

“Jiuzhou Cloud Arrow Liquid Oxygen Methane Engine Image of the scaled-down Dragon Cloud Engine component

Image of the scaled-down Dragon Cloud Engine component

-

Customer Demand: Break through the bottleneck of overall manufacturing of complex components, eliminate quality risks from multiple part splicing, and simultaneously achieve high precision, lightweight, and high reliability production.

-

Cooperation Results: Optimized the internal topology of the turbine pump casing, reduced the number of welds, and improved component reliability; through lightweight solutions, increased the material utilization rate for manufacturing the thrust chamber cover from below 20% to over 95%, significantly reducing manufacturing costs; the engine pipeline adopted integrated forming technology for irregular flow channels, achieving part structure optimization and lightweight.

“Blue Arrow Aerospace Liquid Oxygen Methane Engine

Image of the ignition bend pipe developed in collaboration with BLT and Blue Arrow Aerospace

-

Customer Demand: Provide comprehensive additive manufacturing service support, effectively balancing product quality performance, manufacturing cycle, and economic cost.

-

Cooperation Results: Utilizing BLT-S400 equipment achieved batch production of irregular thin-walled parts, quickly manufacturing while ensuring quality precision, helping customers save production costs and accelerate technology iteration.

“Zhi Xing No. 2 A Star Synthetic Aperture Radar Satellite

-

Customer Demand: Lightweight and rapid manufacturing of small batches of components, ensuring component quality performance, achieving cost reduction and efficiency increase.

-

Cooperation Results: Successfully solved the deformation problem of large-sized panel skin lattice structure parts, using two BLT-S1000 devices for parallel printing, ensuring project progress while successfully delivering the largest 3D printed satellite structure for domestic on-orbit applications, achieving cost reduction and efficiency increase.

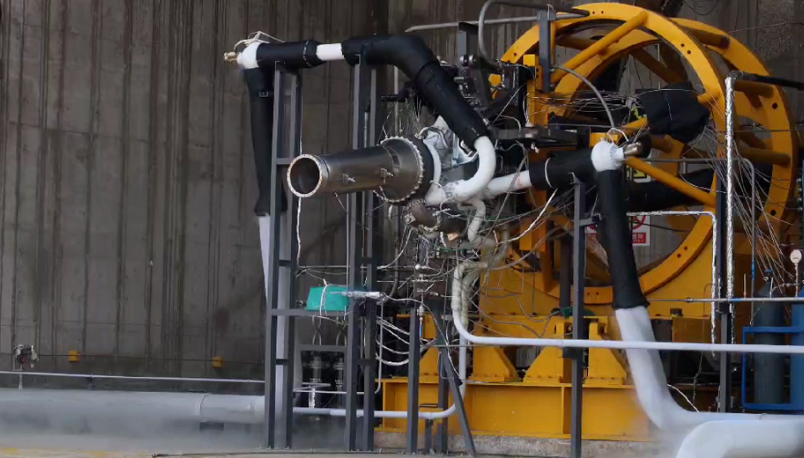

“A Certain Liquid Oxygen Methane Reusable Verification Rocket

Image of the hundred-ton liquid oxygen methane rocket engine test site

-

Customer Demand: Achieve lightweight while ensuring rocket performance; meet efficiency, cost, and iteration speed requirements.

-

Cooperation Results: Assisted customers in developing multiple key components of the engine, completed structural optimization design and rapid trial production, helping customers shorten production cycles, save production costs, accelerate product iteration, and improve development efficiency.

03

Equipment Empowerment: Dual Breakthrough in Cost Reduction and Quality Improvement

In response to the growing technical demands for large structural components in the aerospace field, Platinum has constructed a device R&D strategic framework based on in-depth industry research, launching the BLT-S series metal additive manufacturing equipment, which has various width specifications to meet the production needs of different size parts, as well as combined manufacturing, rapid iteration verification, and mass production requirements. Currently, multiple models of equipment have participated in the R&D and mass production of key components.

Based on its profound engineering accumulation in the R&D of aerospace components, Platinum has innovatively integrated the BLT series intelligent equipment, process parameters, and intelligent software modules, successfully landing multiple landmark engineering application cases:

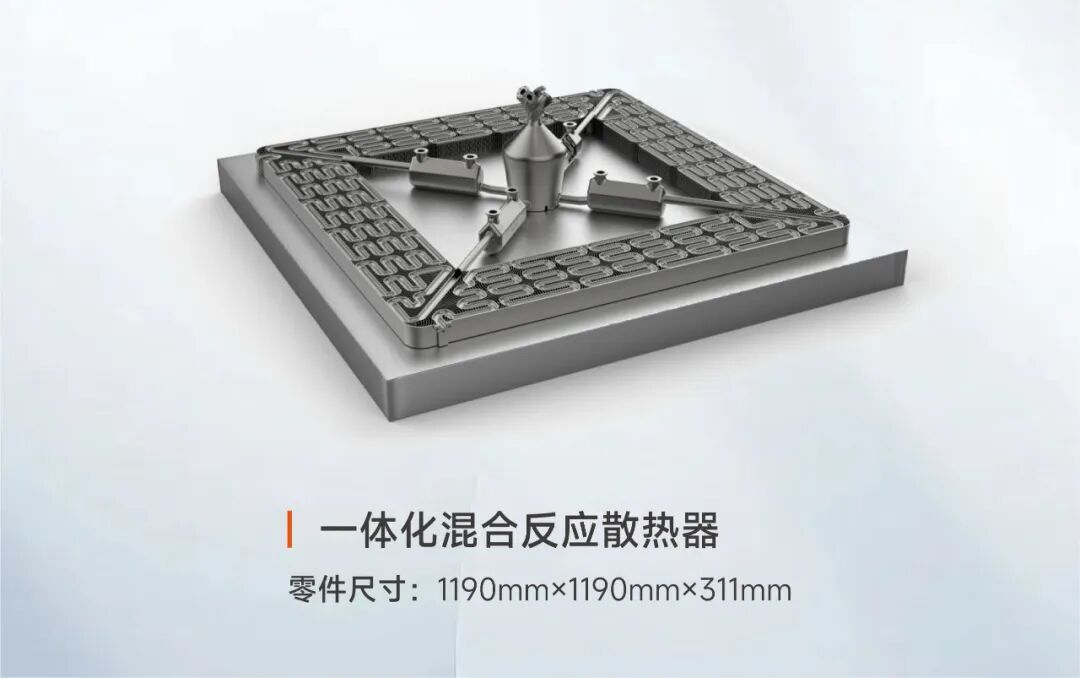

“Integrated Mixed Reaction Heat Exchanger

-

Printing Equipment: BLT-S1500 (26 lasers)

-

Technical Description: This part integrates the functions of a mixer, reactor, and heat exchanger, achieving an integrated process of thorough mixing, reaction, and cooling, reflecting the unique advantages of additive manufacturing in the production of complex structural parts, eliminating the multi-part assembly steps in traditional processes. The interior of the mixer and reactor adopts extremely small curved surface structures, with a large porosity and good connectivity, conducive to thorough mixing and reaction of materials.

“Hanging Device

-

Printing Equipment: BLT-S825 (Z-axis net forming height of 2.5 meters)

-

Technical Description: Based on the characteristics of the part, Platinum optimized the structure of the hanging device, adopting a large number of hollow structures and selecting the lightweight, high-strength BLT-TA15 material, significantly reducing the weight of the part while ensuring functionality and strength, achieving a large-span connection function.

In addition, Platinum has launched a series of new technologies and processes based on industry pain points, including support-free forming technology, large layer thickness/variable layer thickness printing technology, high-strength aluminum forming processes, and copper material solutions, providing a more efficient and cost-effective manufacturing path for the aerospace field.

The CIMT 2025 is still in full swing, welcome to visit booth E3-B313 for in-depth discussions on technological development and to explore opportunities for industrial cooperation.

END