The specific strength of magnesium alloys is higher than that of aluminum alloys. In the aerospace field, magnesium alloys can be used to replace aluminum alloys in the manufacture of components such as aircraft seats, floors, hatches, and structural parts of spacecraft, which can make the aircraft lighter while ensuring structural strength. In our country the Tianwen-1 probe has relevant applications of magnesium alloys. Especially for aerospace applications, the application scenarios of materials may span various temperature ranges. This places higher demands on the mechanical properties of lightweight metals such as magnesium alloys at room and high temperatures. However, the rapid diffusion of atoms at high temperatures may lead to abnormal growth of strengthening phases and grain boundary sliding, thereby reducing the material’s strength at high temperatures.

Adding rare earth elements (RE) to magnesium alloys is widely regarded as an effective method to improve their high-temperature mechanical properties, but the tensile strength above250°C remains unsatisfactory. Introducing a large number of high melting point intermetallic compounds or eutectic phases can further enhance heat resistance; however, the high density of precipitated phases or second phases in Mg alloys can lead to a significant loss of room temperature ductility, making it difficult to balance high-temperature strength and room temperature ductility. For example, the liquid die-cast Mg-10Gd-3Y-0.5Zr alloy exhibits a significant tensile strength of 282MPa at 300°C, but the elongation at fracture is only 2.4%. Therefore, new methods need to be explored to guide the design of magnesium alloys with high high-temperature strength and good room temperature tensile ductility.

Friction Stir Additive Manufacturing of Bulk Magnesium Alloys

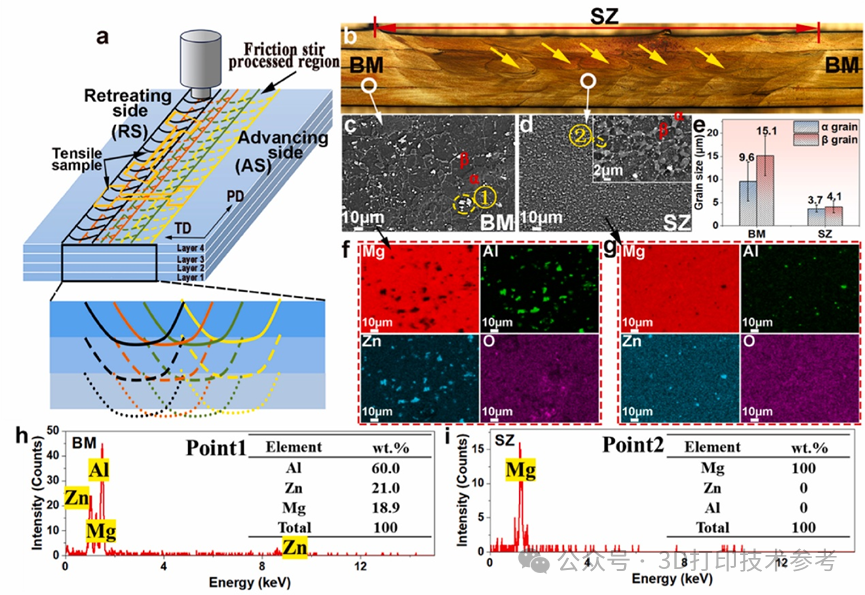

Researchers from Tsinghua University have used Friction Stir Additive Manufacturing (FSAM) technology to prepare Mg-Li-Al-Zn dual-phase magnesium alloys. Through the combined effects of grain refinement and solid solution strengthening, the magnesium alloy prepared by friction stir exhibits refined grains and uniform phase distribution, showing a synergistic improvement in strength, plasticity, and corrosion resistance.

Article link:https://doi.org/10.1016/j.msea.2024.146239

In the base sample, there are coarse precipitates dispersed in the β-Li phase with a larger grain size. The grain size in the stirring zone is refined, and small spherical precipitates are uniformly distributed within the equiaxed β-Li grains and along the grain boundaries. After FSAM, the grain size of the β-Li phase decreases from 15.1 ± 4.3 μm to 4.1 ± 1.3 μm.

The yield strength of the base sample (BM) is 156.8± 1.0 MPa, and after FSAM, the yield strength of samples in different directions PD and TD increases to 168.9± 9.3MPa and 171.1 ± 4.8MPa. The elongation of the PD sample shows a maximum value of 49.4± 7.9%; the elongation of the TD sample is lower than that of the PD and BM samples. The strength after FSAM is mainly due to the uniform dispersion strengthening and fine grain strengthening of the precipitated phases. In addition, due to the dissolution of AlLi and MgLi2Al, the strength of the alloy is improved through solid solution strengthening.

Laser Powder Bed Fusion of WE43 Magnesium Alloy

Researchers from Huazhong University of Science and Technology successfully prepared fine-grained, highly densified, and mechanically superior WE43 alloy samples using laser powder bed fusion additive manufacturing technology. Under a combination process of laser power of 200 W and scanning speed of 600 mm/s, samples with a density of up to 99.89% were obtained. The deposition direction produced a periodic heterogeneous structure, with fine grains (~ 4.1 μm) at the melt pool boundary and coarse grains (~ 23.6 μm) inside the melt pool. The tensile yield strength, ultimate tensile strength, and fracture elongation were 276 ± 1 MPa, 292 ± 1 MPa, and 6.1 ± 0.2%, respectively. Its tensile properties surpass those of other magnesium alloys and magnesium alloys produced by other processes. Solid solution strengthening ( 24.5%), grain boundary strengthening ( 14.4%), and HDI strengthening ( 32.2%) are the main sources of high yield strength.

Article link:https://doi.org/10.1016/j.jma.2024.03.012

At different laser volumetric energy densities, LPBF printed WE43 alloys exhibited variations in tensile mechanical properties. When the energy density increased from 88 J/mm3 to 138 J/mm3, the yield strength increased from 252 ± 4 MPa to 276 ± 1 MPa, the ultimate tensile strength increased from 286 ± 1 MPa to 292 ± 1 MPa, and the fracture elongation increased from 3.5 ± 0.5% to 6.1 ± 0.2%. Among them, the samples printed at 138 J/mm3 exhibited significantly higher work hardening rates than other samples. In the early stages of deformation, it had a constant work hardening rate of about 2.3 GPa.

Arc Melt Wire Additive Manufacturing of ZM 6 Alloy

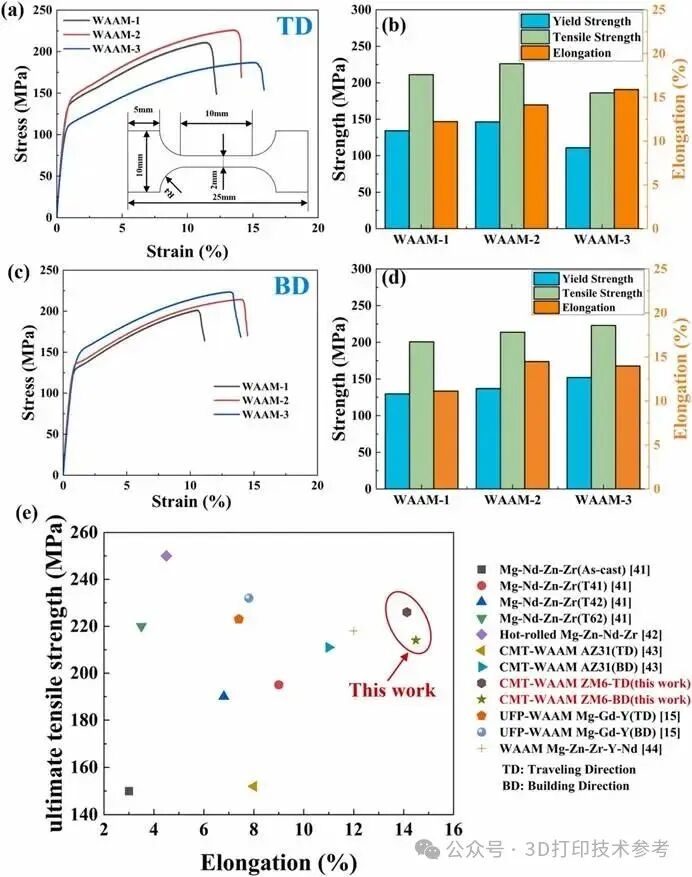

Researchers from Taiyuan University of Technology used Cold Metal Transfer (CMT) – Arc Melt Wire Additive Manufacturing (WAAM) to prepare Mg2.4Nd-0.3Zn-0.6Zr (ZM 6, wt%) alloy thin-walled materials. The forming quality, microstructural evolution, and mechanical properties of WAAM ZM 6 alloy thin-walled components were studied. The ultimate tensile strengths on TD and BD were 226 MPa and 214 MPa, with no significant anisotropy, and an elongation of 15%, indicating good plasticity.

Article link:https://doi.org/10.1016/j.jallcom.2025.180096

The changes in mechanical properties are attributed to differences in microstructure. Based on the layer-by-layer stacking technology of WAAM, the thin-walled components exhibit a distinct layered structure. WAAM ZM 6 has higher UTS and EL than cast alloys, showing similar YS to heat-treated ZM 6 alloys, but with significantly improved EL. This is due to the use of the “Z” path to oscillate the melt pool in the CMT-WAAM process, which promotes grain refinement.

Heat Treatment + Arc Melt Wire Additive Manufacturing of Mg Alloys

Researchers from Harbin University of Science and Technology used arc additive manufacturing technology to prepare Mg-2.8Nd-0.5Zn-0.4Zr ( NZ 30 K) thin-walled structural components, systematically studying the microstructural evolution and mechanical properties during the printing deposition and heat treatment processes. Compared to cast alloys, the deposited alloys have finer grains, with an average grain size ranging from 13.2 μm ~ 20.1 μm, and the grains exhibit a completely equiaxed structure with random orientation. After solid solution treatment at 520 ℃ for 12 hours, the eutectic completely dissolves, and the grain size slightly increases, averaging 18.2 μm ~ 23.1 μm. After aging at 200 ℃ for 8 hours, a high density of nanoscale β′ phases appears in the alloy, resulting in a significant aging hardening effect, with peak-aged alloy tensile strength and elongation reaching 334.6MPa and 14.3%, showing good application potential in terms of cost and performance.

Article link:https://doi.org/10.1016/j.msea.2025.148060

After solid solution treatment, the strength decreases while plasticity increases. After solid solution + peak aging treatment, the strength of the alloy significantly increases while plasticity decreases, with UTS, YS, and EL values of 334.6MPa, 169.7MPa, and 14.3%, respectively. This high strength allows WAAM NZ 30 K alloys to achieve significant strength enhancement through heat treatment. Compared to cast NZ 30 K alloys, WAAM NZ 30 K alloys exhibit improved mechanical properties. Compared to other WAAM Mg-RE alloys, WAAM NZ30K shows better synergy of strength and plasticity across all three states. At the same time, WAAM NZ30K has the lowest rare earth content, and the alloy achieves moderate strength after T6 heat treatment, which can reduce production costs and thus bring better economic benefits.

Researchers from Xi’an University of Science and Technology studied the effects of heat treatment processes on the mechanical and corrosion properties of Cold Metal Transfer – Arc Melt Wire Additive Manufacturing ( CMT-WAAM LA 103 Z magnesium-lithium alloy. Both solid solution treatment and aging treatment improved the mechanical properties of LA 103 Z magnesium-lithium alloys. Solid solution treatment ( 340 °C) dissolves fine needle-like α-Mg phases and AlLi phases, with the precipitated Li2MgAl phase dispersed. After solid solution treatment, the tensile strength of the alloy increased from 144 ± 6.2MPa to 299 ± 1.2MPa, an increase of nearly 107.6%. High-temperature ( 225 °C aging treatment makes the grain distribution of the alloy more uniform, AlLi phase particles gradually coarsen, Li 2 MgAl phase transforms into numerous fine AlLi phase particles. The yield strength increases from 100 ± 5.0 MPa to a maximum of 182 ± 2.6 MPa, an increase of about 82%, with a maximum elongation of 24.1% ± 2.0%.

Article link:https://doi.org/10.1016/j.jmst.2025.01.092

END

In summary, magnesium alloys are widely used in aerospace, automotive, and other fields due to their lightweight and high specific strength. The 3D printing method meets the requirements for personalized customization of magnesium alloys, further expanding their applications. By using different 3D printing processes combined with heat treatment, the strength and plasticity of magnesium alloys can be significantly improved, while achieving mechanical properties comparable to those of high rare earth content alloys at low rare earth content, thus reducing economic costs in actual production.

Note: This article is created with reference to 3D printing technology and is not authorized for reproduction without contact..Welcome to share

Industry expert exchange group Q group: 248112776

Further reading:

1. Fuzhi Technology 3D printing solutions help Purdue University run out the “innovation curve” in engineering education

2. New breakthrough: CRRC Research Institute successfully 3D prints large-sized high-speed train head window frame structural components

3. 865MPa! The Institute of Metal Research, Chinese Academy of Sciences develops ultra-high strength and heat-resistant 3D printed aluminum alloys

4. Taiwanese companies use electrochemical 3D printing to develop pure copper artificial intelligence system thermal management solutions