#AM易道 Introduction

When missiles roar out of their launch tubes, few would think that the framework supporting these deadly weapons might come from a 3D printer.

Recently, the U.S. Army’s Small Business Innovation Research (SBIR) program awarded $2 million to Continuous Composites, in collaboration with Boeing’s Aurora Flight Sciences, to use continuous fiber 3D printing technology to create the next generation of air-launched effector airframe structures.

This news comes from multiple media reports, marking a shift in #military 3D printing from accessory manufacturing to the production of structural components for core combat systems.

Air-Launched Effectors: A New Type of Unmanned Warfare

Air-Launched Effectors (ALE) represent a significant shift in modern military operational concepts.

In simple terms, air-launched effectors (ALE) refer to various unmanned systems launched from aircraft, which can be controlled by crew members or fly autonomously, providing information back to helicopters and networked ground forces.

This is a family of systems that includes aerial vehicles, various payloads, mission systems, and related support equipment, designed to autonomously or semi-autonomously deliver combat effects, acting as a single agent or team member to execute missions.

In operational use, air-launched effectors can be launched from platforms such as the UH-60 Black Hawk helicopter, AH-64 Apache attack helicopter, and MQ-1C Gray Eagle drone, performing a variety of tasks from target identification and communication relay to precision strikes.

The range of air-launched effectors is extensive: short-range effectors have a detection range of about 40 kilometers, medium-range about 100 kilometers, and long-range can reach up to 200 kilometers, with these distances being the lower limits of their range.

The core value of air-launched effectors lies in extending the organic operational radius, lethality, and survivability of manned platforms, enabling operators to conduct autonomous combat operations.

They are a key component of the advanced team concept for future armed reconnaissance ecosystems, enhancing the survivability, threat identification, target locking, and lethality of Army aviation brigades and ground force commanders’ assets.

AM易道 believes that the introduction of the air-launched effector concept marks a transition from traditional large manned platform combat modes to small, distributed, intelligent unmanned system swarm operations.

This reflects not only technological advancement but also a response to the dual demands of survivability and combat effectiveness in future high-intensity conflicts.

Launch Tube Deployment Systems: Structural Integrity Challenges of Canned Launch

This project focuses on enhancing the structural integrity of systems designed for launch from tubes—similar to missile deployment systems, aiming to set new performance benchmarks for these #air-launched platforms.

The launch tube deployment method presents unique engineering challenges for the airframe structure: the system must withstand high acceleration loads during launch while remaining lightweight to optimize flight performance.

SBIR Project Phase II: Successful Transfer of Naval Technology to the Army

This SBIR project’s technical path showcases the U.S. military’s cross-service collaboration model.

The project was initially funded by the Navy and, after completing Phase I validation, successfully transitioned to the Army for further advancement, now entering the $2 million Phase II stage.

Continuous Fiber 3D Printing Process Analysis: In-Situ Impregnation and Instant Curing Technology

Continuous Composites’ continuous fiber 3D printing technology represents a typical technical route in composite material manufacturing processes.

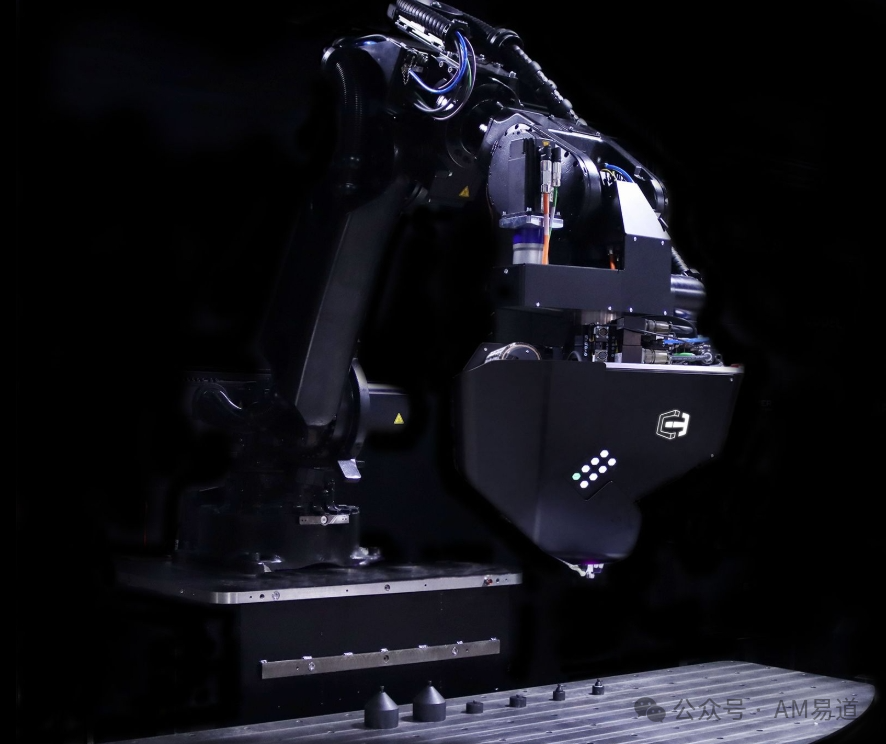

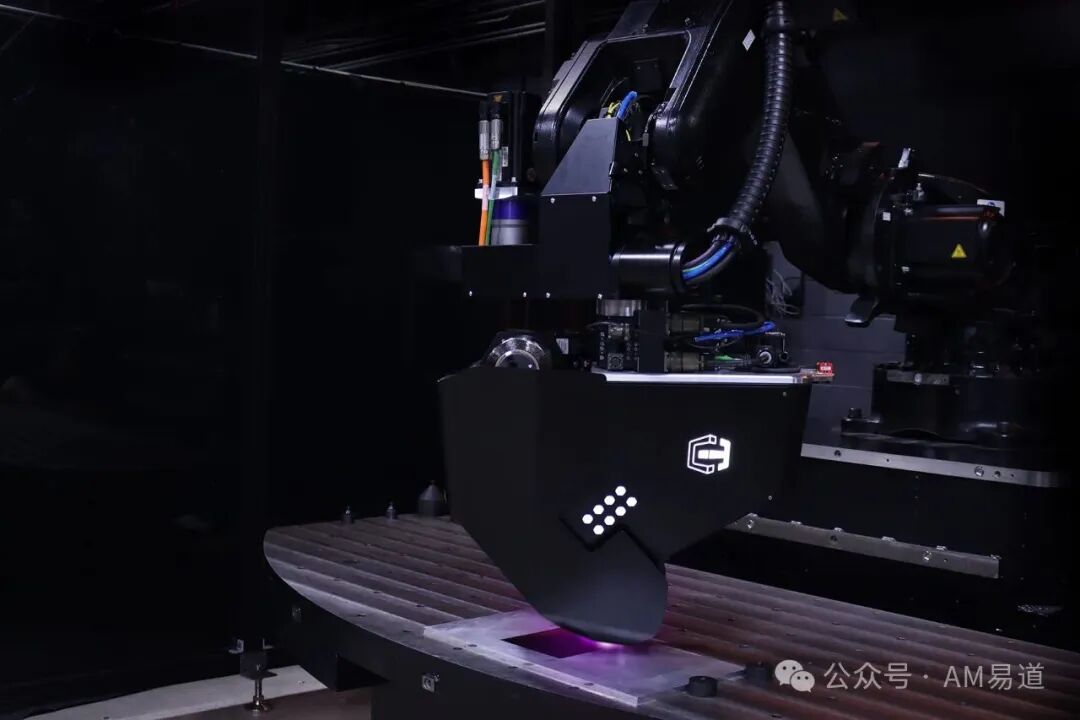

This process achieves in-situ impregnation of continuous dry fibers within the print head, using liquid thermosetting resin to output wet fiber bundles, which are then rapidly cured immediately after extrusion using a high-intensity curing source.

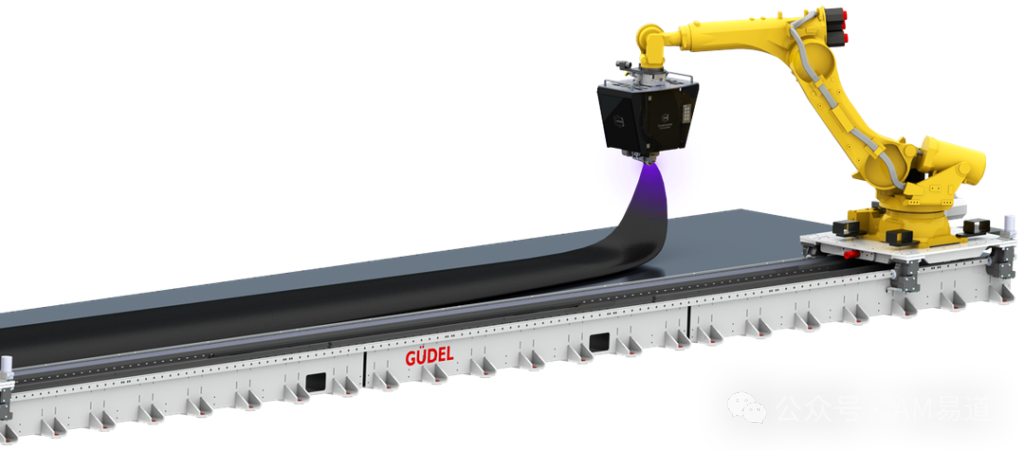

The system employs a motion platform-agnostic design, with scalable hardware solutions available on both robotic and gantry systems.

Compared to traditional processes that require prepreg materials, continuous fiber 3D printing reduces costs and storage requirements through impregnation technology while enabling real-time customization.

According to publicly available information, this process can print structural fibers (such as carbon fiber, glass fiber, aramid fiber) and functional fibers (such as optical fibers, metal fibers) in a single step.

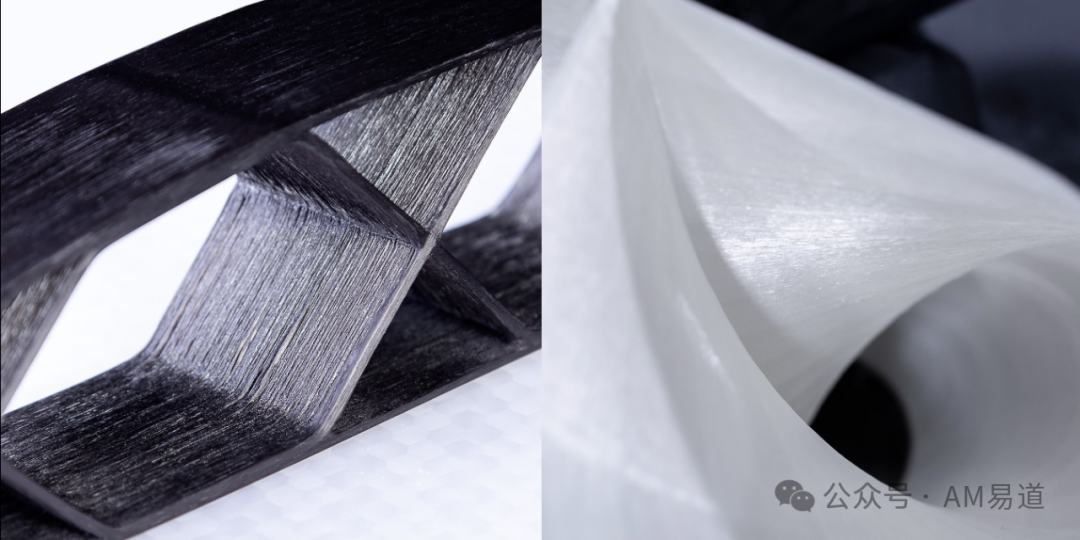

Technical data shows that this process is achieving a fiber volume fraction of 50-60%, a metric close to that of traditional high-performance composites.

Unlike traditional composite manufacturing that requires molds, lamination, and long curing times, continuous fiber 3D printing unifies software, hardware, and materials science into a single motion, unlocking previously unattainable geometries, speeds, and structural performance.

Fiber Orientation and Topology Optimization: Precise Control of Material Properties

In this project, Aurora Flight Sciences provides critical flight load data and geometric design parameters, which will be utilized to develop optimized airframe structures through its proprietary technology.

Leveraging its expertise in #fiber orientation and #topology optimization, the company will design lightweight, high-performance airframe structures that maximize internal volume, directly increasing payload capacity without compromising overall performance.

The continuous fiber 3D printing process enables precise fiber orientation at the tow level, unlike traditional composites that place fibers in predefined layers; this technology can accurately position fibers to maximize strength at desired locations.

This innovative approach reimagines internal structures, using less material while embedding greater strength in the design, thereby reducing weight and enhancing efficiency for critical aerospace applications.

Defense Supply Chain Strategic Positioning: Lightweight Rapid Deployment Solutions

This SBIR contract marks a critical step in the scaling of continuous fiber 3D printing technology for high-performance defense applications, validating the technology’s #industrialization potential for launching effector structural components and other aerospace technologies.

AM易道 believes that traditional composite manufacturing often relies on processing large blanks to produce thin-walled structures—this process wastes materials, is costly, and time-consuming.

Continuous fiber 3D printing eliminates these inefficiencies by creating near-net-shape parts, reducing machining requirements and production cycles.

Additionally, this technology achieves tow-level fiber orientation, allowing for efficient densification and customized thermal or mechanical properties in the final product.

In the context of increasing global military technology competition, this $2 million investment represents the U.S. military’s strategic positioning in next-generation manufacturing technologies.

The transition from technology validation to actual deployment will directly impact the structural design concepts and manufacturing process standards for future unmanned combat systems.

#Additive Manufacturing #Composite Materials #Defense Technology #Continuous Fiber 3D Printing #Carbon Fiber 3D Printing #SBIR Project

Further Reading:

-

The U.S. Military Launches Large-Scale 3D Printing of Drones

-

New Tactics on the Russia-Ukraine Battlefield? FDM 3D Printing Used for Anti-Drone Munitions!

-

3D Printing: The King of Modern Warfare! A Killer Drone is Born Every 23 Seconds in a Secret Factory in Ukraine

-

General Atomics and Divergent Team Up to Break Industry Boundaries, Launching Metal 3D Printed Drone Airframes

-

Breaking: The Legendary 101st Airborne Division is Reshaping Modern Warfare with 3D Printed Drones!

Corporate Partner Program: Become a partner in the additive industry with AM易道, gaining free access to resources for customer acquisition, financing, international expansion, and industry-academia-government collaboration.Reader Reminder: Add amyidao to join the reader group (note to join), to obtain original source links or content that is inconvenient to publish, and discuss everything about 3D printing with fellow readers of AM易道,AM易道 also suggests readers star the public account to receive updates from AM易道 promptly.Disclaimer:AM易道 has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in this article.AM易道 ImageVideo clips are sourced from the internet and are for auxiliary reading purposes only, with no commercial intent.All rights belong to the original authors; if there are any infringement issues, please contact the rights holders, and we will delete them promptly. The copyright of images in this article belongs to the copyright holders, and the AM易道 watermark is automatically added for auxiliary reading, not representing ownership of the images. For image usage, please consult the relevant copyright holders. AM易道 articles do not constitute any investment advice, and AM易道 is not responsible for any direct or indirect losses caused by the use of the information in this article.