Click the blue text to follow us

Multiwave 5000 Anton Paar Microwave Digestion System

The microwave digestion instrument is a laboratory device used for sample pretreatment, primarily for rapidly decomposing organic or inorganic samples through high-temperature and high-pressure microwave heating technology, facilitating subsequent element analysis (such as ICP-MS, AAS, etc.)

The Resource and Environmental Large Instrument Testing Platform has purchased aMultiwave 5000 Anton Paar Microwave Digestion System, which is a high-performance microwave digestion system launched by Anton Paar in Austria, specifically designed for the pretreatment of complex samples in laboratories, suitable for rapid and safe digestion under high-temperature and high-pressure conditions.

Core Components

01

Microwave Generation and Control System

Magnetron: High-frequency microwave generator (2450 MHz), providing stable and uniform microwave energy.

PowerTOP Technology: Optimizes microwave field distribution, avoids hot spot effects, ensuring uniform heating of all samples.

Intelligent Power Regulation: Dynamically adjusts microwave power based on real-time temperature and pressure (up to 1500W).

02

Digestion Vessel and Rotor System

Material of Digestion Vessel:

PTFE-TFM (modified polytetrafluoroethylene): High-temperature resistant (≤300°C), resistant to strong acids (such as HNO₃, HCl).

Quartz Outer Vessel (optional): Used for HF acid digestion, with stronger corrosion resistance.

Type of Rotor:

Standard Rotor (8/14 positions): for routine sample digestion.

High-Pressure Rotor (e.g., HPR-1000): supports up to 199 bar pressure, suitable for difficult-to-digest samples.

Dedicated HF Rotor: used for hydrofluoric acid (HF) digestion to avoid corrosion of standard rotors.

Sealing System:

Double Safety Lock Lid: ensures high-pressure sealing.

Pressure Relief Membrane: automatically ruptures during overpressure, directing pressure release.

03

Sensor and Monitoring System

Temperature Monitoring:

Each digestion vessel is equipped with an infrared temperature sensor for real-time monitoring (accuracy ±1°C).

Optional fiber optic temperature sensor (direct contact with sample liquid).

Pressure Monitoring:

Each digestion vessel is independently equipped with a piezoelectric pressure sensor for real-time data feedback (accuracy ±0.1 bar).

Real-time Feedback Control: The system automatically adjusts power to prevent overheating/overpressure.

04

Cooling and Exhaust System

Rapid Cooling Module:

-

Air Cooling System: built-in powerful fan for automatic cooling after program completion.

-

Optional Water Cooling (external circulating water machine): accelerates cooling to a safe temperature (<60°C).

Exhaust Gas Management:

-

Acid Vapor Condensation Device: reduces corrosive gas emissions.

-

Ventilation Interface: can be connected to laboratory exhaust systems.

05

Safety Protection Structure

Full Metal Explosion-Proof Casing: Made of 316 stainless steel, resistant to accidental explosion impacts.

Multiple Interlock Protections:

-

Door Lock Sensor: door cannot be opened when pressure is not released.

-

Microwave Shielding: prevents leakage, complies with international safety standards (e.g., CE, UL).

06

Software and User Interface

Multiwave GO Operating System:

-

Touchscreen interface, supports method presets (e.g., EPA 3052, ISO 11466).

-

Real-time curve display of temperature/pressure changes, data can be exported (CSV format).

Remote Monitoring: Optional computer control software for remote operation and data recording.

Basic Principles

01

Microwave Energy Transfer Mechanism

-

Uses 2450MHz microwave frequency, heating throughdipole polarization and ionic conduction dual mechanisms

-

Polar molecules (e.g., H₂O, HNO₃) undergo 2.45 billion orientation changes per second in an alternating electric field

-

Charged particles in ionic solutions (e.g., HCl) migrate and generate collision heating

-

Patented PowerTOP technology ensures uniform distribution of microwave fields (field strength non-uniformity <5%)

02

High-Pressure Reaction Thermodynamics

-

The closed system follows theClausius-Clapeyron equation: dP/dT=ΔH/(TΔV)

-

Under typical working conditions:

Temperature can reach 300℃ (573K)

Pressure can reach 199 bar (about 200 atmospheres)

The oxidation potential of nitric acid increases from 1.0V to 1.5V (vs. SHE)

03

Kinetic Acceleration Principle

-

The temperature effect reflected in the Arrhenius equation:k=Ae^(-Ea/RT)

-

For every 10℃ increase in temperature, the reaction rate increases by 2-4 times

-

Pressure promotes gas-liquid mass transfer, increasing acid diffusion coefficients by 10^3 times

04

Intelligent Control System

-

UsesPID closed-loop control algorithm: Temperature control accuracy: ±1℃; Pressure control accuracy: ±0.1bar; Sampling frequency: 10Hz

-

Safety interlock response time <10m

05

Material Science Design

-

The digestion vessel uses a gradient material design:

Inner layer: high-purity PTFE (in contact with the sample)

Middle layer: carbon fiber reinforced composite material

Outer layer: PEEK high-temperature resistant polymer

-

The burst membrane is optimized through finite element analysis, with a burst pressure tolerance of ±2%

06

Energy Efficiency Analysis

-

Microwave energy conversion efficiency >85%

This system achieves efficient decomposition of complex samples through precise control of microwave field parameters (frequency, power, mode) and reaction conditions (T, P, t), while ensuring experimental safety and data reliability. Its design complies with international standards such as the ASME Boiler and Pressure Vessel Code.

Operating Procedure

01

Preparation Before Startup

-

Environmental Check

Confirm that the laboratory ventilation system is functioning normally (exhaust volume ≥10 times/h)

Check power supply: 220V±10%, 50Hz, grounding resistance <4Ω

Work surface load ≥50kg, levelness <0.2°/m

-

Equipment Check

Confirm that the microwave cavity is clean and free of residues

Check rotor support for cracks (using a 10x magnifying glass)

Verify that the safety door interlock device is functioning properly

-

Consumable Preparation

Select the appropriate digestion vessel (based on sample type):

Routine samples: PTFE-TFM vessel (maximum filling volume 30%)

HF digestion: quartz vessel + PTFE lining

Prepare a new burst membrane (recommended replacement every 50 uses)

02

Sample Preparation

1. Weighing

Solid samples: 50-500mg (accuracy 0.1mg) (usually not exceeding 0.5g to avoid excessive reactions)

Liquid samples: 0.5-2mL (pipette calibrated)

Record sample moisture content (affects microwave absorption)

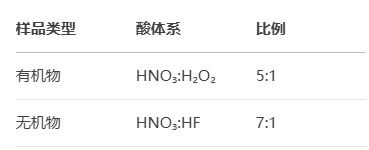

2. Acid Addition Scheme

Typical ratio (volume ratio):

Total liquid volume control: 8-10mL (explosion safety limit)

3. Vessel Loading

Use a dedicated funnel to prevent splashing; clean the vessel threads and apply graphite lubricant; tighten with a torque wrench (25N·m±5%)

03

Program Settings

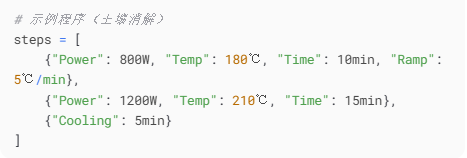

1. Parameter Input

Through the MultiWave GO interface:

Pressure limit: set according to vessel type (standard vessel ≤80bar)

2. Method Validation

-

Run blank control (3 parallels)

-

Check recovery rate of standard materials (e.g., NIST 2711a)

04

Operation Monitoring

1. Real-time Data Observation

Key parameters on the monitoring interface: actual power fluctuation range (±50W); temperature gradient (inter-vessel difference <5℃); pressure rise rate (normal <3bar/min)

2. Abnormal Handling

05

Post-Digestion Processing

1. Cooling Stage

Forced air cooling to <80℃ (about 15min)

Water cooling option (requires prior connection to circulating water machine)

2. Vessel Opening Operation

Use dedicated vessel opening tools

Stepwise pressure release (operate each vessel separately)

Record final pressure value (normal residual pressure <0.5bar)

3. Sample Transfer

Quantitative transfer to 50mL centrifuge tube

Wash three times with 2% HNO₃ (5mL each time)

Make up to 25mL (Class A volumetric flask)

06

Maintenance

1. Daily Maintenance

Cavity cleaning: ultrapure water + ethanol (1:1) wipe

Seal ring check: measure thickness monthly (wear <0.2mm)

2. Regular Calibration

Temperature sensor: annually NIST traceable

Pressure sensor: quarterly verified with standard pressure gauge

3. Consumable Replacement Records

Establish replacement log

07

Precautions

1. Safety Warnings

Absolutely prohibited to digest: perchlorates (explosion risk), reactive metals (Na/K), unknown composition samples

2. Data Integrity

Automatically generates electronic experimental records (compliant with 21 CFR Part 11); original data backup: dual hard drives + cloud storage

3. Performance Verification

Run QC samples monthly (e.g., GBW07405)

Acceptance criteria: RSD <5%, recovery rate 95-105%

The above is a brief introduction to the Multiwave 5000 Microwave Digestion System. Students in need can make an appointment at Resource and Environmental 144.

Editor 丨Xu Fei

Proofreader 丨Zhao Haiyan

Reviewer 丨Zhang Xuhui