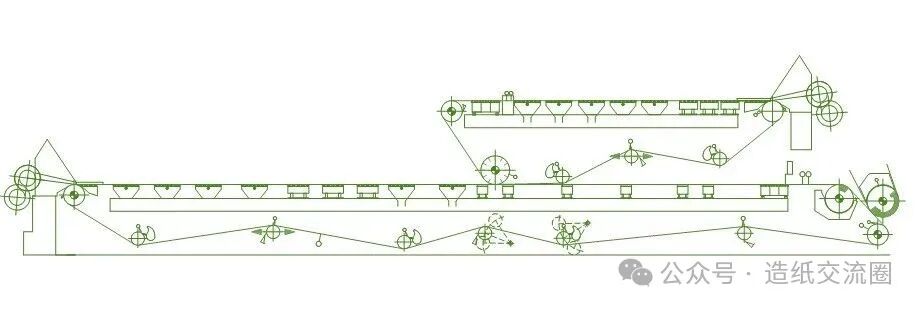

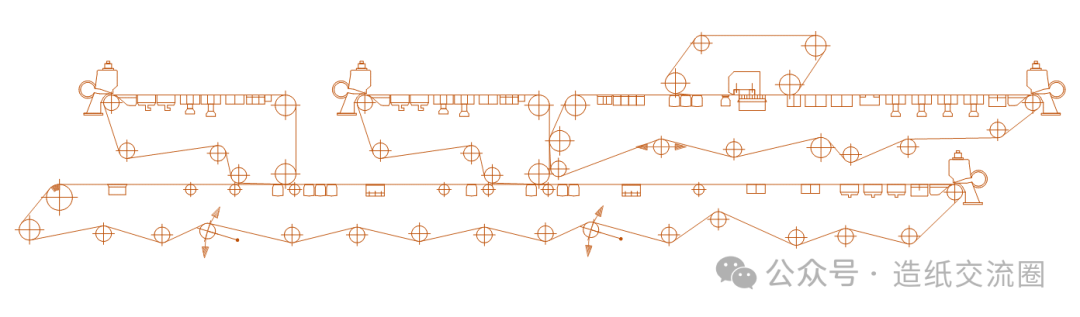

The Multi Fourdrinier is a paperboard forming machine that adds several individual forming devices on a long wire. First, a paper sheet is formed on the long wire using standard methods, and then the sheets formed on the additional devices are layered on top. Since the flow box, wire speed ratio, basis weight differences, and dewatering rates of each layer of wet paper can be controlled and adjusted separately, it is easy to produce satisfactory paperboard. The Multi Fourdrinier is currently the most popular paperboard forming machine. The Multi Fourdrinier can have different configurations such as double, triple, or quadruple layers depending on the product type. The more layers used, the more flow boxes, supply systems, and wire sections are required, which increases the overall cost of the machine. However, having more layers allows for the use of different pulp materials in each layer, facilitating the use of inexpensive secondary fibers as the core layer, thus achieving better economic benefits while ensuring the intrinsic quality of the paperboard. Additionally, it can reduce the basis weight of each layer, which helps improve the forming quality. The number of layers can be determined based on the product’s basis weight range and potential variations.

The Multi Fourdrinier is a paperboard forming machine that adds several individual forming devices on a long wire. First, a paper sheet is formed on the long wire using standard methods, and then the sheets formed on the additional devices are layered on top. Since the flow box, wire speed ratio, basis weight differences, and dewatering rates of each layer of wet paper can be controlled and adjusted separately, it is easy to produce satisfactory paperboard. The Multi Fourdrinier is currently the most popular paperboard forming machine. The Multi Fourdrinier can have different configurations such as double, triple, or quadruple layers depending on the product type. The more layers used, the more flow boxes, supply systems, and wire sections are required, which increases the overall cost of the machine. However, having more layers allows for the use of different pulp materials in each layer, facilitating the use of inexpensive secondary fibers as the core layer, thus achieving better economic benefits while ensuring the intrinsic quality of the paperboard. Additionally, it can reduce the basis weight of each layer, which helps improve the forming quality. The number of layers can be determined based on the product’s basis weight range and potential variations.

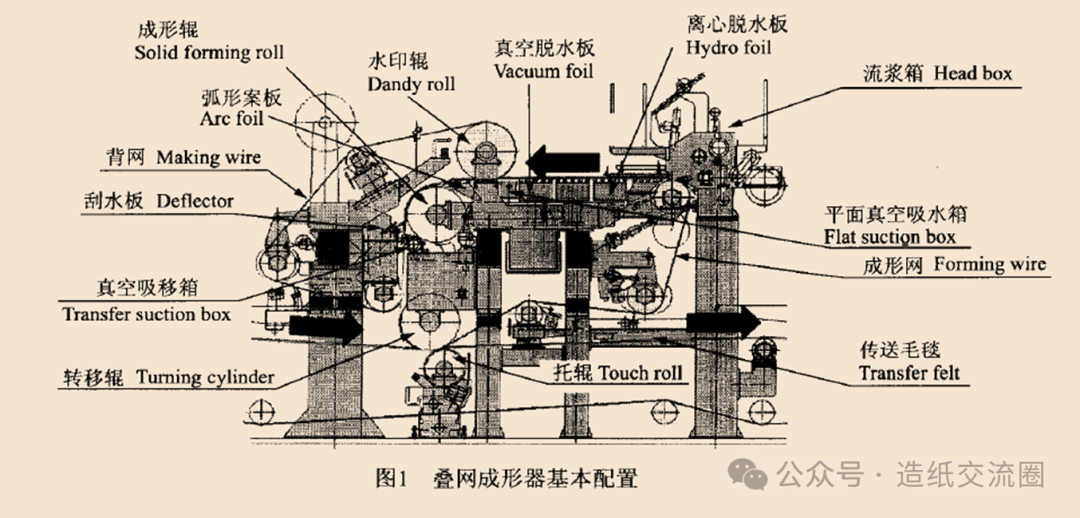

Inter-layer bonding is an important issue for the Multi Fourdrinier. Generally, the lower the dryness of the paper, the higher the inter-layer bonding strength. However, if the dryness is too low, factors such as speed fluctuations can damage the bonding of the paper layers, and in severe cases, it can even disrupt the forming process. This presents a contradiction; in actual production, the bonding dryness of the paper layers is typically around 10% to 14%. Another way to improve bonding strength is to control the pressure during the bonding of the paper layers (especially between the side with fewer fine fibers and the side with more fine fibers). However, if the bonding pressure is too high, it can leave marks on the surface. Sometimes, starch glue can be sprayed at the bonding points to enhance bonding strength. The characteristics of the Multi Fourdrinier include: ① Good forming quality (especially surface quality) and good printability. ② The quality of each layer of paper can be controlled separately based on the different raw materials used, resulting in smaller basis weight differences and lower longitudinal-to-transverse tensile ratios. ③ Wide product adaptability, with a large range of basis weights and speeds that can be produced. It can operate at higher working speeds. ④ The basis weight of the core layer can be higher, allowing for a significant use of secondary fibers. ⑤ The dryness at the bonding points of the paper layers can be controlled and adjusted to ensure optimal bonding moisture. Next, we will focus on the Multi Fourdrinier from Kobayashi Paper Machine (Success Former), whose basic configuration is shown in the following diagram, consisting of a flow box, forming wire, backing wire, and transfer blanket. Depending on the type of paperboard, basis weight, raw materials, and production speed, it is common to use 2 to 5 sets of formers (2 to 5 layers). The length from the chest roll of each layer to the forming roll is referred to as the forming length, which is calculated based on the distribution of basis weights and the freeness of the raw materials.

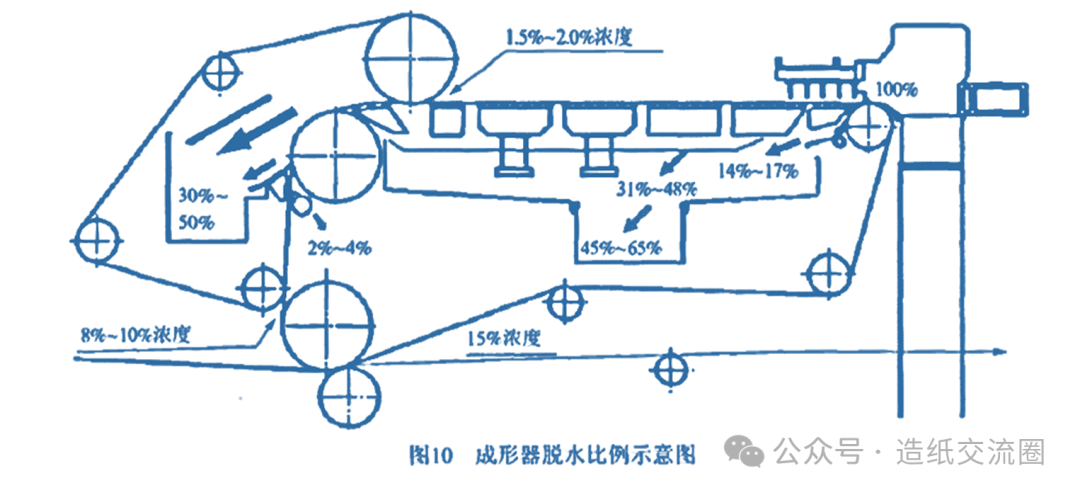

Inter-layer bonding is an important issue for the Multi Fourdrinier. Generally, the lower the dryness of the paper, the higher the inter-layer bonding strength. However, if the dryness is too low, factors such as speed fluctuations can damage the bonding of the paper layers, and in severe cases, it can even disrupt the forming process. This presents a contradiction; in actual production, the bonding dryness of the paper layers is typically around 10% to 14%. Another way to improve bonding strength is to control the pressure during the bonding of the paper layers (especially between the side with fewer fine fibers and the side with more fine fibers). However, if the bonding pressure is too high, it can leave marks on the surface. Sometimes, starch glue can be sprayed at the bonding points to enhance bonding strength. The characteristics of the Multi Fourdrinier include: ① Good forming quality (especially surface quality) and good printability. ② The quality of each layer of paper can be controlled separately based on the different raw materials used, resulting in smaller basis weight differences and lower longitudinal-to-transverse tensile ratios. ③ Wide product adaptability, with a large range of basis weights and speeds that can be produced. It can operate at higher working speeds. ④ The basis weight of the core layer can be higher, allowing for a significant use of secondary fibers. ⑤ The dryness at the bonding points of the paper layers can be controlled and adjusted to ensure optimal bonding moisture. Next, we will focus on the Multi Fourdrinier from Kobayashi Paper Machine (Success Former), whose basic configuration is shown in the following diagram, consisting of a flow box, forming wire, backing wire, and transfer blanket. Depending on the type of paperboard, basis weight, raw materials, and production speed, it is common to use 2 to 5 sets of formers (2 to 5 layers). The length from the chest roll of each layer to the forming roll is referred to as the forming length, which is calculated based on the distribution of basis weights and the freeness of the raw materials. The dewatering ratios and wet paper concentrations of each part of the forming wire are shown in the following diagram. The loop of the forming wire is determined by the minimum number of rolls required. To achieve maximum and most efficient dewatering capability, the dewatering components are configured as follows: ① Forming plate ② Multi-chamber centrifugal dewatering plate ③ Vacuum dewatering plate ④ Flat vacuum suction box ⑤ Arc dewatering plate ⑥ Vacuum suction box.

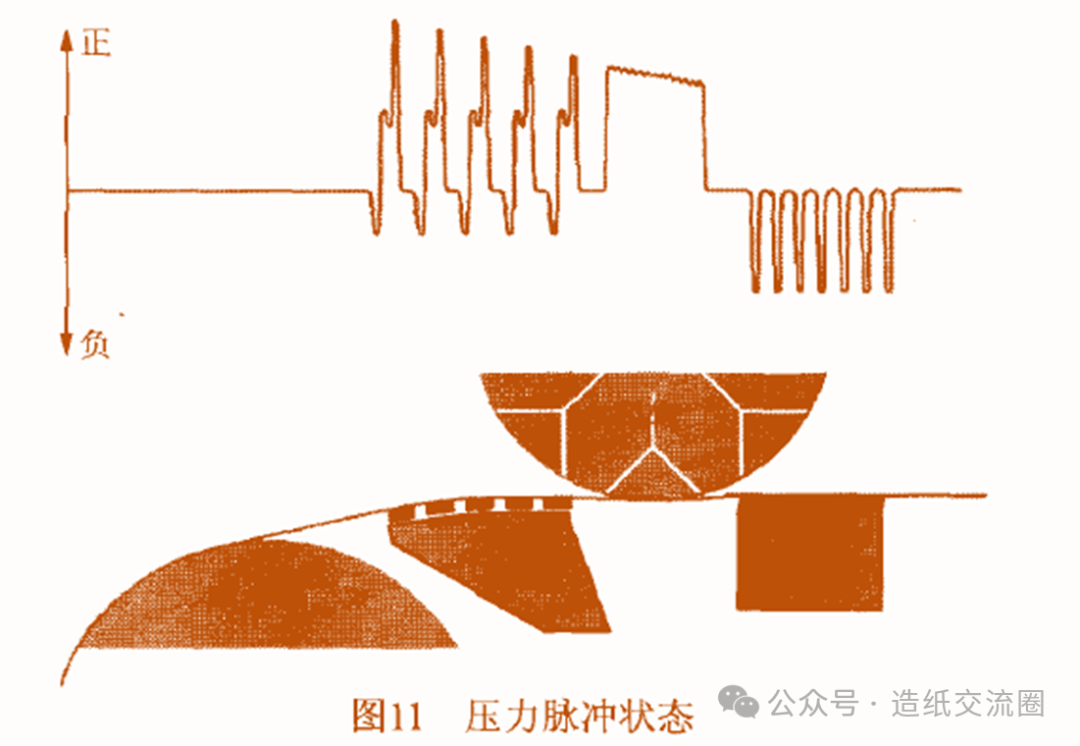

The dewatering ratios and wet paper concentrations of each part of the forming wire are shown in the following diagram. The loop of the forming wire is determined by the minimum number of rolls required. To achieve maximum and most efficient dewatering capability, the dewatering components are configured as follows: ① Forming plate ② Multi-chamber centrifugal dewatering plate ③ Vacuum dewatering plate ④ Flat vacuum suction box ⑤ Arc dewatering plate ⑥ Vacuum suction box. The wet paper sheet is usually transferred from the vacuum suction box to the forming wire, and then conveyed to the transfer blanket via a transfer roll. The most significant feature of the Multi Fourdrinier is the effect produced by the Dandy Roll, which greatly enhances uniformity compared to the Dandy Roll used in long wire systems. The following diagram shows the pressure pulse state generated from the flat vacuum suction box to the Dandy Roll and the arc dewatering plate. The continuous variation of the pulses promotes the dispersion and rearrangement of fibers, but the effect of the Dandy Roll is even greater.

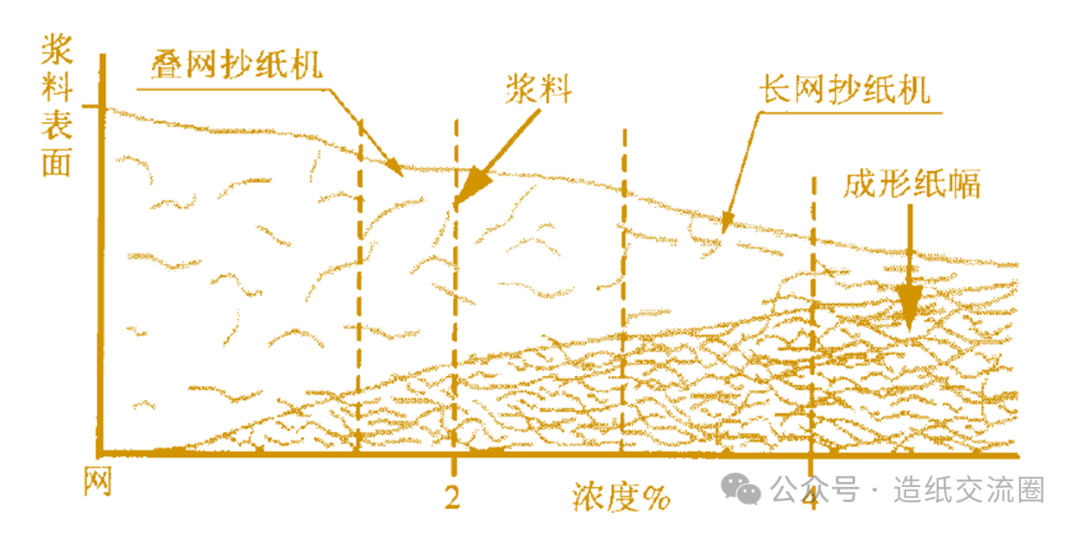

The wet paper sheet is usually transferred from the vacuum suction box to the forming wire, and then conveyed to the transfer blanket via a transfer roll. The most significant feature of the Multi Fourdrinier is the effect produced by the Dandy Roll, which greatly enhances uniformity compared to the Dandy Roll used in long wire systems. The following diagram shows the pressure pulse state generated from the flat vacuum suction box to the Dandy Roll and the arc dewatering plate. The continuous variation of the pulses promotes the dispersion and rearrangement of fibers, but the effect of the Dandy Roll is even greater. Compared to the Dandy Roll of long wire systems, its advantages are as follows:① The wet paper concentration and fiber orientation redistribution at the roll press inlet: In long wire systems, when the concentration is 3% to 4%, the paper sheet is essentially formed, with very little free pulp, making it difficult for fibers to redistribute. Additionally, there is almost no pulp pool generated at the roll press inlet, which is another reason for the inability to achieve fiber redistribution. In contrast, the inlet concentration of the Dandy Roll in the Multi Fourdrinier is 1.5% to 2.0%, where most of the pulp is still free, allowing for easy fiber redistribution, and the pulp pool generated at the roll press inlet has a stirring and homogenizing effect, significantly contributing to uniformity.② Long wire systems are easily affected by centrifugal forces, causing fibers and some water to be splashed off at the roll press outlet, damaging uniformity and splashing onto the water tray, increasing dirt. In contrast, the Dandy Roll of the Multi Fourdrinier is not affected by centrifugal forces, and there is almost no splashing at the roll press outlet. Furthermore, the wet paper sheet is protected by the wire on top, preventing fiber detachment and uniformity reduction.

Compared to the Dandy Roll of long wire systems, its advantages are as follows:① The wet paper concentration and fiber orientation redistribution at the roll press inlet: In long wire systems, when the concentration is 3% to 4%, the paper sheet is essentially formed, with very little free pulp, making it difficult for fibers to redistribute. Additionally, there is almost no pulp pool generated at the roll press inlet, which is another reason for the inability to achieve fiber redistribution. In contrast, the inlet concentration of the Dandy Roll in the Multi Fourdrinier is 1.5% to 2.0%, where most of the pulp is still free, allowing for easy fiber redistribution, and the pulp pool generated at the roll press inlet has a stirring and homogenizing effect, significantly contributing to uniformity.② Long wire systems are easily affected by centrifugal forces, causing fibers and some water to be splashed off at the roll press outlet, damaging uniformity and splashing onto the water tray, increasing dirt. In contrast, the Dandy Roll of the Multi Fourdrinier is not affected by centrifugal forces, and there is almost no splashing at the roll press outlet. Furthermore, the wet paper sheet is protected by the wire on top, preventing fiber detachment and uniformity reduction.