Traditional phase change materials (PCMs) face challenges such as low thermal conductivity, easy leakage in the molten state, and single functionality, making it difficult to meet the demands for efficient utilization of clean energy and multi-scenario applications. Existing organic/inorganic aerogel-based composites can partially address these issues, but they generally suffer from poor mechanical properties and low functional integration.Wang Xiaodong and Liu Huan from Beijing University of Chemical Technology have innovatively designed and developed a “five-in-one” multifunctional phase change composite material, utilizing carbonized polyimide (PI)/Kevlar nanofibers (KNF)/graphene oxide (GO)@ZIF-67 bidirectional composite aerogel (C/RGO@CoNC) as the supporting matrix, encapsulating paraffin wax (PW) as the phase change material, achieving synergistic optimization of solar-thermal, thermoelectric, electrothermal, and magnetothermal multi-energy conversion and electromagnetic shielding.The composite material constructs a bidirectional layered porous structure through unidirectional freeze-drying and high-temperature carbonization processes, combining the synergistic effects of ZIF-67-derived CoNC magnetic nanoparticles and reduced graphene oxide (RGO), significantly enhancing thermal conductivity (0.96 W m⁻¹ K⁻¹), electrical conductivity (232.8 S m⁻¹), and magnetic saturation intensity (18.61 emu g⁻¹). Its phase change enthalpy reaches 209.2 J g⁻¹, and the electromagnetic shielding effectiveness (EMI SE) reaches 66.2 dB in the X-band, with a solar-thermal conversion efficiency of up to 95.1%. Additionally, the composite material exhibits excellent performance in Joule heating (90.8°C at 4.5 V), magnetothermal response (rapid heating under a 1.05 MHz magnetic field), and hydrophobicity (contact angle of 113.2°), making it applicable in fields such as human thermal therapy, de-icing, and electronic protection. The related research is published in “Nano-Micro Letters”, with Shi Tao as the first author.

Figure Analysis

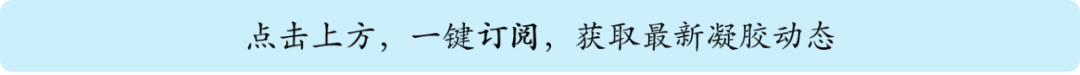

Figure 1 Preparation Strategy and Structural Design of Composite Aerogel

Through SEM, AFM, and TEM, the dispersion of GO nanosheets (lateral size 2-6 μm, thickness 5 nm) and KNF (length 3-5 μm, diameter 45 nm) was confirmed, combined with the in-situ deposition of the PI precursor and ZIF-67 (Figure 1b₃-b₄), constructing a bidirectional layered porous aerogel. XPS and FTIR analyses show that the sp² carbon ratio of RGO increases after carbonization (Figure 1h), and the Co 2p spectrum confirms the presence of magnetic Co (Figure 1i), while Raman spectroscopy (ID/IG=0.94) and XRD (graphite (002) peak at 26.2°) verify the high degree of graphitization, laying the foundation for multifunctional performance.

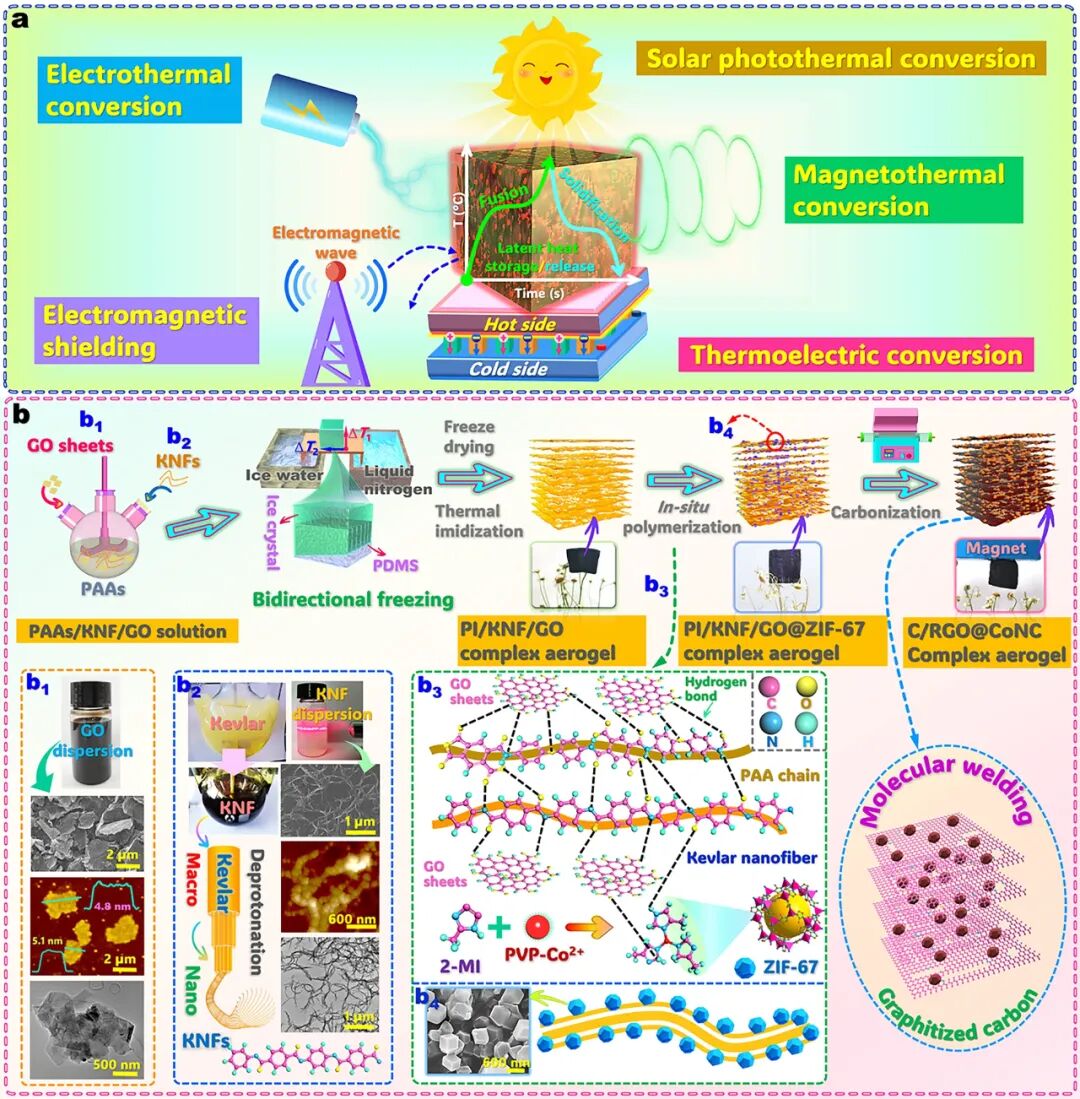

Figure 2 Microstructure and Chemical Characterization of Aerogel

SEM shows that the PI/KNF/GO@ZIF-67 aerogel framework uniformly loads ZIF-67 nanoparticles on the surface (Figure 2b₁-b₂), and after carbonization, forms a dense layered structure of C/RGO@CoNC aerogel (Figure 2c₁-c₃). HR-TEM (Figure 2d-e) and SAED (Figure 2f) confirm the coexistence of CoNC nanoparticles and RGO, and EDX elemental mapping (Figure 2g) shows a uniform distribution of Co, C, N, and O. XPS narrow spectrum (Figure 2h-i) reveals that Co²⁺ is reduced to metallic Co after carbonization, and the sp² carbon ratio of RGO increases, combined with porosity testing (Figure S14), the porosity of the aerogel reaches 92.6%, providing structural support for the high loading of PW (209.2 J g⁻¹).

Figure 3 Structure and Thermophysical Properties of Composite Material

SEM shows that PW is successfully impregnated into the pores of the aerogel (Figure 3b₁-b₃), DSC testing (Figure S18) indicates that the phase change temperature of the composite material (Tm≈42°C) is consistent with that of pure PW, and the thermal conductivity is enhanced to 0.96 W m⁻¹ K⁻¹ (Figure 3d). Infrared thermal imaging (Figure 3h-i) and finite element simulation (Figure 3j-k) confirm that the bidirectional layered structure promotes directional heat conduction, with faster thermal response in the parallel layer direction (76.9°C vs. 73.5°C). The porosity is positively correlated with the PW loading ratio (Figure 3g), C/RGO-20@CoNC/PW phase change enthalpy reaches 209.2 J g⁻¹, and energy storage efficiency exceeds 94%.

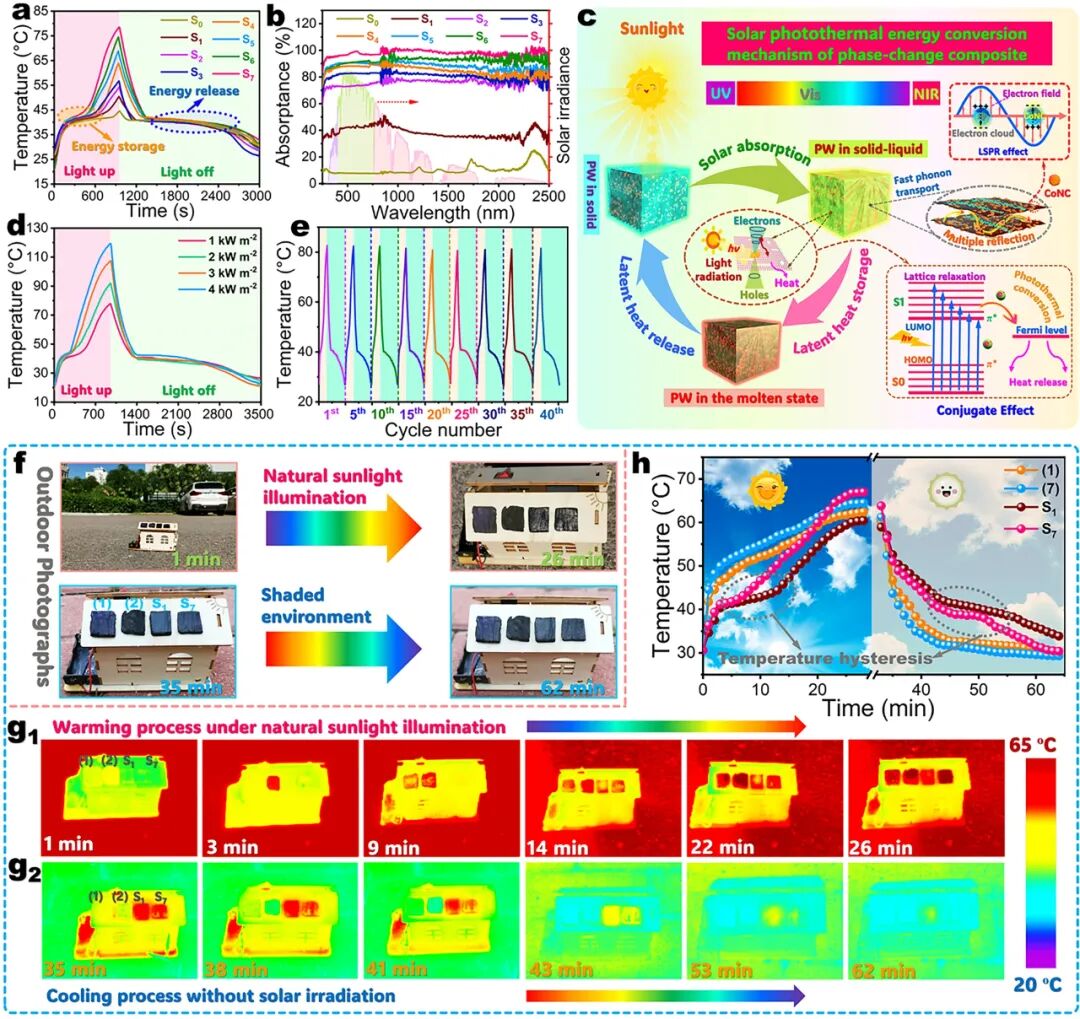

Figure 4 Solar-Thermal Conversion and Storage Performance

The composite material reaches a surface temperature of 78.6°C under 1.0 kW m⁻² illumination (Figure 4a), with a full-spectrum absorption rate of 77.5% (Figure 4b), and a solar-thermal conversion efficiency of 95.1%. Mechanism analysis (Figure 4c) indicates that the conjugated effect of RGO and the localized surface plasmon resonance (LSPR) of Co synergistically enhance light absorption. Outdoor experiments (Figure 4f-h) show that its rooftop coverage can raise the temperature of a wooden house model to 67.5°C, outperforming the control group. Cycling tests (Figure 4e) verify its stability, reaching a temperature of 119.4°C under 4.0 kW m⁻² illumination, suitable for efficient solar utilization.

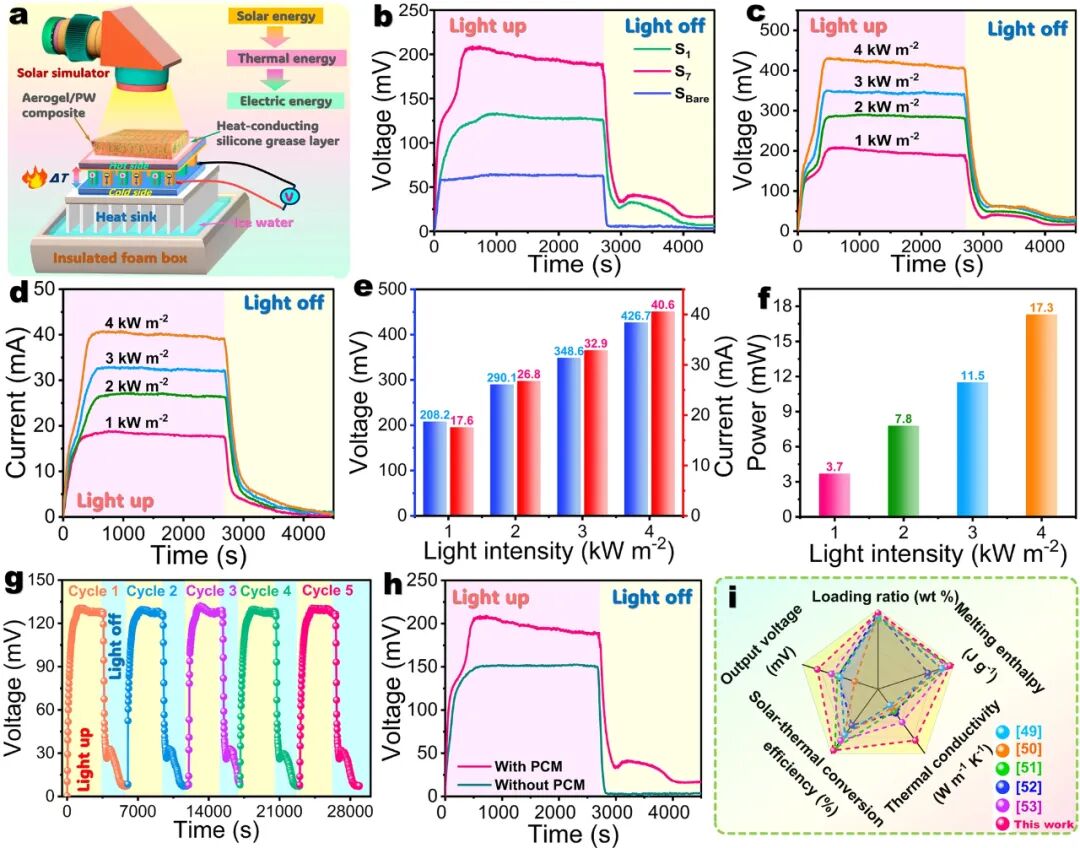

Figure 5 Solar-Thermal Electric Conversion Performance

Based on C/RGO@CoNC/PW thermoelectric generator (STEG), it outputs a voltage of 188.2 mV under 1.0 kW m⁻² illumination (Figure 5b), reaching 426.7 mV at 4.0 kW m⁻² (Figure 5c-d), with an output power of 17.3 mW (Figure 5f). Cycling tests (Figure 5g) show excellent stability, with the latent heat storage of PW allowing the STEG to maintain output voltage even in the absence of light (Figure 5h). Performance comparison (Figure 5i) indicates that its comprehensive performance surpasses that of similar materials reported in the literature, making it suitable for sustainable power generation.

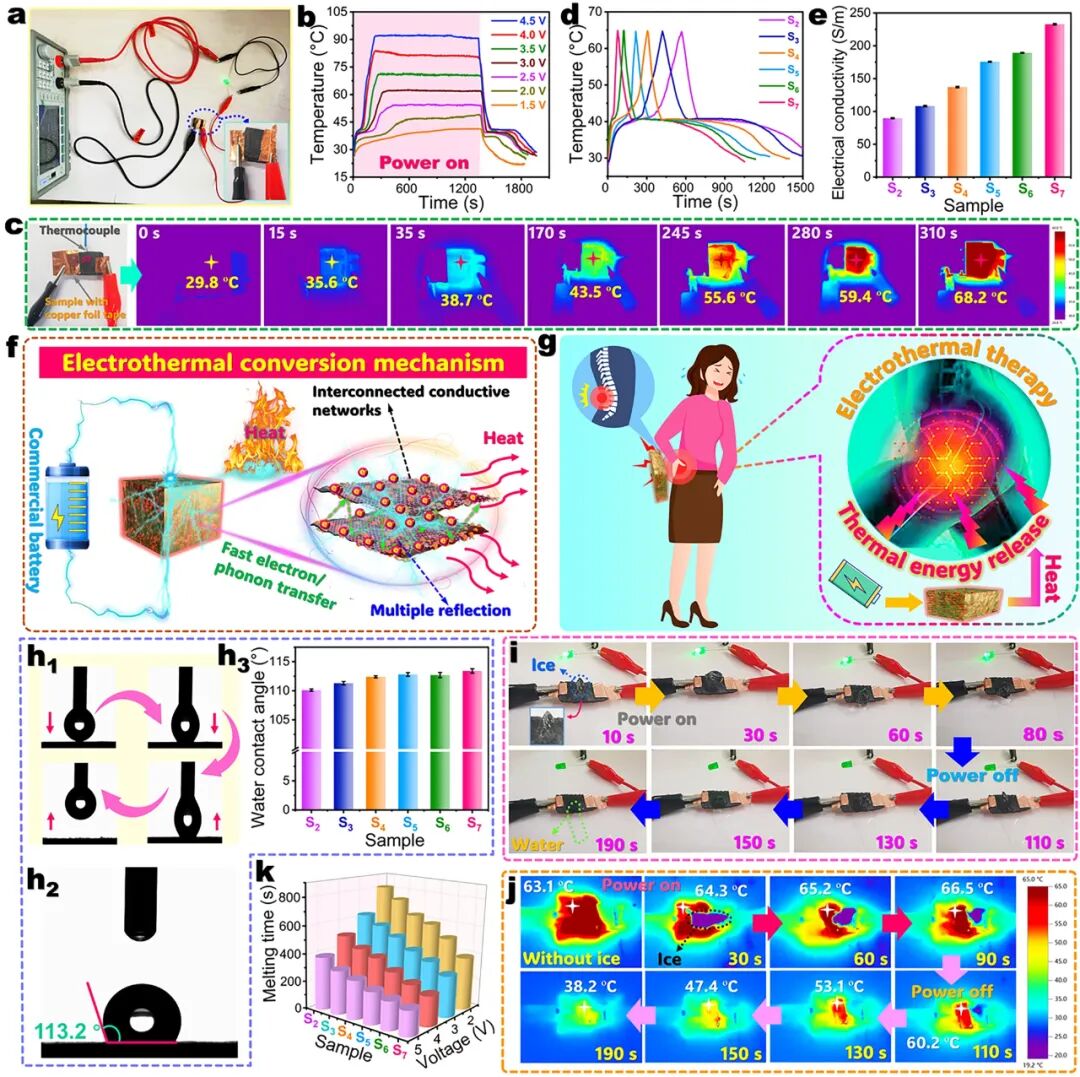

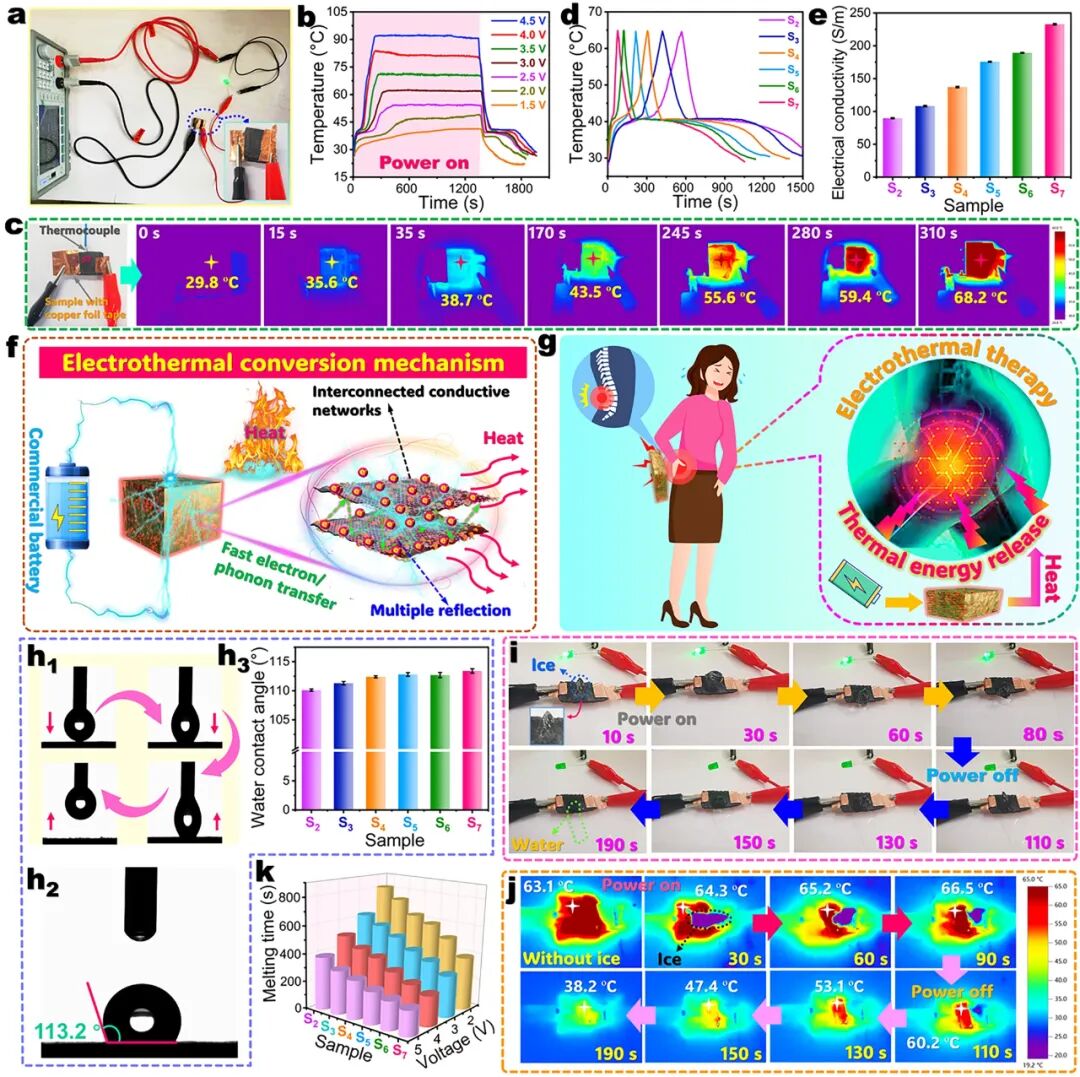

Figure 6 Electrothermal Conversion and Hydrophobic De-Icing Applications

The composite material heats up to 90.8°C in 3 seconds at 4.5 V (Figure 6b), with an electrical conductivity of 232.8 S m⁻¹ (Figure 6e), forming a three-dimensional conductive network with RGO and CoNC (Figure 6f). Hydrophobic tests (Figure 6h₁-h₃) show a contact angle of 113.2°, and electrothermal de-icing experiments (Figure 6i-j) indicate that it can melt ice blocks in 80 seconds, making it suitable for human thermal therapy (Figure 6g) and de-icing in low-temperature environments.

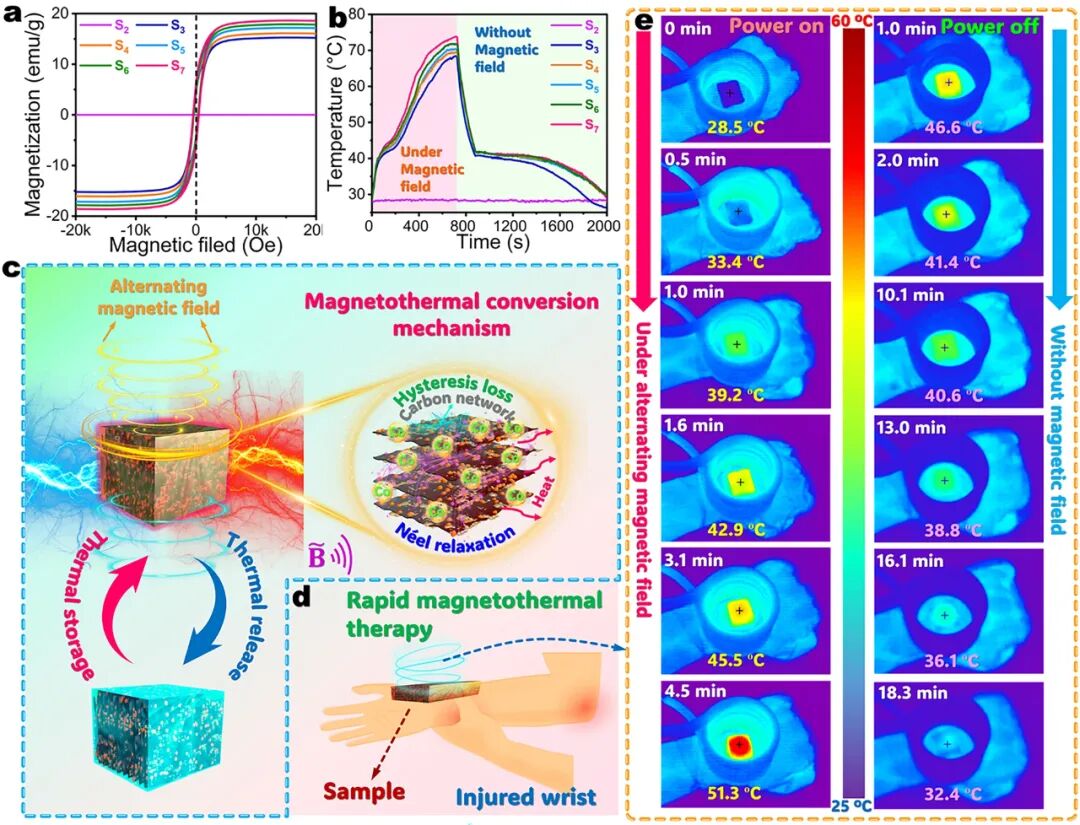

Figure 7 Magnetothermal Conversion and Medical Applications

The composite material exhibits a saturation magnetization of 18.61 emu g⁻¹ (Figure 7a), heating up to 50°C in 4.5 minutes under a 1.05 MHz alternating magnetic field (Figure 7b), with latent heat release maintaining 38°C for over 13 minutes (Figure 7e). Mechanism analysis (Figure 7c) reveals the synergistic effects of hysteresis loss and Néel relaxation, applicable in wrist thermal therapy (Figure 7d-e), demonstrating its potential in precision temperature-controlled medical applications.

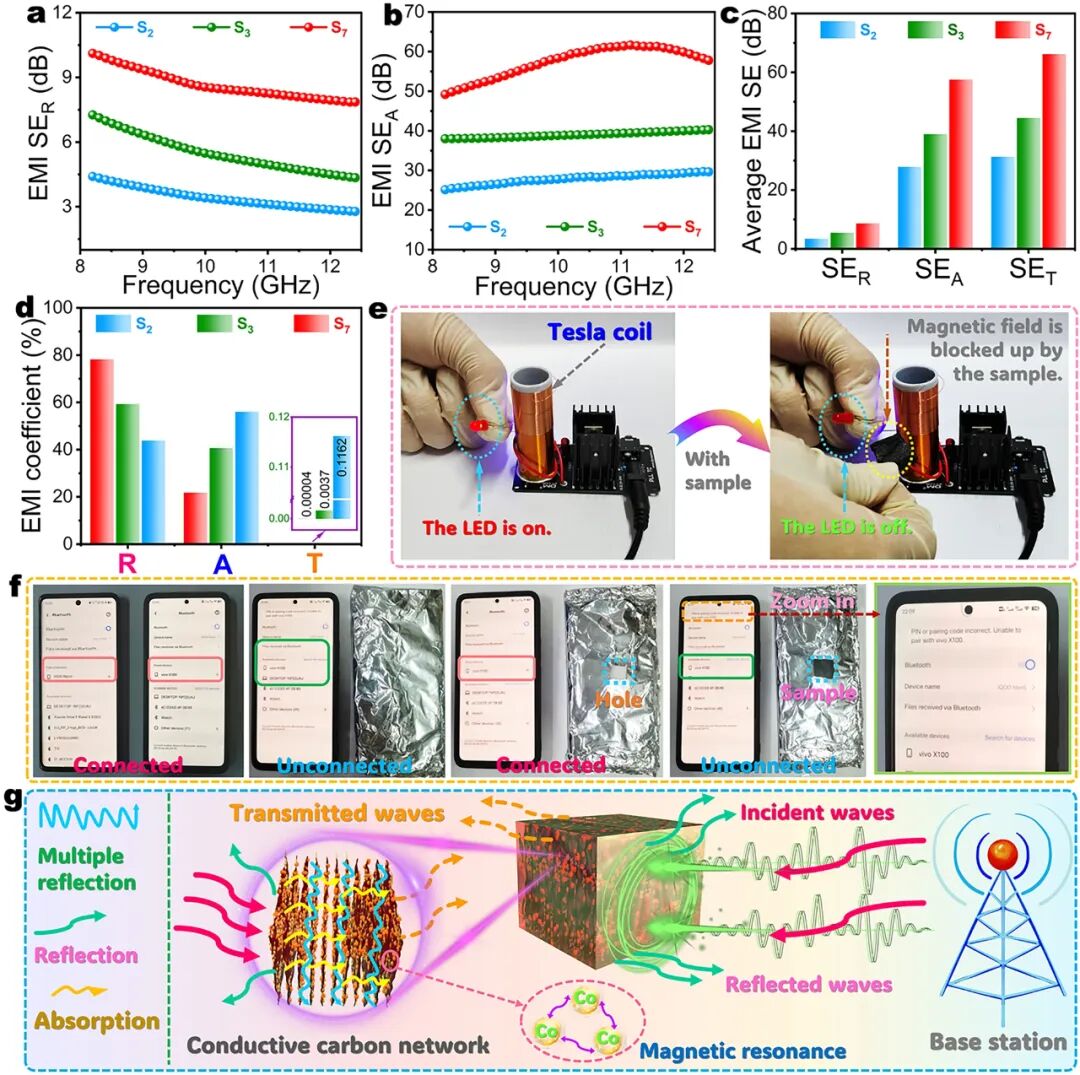

Figure 8 Electromagnetic Shielding Performance and Mechanism

The EMI SE of C/RGO@CoNC/PW reaches 66.2 dB (Figure 8a-c), with a reflection coefficient of 78.2% (Figure 8d), the reflection-absorption synergistic mechanism of the carbonized skeleton and CoNC (Figure 8g) effectively attenuates electromagnetic waves. Tesla coil (Figure 8e) and Bluetooth shielding experiments (Figure 8f) validate its practical protective capability, with SE further enhanced at high temperatures (Figure S33), suitable for 5G base stations and electronic device protection.

Conclusion and Outlook

The research successfully developed a “five-in-one” phase change composite material with multi-energy conversion and electromagnetic shielding functions by innovatively designing carbonized PI/KNF/GO@ZIF-67 bidirectional composite aerogel encapsulating paraffin wax.The core innovation lies in constructing a highly conductive and thermally conductive layered porous framework through the synergistic effects of ZIF-67-derived CoNC and RGO, combined with the latent heat storage capacity of PW, achieving efficient conversion of solar-thermal (efficiency 95.1%), thermoelectric (output power 17.3 mW), electrothermal (90.8°C at 4.5 V), and magnetothermal (50°C in 4.5 minutes), while also exhibiting excellent electromagnetic shielding effectiveness (66.2 dB) and hydrophobicity (contact angle 113.2°). Structurally, the bidirectional layered porosity and CoNC/RGO network optimize thermal/electrical transport pathways, while the high-temperature carbonization strategy effectively suppresses aerogel shrinkage, enhancing mechanical strength (compressive strength 61.0 kPa) and PW loading rate (209.2 J g⁻¹). This material shows broad application prospects in solar energy utilization, human thermal therapy, electronic protection, and low-temperature de-icing, providing a new paradigm for the development of multifunctional energy materials.

Original link:

https://doi.org/10.1007/s40820-025-01761-w

Gel LabOriginal article. Personal forwarding and sharing are welcome. For reprints by publications or media, please contact via email:[email protected]

Research scholars are welcome to submit manuscripts (papers, project introductions, new technologies, academic exchanges, unit news, conference information, recruitment, and enrollment, etc.) to[email protected], and please indicate detailed contact information.

Disclaimer: The information is sourced from the internet, and the purpose of reprinting is to convey more information and share. It only provides a communication platform and is not responsible for its copyright. If there is any infringement, please contact us for timely modification or deletion. Original articles are welcome for personal forwarding and sharing; for reprints by publications or media, please contact us.