© Amira Abdel-Rahman / MIT Center for Bits and Atoms

Construction is not a simple task. Take prefabricated buildings as an example; typically, components are manufactured in different facilities, transported by large machinery, and assembled in the final stages. This is a time-consuming and expensive process. However, imagine a new manufacturing method where robots play the role of a child with LEGO blocks, effortlessly constructing structures. This is where assembly robots come into play.

These marvelous little assistants are changing the game. They move gracefully through the structures they are building, resembling mechanical arms. Interestingly, they do not see themselves as mere tools but as an integral part of the structures they create.

Let us enter the world of intelligent robots, a revolutionary field of robotics created by Professor Neil Gershenfeld of MIT’s Center for Bits and Atoms and his PhD student Benjamin Jenett: pioneering the future of assembly robots.

© https://news.mit.edu/2022/assembler-robots-structures-voxels-1122

Make Big Things Out of Small Pieces

Make Big Things Out of Small Pieces

Digital Discrete Structures

© Kenneth Cheung / MIT

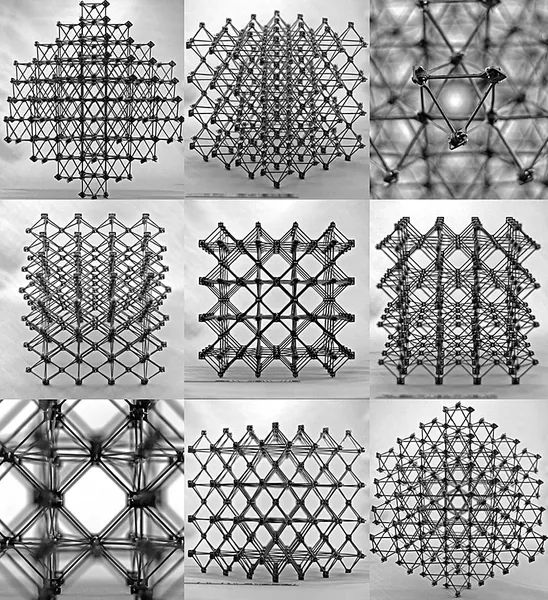

Researchers at MIT have developed a lightweight structure whose tiny building blocks can be assembled like children’s building toys. They claim that this new material could revolutionize the assembly of aircraft, spacecraft, and even larger structures such as levees. Neil Gershenfeld compares this structure, made of tiny, identical, interlocking parts, to chain mail. These components are based on novel geometries developed by Cheung and Gershenfeld, resulting in a structure that is ten times stiffer than existing ultra-light materials for a given weight. Moreover, this new structure can be easily disassembled and reassembled— for example, to repair damage or recycle parts into different configurations.

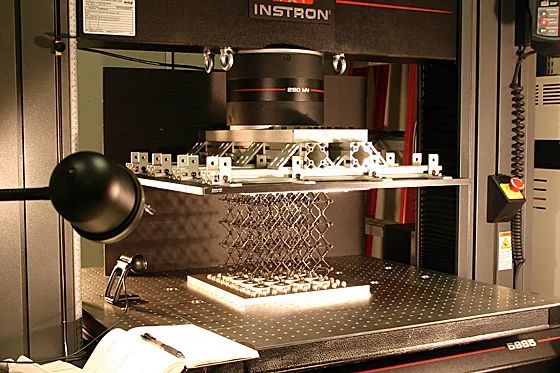

Strength Testing of Digital Discrete Structures

© Kenneth Cheung / MIT

The possibility of connecting various types of parts brings new design freedom to composite manufacturing.

Self-replicating Hierarchical Modular Robotic Swarms[1]

Self-replicating Hierarchical Modular Robotic Swarms [1]

1

Material-Robot Systems

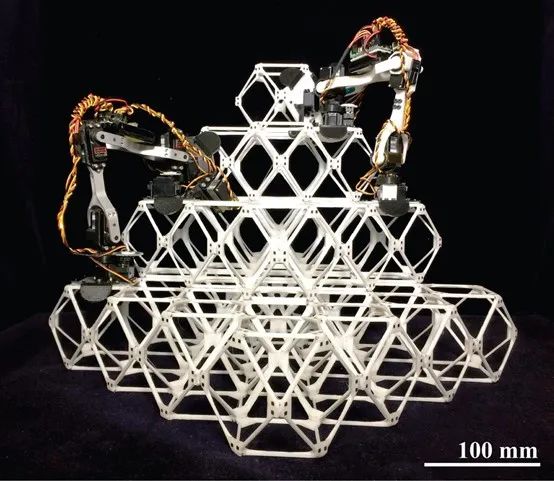

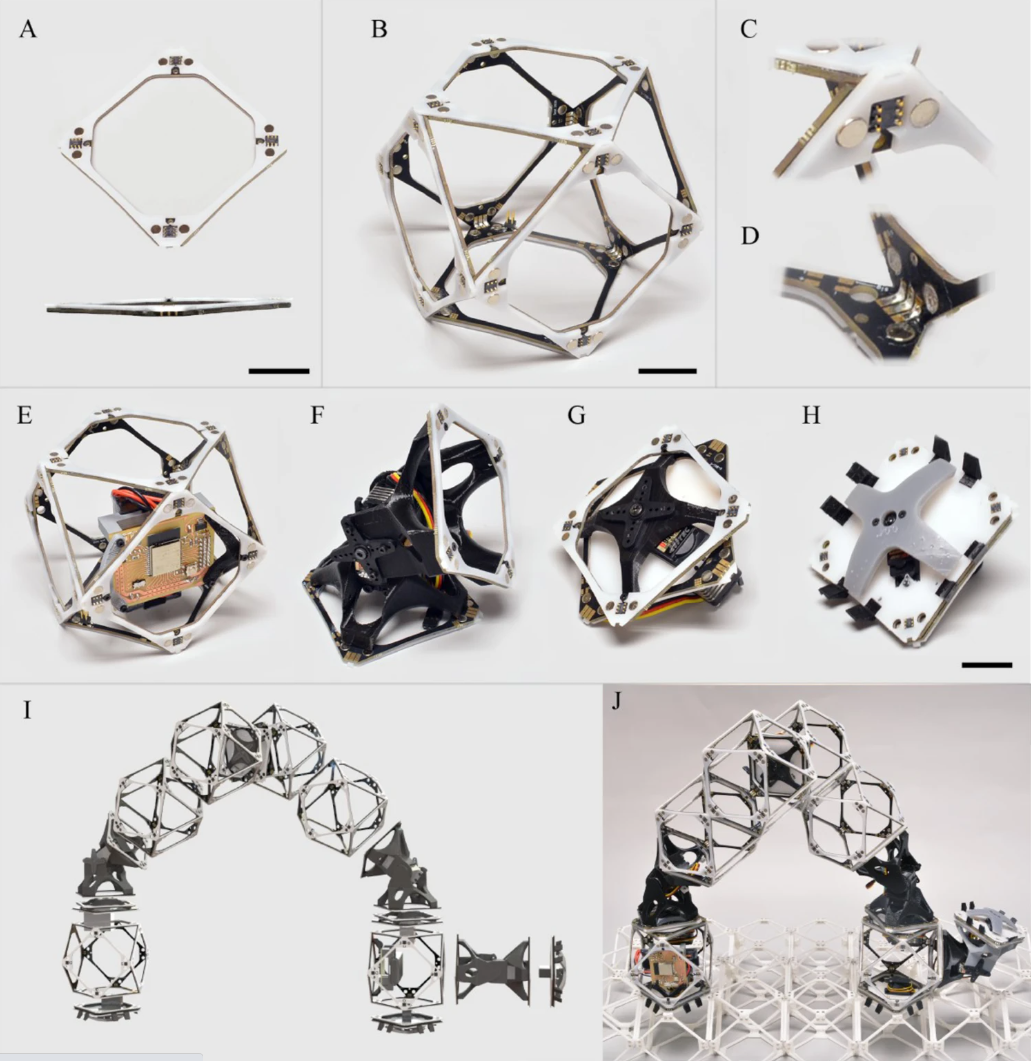

The system consists of structural grid units that form a specialized base for inchworm robots capable of rearranging and placing additional structural components. This combination of grid units and robots forms a material-robot system [2], enabling simple small robots to precisely assemble large structures by labeling the underlying grid. They created a modular robotic toolkit to enhance the connections of the material-robot system. The active grid units serve as the primary structural building blocks. By integrating these active grid units with actuators, controls, and power, unique behaviors are achieved, including robot self-replication and hierarchical robotic assembly. A robot responsible for constructing large structures can create a heterogeneous constructor swarm to maximize material throughput for a given target geometry.

Modular Building Blocks and Assemblers

© Self-replicating hierarchical modular robotic swarms

2

Self-replicating Robots and Systems

In the above image (I) and (J), it adopts a crawling method, positioning itself on the grid structure of the base volume element using two grippers. Meanwhile, the elbow joint with grippers allows the robot to manipulate volume elements to reconfigure the grid structure.

Discrete Structure Robot Assembly Experiment

© https://news.mit.edu/2019/robots-large-structures-little-pieces-1016

This robot can carry a single volume element or actuator at a speed of one volume element per time step. Although this design constitutes the basic unit of the robotic assembler, the modular system and grid-compatible connections allow the basic assembler to construct additional assemblers, achieving self-replication and producing larger robots, forming a hierarchical structure of programmatically assembled assemblers [3].

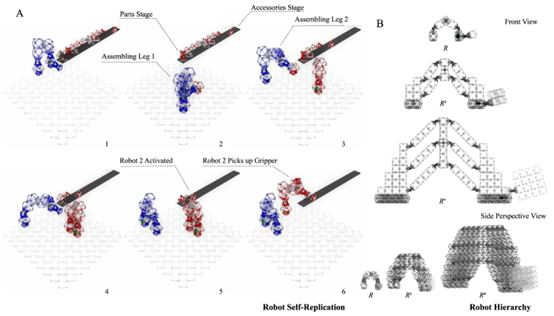

Robot Self-replication and Hierarchical Structure

© Self-replicating hierarchical modular robotic swarms

A swarm of self-replicating small robots will form a large robotic swarm to adapt to construction projects of different scales. So how do they cooperate?

3

From Structure to Swarm

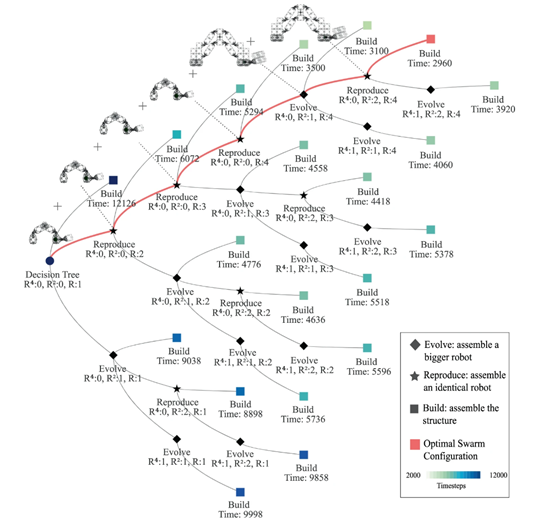

As individuals swarm, they must communicate in some way to guide collective movement. Self-assembly [4] allows nature to build complex forms through the interactions of many limited and unreliable individuals, from multicellular organisms to complex animal structures like flocks of birds.In “Self-replicating hierarchical modular robotic swarms,” a quasi-self-organizing method is introduced to integrate a large number of micro-robots. 1. Utilizing the proposed material-robot system, the next step will introduce algorithms for determining the optimal swarm configuration and path planning required to construct the target structure. First, the path planning and self-replication and hierarchical swarm construction model simulation can be divided into three parts: (1) Processing and discretizing the input target geometry into building blocks. (2) Determining the construction sequence of the building blocks. (3) Task allocation and path planning based on the available robots. 2. By generating a construction sequence tree through an adaptive shape compiler, the central control system can search for the optimal swarm configuration: the number of carrier robots of each size to construct the structure in the least time steps. Inspired by biological analogies, the carrier robots have three options: Build the structure (construction) Build another robot (replication) Build a larger robot (evolution) A tree of all possible alternatives is generated based on the limited inventory of robot building blocks. Next, we search the “tree” for the configuration that requires the least time steps to complete construction (including the time for building robots and structures). Once the optimal number of robots is calculated, the central system sends instructions to the first carrier robot to recursively assemble the remaining robots.

Robot Decision Tree

© Self-replicating hierarchical modular robotic swarms

3. Self-organizing construction: The application of micro-robots in discrete digital structures also involves the concept of self-organizing construction. Multiple micro-robots can complete the construction of structures in a distributed manner through mutual communication and cooperation. They can autonomously choose the best construction strategies and path planning based on environmental conditions and local information, achieving efficient self-organizing construction.

Applications and Future

Applications and Future

© https://news.mit.edu/2019/robots-large-structures-little-pieces-1016

The application of micro-robots in construction is an emerging research field, widely regarded as an important trend for future construction. Due to their small size, flexibility, programmability, and high intelligence, the application prospects of micro-robots in the construction field are very broad. 1. Micro-robots can work collaboratively to achieve rapid and precise assembly of building structures, significantly improving construction efficiency and quality. 2. Micro-robots can be applied to the maintenance and repair of building structures. 3. In the future, micro-robots may play a larger role in space construction. Due to the extreme harshness of the space environment, the construction and maintenance of structures require a high degree of automation and intelligence, and micro-robots are the best choice to meet this requirement. Micro-robots can autonomously collaborate to complete the assembly and maintenance of space structures, greatly enhancing the safety and reliability of space construction. 4. They provide greater freedom for architectural design. Currently, micro-robots have made significant progress in various fields, such as: including morphing wings [5], ultra-lightweight aircraft structures [6], reconfigurable infrastructure [7] (avoiding “road zipper”), and the design of large space structures [8]. As shown below, in the field of aerospace engineering, computer simulations demonstrate the working scenario of four assembly robots constructing a three-dimensional structure. Such robotic swarms can be deployed to create large structures, such as aircraft wings or space habitats. The advantage of this assembly method is that it can easily handle repair and maintenance issues with the same type of robots used for the initial assembly. Damaged parts can be removed from the structure and replaced with new components, resulting in a structure as strong as the original. Gershenfeld believes, “Disassembly and assembly are equally important” [9], and this process can also be used to modify or improve the system over time.

Aircraft Structures Assembled from Unit Modules

© Kenny Cheung / NASA

Benjamin Jenett believes, “For space stations or lunar habitats, these robots will reside on the structures, continuously maintaining and repairing them.” Ultimately, such systems could be used to construct entire buildings, especially in harsh environments like space, the moon, or Mars, eliminating the need to transport large pre-assembled structures from Earth. Instead, large batches of tiny sub-units could be sent to the final destination, or systems capable of generating these sub-units at the final destination could be used.

© https://www.youtube.com/watch?v=G94FDMGLwCc&t=3s

“Building self-replicating systems is a classic challenge not just in science, but even in science fiction literature — something that only nature has really achieved so far, so this is extremely exciting work,”—— Sandor Fekete“Building self-replicating systems is a classic challenge not just in science, but even in the science fiction literature — something that only nature has really achieved so far, so this is extremely exciting work,” —— Sandor Fekete

Micro Robots in Science Fiction © Big Hero 6

References

[1] Abdel-Rahman, A., Cameron, C., Jenett, B. et al. Self-replicating hierarchical modular robotic swarms. Commun Eng 1, 35 (2022). https://doi.org/10.1038/s44172-022-00034-3[2] Jenett, B., Abdel-Rahman, A., Cheung, K. & Gershenfeld, N. Material–robot system for assembly of discrete cellular structures. IEEE Robot. Autom. Lett. 4, 4019–4026 (2019).[3] Jenett, B. & Cheung, K. Bill-e: robotic platform for locomotion and manipulation of lightweight space structures. In Proc. 25th AIAA/AHS Adaptive Structures Conference (2017).[4] Rubenstein, M., Cornejo, A. & Nagpal, R. Programmable self-assembly in a thousand-robot swarm. Science 345, 795–799 (2014).[5] Jenett, B. et al. Digital morphing wing: active wing shaping concept using composite lattice-based cellular structures. Soft Robot.[6] Cramer, N. B. et al. Elastic shape morphing of ultralight structures by programmable assembly. Smart Mater. Struct. 28, 055006 (2019).[7] Jenett, B., Cellucci, D., Gregg, C. & Cheung, K. Meso-scale digital materials: modular, reconfigurable, lattice-based structures. In Proc. International Manufacturing Science and Engineering Conference, vol. 49903, V002T01A018 (American Society of Mechanical Engineers, 2016).[8] Jenett, B., Gregg, C., Cellucci, D. & Cheung, K. Design of multifunctional hierarchical space structures. In Proc. IEEE Aerospace Conference (2017).[9] https://news.mit.edu/2022/assembler-robots-structures-voxels-1122

Contact for Collaboration

WeChat ID:GerryVito

Official Account:DigitalFUTURES

Website:https://digitalfutures.international/

Author: Xincheng Jiang

DigitalFUTURES is launched by College of Architecture and Urban Planning(CAUP), Tongji University and Shanghai Digital Architecture Fabrication Technology Center (SFAB) in 2011. International Union of Architects (UIA), Architectural Society of China (ASC), National Engineering Technology Research Center for Prefabrication Construction in Civil Engineering, and The Architectural Society of Shanghai China (ASSC) collaborate with global renowned scholars, architects, designers, enterprises and academic media in this field to establish an online and offline integrated educational platform relying on DigitalFUTURES. The events are consisting of lectures, conferences, workshops and exhibitions, etc. Nowadays, DigitalFUTURES as a global architecture exchange community, with the platform www.digitalfutures.world, encourages the inheritance and innovation, collaboration and communication of global knowledge in architecture and emphasizes scientific research about digital design theory, technology and artificial intelligence algorithms, robotic fabrication, etc. in the field of architecture and built environment.