Magnesium Alloy Additive Manufacturing (3D Printing): Unlocking a New Era of Lightweight Revolution with the ‘Star Material’

In the wave of the industrial revolution pursuing “lightweighting”, magnesium alloys have become the “star material” in fields such as aerospace, new energy vehicles, and medical implants due to their extremely low density (only 2/3 that of aluminum and 1/4 that of steel), high specific strength, and excellent biocompatibility. However, traditional casting and forging techniques struggle to achieve the integrated forming of complex structures, while the rise of additive manufacturing (3D printing) technology has unlocked new possibilities for magnesium alloys.

From “Subtraction” to “Addition”: A Manufacturing Revolution

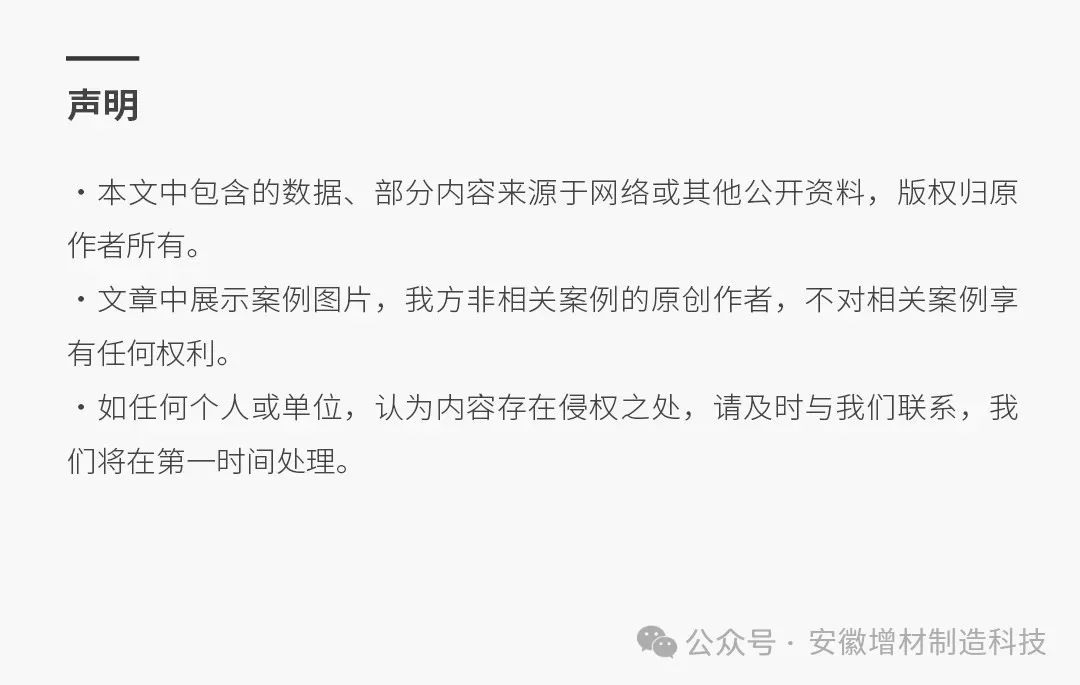

Traditional magnesium alloy processing relies on casting and hot extrusion, but castings are prone to porosity and cracking, while forging is limited by the poor room temperature plasticity of magnesium. Additive manufacturing, on the other hand, builds materials layer by layer, directly “printing” complex geometries, not only saving materials but also achieving precision structures unattainable by traditional processes, such as biomimetic bone scaffolds and lightweight lattice structures.

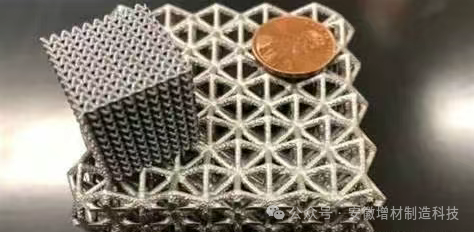

Taking Laser Powder Bed Fusion (LPBF) technology as an example, it can melt magnesium alloy powder layer by layer with micron-level precision, producing components with a density exceeding 99%. For instance, a porous scaffold made from WE43 magnesium alloy formed by LPBF technology has a porosity error controlled within 10%, perfectly simulating human bone structure and providing personalized solutions for orthopedic implants. Meanwhile, Wire Arc Additive Manufacturing (WAAM) has become the “new favorite” for manufacturing large aerospace components due to its high deposition rate, significantly reducing the production cycle of rocket engine parts from 50 hours to 10 hours.

Technological Breakthrough: From Laboratory to Industrial Application

The core challenge of magnesium alloy additive manufacturing lies in its high reactivity—magnesium powder is flammable and explosive, and it is prone to evaporation and oxidation during melting. Research teams have tackled this issue through multiple protective measures: operating in an inert gas environment, optimizing powder storage conditions, and developing real-time monitoring systems to ensure process stability. For example, the team from Chongqing University has significantly improved the precision and repeatability of WAAM forming by precisely controlling arc parameters through a closed-loop control system.

Optimizing process parameters is also crucial. Variables such as laser energy density, scanning strategy, and inter-layer cooling time directly affect the microstructure and performance. Research has shown that WE43 magnesium alloy can achieve a tensile strength of up to 275 MPa and an elongation of 15% under LPBF technology, far exceeding traditional casting levels. Furthermore, post-heat treatment, such as high-temperature annealing, can further release residual stress and enhance ductility.

Application Scenarios: From Bones to Space

Medical Field, the “biodegradable” properties of magnesium alloys make them ideal implant materials. The WE43 alloy scaffold manufactured by LPBF technology not only has mechanical properties close to human bone but can also gradually degrade in the body, avoiding the need for a second surgery. Recent studies have further controlled its degradation rate through surface modification technology, reducing the negative impact of local pH fluctuations on cells.

Aerospace, weight reduction means increased efficiency. Additive manufactured magnesium alloy components have been applied in satellite brackets and aircraft load-bearing structures; for example, certain rocket engine parts achieved a weight reduction of 22%-70% through 3D printing, significantly lowering fuel consumption.

Automotive Industry, lightweighting is central to the electrification transition. Components such as magnesium alloy steering wheel skeletons and battery pack brackets are rapidly formed using WAAM technology, aiding in the range enhancement of new energy vehicles. Data shows that for every 10% reduction in vehicle weight, energy consumption can decrease by 7%, and the potential for magnesium alloy applications far exceeds that of currently popular aluminum alloys.