Author: SHAUN KIRBY

Translated by: Xiaoyu, Yu Zhiwen, Aileen

If we consider cars as the ultimate “objects” in the Internet of Things (IoT), then the “data center on wheels” can draw many lessons from the enterprise data centers of the “Internet of Things”.

The rise of the Internet of Things (IoT) has triggered an astonishing growth in the number of connected devices and sensors across various industries.

It is estimated that more than 80 “objects” connect to the internet every second, and by 2020, there will be 50 billion objects connected to the IoT. The IoT is significantly transforming industries such as manufacturing and retail, enabling companies to improve efficiency, enhance productivity, and gain real-time insights into their customers by adopting technologies like fog computing and advanced analytics, or deploying hundreds of thousands of sensors across the supply chain.

Today, the connected car market faces many of the same challenges as the IoT industry. However, some companies in the IoT space have already tackled these challenges, so I have compiled a list of best practices and lessons learned—many of which can be applied to the connected car market to help automotive manufacturers and their partners fully leverage the potential of the IoT.

In many ways, connected cars are considered the ultimate “objects” in the IoT. The data center on wheels truly embodies the greatest hopes and challenges everyone has for the IoT.

Typically, there are over 100 onboard computers continuously monitoring location, component performance, driving behavior, and more. Experts estimate that highly automated vehicles will generate 4TB of data every hour! Moreover, as our transportation systems increasingly connect through vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications, the volume of data generated by connected cars will reach overwhelming levels.

As a result, like companies in other industries, automotive manufacturers and their partners face a multitude of the same challenges, including managing a vast number of connected devices and the massive data they produce, as well as technical issues related to security, ubiquitous connectivity, bandwidth optimization, and more.

Not long ago, IT companies were focused on managing a handful of large mainframes. Suddenly, the emergence of new paradigms such as client-server, distributed, and mobile computing forced IT companies to innovate continuously. The trend of Bring Your Own Device (BYOD) brought additional challenges, as IT professionals were responsible not only for managing a vast number of machines but also for managing a large number of connected personal devices, which pose potential security risks.

The same situation exists in the connected car market. Initially, the number of internet-connected cars was very small. However, today, with the increasing number of sensors and electronic control units, driving a connected car is almost like operating a small business on wheels. Different road conditions transmit different types of data to different destinations, while connected cars must also meet the requirements of various destinations, privacy, and security.

The diversification of suppliers further complicates the ecosystem. The number of suppliers multiplied by the skyrocketing number of connected vehicles (expected to exceed 380 million connected vehicles on the road by 2021) makes it easy to imagine the magnitude of the challenge in managing all connected devices.

Take a typical retailer as an example. Typically, an IT staff member in a retail company can manage about 200 devices; however, with the rise of the IoT, retailers now need to manage tens of thousands of devices, even reaching millions. If traditional IT methods are used, this would mean hiring tens of thousands of additional IT staff!

Emerging automated network management software and service projects have made it possible for each IT staff member to manage over 1 million devices. Through network automation, connected car manufacturers can clearly see the performance of each part across the entire fleet and identify areas where the safety and reliability of parts can be improved, even discovering new characteristics of parts.

With the increase in the number of connected vehicles, another challenge arises: how to manage the changes and software updates of the numerous related components and applications in connected vehicles. Each connected car already has an average of over 100 million lines of code in the background, but with the rise of advanced driver-assistance systems and highly automated driving, the quantity and complexity of software in vehicles will explode.

Similarly, as connected cars bring more new experiences to drivers and passengers, the management policies for vehicles and usage will become more complex and personalized, making it daunting to manage various widespread configuration changes.

Today, most vehicles undergo software and configuration updates at repair shops, leading to lower update frequencies and making it easier to bundle updates, which have passed rigorous quality assurance and security testing. However, with over-the-air (OTA) updates, automotive manufacturers can instantly push new software and configurations to vehicles.

Wireless updates allow consumers to perform repairs on-site without needing to schedule service appointments and patch vulnerabilities, while meeting consumer demands for new features when purchasing new products. Imagine not having to make a special trip to the repair shop when the annoying “check engine” or “maintenance required” warning lights up on your dashboard! However, ensuring that all these updates are compatible and work correctly with the existing code in the vehicle is a daunting task.

By automating the onboard network and using the cloud for centralized management and control, automotive manufacturers can manage all vehicles and their devices while reducing the complexity of software version control across different vehicle models. Although the connected car market is still in its infancy, automotive manufacturers can apply many best practices developed by IoT companies to get the connected car market on track, enabling better management of millions of connected cars on the road in the coming years.

As the demand for connected cars continues to grow, a significant challenge for automotive manufacturers is security. All data can be collected from the car (such as driver physiological characteristics and behavior data, and user consumption habits generated from fuel bills), which means that if the security of the car is not high, it will impact user privacy and safety.

From a business perspective, as more and more companies connect to the IoT, it also means that new network vulnerabilities will soon be targeted by more hackers.

From employees’ smartwatches to the company’s IoT lighting/cameras, everything will become a target for hackers. In the era of IoT, companies have realized that even the most reliable devices cannot maintain long-term security. The IoT not only allows companies to build their ecosystems but also connects companies with the world, even across industries. Therefore, there is an urgent need for new cybersecurity measures to maintain a defense system from the cloud to the network edge, as well as to adopt smart detection of network threats and prevent their spread within the network.

Of course, automotive manufacturers face the same challenges. There are numerous ways to attack through vehicles—such as mobile phones, Wi-Fi, even on the satellite connection links between cars and the cloud, as well as V2V (vehicle-to-vehicle communication) and V2I (vehicle-to-infrastructure communication), all of which can become targets for hackers. In addition, Bluetooth, near-field communication, and physical interfaces connected to onboard diagnostics, even the wireless signals from tire pressure monitoring systems can be hacked. Listing all these potential points of intrusion could take a while…

To defend against such a multitude of attack vectors, automotive manufacturers and their partners have established numerous security protocols within the automotive ecosystem to ensure that companies can utilize a safer IoT. Merging different networks within the car into a single architecture is a crucial step, allowing verified security technologies—such as encryption and authentication, firewalls, and intrusion detection and prevention systems (IDS/IPS)—to be deployed to provide deep defense for connected cars. Artificial intelligence is also increasingly used, whether in the cloud or now in connected vehicles and other edge devices, to detect new malicious behavior patterns (or possibly non-malicious anomalies that require maintenance).

Another key point in defending against potential attacks is to ensure that network connections are correct at the right times throughout the entire lifecycle of the vehicle. Just as a company’s IT team must learn to continuously monitor network channels and IoT devices for potential issues, automotive manufacturers must continuously monitor and manage their vehicles’ connectivity. They must know when the vehicle’s link should be open and when it should be closed. The permissible connections of the vehicle vary at different stages of its lifecycle…

For an automotive manufacturer, tracking and monitoring connections while transporting millions of vehicles globally is a very complex task. For instance, during the testing phase of a vehicle, the connection channel must be open to allow the manufacturer to verify that the connectivity services are functioning correctly. Then, when the vehicle is in a shipping container, the manufacturer should automatically disable these services to prevent hackers from compromising the vehicle while it is en route to the dealer. However, a certain level of connectivity must be maintained to allow real-time tracking of the vehicle during transit. When the vehicle arrives at the dealership, automated systems allow the manufacturer to safely restore connectivity so that sales personnel can demonstrate the vehicle and its connected services to customers.

As companies in other industries begin to widely use IoT processes and install large numbers of sensors in their networks, they gradually realize that the IoT presents challenges in various resource aspects. It is not only the demands of these devices themselves (to design their applications to use storage, computing, bandwidth, and power more efficiently) but also the massive number of connected devices generating piles of data, making it difficult for networks and storage devices to bear. Before the IoT began to flourish, the surge in server usage greatly saved companies’ computing and storage resources.

The connected car market also faces many of the same challenges. For automotive manufacturers, they want to add new features while also considering the important factor of cost; energy is also precious, and every ounce in vehicle weight matters. Moreover, highly automated vehicles can generate over 4TB of data every hour.

Here, it is worth mentioning some application strategies from IoT companies once again. For example, when each car generates terabytes of data, while it is ideal to store all generated data in the cloud, some of that data is more valuable than others.

Additionally, some data is time-sensitive while others are not. Many connected vehicles have data plans, and since data rates are cheaper at night, determining when to send data is crucial. By embedding intelligent applications into the onboard network, automotive manufacturers can decide at any given moment which remote diagnostics data or connected applications need to be sent, as well as select data or applications to wait for better data rates at night.

Similarly, fog computing (a model that brings the cloud closer to distributed computing and storage) is beginning to rise in enterprises. Through IoT devices and gateways, fog computing enables smart filtering and adaptive compression, reducing the amount of data that needs to be sent to the cloud. The same local processing and data transmission configuration rules within vehicles significantly improve the efficiency of mobile bandwidth usage in connected vehicles, such as some data needing to be sent immediately while others need to be stored and transferred later.

Finally, the “data center on wheels” can learn another lesson from enterprise data centers: the use of hardware virtualization. By virtualizing some common logic in hardware, many electronic control units in cars can be simplified, while also reducing costs and complexity. This is why highly automated vehicles require a central computing platform, which is efficiently and flexibly integrated from over a hundred small computers in the background, and can also embed artificial intelligence. Creating new applications and services from reusable components, reducing manufacturing and maintenance costs, and improving quality, hardware virtualization and integration provide a more flexible space.

Lastly, and perhaps most importantly, the IoT era demands rapid iteration and continuous testing of numerous ideas to achieve optimal performance and deliver business value. The thorough reconfiguration and almost limitless possibilities of the IoT make rapid iteration and continuous testing an essential part of the early stages of the IoT, as the outcomes are often unpredictable. The automotive industry has been accustomed to long and predictable innovation cycles, planning major releases for new vehicles at least five years in advance and spending years testing various aspects. However, as we are still in the early stages of the popularization of IoT and connected cars, it remains uncertain where companies will derive the most value from technological investments.

Therefore, automotive manufacturers should consider rapidly designing prototypes and immediately testing new ideas. They also need to adopt flexible architectures to shorten development and unit testing cycles, as strict road testing cycles are difficult to compress. Such architectures can make connected cars more adaptable, allowing manufacturers to integrate new sensors, brakes, or other devices, analyze data, measure value, and make quick adjustments. By shortening the time to confirm the value of new features and the time for development and unit testing, automotive manufacturers can significantly shorten innovation cycles and launch industry-leading new versions.

The IoT is transforming various industries, but the connected car market is still in its infancy. Fortunately, automotive manufacturers can draw on a wealth of best practices from IoT companies and apply them to connected cars to address similar challenges, including managing complex and numerous connected cars and their components, while ensuring security and optimizing bandwidth, computing power, vehicle weight, and energy. This will help the automotive industry step into the future, where cars will communicate with the cloud, other vehicles, and the infrastructure around us to provide a safer, more efficient, and seamless transportation experience.

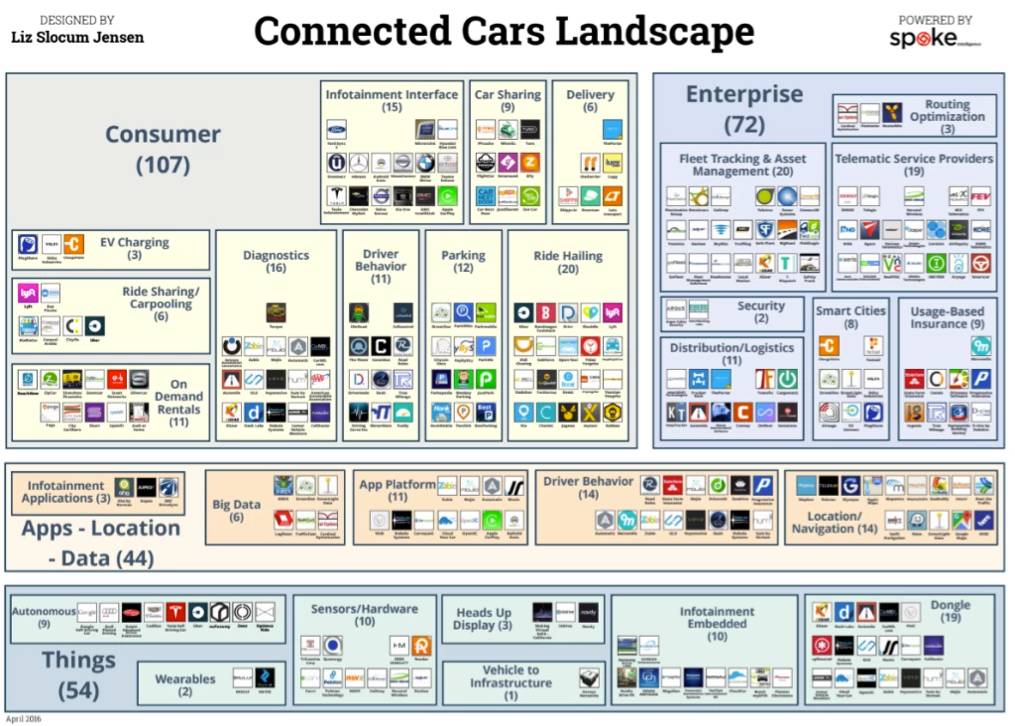

Connected Car Ecosystem Overview

Note: The author of this article, Shaun Kirby, is the director of autonomous driving and connected cars at multinational technology group Cisco.

Original article link: https://venturebeat.com/2017/06/02/what-connected-car-makers-can-learn-from-the-iot-sector/

Volunteer Introduction

Reply “Volunteer” to join us

Previous Exciting Articles

Click the image to read

If the annual Spring Festival Gala were rolled up like incense, it would look like this | A Session