KEBA (Chinese name: 科控) is a company that provides automation control products and services, headquartered in Austria (it shares a hometown with Beckhoff). Founded in 1968, KEBA has a subsidiary in China with a total of fewer than 1,000 employees and achieved a revenue of 189 million euros in 2015. The company may be small, but its products are impressive, finding applications in many industries including manufacturing, banking, and energy.

Seeing the industrial robot market as a lucrative opportunity, KEBA has launched products aimed at robotic automation applications – KeMotion, which claims to be a complete solution for the automation of robots and machinery. In fact, KeMotion is a robotic control system. KeMotion is widely used in China, with many robot manufacturers using KEBA’s controllers, such as Efort and Estun, and even more by lesser-known small manufacturers. Despite its fame, I found it nearly impossible to find information about KEBA controllers online, indicating that the industrial robot control community is quite closed off, and I am trying to stir the waters. Interestingly, although KEBA develops robotic controllers, it does not manufacture robots itself. Does this imply that the profit from the hardware is far less than that from the controllers? Moreover, with such core components being held by others, it’s understandable that robot manufacturers would feel uneasy.

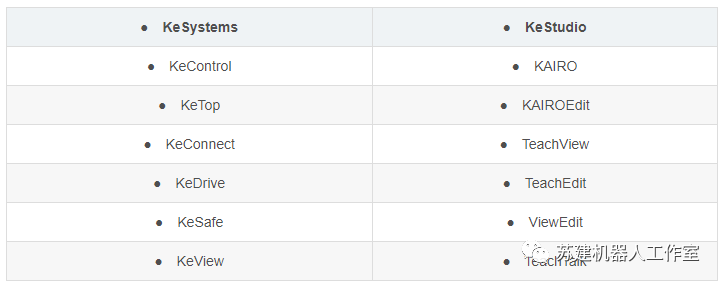

In this article, we will explore the features of KEBA’s controllers.Since KeMotion is a system, it includes a series of software, hardware, standards, languages, etc. I have summarized them in the table below:

Looking at a bunch of unfamiliar English terms, I wonder what those with poor English in China think; I personally feel overwhelmed. KEBA’s engineers have made relentless efforts to confuse users, so let me introduce each component one by one.First, let’s look at the tangible hardware part:

Controller KeControl

KeControl is the controller, more accurately, it is the CPU module of the controller, with several models such as CP and DU. The model I am holding in the picture is CP263/X (left picture); it is slightly longer and thinner than an A4 sheet of paper, and from the front, it appears to be made up of segments of plastic. You can think of KeControl as a fully functional small computer (PC – Personal Computer), which contains a central processor, memory, and hard drive (using a CF card), and runs the VxWorks operating system. Although KeControl is a PC, it uses PLC terminology, referring to the entire box (the one in my hand) as the “CPU module”.

The CPU module can be considered the core of the entire KeMotion system, where all control programs run. What kind of central processor does this important CPU module use? The model I am showcasing uses a 1.6 GHz Intel ATOM paired with 1 GB DDR3 memory. This configuration may not even match your home computer (but it could cost several times more, around ten thousand yuan). This extra cost is the price paid for reliability. Can you imagine a robot suddenly failing or going out of control because the controller crashes during operation? The loss to the factory would not be easily compensated by just a few tens of thousands of yuan.

All the interfaces for the CPU module are located at the front. My model has:2 USB ports, 3 Ethernet ports, one CAN port, one VGA port, and a 24V power port for powering the controller. If the interfaces are insufficient, what can be done? KEBA provides expansion interface modules. The DM 272/A shown on the right is the most commonly used digital I/O expansion interface, with 8 input and 8 output interfaces. DM 272/A can be directly plugged into the right side of the CPU module, and if that’s not enough, additional modules can be added.KeControl’s top is filled with ventilation holes, as shown in the picture below. Through these holes, you can vaguely see a small fan inside.

Different models of KeControl have slight differences in their interfaces and functions, as shown in the picture below (check marks indicate the presence of that function, and crosses indicate its absence).

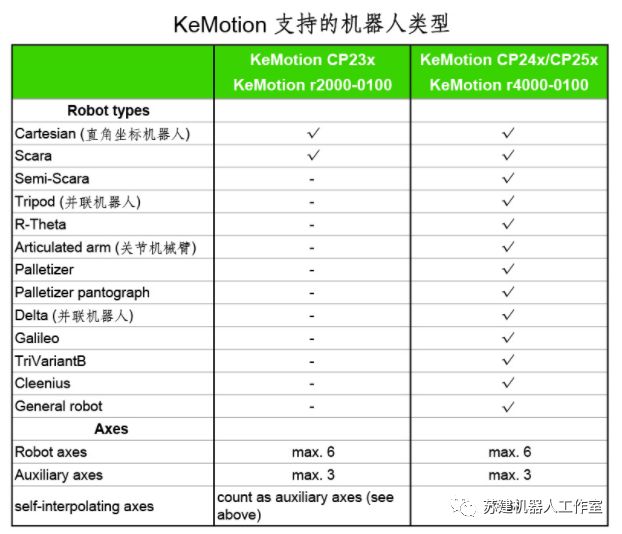

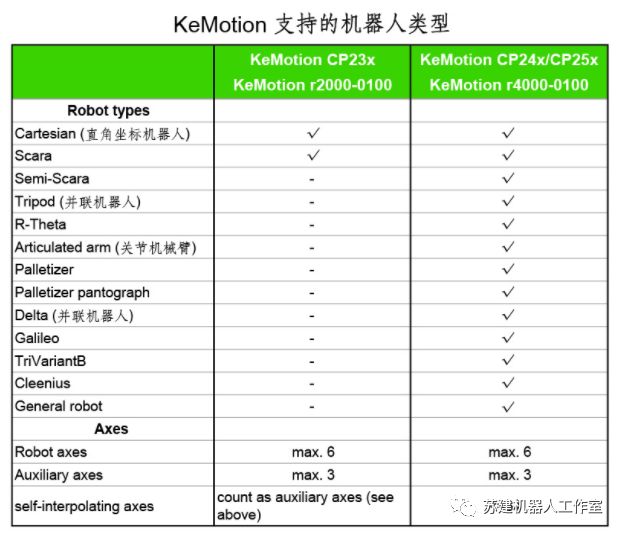

What types of robots does the KeMotion system support? See the picture below. It can be seen that KEBA supports a wide range of robot types.

Drive KeDrive

From a mechanical perspective, a robot is just a bunch of motors and linkages. The controller cannot directly control the motors; it must use servo drives to drive the motors. Smart KEBA not only sells controllers but also packages drives together, providing a complete solution. The KeDrive drive is shown in the red box below. The controller outside the red box (model DU, optionally equipped with Intel Core i3 processor) is used in conjunction with KeDrive. This integrated design saves space.

Tutorial KeTop

KeTop has multiple models such as T10, T20, T55, T70. Taking the commonly used T70 as an example (shown below, designed beautifully; Europe is indeed a place that has experienced the Renaissance), it is equivalent to a tablet computer, using an ARM Cortex A9 processor and running the Windows CE operating system. Users can write robot operation programs and set teaching parameters on it. How does KeTop connect to the CPU module? It uses a standard network cable, forming a local area network where each has its own IP address.

Display Panel KeView

KeView will not be elaborated; it is used to monitor and display various LCD screens showing the robot’s operating status, which is not widely used in China.Safety Software Package KeSafe

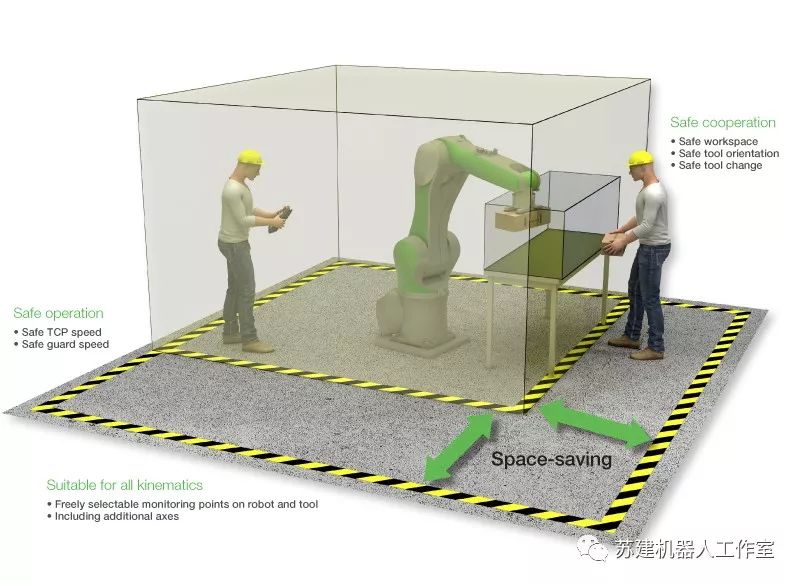

KeSafe is a safety protection software designed for human-machine collaboration.

Programming Software Section

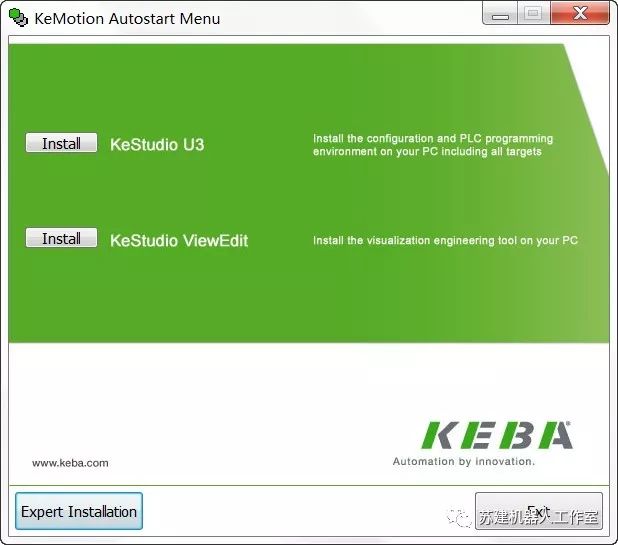

The stingy KEBA refuses to disclose its software unless you purchase its products. After purchasing the controller, the accompanying disc Kemro Automation contains the installation program (Installation) and documentation (Documentation), as shown below. In the installation interface, users can install the two software, KeStudio U3 and ViewEdit; if you wish to perform expert-level programming, also known as secondary development, you can click Expert Installation to install other software.

KeStudio:PLC Programming Development Software

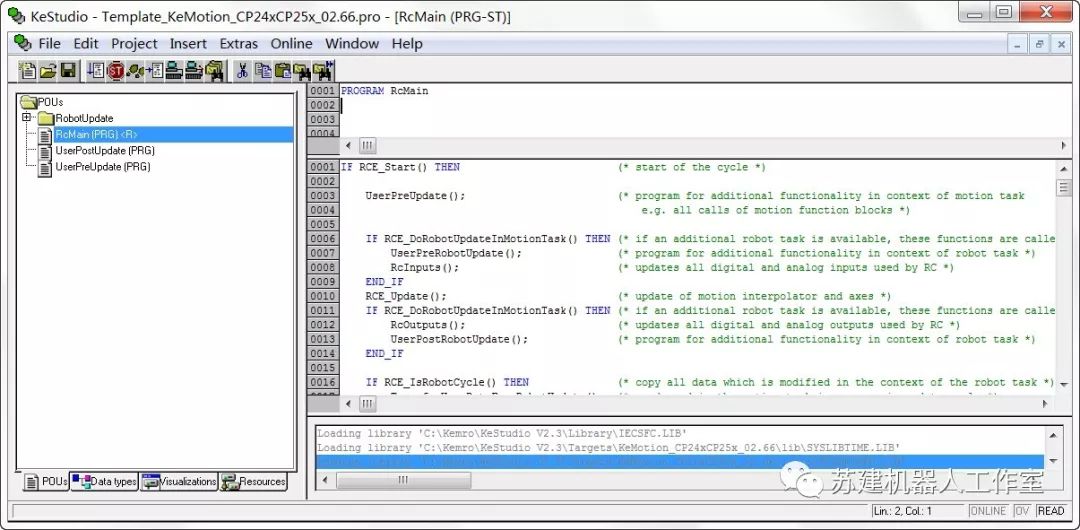

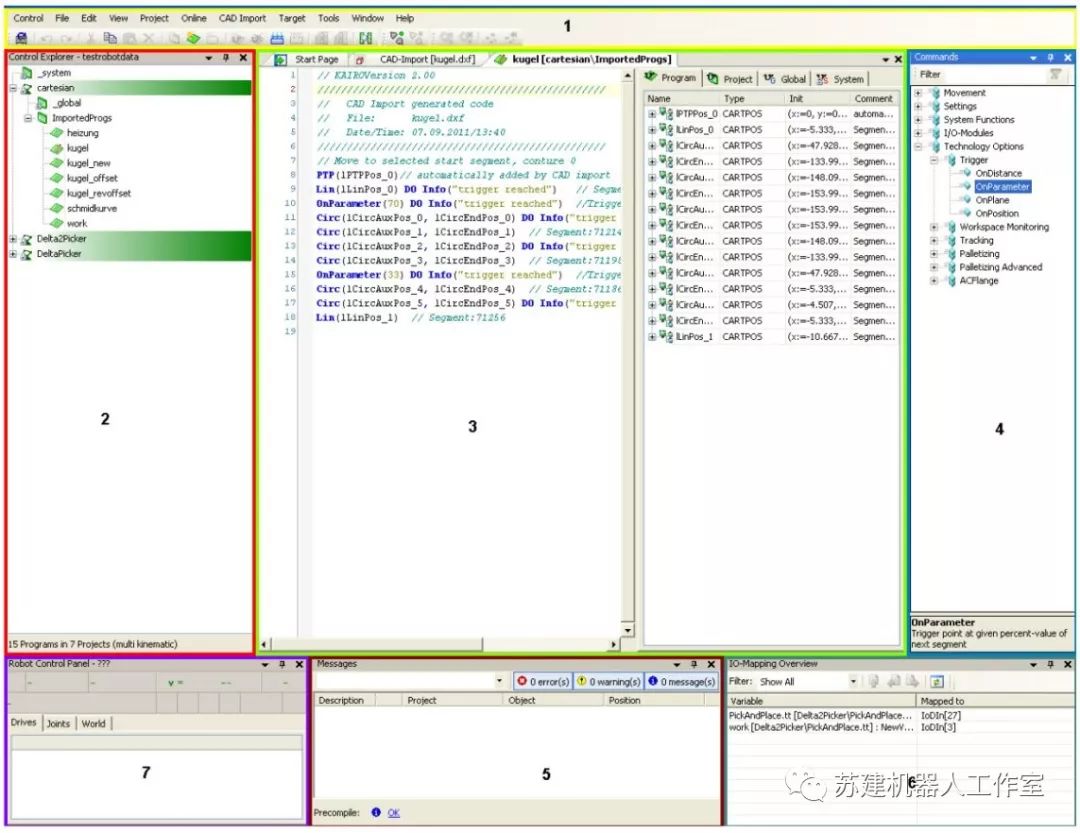

To control KeControl hardware, we need to write control programs, and KeStudio is the development software used for writing code and debugging, as shown in the interface below. I opened a template that comes with the software, and the code is displayed on the right side of the interface. Those who have never used PLC may find it strange; this is actually the style of PLC programming language (a series of uppercase IF THEN statements). Those who have used Visual Studio to write C++ programs will find that this development environment is far less user-friendly than VS.

KAIRO:Robot Operation Programming Language

KEBA possibly thinks that the variety of robot programming languages is still not enough, so it proposed the KAIRO language (robot operation programming language should also have an international standard like PLC; otherwise, each robot manufacturer can shamelessly define its own programming language, increasing the learning cost for customers). KAIRO is a programming language aimed at robot operation users (End Users), similar to ABB’s RAPID language (essentially for on-site operators, not for engineers to develop advanced algorithms). In the help documentation, KAIRO is introduced as follows:

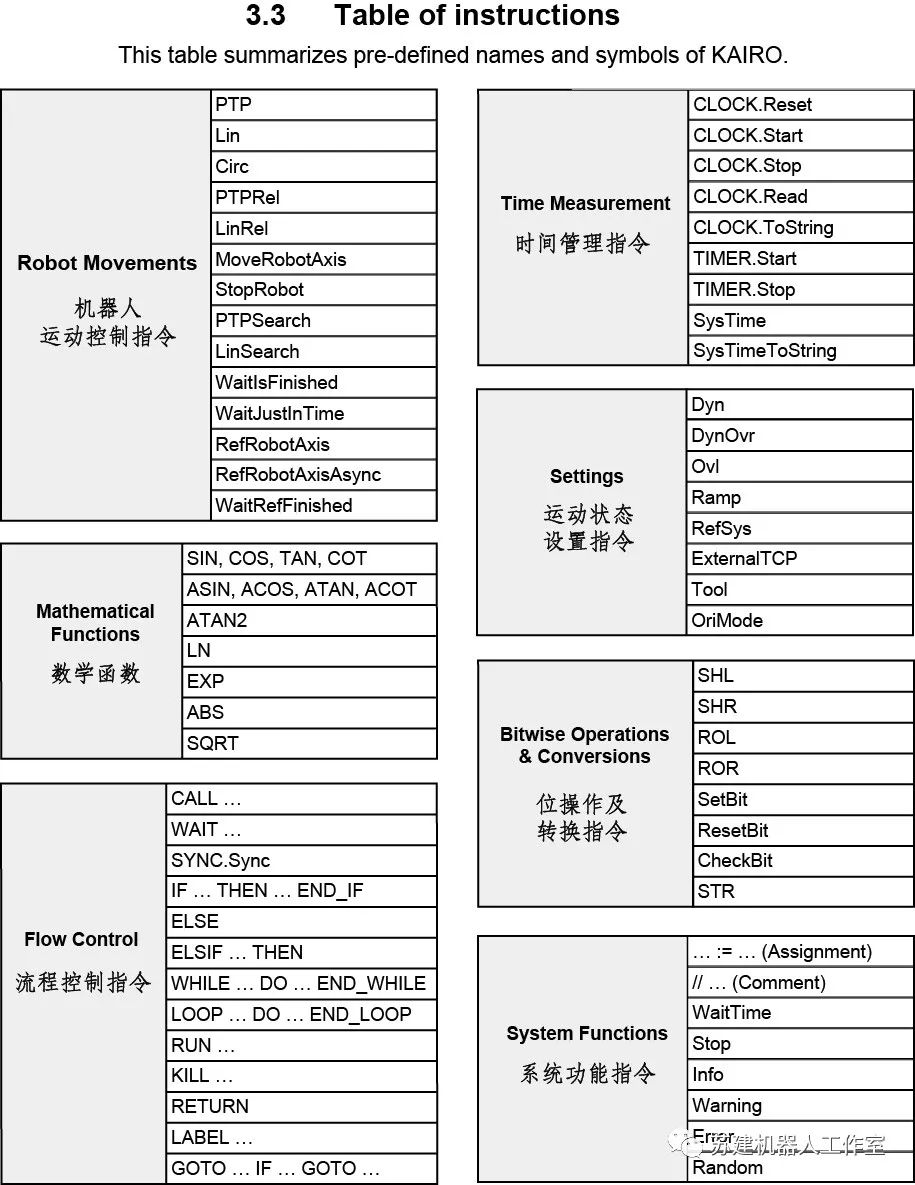

Some commands of KAIRO are shown in the table below. Defining a robotic programming language is not too difficult; it belongs to the upper-level programming, and a master’s student can accomplish it. Since KAIRO is mainly used to control robot movements, let’s take a closer look at the motion control commands; the rest are quite similar.

KAIRO Language Editing Software KAIROEdit

To write robot motion control programs using KAIRO instructions, it needs to be completed in the KAIROEdit development software, which looks like this:

TeachTalk:Secondary Development Language

If you find that KAIRO’s instruction set does not meet your needs, you can define your own instruction set to extend KAIRO using the TeachTalk language, which is the language for creating KAIRO instructions. In the development tool TeachEdit, custom instructions can be written using TeachTalk language (this process is called secondary development).

One of the difficulties in using KeMotion is the need to waste a lot of brain cells distinguishing various similar software tools and concepts; I feel overwhelmed seeing a bunch of TeachEdit, TeachView, ViewEdit, TeachTalk. Another motion control platform, TwinCAT, is much smarter; it implements all functions with one software, eliminating the user’s hassle of remembering a multitude of randomly defined names and concepts.

———————

Copyright Statement:This article is an original work by CSDN blogger “robinvista”, following the CC 4.0 by-sa copyright agreement. Reproduction must include the original source link and this statement.

Original link:https://blog.csdn.net/robinvista/article/details/61925002