Author: Liu Ran1, Xie Xiaolei2

Affiliation: 1. Shanghai Jiao Tong University Department of Industrial Engineering and Management; 2. Tsinghua University Department of Industrial Engineering

Citation: Ran LIU, Xiaolei XIE. Improve the industrial digital transformation through Industrial Internet platforms. Frontiers of Engineering Management, 2024, 11(1): 167–174 https://doi.org/10.1007/s42524-023-0286-9

Article Link:

https://journal.hep.com.cn/fem/EN/10.1007/s42524-023-0286-9

https://link.springer.com/article/10.1007/s42524-023-0286-9

Keywords: Industrial digital transformation; Industrial Internet platforms; Manufacturing; Big data

1.

Introduction

1.1 Definition and Key Participants in the Industrial Internet

The Industrial Internet represents an innovative network technology system that applies Internet of Things (IoT) technologies in manufacturing and industrial sectors. This technology system connects numerous sensors, devices, systems, factories, and enterprises to achieve data sharing and exchange, aiming to enhance production efficiency, reduce costs, improve product quality, and promote the realization of intelligent manufacturing. As a key foundation and pillar of the Fourth Industrial Revolution, the Industrial Internet provides practical solutions for industrial digital transformation. By achieving comprehensive connectivity among people, machines, and objects, the Industrial Internet can analyze various data from intelligent feedback, driving the formation of new manufacturing and service systems.

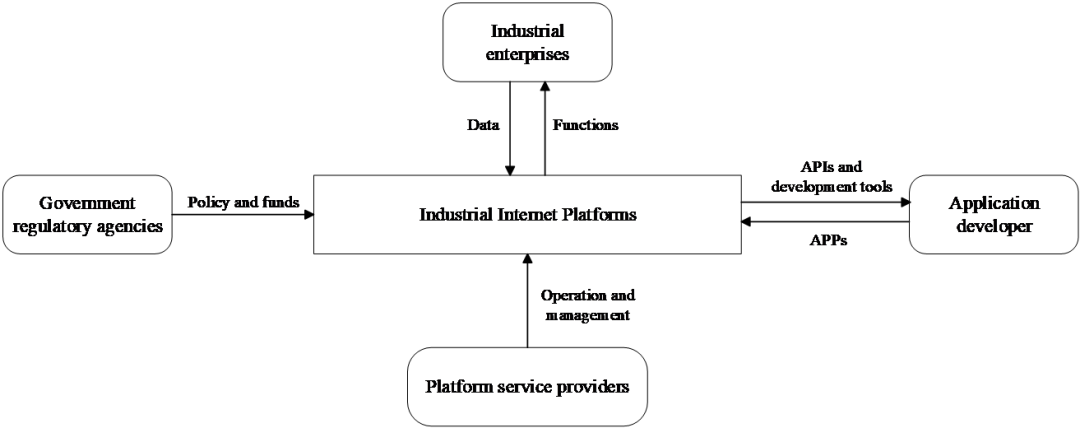

In the conceptual system of the Industrial Internet, the data platform is a crucial component. Enterprises typically establish and utilize their proprietary data platforms. Unlike existing data platforms, the Industrial Internet platform brings together key roles including industrial enterprises, application developers, platform service providers, and government regulatory agencies. These roles collaborate within the Industrial Internet platform, as shown in Figure 1.

Figure 1. Key Participants in the Industrial Internet

Below is a brief introduction to the roles of these key participants: Firstly, industrial enterprises are the main users of the Industrial Internet platform and contributors to application scenarios. They connect physical devices such as sensors, programmable logic controllers, and equipment to the platform, utilizing the data collection, storage, analysis, and optimization functions provided by the platform to drive the optimization and intelligence of production lines, thereby improving production efficiency and quality while reducing costs and risks. Secondly, application developers play a key role in the platform, developing diverse applications for industrial enterprises, including data collection, monitoring, analysis, and prediction, which requires them to utilize the APIs and development tools provided by the platform. Effective collaboration with industrial enterprises and a deep understanding of their business needs and data sources are crucial for developing customized applications, while close cooperation with platform service providers ensures understanding of the latest technologies and functionalities of the platform, as well as optimal utilization of development tools and APIs. Platform service providers are responsible for the operation, management, technical support, and security of the platform, ensuring its stability and safety. Finally, government regulatory agencies play a dual role in promoting and regulating the development of Industrial Internet platforms, fostering innovation and development through policies, funding, talent support, and other means while overseeing compliance, standardization, and safety of the platforms.

In addition to expanding the participation of key roles, the Industrial Internet platform demonstrates more powerful capabilities compared to traditional data platforms. This platform emphasizes the use of big data technologies to optimize the processes of data collection, storage, processing, and analysis. With the help of big data technologies, enterprises can process and analyze massive datasets, including structured and unstructured data, facilitating accurate predictions and real-time decision-making based on advanced computational technologies. Furthermore, the Industrial Internet platform integrates artificial intelligence technologies, enhancing enterprises’ ability to gain insights into data patterns and trends, thereby supporting intelligent decision-making and business growth.

1.2 Digital Transformation in China

Currently, the cost advantage of China’s manufacturing industry, which has persisted for a long time, is gradually diminishing, facing challenges of “industrial hollowing out” in advanced manufacturing. For instance, many manufacturing enterprises have shifted processing and assembly operations overseas. China’s manufacturing industry has historically occupied a lower tier in the industrial value chain, necessitating an increase in the production of high-end products. The industrial digital transformation upgrade based on the Industrial Internet has become particularly important, as it not only helps to reduce labor but also promotes the extension and expansion of industrial chains and value chains. For example, a large electronic information manufacturing enterprise in China achieved significant results by implementing a comprehensive Industrial Internet solution to upgrade its factory, reducing the workforce by 50% and increasing production efficiency by 30% (Dong, 2019).

Observing the latest progress in the digital transformation of the Industrial Internet industry, it is evident that the government is accelerating the pace of promoting the Industrial Internet and digital transformation. However, enterprises appear to lag behind in adapting to market changes, talent acquisition, and management. The digital transformation of China’s industry is a long-term process. This transformation requires deep integration with industrial technologies, knowledge, and expertise, making it a complex and arduous task. Additionally, China’s industrial layout is characterized by its large scale and relatively low level of digitalization, indicating that building digital industrial clusters will face enormous costs and long time spans (Lu, 2022). Despite this, enterprises still face pressures from capital and survival, urgently needing the rapid returns and immediate benefits brought by industrial digital transformation. Under these constraints, achieving industrial digitalization becomes particularly challenging. Moreover, the data generated by the Industrial Internet belongs to the enterprises, increasing the barriers to entry into the big data market. This situation may lead to market monopolies and hinder the widespread application of industrial digitalization.

At the same time, the shortage of talent resources poses a significant obstacle to industrial digital transformation. Successful digitalization requires talents not only with information and communication technology skills but also with the ability to understand digital concepts. In the current talent market, there is a lack of interdisciplinary professionals who understand industry trends and possess digital expertise, collaborative efficiency, and innovative capabilities (Li et al., 2022). In the digital age, the product lifecycle is significantly shortened, and enterprises are facing a shrinking window of opportunity to compete for users, posing great challenges to their survival and development. Talent is the foundational driving force for enterprise development, and enterprises need to build high-skilled digital teams to promote digital transformation.

In terms of management challenges, the government needs to strengthen its ability to coordinate digital transformation. The digital transformation of the Industrial Internet industry requires collaboration across departments, industries, enterprises, and regions. Furthermore, the large scale, extensive range, technological complexity, and regulatory challenges of digital data flow make effective regulation a daunting task. The organizational structure differences of digital management entities hinder their ability to effectively supervise industrial digital transformation (Yu et al., 2020). There is an urgent need for top-level strategic planning for digital transformation at the enterprise level. Most companies require comprehensive strategies, long-term planning, and in-depth discussions and strategy formulation to address the complexities of digital transformation. Therefore, manufacturing enterprises often face the question of “what to transform and how to transform” (Dong, 2020). Additionally, China’s industrial digital transformation also faces technical management issues such as the complexity of data acquisition and application, data security, data management, and data sharing.

2.

The Role of Industrial Internet Platforms in Digital Transformation

In China, the Industrial Internet has transitioned from a mere conceptual advocacy to a stage of deep cultivation of practical applications. Chinese Industrial Internet companies have achieved rapid development and continue to innovate and improve technologies. According to data from the Ministry of Industry and Information Technology of the People’s Republic of China, by the end of 2022, more than 150 industrial internet platforms with regional and industry influence had been established in China. The application technology of the Industrial Internet in China has evolved from single device control to intelligent manufacturing, widely applied in ten key industries including electronic equipment manufacturing, steel production, and power generation (Han, 2021).

As one of the emerging infrastructures, the Industrial Internet enhances the digital capabilities of enterprises through digital technologies and automation solutions, promoting intelligent manufacturing.

In the field of business model analysis, leveraging big data analysis and machine learning technologies, the Industrial Internet can acquire real-time market data and conduct in-depth data analysis. This helps enterprises refine their business models and enhance business value. By establishing enterprise information systems and customer relationship systems, the Industrial Internet realizes and evaluates customer preferences, enabling enterprises to align with market demands amid rapid changes in enterprise and customer information (Wang et al., 2020). For example, under different market conditions, manufacturing enterprises can offer products, predictive maintenance services, and other solutions to establish lasting partnerships with customers while increasing revenue (Jacobson et al., 2017).

In terms of production, the Industrial Internet enables enterprises to optimize production processes by reviewing vast amounts of production data and monitoring real-time production procedures, reducing waste. Through data analysis facilitated by the Industrial Internet, mass manufacturing can reduce costs caused by misjudgments and production line oversights. For instance, Bosch factories utilize the Industrial Internet platform to examine their industrial data and improve production efficiency. By analyzing the root causes of production line issues, they achieve complete digital connectivity and transformation (Lade et al., 2017). In industries characterized by small batch manufacturing, such as aerospace manufacturing, the Industrial Internet reduces information delays and can automatically track equipment information during component assembly (Szymanski, 2016).

Regarding the industrial chain, the Industrial Internet promotes coordination and optimization among various links. Enterprises can achieve optimal resource allocation and collaborative management of production processes through data sharing and coordinated links (including supply chains, production chains, and sales chains). For instance, the Industrial Internet employs deep learning algorithms for product maintenance, predictive analysis, product development, and supply chain management. This promotes connectivity among internal departments of enterprises and drives data collaboration along the industrial chain (Latif et al., 2021). Technologies such as digital twins integrate product production and sales channels, bridging the virtual network world with the physical world, enhancing the efficiency and quality of the entire industrial chain, thereby improving the competitiveness of the entire industry (Kiel et al., 2017).

3.

Structure, Key Technologies, and Applications of Industrial Internet Platforms

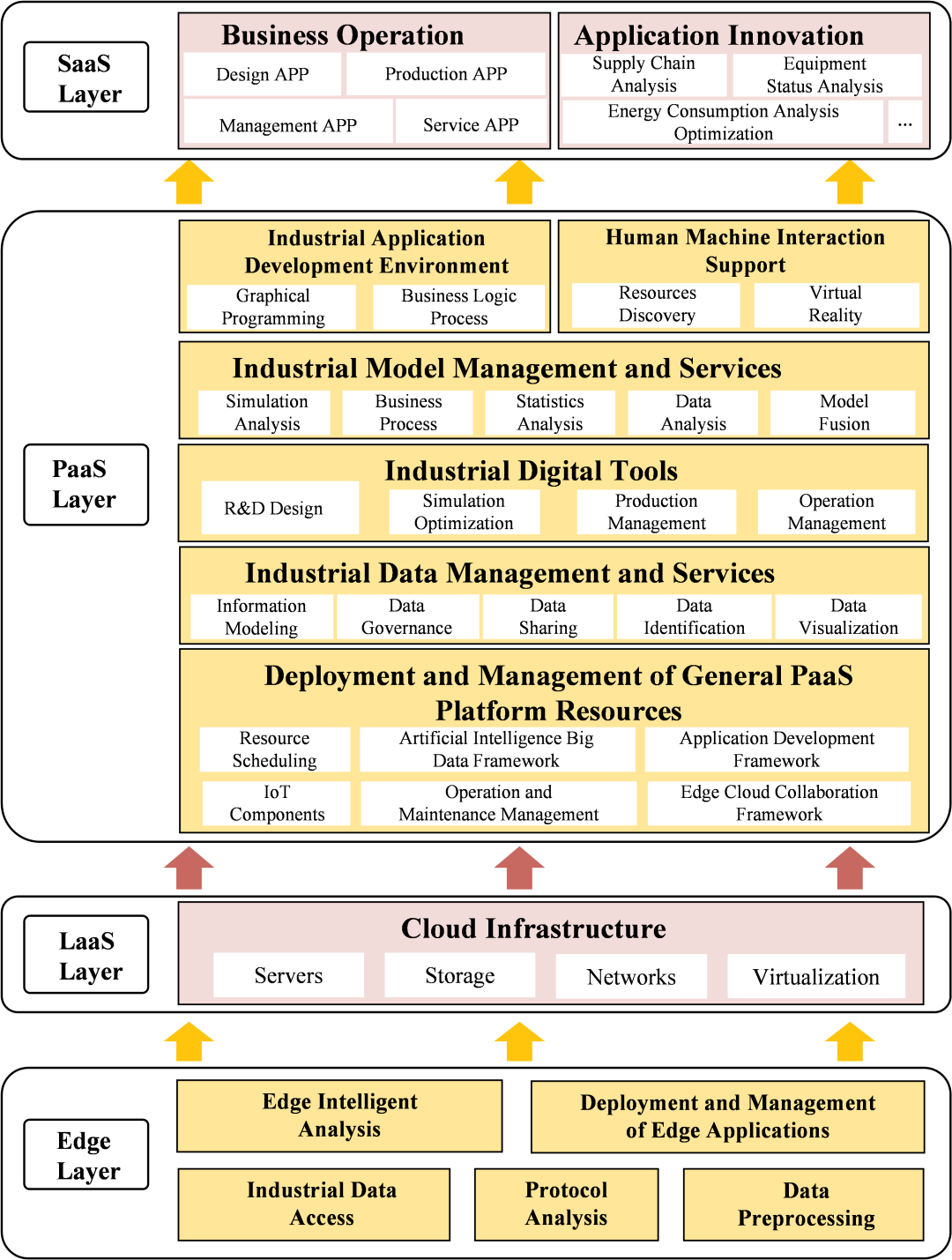

Industrial Internet platforms enhance industrial processes through advanced connectivity and data exchange technologies. Their success relies on innovative architecture and the seamless integration of necessary technologies. We present a typical architecture of an Industrial Internet platform, as shown in Figure 2. This architecture can be divided into four distinct layers: edge layer, Infrastructure as a Service (IaaS) layer, Platform as a Service (PaaS) layer, and Software as a Service (SaaS) layer.

As shown in Figure 2, the edge layer primarily provides functions such as extensive industrial data collection, transformation, data preprocessing, and edge analytics applications. The Infrastructure as a Service layer mainly includes infrastructure related to hardware servers, data storage, 5G networks, and virtualization technologies. These elements provide the necessary hardware foundation to ensure the stable and secure operation of the Industrial Internet platform. The PaaS layer offers a range of functions, including resource management, industrial data and model management, industrial modeling analysis, and support for industrial application innovation. Finally, the topmost Software as a Service layer facilitates business operations and drives application innovation.

Figure 2. Architecture of Industrial Internet Platforms

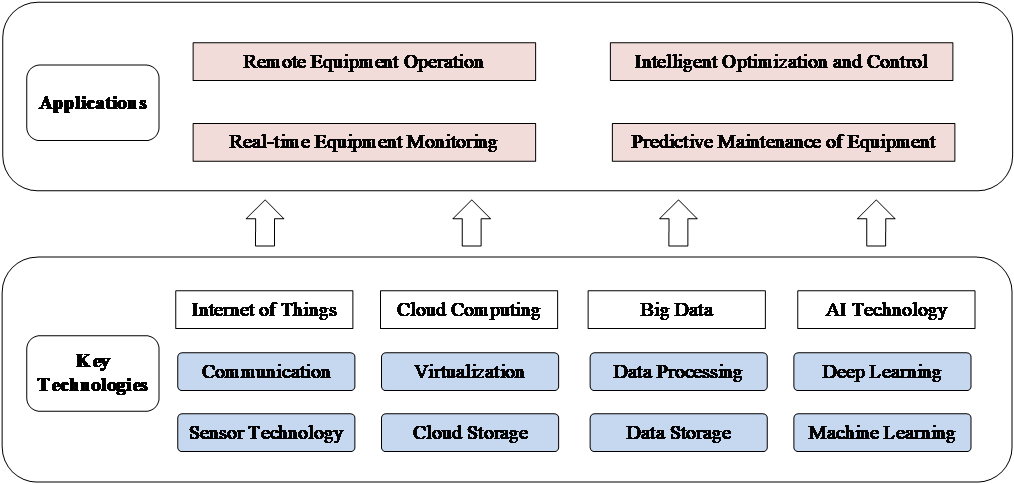

Industrial Internet platforms employ several key technologies to support the aforementioned architecture. These core technologies include sensing technology, big data analysis, cloud computing, artificial intelligence, and security technology. Sensing and data collection technologies gather and transmit data from sensors and devices embedded in industrial infrastructure. Big data analysis is crucial for extracting valuable strategies from accumulated data. Furthermore, security technology is essential for protecting Industrial Internet platforms from cyber threats and ensuring data integrity and privacy. Figure 3 illustrates the key technologies and their application areas. Currently, many successful Industrial Internet platforms have emerged both domestically and internationally.

Figure 3. Key Technologies and Applications of Industrial Internet Platforms

The pioneer of Industrial Internet platforms in China is the Industrial Intelligent Cloud System (INDICS), introduced by Chai et al. in 2018. In the PaaS layer of the INDICS platform, over 200 APIs are designed to support application lifecycle management. INDICS provides industrial services, workflow management, and simulation engines, thereby enabling software-based application manufacturing. This platform has played a key role in facilitating the successful digital transformation of small and medium-sized enterprises. For example, it connects 1,022 fans and processes 200 million data entries daily, enabling real-time data monitoring of grid fans. This functionality helps wind farms identify equipment failures and automatically assess power generation (Chai et al., 2018). Additionally, INDICS connects 266 robotic devices for monitoring robotic operations in computer numerical control companies, reducing unplanned downtime through fault data analysis and optimizing robotic performance. These solutions rely on two core technologies: the ability to collect diverse production data from sensors and devices, and extensive data storage, management, and processing based on cloud computing architecture. These technologies ensure product quality throughout the product lifecycle.

Li et al. (2017) explored the applications of Industrial Internet platforms in the energy sector. Industrial Internet technologies are fundamentally transforming the traditional energy industry. The platform first collects real-time sensor data through extensive sensing capabilities provided by industrial sensing and wireless communication technologies (Luo et al., 2006). Subsequently, the collected data is processed and integrated into energy management systems. This helps decision-makers identify waste and formulate more effective energy-saving strategies. Moreover, the platform integrates energy data into production management practices to improve energy efficiency. The platform largely relies on advanced information and communication technologies such as software-defined machines, intelligent sensing, and big data analysis. Notably, big data and data analysis provide insights for predictive analysis, minimizing unplanned system downtime and preventing unexpected shutdowns. The adoption of Industrial Internet platforms in the energy sector has brought advanced control, remote monitoring, predictive maintenance technologies, and improved safety and efficiency (Zbunjak et al., 2013).

Outside of China, General Electric (GE) pioneered the concept of the Industrial Internet, including the “Infrastructure Layer” and “Platform Layer.” The Infrastructure Layer manages data centers that handle structured and unstructured data, while the Platform Layer consists of scalable software programming that overlays the Infrastructure Layer (Agarwal et al., 2015). GE launched the Predix Industrial Internet Cloud platform for use on GE and non-GE devices. Predix plays a key role in developing industry-specific applications, leveraging advanced software technologies and cloud computing paradigms. Several GE business lines standardize Predix as the technical platform for big data and analytics-driven software development. For instance, it enables predictive maintenance and repair for GE’s jet engines and gas turbines while providing customers with analytical and optimization solutions.

On the other hand, Siemens developed an Industrial Internet platform called MindSphere. This platform connects approximately 1 million devices and systems while providing predictive maintenance services for these devices (Wang et al., 2020). Many companies have created software applications for specific stages of the product manufacturing process, but integration challenges arise when transferring data between different systems.

MindSphere utilizes information fusion technology to address multi-source heterogeneous data, providing a comprehensive automation solution that covers the entire product lifecycle.

4.

Challenges and Countermeasures of the Industrial Internet

Despite the immense potential of the Industrial Internet to transform manufacturing, it faces a series of challenges that need to be addressed. These challenges include mixed criticality, network latency, security vulnerabilities, and legacy industrial systems (Breivold et al., 2015). In the following sections, we will briefly summarize the obstacles that must be overcome to facilitate digital transformation through Industrial Internet platforms.

4.1 Mixed Criticality

Industrial Internet platforms need to integrate numerous functions between multiple components, devices, and stages to achieve higher levels of intelligent control and collaboration. However, when an industrial system mixes functions of different criticality levels internally, the challenge of mixed criticality arises. To prevent low-criticality functions from interfering with high-criticality functions, the platform must ensure the autonomy of software applications. While multi-core processor hardware provides a feasible solution to this problem, a significant amount of legacy software was initially designed for single-core execution. When transitioning to multi-core processing, the platform must support software partitioning. Virtualization serves as a valuable technology in this context, allowing different operating systems to run simultaneously on different virtual machines, ensuring effective separation and isolation of resources within the same system.

4.2 Network Latency

Within Industrial Internet systems, thousands of sensors, devices, and programmable logic controllers are interconnected through industrial field buses and communication protocols such as IoT and 5G. To achieve real-time monitoring, Industrial Internet platforms must ensure reliable and low-latency data transmission. However, with the rapid increase of sensors and distributed devices in modern factories, network latency has become a severe challenge. Research by Hegazy et al. (2014) indicates that round-trip latency on the internet typically ranges from tens to hundreds of milliseconds, which can significantly impact latency-sensitive industrial applications.

To address this challenge, the literature introduces the concepts of fog computing or edge computing (Hegazy et al., 2014). In fog computing, applications or services with real-time performance requirements are moved to the network edge or end devices to reduce response times and latency. Edge computing shifts services that are unsuitable for execution in the cloud to end devices, thereby minimizing response times. To achieve digital transformation in the industry through Industrial Internet platforms, researchers must make substantial progress in fog computing or edge computing.

4.3 Security Challenges

There is a common assumption that the networks of industrial control systems are secure and not subject to external interference. However, Industrial Internet platforms connect sensors, actuators, machinery, and industrial networks, posing challenges for system designers regarding data privacy. The secure storage of data collected from multiple devices is crucial for preventing malicious attacks.

Existing platforms generally adopt signature-based security technologies. However, attackers can easily manipulate the syntactical representation of these signatures to launch attacks. Therefore, a key challenge faced by Industrial Internet platforms is to represent attacks with a balanced abstraction that can adapt to specific attack variants (Li et al., 2017). Additionally, platforms require regular security upgrades. However, for certain systems, even millisecond-level downtime is unacceptable. Therefore, ensuring seamless security upgrades that do not hinder functional safety or interrupt control processes is another significant challenge faced by Industrial Internet platforms (Breivold et al., 2015).

4.4 Legacy Industrial Systems

Currently, the industrial sector primarily uses legacy software systems, which typically have lifespans ranging from ten to thirty years. These systems exhibit certain drawbacks, such as increasing complexity, insufficient documentation, and limited understanding by modern developers (Breivold et al., 2015). Moreover, legacy systems struggle to adapt to rapidly changing market demands. Therefore, effectively utilizing and transforming these legacy systems poses a significant challenge for Industrial Internet platforms. These platforms need to continually deploy new functions and services to meet unpredictable market dynamics.

In China, many factories are at the Industrial 2.0 stage, with relatively low levels of automation. Digital transformation and intelligent upgrading of equipment require enormous costs and complexity, presenting additional challenges. For example, the data collected from these factories may be incomplete, inaccurate, or even unavailable. Addressing the current needs of small and medium-sized manufacturing enterprises while enhancing the depth of platform applications is a daunting task.

5.

Prospects for Industrial Digital Transformation

With the emergence of technologies such as artificial intelligence, information transmission, and blockchain, Industrial Internet platforms exhibit immense development potential. At the same time, the industrial digital transformation through these platforms continues to progress. The following are potential future directions in this field.

Firstly, a key future direction involves the integration of Internet of Things (IoT) and artificial intelligence (AI) technologies. Industrial Internet platforms will increasingly leverage the integration of IoT devices and AI technologies. IoT devices will collect vast amounts of data from diverse industrial processes, while AI will play a critical role in analyzing and extracting valuable insights from this data. The application of AI in Industrial Internet platforms will gradually expand, enhancing the intelligence of industrial production platforms. Through data analysis and machine learning, machinery can autonomously execute tasks, achieving efficient production and improving product quality. Additionally, AI can assist companies in achieving customized product offerings. Through intelligent production and streamlined supply chain management, companies can rapidly respond to consumer demands and provide products and services that meet consumer needs.

Secondly, integrating autonomous systems and robots into industrial processes is another noteworthy direction. Industrial Internet platforms will facilitate the integration of autonomous systems and robots, which may include autonomous vehicles, robotic assembly lines, and drones for monitoring and inspection. These technologies are expected to improve efficiency, precision, and safety in industrial operations.

Thirdly, the foundation of industrial digital transformation lies in Industrial Internet platforms, which require support from blockchain technology. Given the presence of vast amounts of sensitive data on Industrial Internet platforms, leaks or tampering of this data may lead to risks such as production disruptions and quality issues. The decentralized and encrypted properties of blockchain technology provide safeguards against tampering and leakage, thereby enhancing data security. Additionally, blockchain technology can enhance data transparency. Data exchange and sharing among multiple enterprises on Industrial Internet platforms may lead to information asymmetry due to inconsistent data formats and standards between different enterprises. The inherent distributed ledger mechanism of blockchain technology ensures data consistency and transparency, thereby reducing information asymmetry and improving data accuracy and reliability.

Furthermore, future advancements in information transmission technologies will play a critical role in the operation of industrial digital transformation and Industrial Internet platforms. These technologies will continue to evolve and improve, including higher data transmission speeds, lower latency, broader coverage, stronger security, and smarter interaction modes. For instance, 5G networks support network slicing technology, enhancing the ability of Industrial Internet platforms to adapt to the needs of different industries.

Finally, Industrial Internet platforms constitute the critical technological foundation for supporting Industry 5.0. As a new paradigm, Industry 5.0 emphasizes the integration and collaboration between humans and machines to meet personalized and highly customized production demands. It highlights the active participation and creativity of employees, transforming them from mere operators on production lines into the main drivers of process optimization and technological advancement. Industrial Internet platforms play a key role in advancing Industry 5.0. Firstly, they facilitate human-machine collaboration in Industry 5.0. Through the interconnection of various devices and systems, the Industrial Internet achieves real-time connectivity and information exchange at different stages of industrial production, promoting seamless collaboration between humans and machines. Secondly, Industrial Internet platforms promote real-time interaction in Industry 5.0. Through these platforms, stakeholders including manufacturing enterprises, customers, and suppliers can engage in real-time information exchange and collaboration, better meeting customization needs and enhancing production efficiency and product quality. Lastly, Industrial Internet platforms provide secure support for Industry 5.0. They achieve secure data storage and transmission, ensuring the protection of manufacturing enterprises’ information and strengthening their intellectual property and trade secret protection.

6.

Conclusion

Achieving industrial digital transformation through Industrial Internet platforms plays a key role in promoting rapid economic growth, ensuring stable development in the manufacturing industry, and driving innovation. Specifically, achieving industrial digital transformation requires the indispensable support of Industrial Internet platforms in areas such as business model analysis, production, and industrial chains. This paper analyzes typical Industrial Internet platforms such as INDICS and Predix, explores the key technologies of Industrial Internet platforms, and examines the critical roles played by the Industrial Internet. Notably, Industrial Internet platforms have triggered revolutionary changes in industries such as energy and manufacturing. However, the ongoing progress of the Industrial Internet is hindered by certain emerging technologies. Therefore, future research should prioritize studies in areas such as mixed criticality, network latency, and security management. Additionally, addressing the long-standing legacy industrial systems poses a significant challenge for Industrial Internet platforms. Finally, future research should consider how to resolve biases and errors in physical-virtual mapping within Industrial Internet platforms, which is a key factor in driving the industry’s shift from automation to unmanned operations.

Scan the QR code to read the original text