B&R’s mapp technology helps machine manufacturers easily integrate robotics.

Author | B&R

“

The close integration of robots and machine components provides an ideal foundation for implementing the Industry 4.0 concept. With B&R’s mapp technology, robot manufacturers can enhance the performance of existing systems by 50%.

“

MAJAtronic, a manufacturer of motion systems for cross-platform Delta and DuoPod robots, has added articulated arm systems to its product portfolio. Machine manufacturers can now integrate functions such as loading and palletizing into their preferred machine control systems. MAJAtronic’s six-axis demonstration robot showcases how this can be done quickly and easily using B&R controllers with mapp technology.

When machine manufacturers need Delta or articulated robots for new machines or factories, their first instinct is to turn to the big brands in the robotics industry. They can offer a wide range of industrial robots, specialized solutions (such as for welding, gluing, or feeding applications), dedicated robot controllers, and accessories. Often, it is not possible to order the robot mechanical body and the robot controller separately.

However, an increasing number of machine and factory builders do not want to bundle the purchase of the mechanical body and controller and are looking for alternatives. The reason is simple: having separate controllers for robots and machine control increases the time and costs involved in the entire engineering, commissioning, maintenance, and spare parts storage processes. Additionally, the latency at the interface between the robot and machine controllers makes it more difficult to synchronize robot movements with machine processes (such as conveyor belt movements).

Cross-Controller Robot Motion

Suppliers like MAJAtronic are stepping up to fill this market gap. The company, a subsidiary of the German food industry machinery manufacturer MAJA, has developed around 150 different Delta and DuoPod systems since entering the market in 2010. These systems have a working range from 20 to 200 cm and can handle rated payloads from 0.5 to 350 kg, including a Delta robot with a payload of 50 kg. All MAJAtronic robots feature a robust mechanical body that can operate without controllers, drives, or other accessories, branded as Autonox24.

To enable customers to easily integrate “German-made” robotic technology into their machines and systems, MAJAtronic collaborates closely with control system suppliers like B&R, who have years of experience providing the necessary performance for controllers. Robot manufacturers recommend motors for each controller, allowing users to optimize from tested combinations without having to lay out the motors themselves.

▎In addition to Delta and DuoPod robots, MAJAtronic also offers cross-controller six-axis articulated robots that can be easily integrated into B&R’s machine control systems. With mapp technology, users can achieve this without any specialized robotic know-how.

In the Field: 700 Robots Operating Without Dedicated Controllers

This proposal has been well received by quality-focused machine manufacturers, as MAJAtronic’s managing partner Hartmut Ilch proudly states: “Today, we have over 700 robots working on our customers’ machines.” A significant portion of these is used in packaging machinery within the food industry.

This is the starting point for Autonox24. The first robot developed by MAJAtronic for its parent company was a Delta robot with a hygienic design. “It quickly became clear that machine manufacturers were enthusiastic about our cross-controller concept and wanted these robots to appear in environments that did not require hygienic designs for packaging and sorting,” Ilch said.

Expanding the Concept to Include Articulated Robots

In recent years, there has been an increasing call from the company to expand the cross-controller concept to include articulated robots. The goal is also to integrate operations such as palletizing into the machine control framework. MAJAtronic has kept these requirements in mind and, with the support of four well-known pilot customers who previously used independent robot controllers, has addressed the development of six-axis articulated robots.

This led to the creation of the first two members of the “articc” series, one being a six-axis robot with a payload of 20 kg and a working radius of 4 meters, and the other a smaller version with a payload of 8 kg and a working radius of 2 meters.

Using mapp Robotics for

Robot Applications

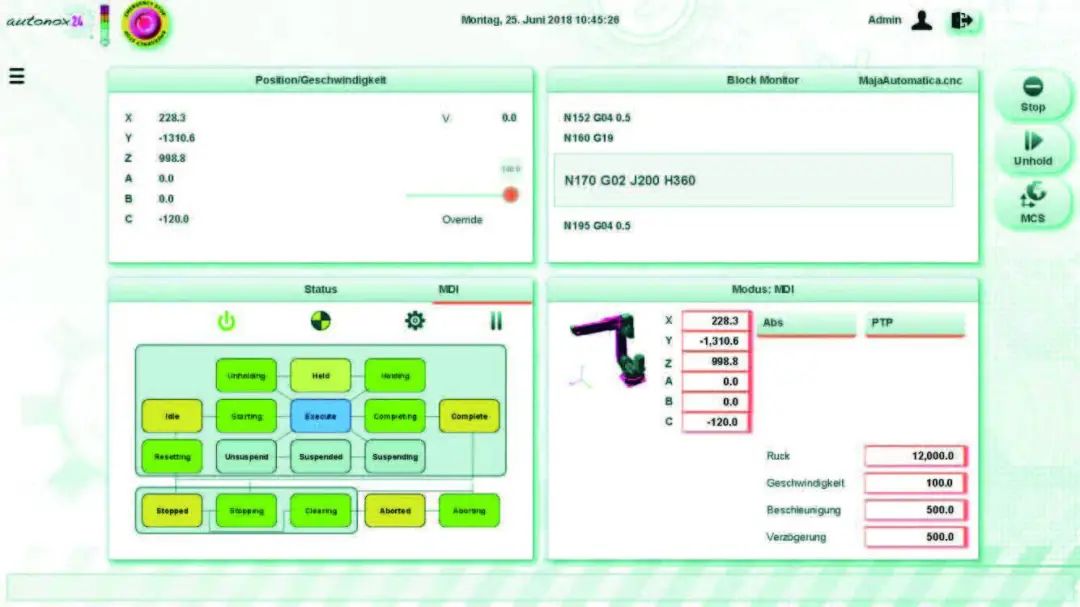

B&R has been involved in these new development projects from the beginning. Waldemar Salzsehler, an application engineer at B&R’s technology office in Heilbronn, programmed the durability tests for the 20 kg robot prototype and MAJAtronic’s exhibition demo with the assistance of B&R Automation Studio engineering environment. The core of the robot application is implemented using mapp Robotics, which is part of B&R’s modular mapp technology software framework. The mapp Robotics library contains modular function blocks and data structures for robot programming, as well as predefined motion models. These include all the information required for inverse transformation.

To create new motion systems, the B&R Scene Viewer tool provided in Automation Studio can be used to generate models based on the CAD data of the robot mechanical body, including transformation parameters. Users can perform virtual debugging in advance using this model, observing and recording robot movements without using any actual robot mechanical body.

▎The user interface of the demonstration robot is created using B&R’s mapp View, an HMI solution based on the latest web technologies that can run on any device with a supported browser.

No Specialized Robot Know-How Required

mapp Robotics provides many core functionalities required for robot applications, such as starting programs, executing linear movements, opening all controllers, or resetting axes. Users without any specialized robot know-how can achieve these functionalities without programming from scratch.

The corresponding mapp components are also available for most other (robot) control applications, such as user management, alarm handling, state machines, or HMI applications, resulting in a significantly lower overall programming workload compared to traditional programming methods.

On this basis, B&R’s application engineers began modeling the motion system, creating basic control and HMI applications, and placing the robot in virtual operation, all within less than a week.

Debugging Takes Only 4 Hours

Once the prototype with the MAJAtronic robot mechanical body and B&R controller is ready, as used in one pilot customer’s machine, the next step is to perform the actual debugging of the robot. “The robot was up and running in just 4 hours. This is truly astonishing,” Ilch said. “We were immediately impressed by such a short debugging time and such high-quality path control. B&R clearly holds a leading position among control system manufacturers.”

With the help of B&R’s Scene Viewer, users can easily create models of the robot mechanical body, displaying and recording robot movements without using any actual hardware. This allows for early testing of robot applications and reduces the time required for debugging on the machine.

Including durability testing, where all axes move through all positions at maximum speed and acceleration, Salzsehler completed the on-site debugging in just three days. He was able to reuse the modular solution he created in just one day to implement the six-axis demonstration robot. The modular structure of mapp technology allows for easy expansion of applications as needed and integration of components such as conveyor belts or other machine components into the same control platform.

Sustainability Trends in Integrated Solutions

“The close integration of robots and machine components provides an ideal foundation for implementing the Industry 4.0 concept. It also has a positive impact on the overall performance of the machine,” Ilch explained. “In benchmark tests, we were able to demonstrate to users that our concept can enhance the performance of existing systems by 50%.”

As a result, neither standard control system manufacturers nor standard robot manufacturers are involved anymore. “Due to the impressive advantages of cross-controller robots, we will see this approach from an increasing number of machinery manufacturers,” the manager of MAJAtronic confidently stated about the future.

– END –

This article is from Control Engineering China, September 2020 issue, in the “Application Cases” section, originally titled:Integrating Robotics 4.0

Recommended Reading

How to Successfully Implement Machine Vision Projects? The Three Major Reasons for Project Failure and Three Countermeasures

[Strategic Choices] When to Upgrade Process Control Systems (DCS)? Overall Upgrade or Phased Upgrade?

The Future of Industrial Automation Training – Learning with a Brain Beyond Your Own

Simplifying Automation – Basic Tips and Best Practices for Factory HMI Design

Revolutionizing Traditional Manufacturing Processes – Digital Engineering

We invite you to join the Industrial Automation Circle

We invite you to join the Industrial Automation Circle

Since 2020, to strengthen communication between editors and readers, as well as among readers, we have established various WeChat groups for professional readers in industrial automation technology.

We have formed the following technical category groups:

TSN Network Group

PLC Group

DCS Group

Machine Vision Group

Robot Group

Industrial Software Group

Human-Machine Interface Group

Motion Control Group

Sensor Group

Industrial Safety Group

Instrumentation Group

Industrial AI Group

Scan the QR code on the right,send “Name + Technical Interest + City” to add the editor’s WeChat (cec_editor), and after review, you will be invited to join the corresponding technical group.