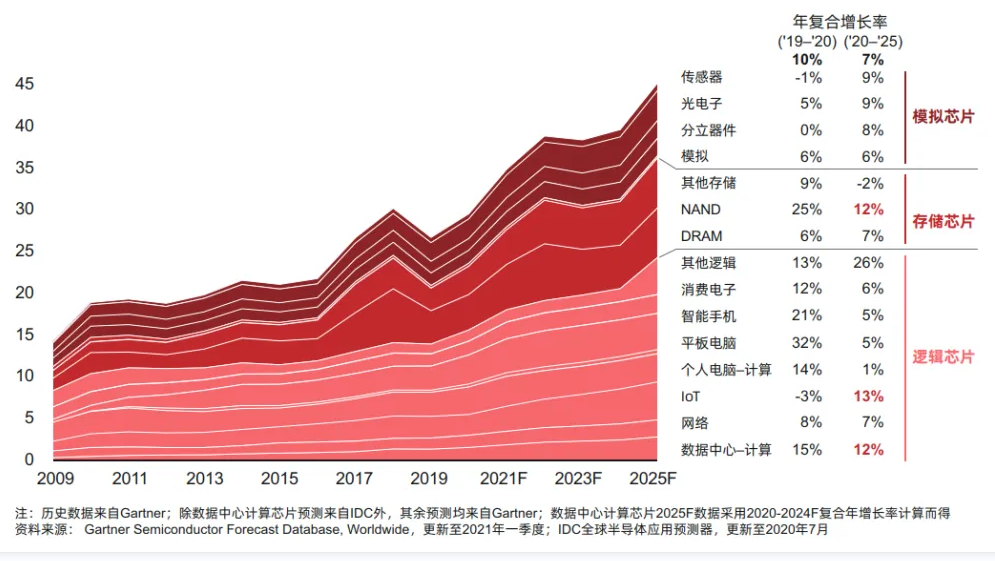

The semiconductor industry, as the cornerstone of the information technology sector, is a strategic, foundational, and leading industry that supports the economic and social development of our country and ensures national security. It has received significant attention and support from the government. In 2014, to fully leverage the advantages of the domestic semiconductor market scale and create a favorable development environment for promoting the localization of semiconductors, the State Council issued the “National Integrated Circuit Industry Development Promotion Outline” to accelerate the leapfrog development of the semiconductor industry.

The semiconductor industry, as the cornerstone of the information technology sector, is a strategic, foundational, and leading industry that supports the economic and social development of our country and ensures national security. It has received significant attention and support from the government. In 2014, to fully leverage the advantages of the domestic semiconductor market scale and create a favorable development environment for promoting the localization of semiconductors, the State Council issued the “National Integrated Circuit Industry Development Promotion Outline” to accelerate the leapfrog development of the semiconductor industry. Flexible Logistics Empowering Flexible ProductionUninterrupted Information LinksTo assist the sustainable development of the semiconductor industry chain, Jiafan Technology has repeatedly collaborated with Youbuxun to create multiple practical, quickly implementable, and highly replicable demonstration cases of smart factories in the semiconductor sector. Addressing challenges in factory applications such as lean production, dense warehousing, and logistics distribution in the semiconductor industry, we jointly developed the intelligent hardware and software product “Robot Controller,”efficiently achieving scientific planning of smart factory warehousing logistics and comprehensive flexible intelligent operations.

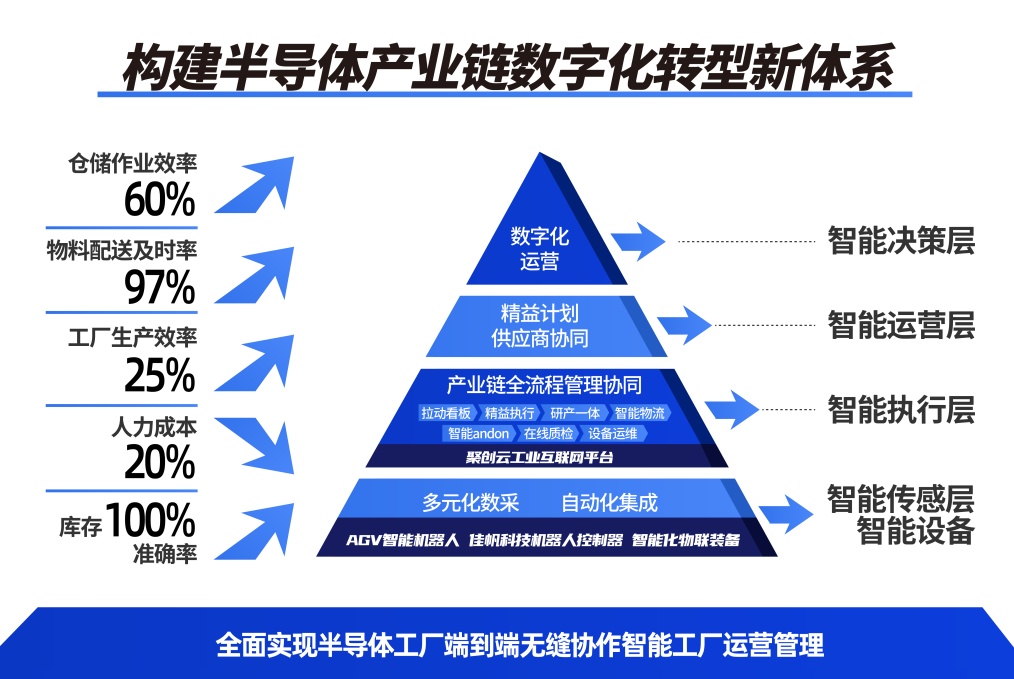

Flexible Logistics Empowering Flexible ProductionUninterrupted Information LinksTo assist the sustainable development of the semiconductor industry chain, Jiafan Technology has repeatedly collaborated with Youbuxun to create multiple practical, quickly implementable, and highly replicable demonstration cases of smart factories in the semiconductor sector. Addressing challenges in factory applications such as lean production, dense warehousing, and logistics distribution in the semiconductor industry, we jointly developed the intelligent hardware and software product “Robot Controller,”efficiently achieving scientific planning of smart factory warehousing logistics and comprehensive flexible intelligent operations. Based on the Juchuang Cloud Industrial Internet platform, equipped with the Juxin Cloud leveling distribution algorithm, Jiafan Technology integrates multiple campus-level logistics chain software systems, connecting all intelligent logistics equipment and robot controller modules within the campus, providing the semiconductor industry with an integrated hardware and software overall solution for smart factories across all scenarios and elements.

Based on the Juchuang Cloud Industrial Internet platform, equipped with the Juxin Cloud leveling distribution algorithm, Jiafan Technology integrates multiple campus-level logistics chain software systems, connecting all intelligent logistics equipment and robot controller modules within the campus, providing the semiconductor industry with an integrated hardware and software overall solution for smart factories across all scenarios and elements.

Dense Storage

Managers can utilize the Juchuang Cloud smart logistics operation platform to achieve multi-functional area dense storage within the factory, real-time monitoring of goods in and out of storage, turnover data, intelligently optimizing goods distribution, activating idle shelf storage locations, enhancing the utilization rate of storage locations, warehouse spaces, and site resources, optimizing space planning and leveling distribution algorithms,reducing storage costs and improving capital turnover.

Vehicle Height Coordination / Automatic Avoidance

Frontline personnel in the factory can use the robot controller to globally track Juxin Cloud intelligent logistics equipment, such as automated handling robots and smart forklifts, and achieve multi-layer material transport coordination across floors and buildings. By combining real-time location information of intelligent logistics equipment and the traffic conditions of on-site passages, it can automatically sense personnel, vehicles, and goods, quickly adjust navigation routes and driving speeds, and achieve automatic handling in extremely narrow passages, optimizing on-site safety, efficiency, path, distribution dispatch algorithms, and management.

Automatic Elevator Control

After automation transformation, the freight elevator interacts with automated handling robots. The robot controller schedules the robots to automatically dock with the freight elevator and logistics doors, and quickly passes through the gaps of the freight elevator, achieving real-time acquisition of handling tasks and guiding operational objectives, saving transportation and delivery time within the factory. Based on the Juchuang Cloud Industrial Internet platform and the robot controller, the internal logistics chain and supply chain capabilities of major semiconductor companies have been deeply optimized, with material delivery timeliness improved to 97%, and turnover time reduced to a minimum of 1.5 days, achieving highly refined closed-loop management of dynamic configuration of all elements in on-site logistics, completing a digital transformation centered on high efficiency, high matching, low risk, and low cost. As the demand for lean manufacturing in the semiconductor industry and market scale continues to change, how to utilize digital intelligence to build a competitive “moat” for semiconductor enterprises is key for companies to achieve healthy development and maintain strong brand core competitiveness in the fierce global market competition.

As the demand for lean manufacturing in the semiconductor industry and market scale continues to change, how to utilize digital intelligence to build a competitive “moat” for semiconductor enterprises is key for companies to achieve healthy development and maintain strong brand core competitiveness in the fierce global market competition. Currently, Jiafan Technology has gradually delved into the development of big data, cloud computing, and Internet of Things technologies, developing over 100 independent intellectual property rights around the Juchuang Cloud Industrial Internet platform and the Juxin Cloud IoT intelligent equipment platform, and in 2022, obtained more than 10 independent intellectual property rights related to management systems, algorithm software, and intelligent quality inspection in the semiconductor industry. Jiafan Technology will continue to strengthen innovations in IoT, artificial intelligence interaction, and industrial robot technology, efficiently promoting the “precision, flexibility, and intelligence” upgrade of the semiconductor and related precision electronics industries, helping enterprises run faster, more steadily, and further in global market competition.

Currently, Jiafan Technology has gradually delved into the development of big data, cloud computing, and Internet of Things technologies, developing over 100 independent intellectual property rights around the Juchuang Cloud Industrial Internet platform and the Juxin Cloud IoT intelligent equipment platform, and in 2022, obtained more than 10 independent intellectual property rights related to management systems, algorithm software, and intelligent quality inspection in the semiconductor industry. Jiafan Technology will continue to strengthen innovations in IoT, artificial intelligence interaction, and industrial robot technology, efficiently promoting the “precision, flexibility, and intelligence” upgrade of the semiconductor and related precision electronics industries, helping enterprises run faster, more steadily, and further in global market competition.

As a provider of overall solutions for smart factories, Jiafan Technology is based on domestically developed AIoT hardware and software technology, creating a new flexible lean production management system for artificial intelligence computing, dedicated to providing overall solutions for smart manufacturing and industrial internet for the transformation and upgrading of the manufacturing industry, creating a one-stop turnkey project, and providing full lifecycle data management services for China’s intelligent manufacturing transformation and upgrading.