Company Overview

The Huaneng Clean Energy Research Institute is committed to serving the country’s high-level technological self-reliance and strength, taking the lead in the innovation of new energy technologies in China’s power industry. It aims to build a first-class international research institution characterized by low-carbon clean energy, positioning itself as the technological engine for the high-quality development of the group company. Currently, it has 14 national and provincial-level R&D platforms and 12 specialized laboratories. It has initiated the establishment of 7 technology innovation industrial alliances and serves as the supporting unit for the “Carbon Capture, Utilization, and Storage Technology” and “Offshore Wind Power Industry Technology” innovation consortiums, as well as the secretariat unit for the “National Carbon Capture, Utilization, and Storage Industry Technology Innovation Strategic Alliance.”

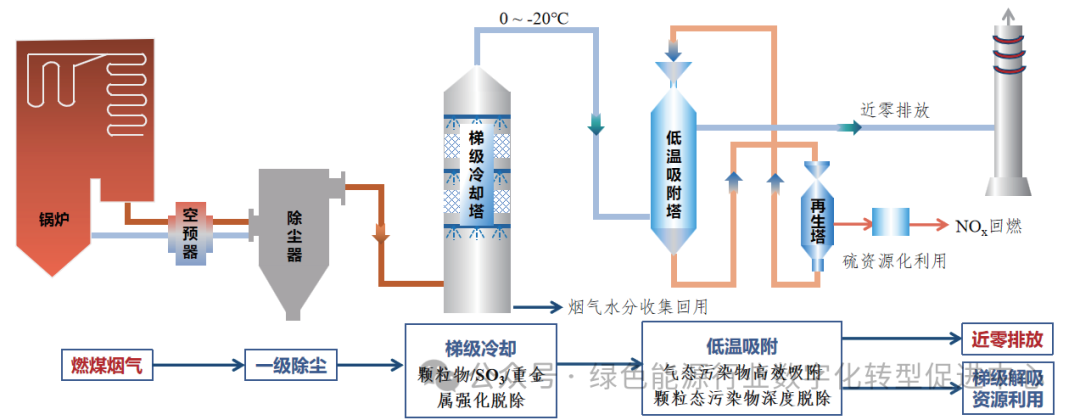

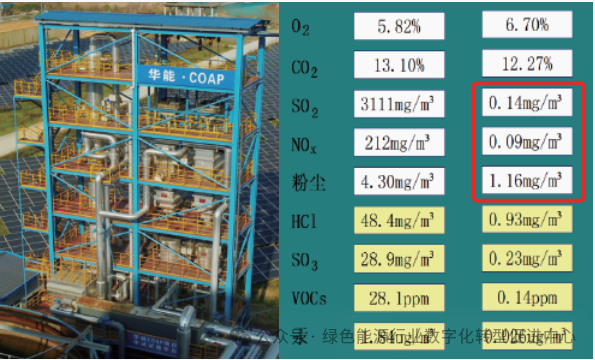

This presentation showcases the 44th issue of the “2023 Annual Collection of Typical Cases of Green Technology Innovation”: Near-Zero Emission Control Technology for Flue Gas Pollutants Using Low-Temperature Method (COAP) — Huaneng Group Clean Energy Technology Research Institute Co., Ltd.

Case Overview

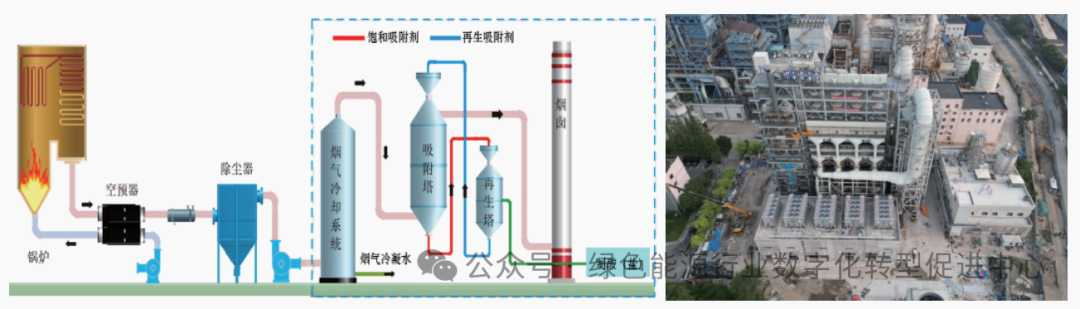

The COAP technology is an original transformative flue gas pollutant control technology developed in China. It achieves integrated removal and near-zero emissions of multiple pollutants such as SO2, NOx, dust, SO3, heavy metals, and halides at a low operating cost without the addition of any chemical reagents. Additionally, it enables the resource utilization of water and sulfur in the flue gas. This technology can reduce the concentration of pollutants in flue gas to below 1 mg/Nm3, with key performance indicators reaching international leading levels, effectively addressing many challenges such as secondary pollution emissions and material consumption in coal-fired flue gas treatment.

Application Cases

Pilot verification: Huaneng Yueyang Power Plant;

Coal-fired flue gas treatment capacity: 3,600 Nm3/h.

Full-flow industrial verification: Lianyungang Chemical Park;

Gas flue gas treatment capacity: 50,000 Nm3/h.

First industrial demonstration of 135MW level: Huaneng Linyi Power Plant;

Coal-fired flue gas treatment capacity: 500,000 Nm3/h.

If you are interested in application and utilization, please contact us.

Submissions are welcome.

Submission email:[email protected]