Skip to content

Currently, the energy density of commercial lithium-ion batteries can reach 300 Wh kg−1, with the potential for further improvement. However, while pursuing high energy density, the safety issues of the batteries cannot be ignored. The separator, as one of the key components of lithium-ion batteries, functions to isolate the positive and negative electrodes and conduct lithium ions, which is crucial for the battery’s safety. Internal short circuits are a key trigger for thermal runaway in batteries, usually caused by the shrinkage, melting, or penetration of lithium dendrites through the separator. Traditional polyolefin separators have poor thermal stability, non-uniform pore structures, and are prone to shrinkage at high temperatures, leading to internal short circuits and thermal runaway. Polyimide (PI) is considered an ideal choice for high-safety separators due to its excellent thermal stability, high mechanical strength, and good chemical stability. However, existing preparation technologies are still limited to laboratory scale, and the non-uniform pore structure is difficult to control accurately. Therefore, developing PI separators with uniform pore channel structures and achieving controllable preparation is very important to fully leverage the separator’s role in enhancing battery safety.

Recently, researchers from the Materials Research Center of the Institute of Modern Physics, Chinese Academy of Sciences, in collaboration with teams from Lanzhou University and the Advanced Energy Science and Technology Guangdong Laboratory, utilized the Lanzhou Heavy Ion Research Facility (HIRFL) to develop a new process for preparing high-performance lithium-ion battery PI separators that are resistant to high temperatures using ion track technology. The prepared separator has significant advantages over traditional polyolefin separators, with a mechanical strength of up to 150.6 MPa, excellent high-temperature performance (no structural shrinkage at 450℃), narrow pore size distribution (standard deviation of pore size < 6%), and vertically aligned pore structures (curvature of 1). At a current density of 3 mA cm−2, lithium/lithium symmetric batteries using this separator can cycle stably for 1200 hours; the lithium deposition on the lithium metal electrode surface is uniform and dense, indicating its excellent lithium dendrite suppression performance. Lithium iron phosphate soft-pack batteries using this separator can cycle stably for 1000 times at room temperature, with a capacity retention rate of 73.25%. This battery also demonstrates excellent high-temperature performance, capable of stable cycling at 80℃ and still functioning normally at an ambient temperature of 150℃. The article titled Robust, High-Temperature-Resistant Polyimide Separators with Vertically Aligned Uniform Nanochannels for High-Performance Lithium-Ion Batteries was published in the American Chemical Society journal ACS Nano. PhD students Zhang Qizhong from the Institute of Modern Physics and Chen Linjing from Lanzhou University are the first authors of this paper, while Researchers Liu Jie and Yao Huijun from the Institute of Modern Physics are the corresponding authors.

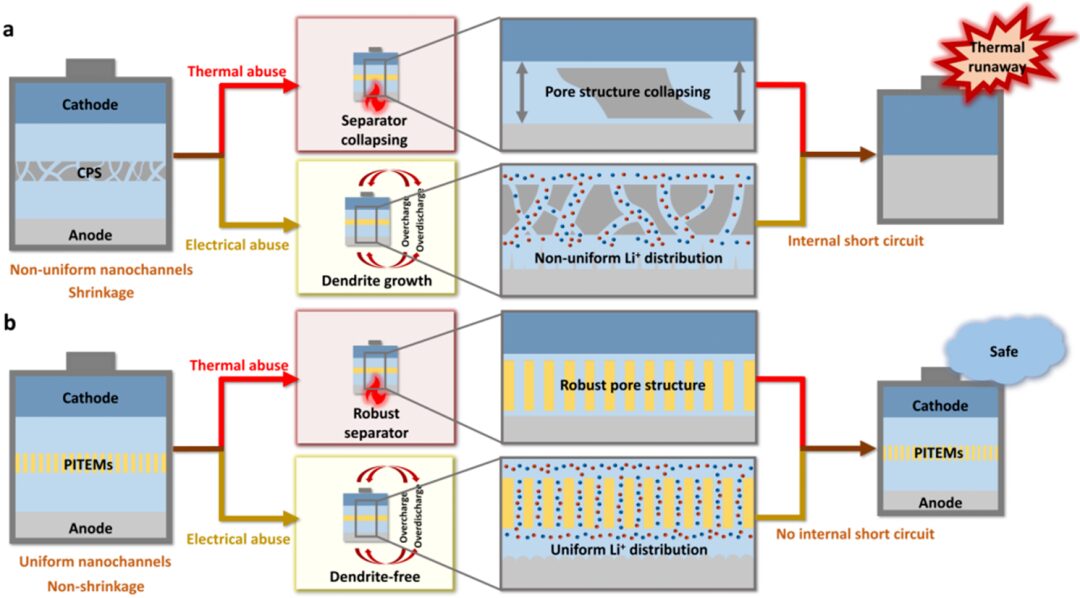

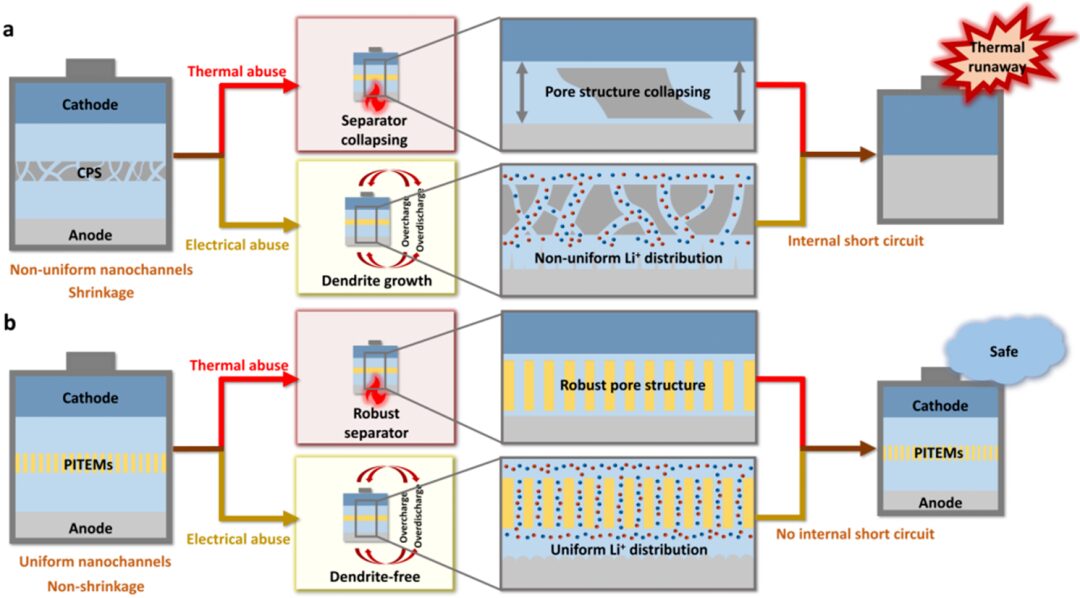

Traditional polyolefin separators have poor thermal stability and non-uniform pore structures, making it impossible to effectively avoid structural shrinkage and suppress lithium dendrite growth under high-temperature conditions. The PI separator proposed in this work, based on ion track technology, has a uniform pore structure and excellent thermodynamic properties, effectively suppressing lithium dendrite growth and ensuring the battery’s normal operation in high-temperature environments.

Figure 1 Schematic diagram of thermal runaway mechanism and safety state of batteries using traditional polyolefin separators (CPS) and polyimide ion track membranes (PITEM)

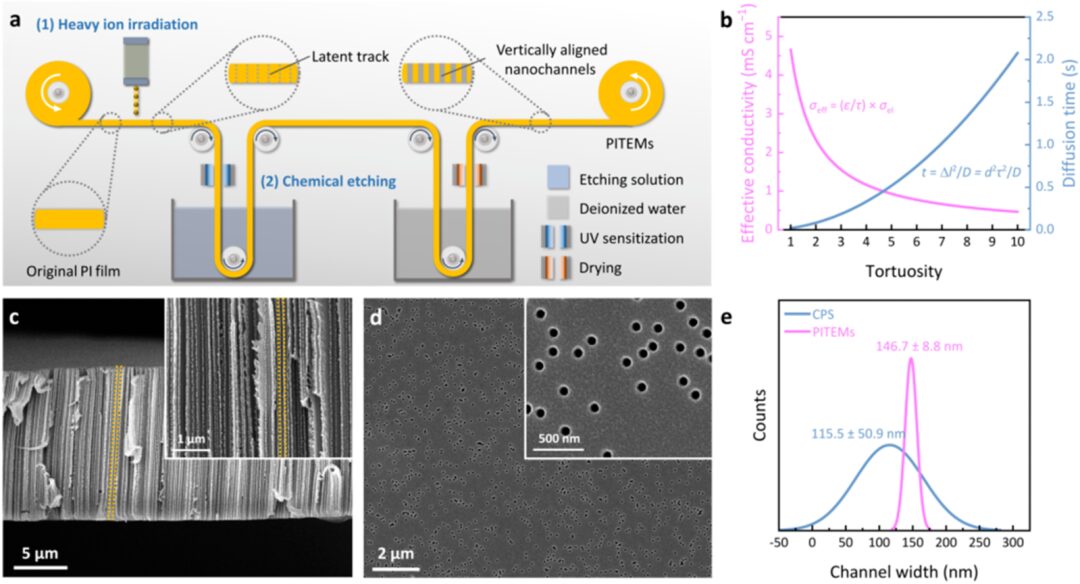

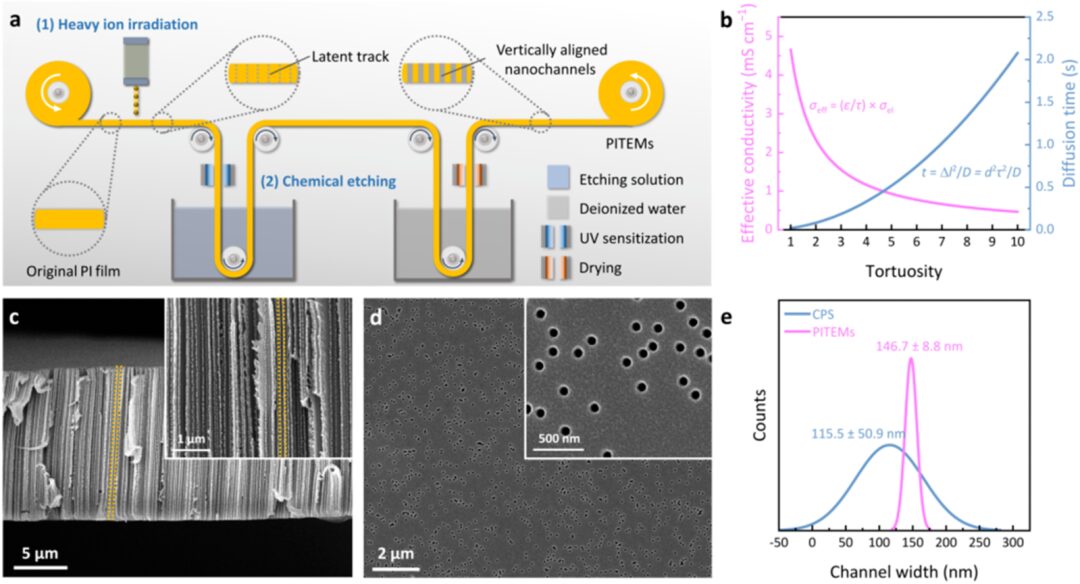

Ion track technology has strong scalability and can achieve large-area continuous separator preparation. The vertically arranged nanochannels of the PITEM separator can shorten the transport distance of lithium ions, thus obtaining a higher effective ionic conductivity. Additionally, compared to polyolefin separators, the PITEM separator has a narrower pore size distribution, allowing for a uniform lithium ion concentration beneath the separator’s pore channels, achieving uniform lithium deposition on the anode surface.

Figure 2 Preparation process and pore structure characterization of PITEM

Compared to reported PI separators, the PITEM separator developed in this work has higher mechanical strength, thanks to its lower porosity (~20%). Notably, although the porosity (ε) is low, its curvature (τ) is 1, which allows for a high effective transport coefficient (0.20,δ = ε/τ) and effective ionic conductivity (σeff = δσ0,σ0 being the intrinsic conductivity of the electrolyte). In comparison, the commercial polypropylene separator (PP, Celgard 2400) has a porosity of about 40% and a curvature of around 2.6, with an effective transport coefficient of only 0.15.

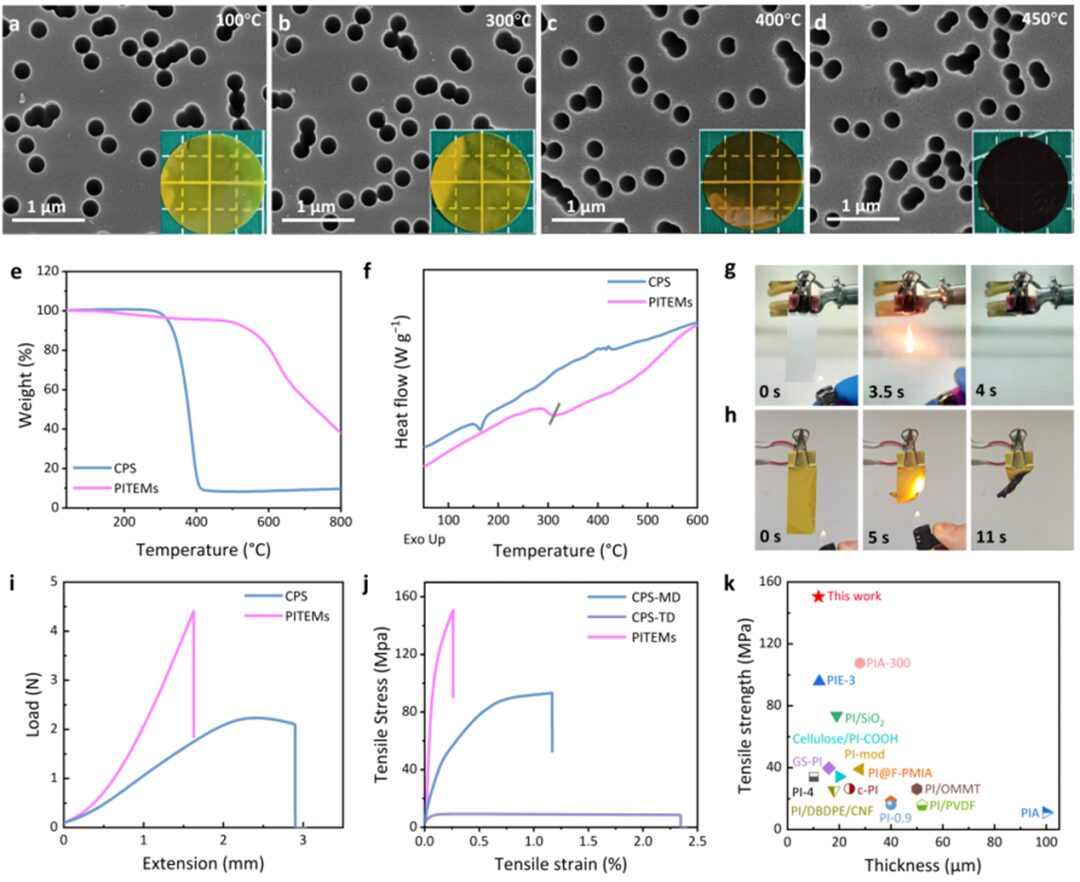

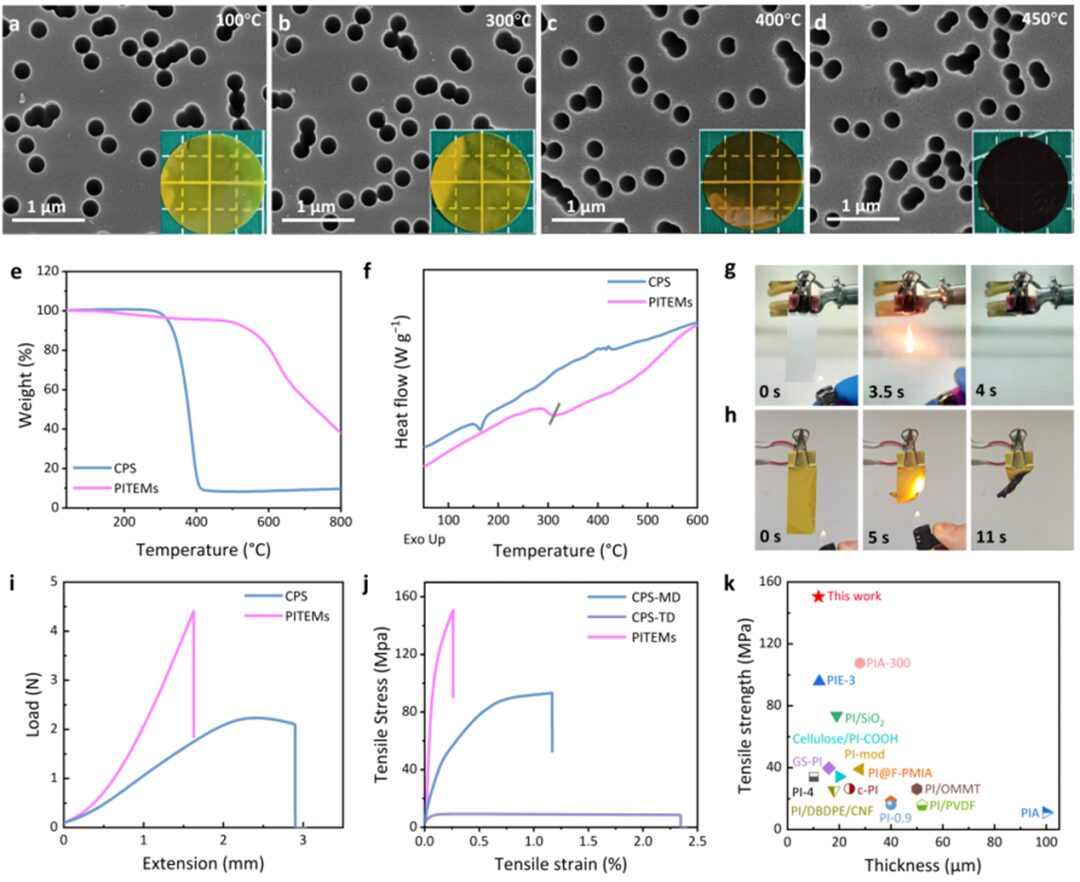

Figure 3 Characterization of thermal stability, mechanical strength, and other key properties of PITEM

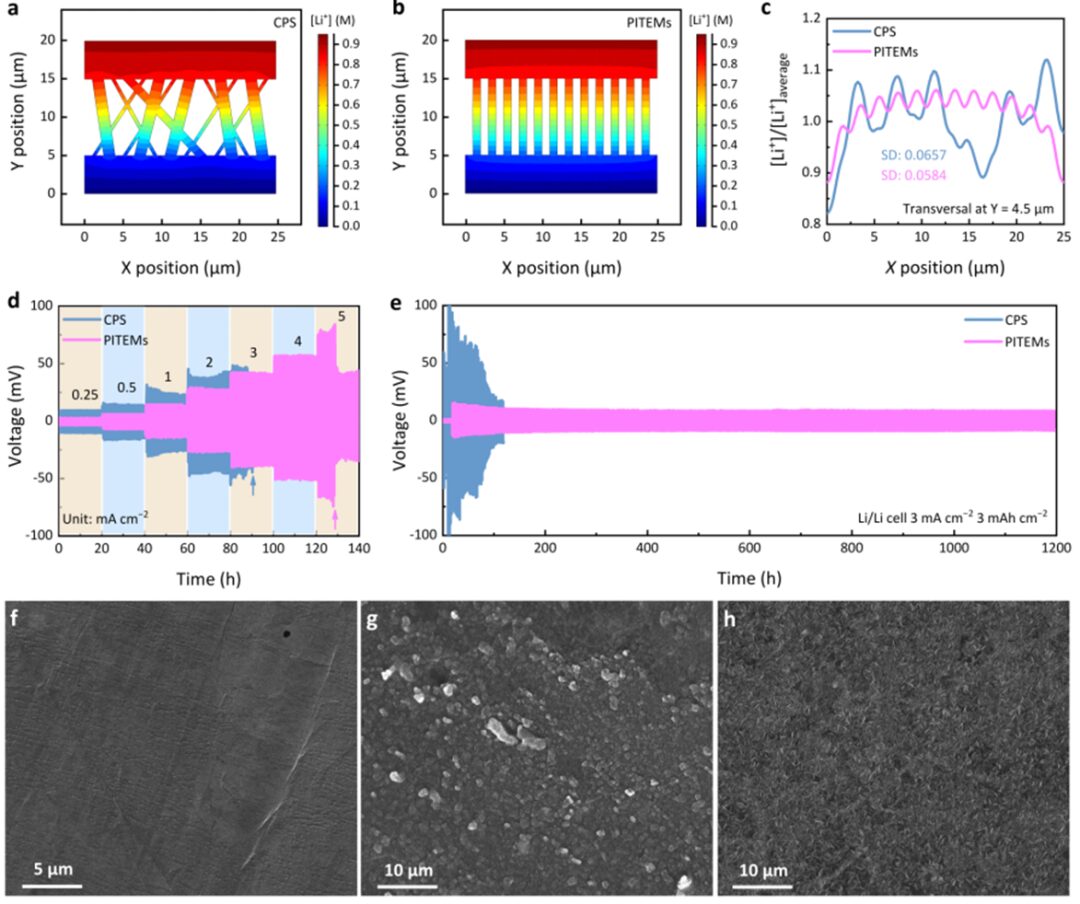

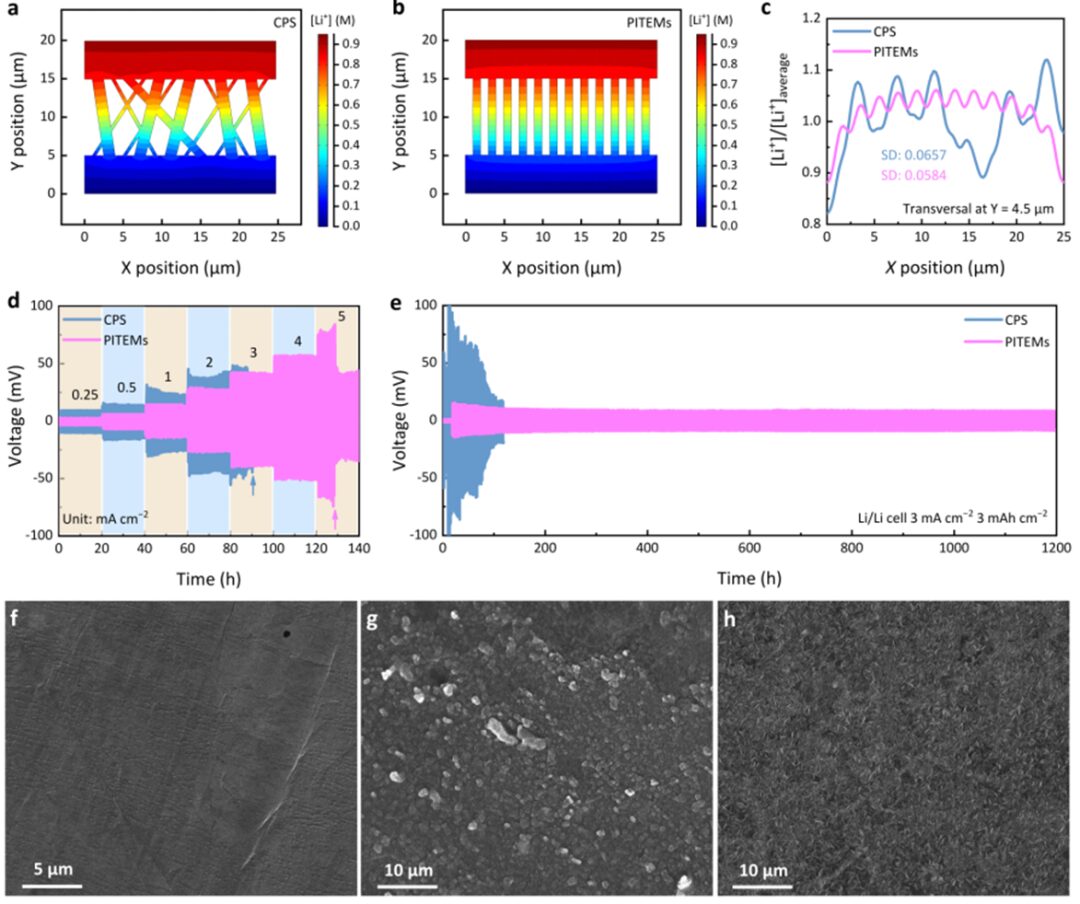

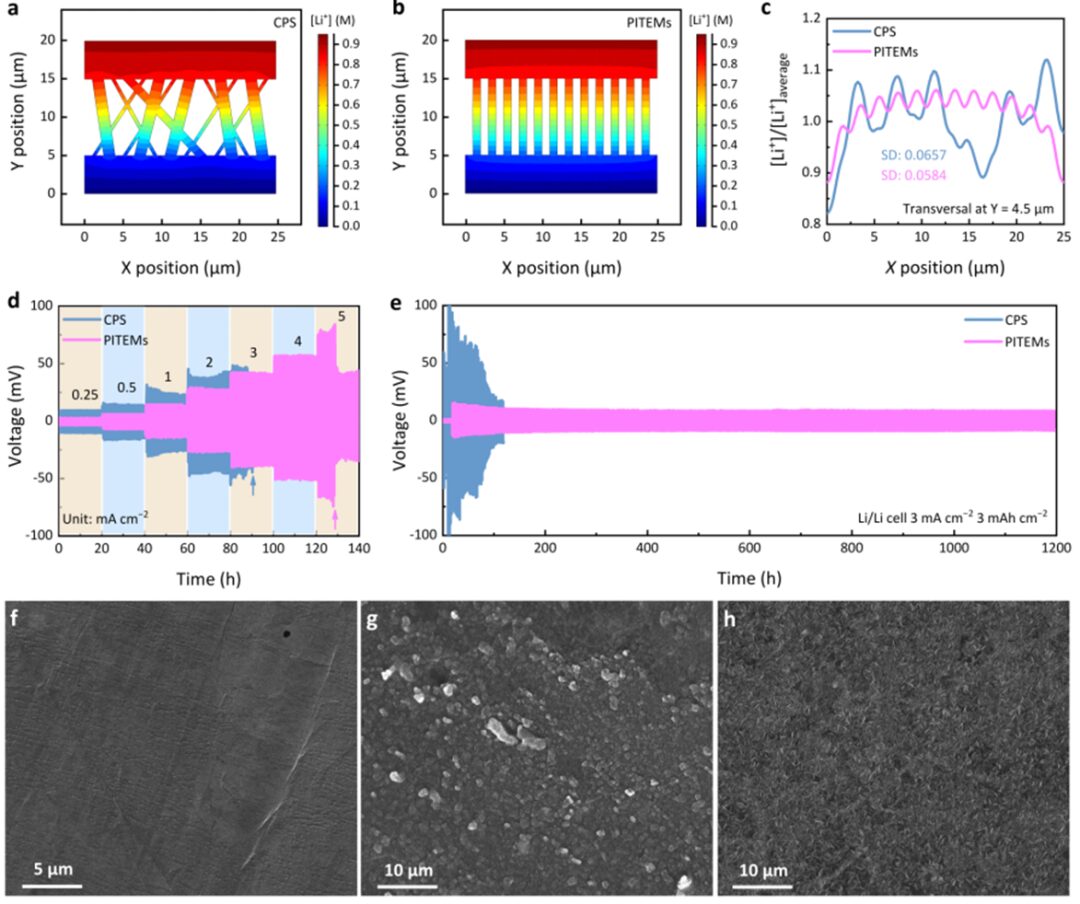

Traditional porous separators have non-uniform pore sizes and convoluted pore channels, leading to uneven lithium ion concentration distribution beneath the pore channels, with higher ion concentration beneath larger or shorter pore channels. In contrast, the PITEM separator features uniformly aligned vertical channels, ensuring consistent lithium ion concentration beneath each channel. The limit current density of lithium/lithium symmetric batteries using the PITEM separator can reach 5 mA cm−2, and at a current density of 3 mA cm−2, they can cycle stably for 1200 hours, exhibiting a small polarization voltage, indicating that the PITEM separator can effectively stabilize the anode interface. After a certain number of cycles, the lithium layer surface using the PITEM separator is uniform and dense, demonstrating its excellent ability to smooth lithium ion concentration fluctuations and suppress lithium dendrites.

Currently, the energy density of commercial lithium-ion batteries can reach 300 Wh kg−1, with the potential for further improvement. However, while pursuing high energy density, the safety issues of the batteries cannot be ignored. The separator, as one of the key components of lithium-ion batteries, functions to isolate the positive and negative electrodes and conduct lithium ions, which is crucial for the battery’s safety. Internal short circuits are a key trigger for thermal runaway in batteries, usually caused by the shrinkage, melting, or penetration of lithium dendrites through the separator. Traditional polyolefin separators have poor thermal stability, non-uniform pore structures, and are prone to shrinkage at high temperatures, leading to internal short circuits and thermal runaway. Polyimide (PI) is considered an ideal choice for high-safety separators due to its excellent thermal stability, high mechanical strength, and good chemical stability. However, existing preparation technologies are still limited to laboratory scale, and the non-uniform pore structure is difficult to control accurately. Therefore, developing PI separators with uniform pore channel structures and achieving controllable preparation is very important to fully leverage the separator’s role in enhancing battery safety.

Recently, researchers from the Materials Research Center of the Institute of Modern Physics, Chinese Academy of Sciences, in collaboration with teams from Lanzhou University and the Advanced Energy Science and Technology Guangdong Laboratory, utilized the Lanzhou Heavy Ion Research Facility (HIRFL) to develop a new process for preparing high-performance lithium-ion battery PI separators that are resistant to high temperatures using ion track technology. The prepared separator has significant advantages over traditional polyolefin separators, with a mechanical strength of up to 150.6 MPa, excellent high-temperature performance (no structural shrinkage at 450℃), narrow pore size distribution (standard deviation of pore size < 6%), and vertically aligned pore structures (curvature of 1). At a current density of 3 mA cm−2, lithium/lithium symmetric batteries using this separator can cycle stably for 1200 hours; the lithium deposition on the lithium metal electrode surface is uniform and dense, indicating its excellent lithium dendrite suppression performance. Lithium iron phosphate soft-pack batteries using this separator can cycle stably for 1000 times at room temperature, with a capacity retention rate of 73.25%. This battery also demonstrates excellent high-temperature performance, capable of stable cycling at 80℃ and still functioning normally at an ambient temperature of 150℃. The article titled Robust, High-Temperature-Resistant Polyimide Separators with Vertically Aligned Uniform Nanochannels for High-Performance Lithium-Ion Batteries was published in the American Chemical Society journal ACS Nano. PhD students Zhang Qizhong from the Institute of Modern Physics and Chen Linjing from Lanzhou University are the first authors of this paper, while Researchers Liu Jie and Yao Huijun from the Institute of Modern Physics are the corresponding authors.

Traditional polyolefin separators have poor thermal stability and non-uniform pore structures, making it impossible to effectively avoid structural shrinkage and suppress lithium dendrite growth under high-temperature conditions. The PI separator proposed in this work, based on ion track technology, has a uniform pore structure and excellent thermodynamic properties, effectively suppressing lithium dendrite growth and ensuring the battery’s normal operation in high-temperature environments.

Figure 1 Schematic diagram of thermal runaway mechanism and safety state of batteries using traditional polyolefin separators (CPS) and polyimide ion track membranes (PITEM)

Ion track technology has strong scalability and can achieve large-area continuous separator preparation. The vertically arranged nanochannels of the PITEM separator can shorten the transport distance of lithium ions, thus obtaining a higher effective ionic conductivity. Additionally, compared to polyolefin separators, the PITEM separator has a narrower pore size distribution, allowing for a uniform lithium ion concentration beneath the separator’s pore channels, achieving uniform lithium deposition on the anode surface.

Figure 2 Preparation process and pore structure characterization of PITEM

Compared to reported PI separators, the PITEM separator developed in this work has higher mechanical strength, thanks to its lower porosity (~20%). Notably, although the porosity (ε) is low, its curvature (τ) is 1, which allows for a high effective transport coefficient (0.20,δ = ε/τ) and effective ionic conductivity (σeff = δσ0,σ0 being the intrinsic conductivity of the electrolyte). In comparison, the commercial polypropylene separator (PP, Celgard 2400) has a porosity of about 40% and a curvature of around 2.6, with an effective transport coefficient of only 0.15.

Figure 3 Characterization of thermal stability, mechanical strength, and other key properties of PITEM

Traditional porous separators have non-uniform pore sizes and convoluted pore channels, leading to uneven lithium ion concentration distribution beneath the pore channels, with higher ion concentration beneath larger or shorter pore channels. In contrast, the PITEM separator features uniformly aligned vertical channels, ensuring consistent lithium ion concentration beneath each channel. The limit current density of lithium/lithium symmetric batteries using the PITEM separator can reach 5 mA cm−2, and at a current density of 3 mA cm−2, they can cycle stably for 1200 hours, exhibiting a small polarization voltage, indicating that the PITEM separator can effectively stabilize the anode interface. After a certain number of cycles, the lithium layer surface using the PITEM separator is uniform and dense, demonstrating its excellent ability to smooth lithium ion concentration fluctuations and suppress lithium dendrites.

Figure 4 Uniform pore structure of PITEM achieving uniform lithium ion distribution and dendrite-free lithium metal anode

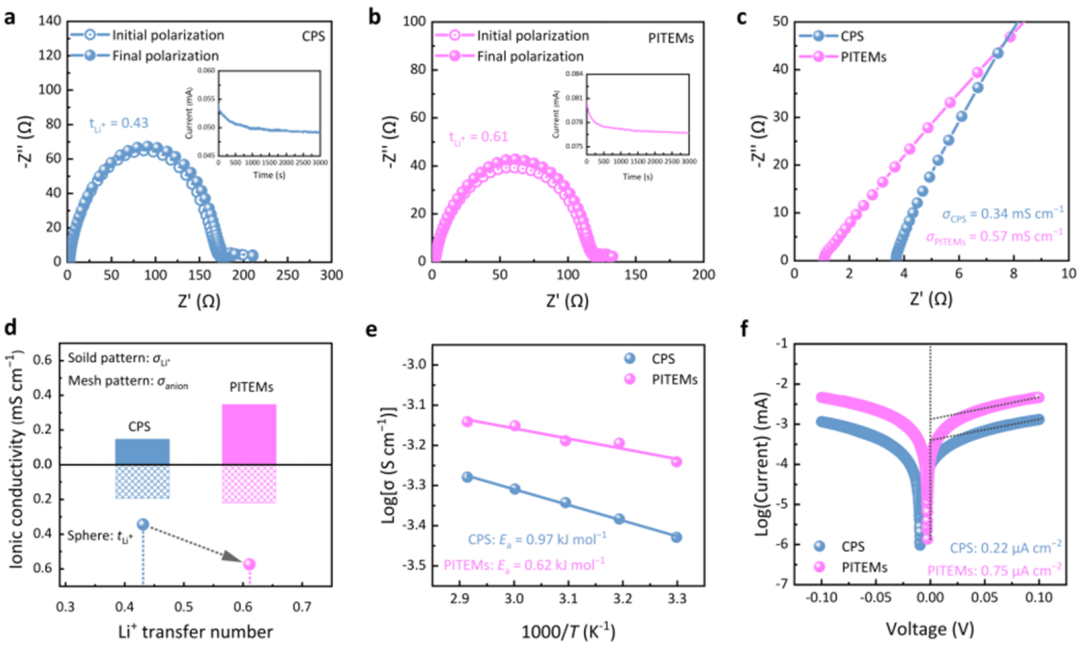

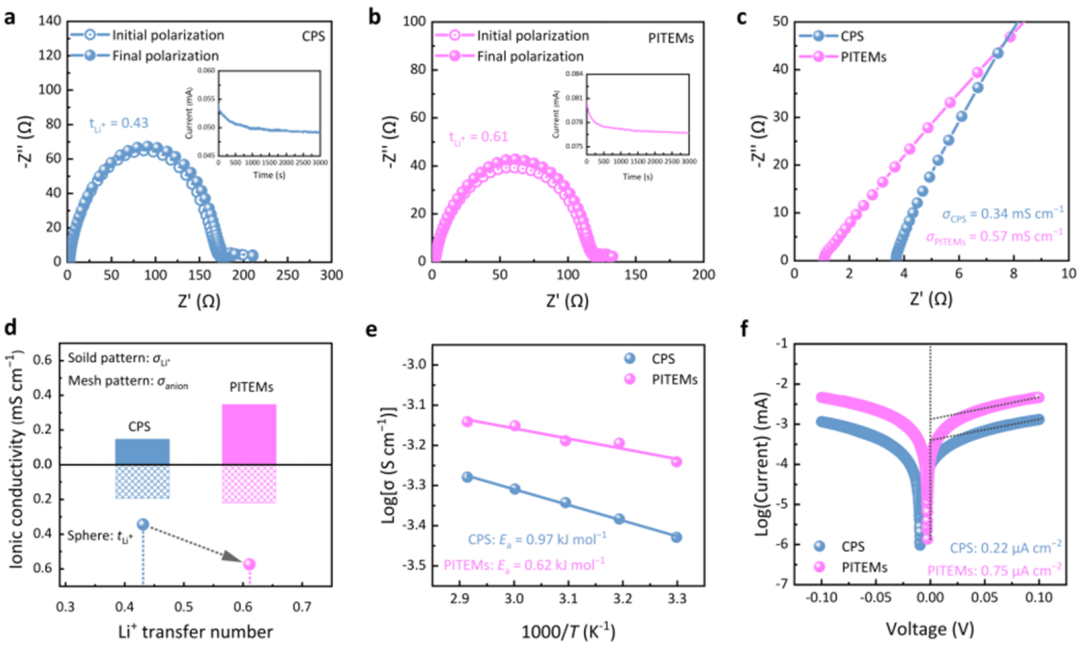

The ionic conductivity of the PITEM separator is 0.57 mS cm−1, higher than the 0.34 mS cm−1 of commercial PP separators. The lithium ion transference number of the PITEM separator is 0.61, with cation conductivity of 0.35 mS cm−1 and anion conductivity of 0.22 mS cm−1; whereas the commercial PP separator has an ion transference number of only 0.43, cation conductivity of 0.15 mS cm−1, and anion conductivity of 0.19 mS cm−1. The improvement in ionic conductivity of the PITEM separator is mainly attributed to enhanced lithium ion conduction, which is related to its surface’s rich polar groups that promote selective and rapid transport of lithium ions.

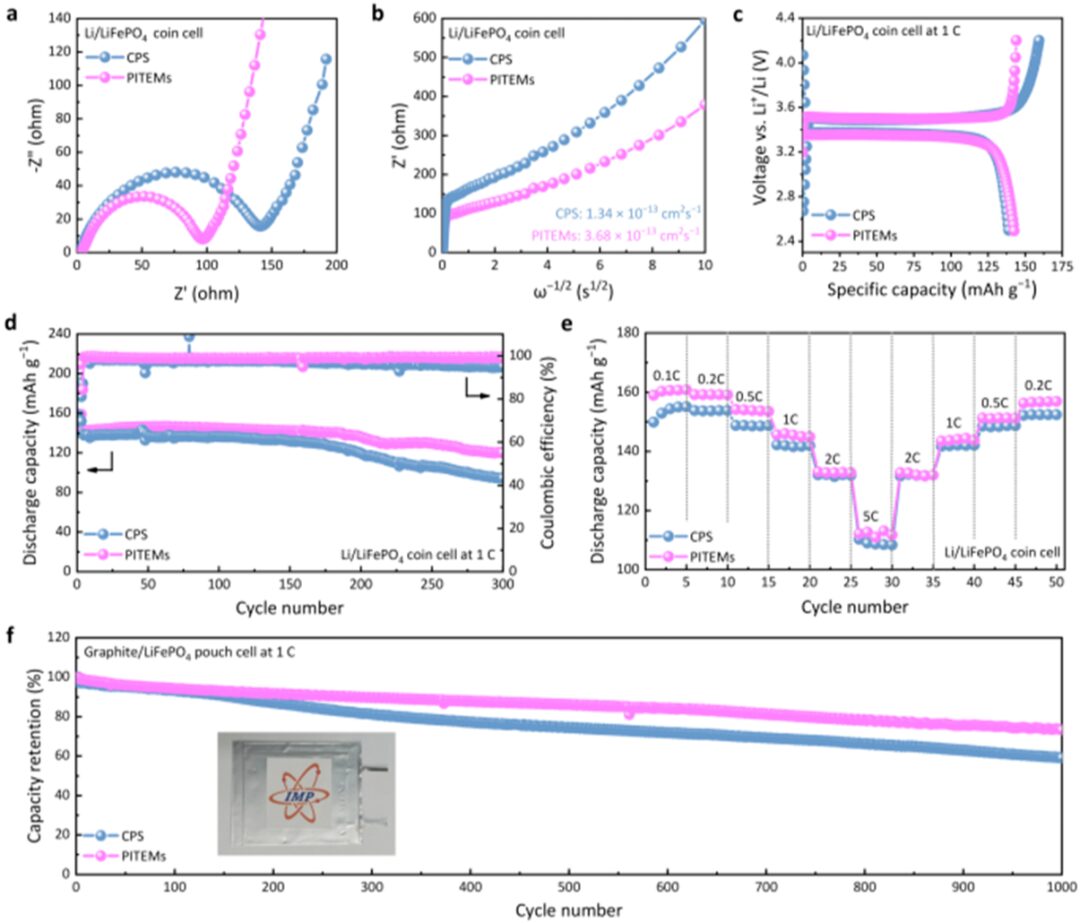

Figure 5 Comparison of electrochemical performance between CPS and PITEM

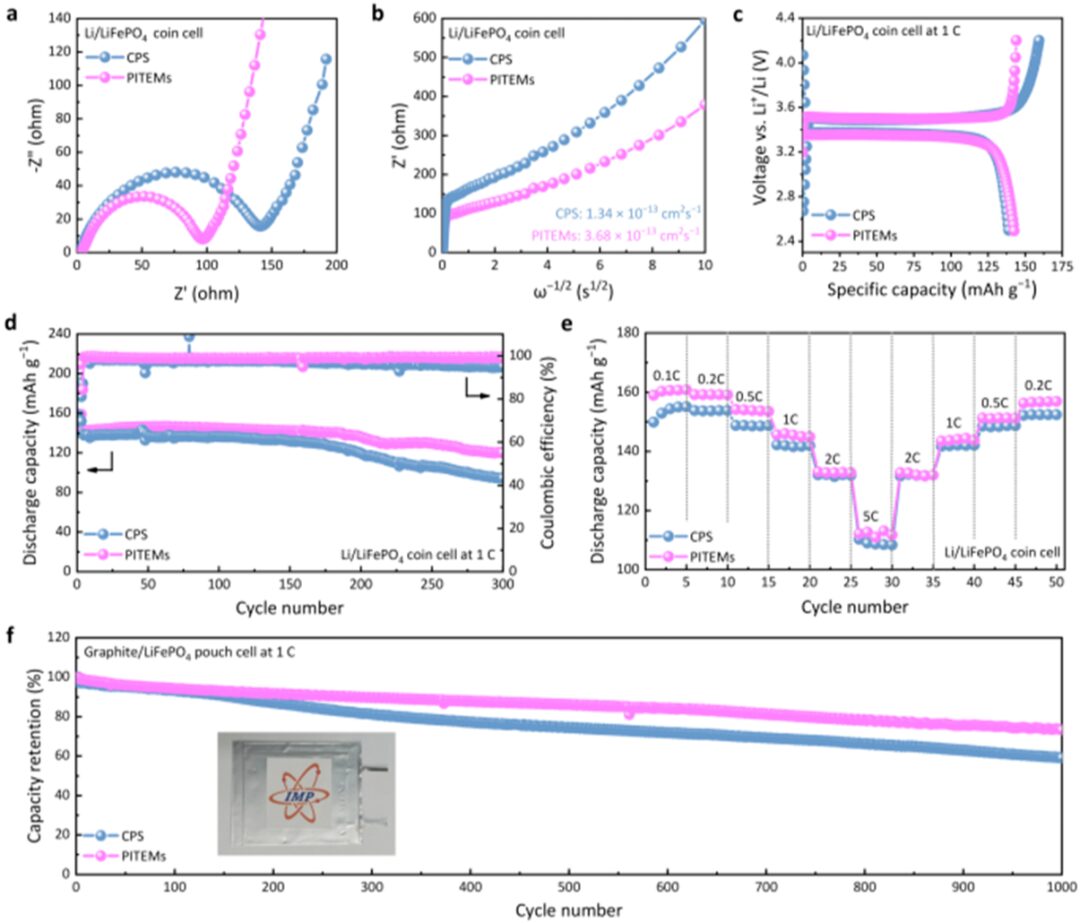

Using the PITEM separator, the initial specific capacity of the lithium iron phosphate battery is 143 mAh g−1, with a capacity retention rate of 83.88% after 300 cycles. In comparison, the battery using the CPS separator has a specific capacity of 139 mAh g−1 and poor cycling stability, with a capacity retention rate of 68.03% after 300 cycles. The lithium iron phosphate soft-pack battery using the PITEM separator can cycle stably for 1000 times at room temperature, with a capacity retention rate of 73.25%, outperforming the battery with the CPS separator.

Figure 6 Comparison of electrochemical performance of lithium iron phosphate batteries using CPS and PITEM

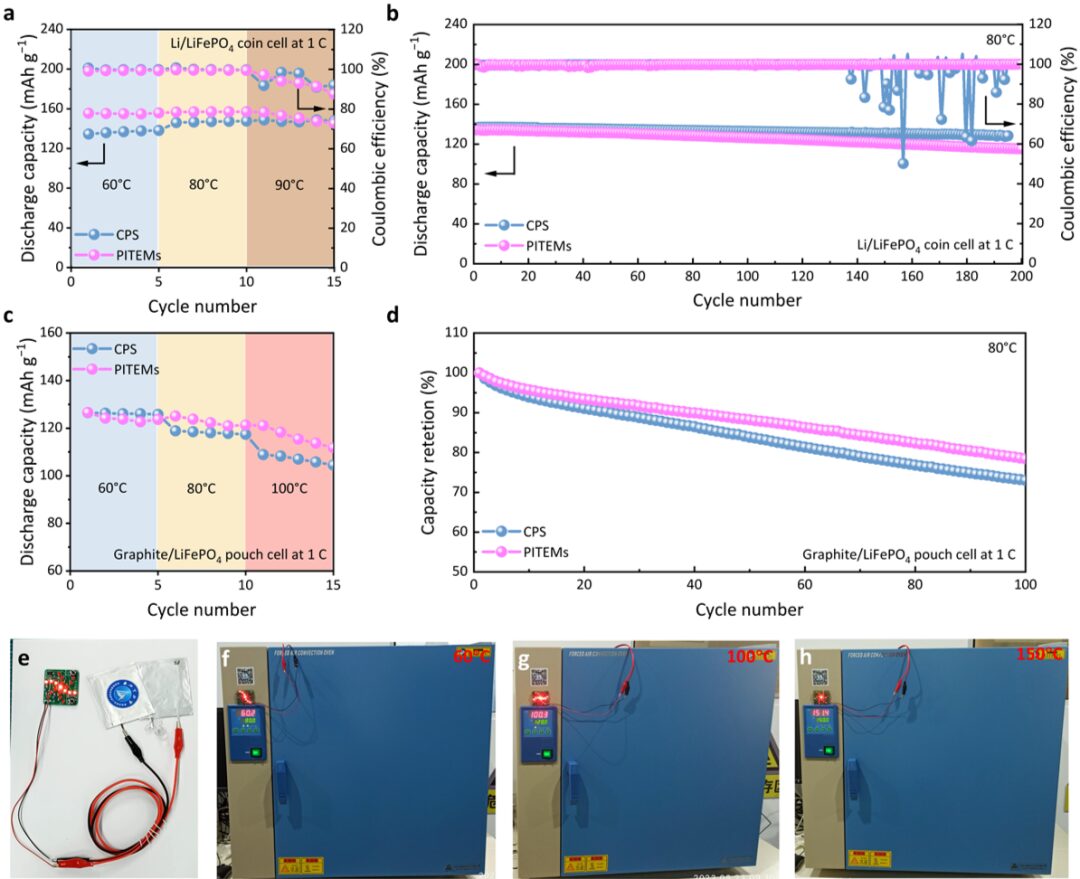

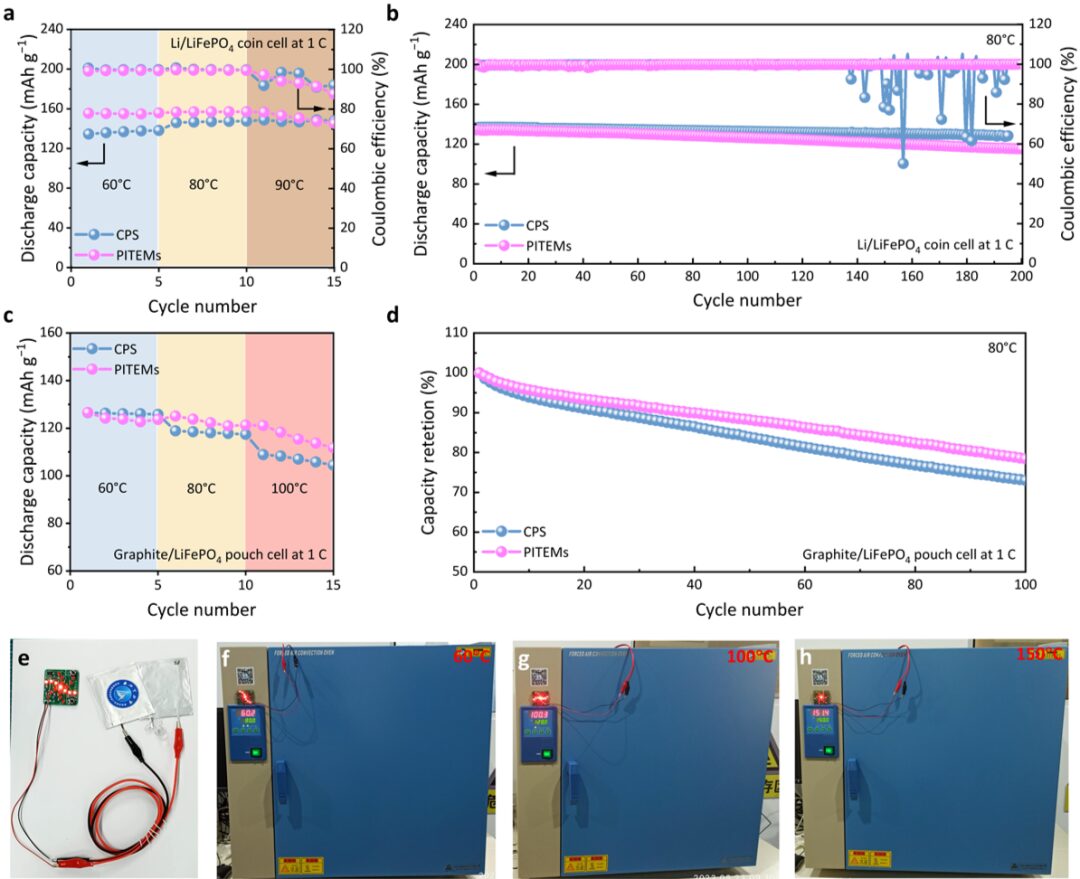

Even when the operating temperature reaches 90℃, the battery using the PITEM separator can still charge and discharge normally; while the battery using the CPS separator fails. Long-term cycling tests at 80℃ show that the battery using the PITEM separator retains 85.10% capacity after 200 cycles; whereas the battery using the CPS separator experiences accelerated capacity decay and minor short circuits after 140 cycles. Furthermore, the soft-pack battery using the PITEM separator maintains a high discharge capacity even at 100℃, cycles stably for 100 times at 80℃, and shows higher capacity. Soft-pack batteries based on the PITEM separator can still operate normally under high-temperature conditions of 150℃, demonstrating its ability to ensure safe battery operation under harsh conditions.

Figure 7 Comparison of high-temperature cycling performance of lithium iron phosphate batteries using CPS and PITEM

This research provides a new approach for developing reliable high-performance lithium-ion battery separators and processes that are resistant to high temperatures, becoming one of the effective means to enhance the safety of lithium-ion batteries.

Q. Zhang, L. Chen, X. Li, B. Hou, X. Wu, X. Gui, D. Cao, J. Liu, J. Li, J. Duan, D. Mo, J. Liu*, and H. Yao*, Robust, High-Temperature-Resistant Polyimide Separators with Vertically Aligned Uniform Nanochannels for High-Performance Lithium-Ion Batteries. ACS Nano, https://doi.org/10.1021/acsnano.4c11217

Figure 4 Uniform pore structure of PITEM achieving uniform lithium ion distribution and dendrite-free lithium metal anode

The ionic conductivity of the PITEM separator is 0.57 mS cm−1, higher than the 0.34 mS cm−1 of commercial PP separators. The lithium ion transference number of the PITEM separator is 0.61, with cation conductivity of 0.35 mS cm−1 and anion conductivity of 0.22 mS cm−1; whereas the commercial PP separator has an ion transference number of only 0.43, cation conductivity of 0.15 mS cm−1, and anion conductivity of 0.19 mS cm−1. The improvement in ionic conductivity of the PITEM separator is mainly attributed to enhanced lithium ion conduction, which is related to its surface’s rich polar groups that promote selective and rapid transport of lithium ions.

Figure 5 Comparison of electrochemical performance between CPS and PITEM

Using the PITEM separator, the initial specific capacity of the lithium iron phosphate battery is 143 mAh g−1, with a capacity retention rate of 83.88% after 300 cycles. In comparison, the battery using the CPS separator has a specific capacity of 139 mAh g−1 and poor cycling stability, with a capacity retention rate of 68.03% after 300 cycles. The lithium iron phosphate soft-pack battery using the PITEM separator can cycle stably for 1000 times at room temperature, with a capacity retention rate of 73.25%, outperforming the battery with the CPS separator.

Figure 6 Comparison of electrochemical performance of lithium iron phosphate batteries using CPS and PITEM

Even when the operating temperature reaches 90℃, the battery using the PITEM separator can still charge and discharge normally; while the battery using the CPS separator fails. Long-term cycling tests at 80℃ show that the battery using the PITEM separator retains 85.10% capacity after 200 cycles; whereas the battery using the CPS separator experiences accelerated capacity decay and minor short circuits after 140 cycles. Furthermore, the soft-pack battery using the PITEM separator maintains a high discharge capacity even at 100℃, cycles stably for 100 times at 80℃, and shows higher capacity. Soft-pack batteries based on the PITEM separator can still operate normally under high-temperature conditions of 150℃, demonstrating its ability to ensure safe battery operation under harsh conditions.

Figure 7 Comparison of high-temperature cycling performance of lithium iron phosphate batteries using CPS and PITEM

This research provides a new approach for developing reliable high-performance lithium-ion battery separators and processes that are resistant to high temperatures, becoming one of the effective means to enhance the safety of lithium-ion batteries.

Q. Zhang, L. Chen, X. Li, B. Hou, X. Wu, X. Gui, D. Cao, J. Liu, J. Li, J. Duan, D. Mo, J. Liu*, and H. Yao*, Robust, High-Temperature-Resistant Polyimide Separators with Vertically Aligned Uniform Nanochannels for High-Performance Lithium-Ion Batteries. ACS Nano, https://doi.org/10.1021/acsnano.4c11217