XAI and 3D Printing Reshape Development Processes to Achieve Technological Breakthroughs

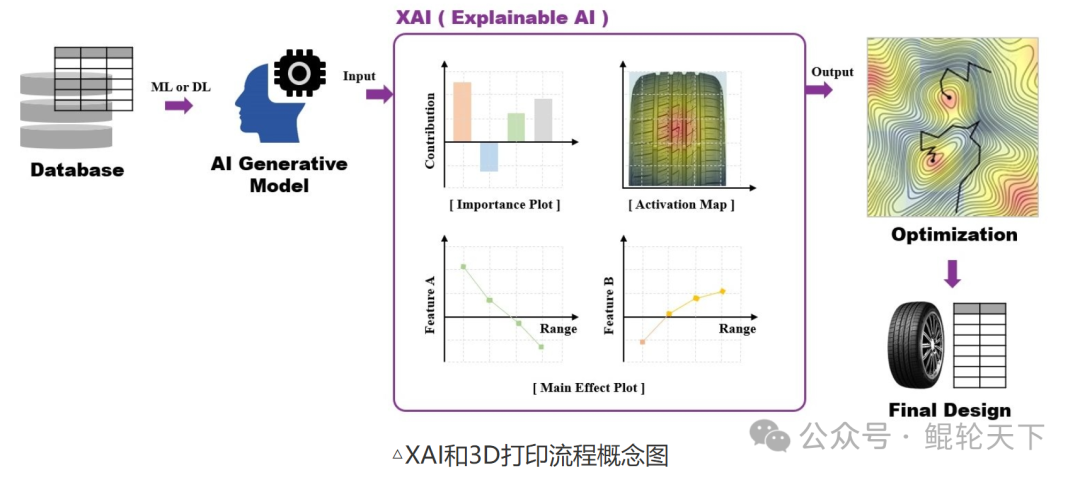

Nexen Tire of South Korea has successfully integrated Explainable Artificial Intelligence (XAI) and 3D printing technology in tire mold production, achieving significant breakthroughs in tire development, greatly enhancing efficiency and precision, and simplifying traditional development processes. The traditional process typically includes designing structures and patterns, creating molds, manufacturing prototypes, and vehicle testing for final approval. XAI technology helps understand and optimize machine learning results through in-depth analysis of foundational designs, key variables, performance contributions, and design directions, maximizing design efficiency and proposing optimal structures and solutions that meet requirements. The XAI-based design enables the company to create virtual tire models and evaluate performance in a virtual environment, significantly improving the accuracy and speed of development, and for the first time introducing driving simulators in the domestic industry of South Korea to further upgrade virtual development levels[1].

3D Printing Drives Efficiency and Innovative Design for Performance Leap

After completing virtual development, Nexen Tire efficiently produces physical prototype molds for final evaluation using 3D printing technology. 3D printing can simultaneously create multiple validated design and specification prototypes, greatly increasing the approval rate of the final product. Compared to traditional mold production, which takes 2-3 months, 3D printing reduces the time by at least 70%, while production costs decrease by over 50%, achieving significant cost benefits. Additionally, this 3D printing technology supports innovative tire designs, including complex patterns and fine grooves (small gaps on the tread), which are crucial for supporting high-performance vehicles and enhancing consumer performance and safety. Nexen Tire has applied for an international patent for this technology.

Enhancing Customer Value and Leading the Industry through Innovation

Nexen Tire states that the ultimate goal of its technological innovation is to enhance customer satisfaction. Through a transformative tire development process, the company not only ensures market competitiveness but also protects the environment during the development process, driving the future of tire manufacturing and committing to leading revolutionary changes in the industry. Relying on breakthroughs in XAI and 3D printing technology, Nexen Tire will continue to advance tire technology development to meet the ever-changing market demands, ensuring high-performance and high-quality tire products for customers.

Kunlun Speaks

The technological revolution is not only an efficiency tool but also a key lever for reconstructing the value chain.

References:

[1] Nexen Tire Official Website

*All content on this platform is created and collected by Kunlun Tianxia, including text, images, and videos, and is copyrighted by Kunlun Tianxia;

Materials collected and organized from public channels are copyrighted by the original authors. If there is any infringement, please contact the platform for deletion.