Click the blue text to follow us

Industrial Computer Tomography System (CT) for High-Precision Intelligent Detection of Fiber-Reinforced Composites

01

Detection Progress

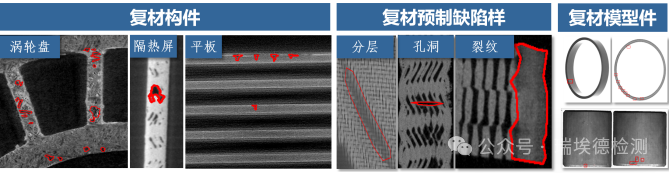

As a core material used in high-tech fields, fiber-reinforced composites possess significant advantages such as high temperature resistance, low density, high specific strength, and high specific modulus, which contain enormous application potential. However, it must be acknowledged that the complex defects within the material have become a key bottleneck hindering the development of its components. These defects are specifically manifested in three important aspects: intrinsic defects, manufacturing defects, and service defects.

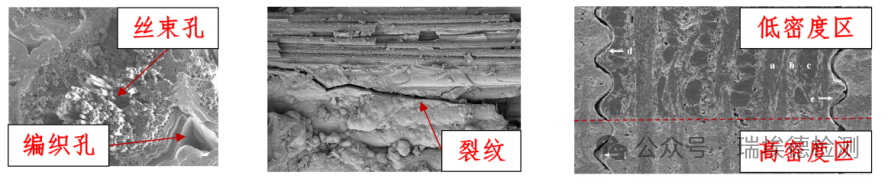

(1) Intrinsic Defects: Fiber-reinforced composites encompass multiple components such as fibers, interfaces, matrices, and coatings, exhibiting distinct characteristics of heterogeneity, anisotropy, and multiple structural units. This complex intrinsic nature makes it extremely challenging to distinguish between “pseudo-defects” and “harmful” defects. In practical applications, due to the complex and diverse structure of CMC, the interactions between different structural units make the manifestation of defects extremely complicated.

(2) Manufacturing Defects: The preparation process of material components is extremely complex, involving multiple manufacturing stages such as preform weaving, matrix densification and processing, coating preparation, and final assembly, where various material defects are easily formed.

(3) Service Defects: Components typically operate under high stress, high temperature loads, and complex oxidative environments. Defects such as “weaving holes”, fiber damage, and matrix voids formed during the component preparation process can become sources under the influence of high temperature, high stress, and gas oxidation environments, leading to the continuous expansion of internal defects and ultimately resulting in component failure.

In summary, the detection of fiber-reinforced composites and components faces four major challenges. First, the detection of harmful defects is extremely difficult. Second, the intelligent recognition of detection technology is challenging. Third, the evolution of defects during preparation and application is hard to grasp. Fourth, accurate measurement of structural dimensions is difficult.

To address these issues, our company has collaborated with Professor Mei Hui from Northwestern Polytechnical University and Professor Qi Fei from Xi’an University of Electronic Science and Technology, using RX Solutions high-precision industrial computer tomography equipment and self-developed defect recognition software to effectively conduct high-precision measurement and automatic identification of defects in fiber-reinforced composites.

02

Team Work

01

Algorithm Principle

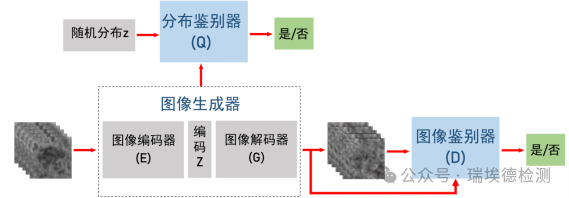

Proposed an adversarial representation learning method targeting the defect characteristics of fiber-reinforced composites.

02

Data Preparation

In collaboration with our company, using RX Solutions high-precision industrial CT equipment, the maximum scanning precision can reach 0.4 microns, establishing a CT slice dataset of fiber-reinforced composites with over 1.2 million images, intelligently detecting over 400 samples/types of composite components.

03

Detection Efficiency

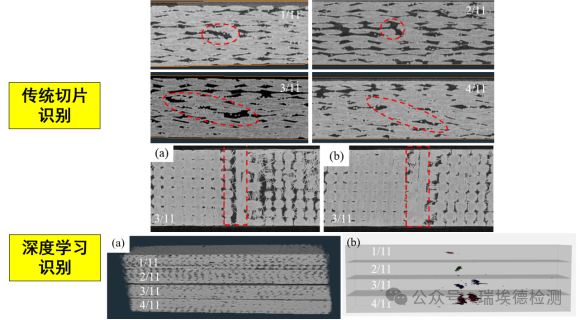

For the thermal insulation screen detection data (1466 images), manual visual inspection took 293 minutes, while intelligent recognition only took 21 minutes, improving efficiency by 13.95 times.

It can be seen that using deep learning methods to identify cracks is faster and more accurate. Deep learning methods, with their powerful data analysis and pattern recognition capabilities, can more effectively capture the characteristics of cracks, thus achieving precise identification of crack defects.

03

Original Work

Meanwhile, the team has done a lot of original work in high-precision detection of materials, including:

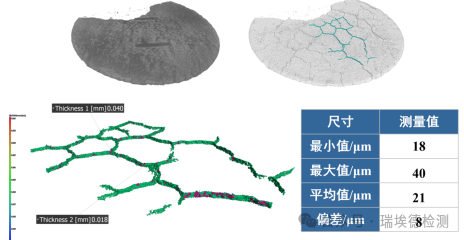

1. Coating micro-crack extraction: High-precision detection of coatings, with an average crack width of 21μm, showing honeycomb-like propagation distribution.

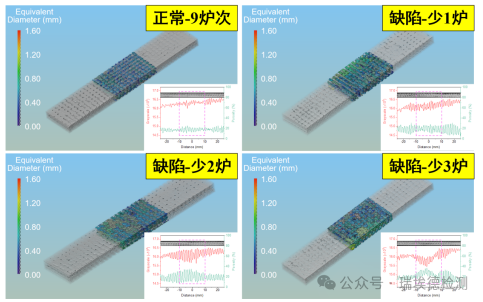

2. Density Defect Recognition: Preparation of local density non-uniform defects. As low-density defects worsen, the material’s gray scale differences and porosity increase.

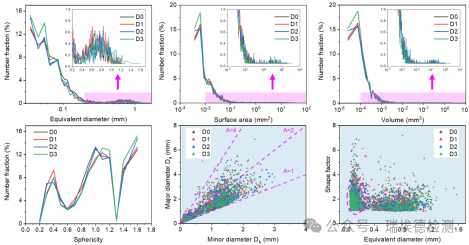

3. Density Defect Statistics: Density non-uniform defects lead to a bimodal distribution of pore sizes and increased morphological differences.

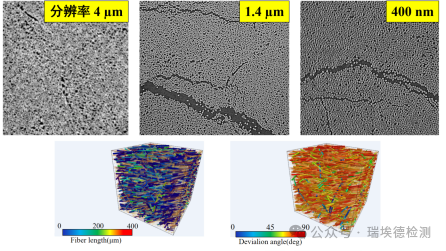

4. Short fiber analysis: Improved resolution benefits high-precision analysis of short fibers. The length of short fibers shows a bimodal distribution at 100μm and 300μm, oriented at 80°.

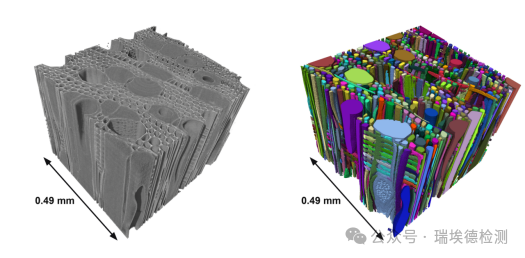

5. Porous material analysis: High-precision detection of porous materials, with micro-nano multi-scale thin-walled channels beneficial for improving adsorption catalytic performance.

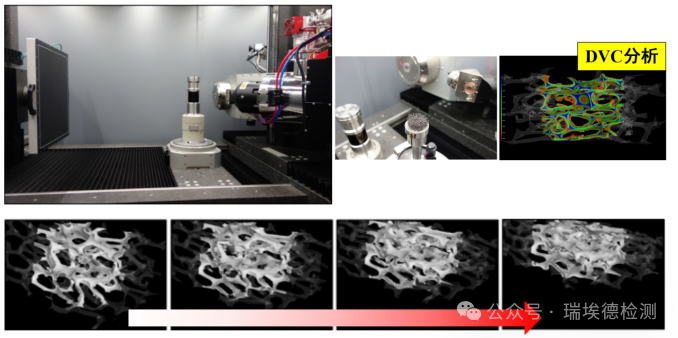

6. In-situ CT experiments (tension, compression, high temperature, low temperature): In-situ CT experiments on foam materials under tension revealed that cracks originated from preparation defects, leading to progressive fracture.

Company Introduction

Wuxi Ruide Detection Technology Co., Ltd. was established in 2015, headquartered in Wuxi, focusing on the sales and technical services of optical measurement and industrial CT systems.

Ruide Detection signed a contract in 2019 to become the general agent for RX Solutions in China, which specializes in micro-nano X-ray 3D tomography technology.

As the general agent for RX Solutions in China, Ruide Detection has established a new industrial CT laboratory at its headquarters in Wuxi, fully responsible for the brand’s equipment sales, technical support, and outsourced testing services in the Chinese region.

The laboratory is equipped with industrial CT equipment with 150kV, 230kV, 300kV, and dual X-ray sources of 150&160kV, as well as in-situ testing platforms (maximum mechanical performance up to 10kN), capable of conducting tensile, compressive, bending, and shear tests. The equipment’s maximum precision can reach 0.4µm, meeting the three-dimensional non-destructive testing needs for industrial analysis and scientific exploration. Through industrial CT scanning, the internal structure of samples can be observed, and the scanning data can be quantitatively and qualitatively analyzed, such as size measurement, porosity inclusion analysis, assembly analysis, etc., obtaining corresponding data and models.