1. Core Fault Characteristic Analysis

-

Fault Phenomenon: ECU not functioning → Restored by reconnecting the harness → No physical damage to the connector

-

Essential Cause: Connection stability issue (not a permanent disconnection, but abnormal contact resistance or momentary signal interruption)

2. Five Fundamental Causes and Troubleshooting Methods

1. Poor contact of terminal micro-switches (approx. 40%)

-

Detection Method:

-

Contact resistance testing: Measure the resistance after terminal insertion with a milliohm meter (normal ≤ 5mΩ)

-

Micro-vibration testing: Monitor ECU power supply voltage while lightly tapping the connector (fluctuation > 0.2V is abnormal)

-

Typical Scenarios:

-

Insufficient pre-tension of terminal spring ( < 1N)

-

Oxidation of the coating surface (caused by storage humidity > 60%)

2. ECU Wake-up Logic Conflict

-

Abnormal wake-up signal:

Wake-up Type Detection Point Normal Signal Hard-wired wake-up KL15 line voltage (ignition switch) Instantaneous ≥ 10.5V CAN wake-up CAN-H/L differential voltage (during sleep) 0V → 2.5V transition -

Diagnostic Tool: Oscilloscope captures wake-up signal timing (if the interval between KL15 and CAN wake-up > 500ms, it will cause ECU reset)

3. Harness Assembly Stress Release

-

Fault Mechanism: Excessively sharp installation angle of the harness (bending radius < 6D, where D is the wire diameter) → Partial internal wire fracture → Temporary reset during insertion/removal

-

Verification Method:

-

X-ray inspection: Check the condition of the wires at the connector’s rear

-

Tensile testing: Apply a force of 50N to a single wire (displacement > 2mm indicates failure)

4. Abnormal Ground Loop Impedance

-

Key Detection Points:

Ground Point Allowed Impedance Failure Consequence ECU chassis ground < 0.1Ω ECU cannot start Sensor reference ground < 0.5Ω Signal drift leads to logical errors -

Case: A certain model’s ECU grounding bolt was coated with sealant (insulation resistance > 100MΩ)

5. Software Initialization Timeout

-

Diagnostic Codes Pointing To:

-

U0140 (communication loss with ECU)

-

P0606 (ECU processor fault)

-

Trigger Conditions:

-

CAN bus load rate > 95% (e.g., production line testing equipment broadcasting interference)

-

ECU power-on self-test > 3s (calibration requirement ≤ 2s)

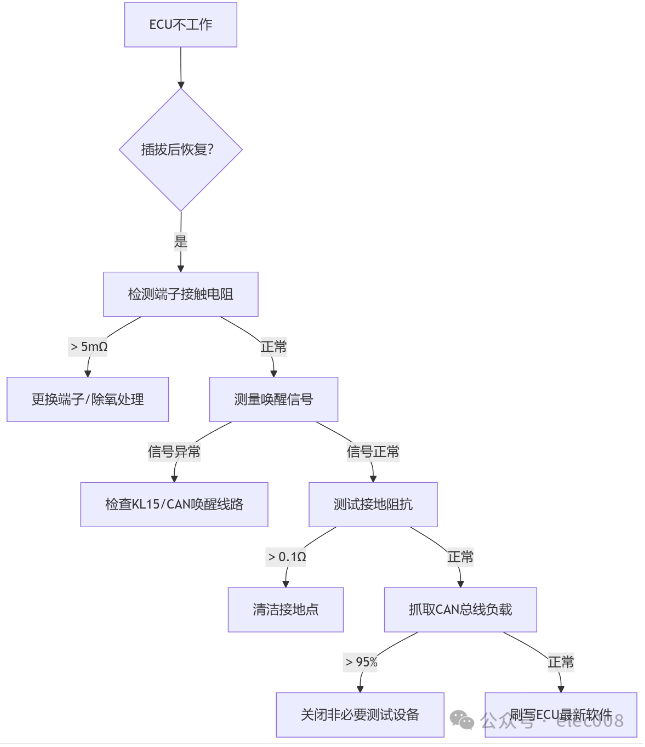

3. Quick Troubleshooting Process on the Production Line

4. Root Cause Mitigation Measures (Production Optimization)

1. Connector Process Upgrade

| Improvement Item | Original Process | Optimized Plan |

|---|---|---|

| Terminal crimping force | 50±10N | 80±5N (to enhance contact stability) |

| Coating process | Tinning (0.5μm) | Gold plating (0.8μm) + anti-oxidation coating |

| Insertion and extraction life testing | 50 cycles | 100 cycles + micro-vibration monitoring |

2. Wake-up Logic Error Prevention Design

-

Hardware Improvement: Add wake-up signal filtering capacitor (10μF) → Avoid voltage spikes

-

Software Fault Tolerance:

-

// Example: Dual wake-up signal interlock logicif(KL15_Status || CAN_Wakeup){ ECU_Enable =1;// Any wake-up valid triggers start}else{ ECU_Enable =0;}

3. Harness Assembly Specifications

-

Bending Radius: Enforced ≥ 8 times the wire diameter (e.g., wire Φ2mm → bending radius ≥ 16mm)

-

Stress Relief: Add tie-down points within 150mm of the connector’s rear

4. Electrostatic Protection (ESD)

-

High-Risk Workstations: ECU installation area, harness insertion and extraction stations

-

Control Measures:

-

Ion wind machines neutralize charges (static voltage < 100V)

-

Operators wear wrist straps (ground resistance 1MΩ)

5. Typical Fault Cases

Case 1: Micro-corrosion of terminals leading to intermittent ECU failure

-

Phenomenon: 8% ECU failure rate for new cars off the production line, restored after reconnection

-

Analysis:

-

Terminal contact resistance reached 120mΩ (standard 5mΩ)

-

Storage environment humidity of 70% accelerated oxidation of the tin layer

-

Solution:

-

Add dehumidifiers in the warehouse (humidity controlled at 40±5%)

-

Add vapor corrosion inhibitor (VCI) packaging for terminals

Case 2: CAN wake-up conflict causing ECU crash

-

Phenomenon: ECU unable to wake up at the end of the assembly line

-

Root Cause:

-

Diagnostic equipment continuously sending wake-up frames → CAN bus load rate 98%

-

ECU unable to process its own wake-up request

-

Optimization:

-

Modify diagnostic protocol: turn off broadcast messages after entering production line mode

-

Add hardware watchdog (reset ECU after 500ms timeout)

6. Long-term Prevention Mechanism

-

Data Monitoring

-

Establish ECU failure parts database (record VIN, workstation, fault codes)

-

Use AI clustering to analyze high-frequency failure modes (e.g., specific terminals/ground points)

Testing Reinforcement

-

Add ECU “Insertion-Extraction-Vibration” Combined Testing (simulating vehicle vibrations)

-

100% execution of automated ground impedance testing (add milliohm meter at EOL workstation)

Summary: The core of such faults is the “contact resistance + signal timing + environmental stress” superposition effect. The production side needs to focus on:

-

Terminal Reliability: Increase gold plating thickness to 0.8μm + crimping force 80N

-

Wake-up Robustness: Dual wake-up redundancy + CAN load rate control

-

Stress Control: Minimum bending radius of harness 8D + electrostatic protection Through precise measurement of contact resistance and strict timing analysis, the root cause can be quickly identified, reducing the offline failure rate to below 0.1%.